Professional Documents

Culture Documents

LK-XRF XRD Presentation

LK-XRF XRD Presentation

Uploaded by

saji kumarCopyright:

Available Formats

You might also like

- Cement Class NoteDocument19 pagesCement Class NoteEstiak AhmedNo ratings yet

- FLSmidth - Cement Training Catalogue 2018 PDFDocument12 pagesFLSmidth - Cement Training Catalogue 2018 PDFbertawan bastiarNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Cement GrindingDocument102 pagesCement GrindingSatish Kumar100% (1)

- New Hardware Grinding Aid - ECOFORDocument5 pagesNew Hardware Grinding Aid - ECOFORlovjnxNo ratings yet

- Cement Process Engineering Vade-Mecum: 1. MathematicsDocument7 pagesCement Process Engineering Vade-Mecum: 1. MathematicsTamer FathyNo ratings yet

- Cpb-Sem2011-P11-Axial Sampling and Tromp CurveDocument54 pagesCpb-Sem2011-P11-Axial Sampling and Tromp Curvechibssa alemayehu100% (1)

- Lafarge Cement Optimization SolutionDocument2 pagesLafarge Cement Optimization SolutionRaja Shannmugam100% (1)

- Cooling Cement Clinker Exercise2.3.4Document2 pagesCooling Cement Clinker Exercise2.3.4Mohammed AbdoNo ratings yet

- Safety PauseDocument4 pagesSafety PauseSafrin SangiaNo ratings yet

- 04 MillingDocument21 pages04 MillingMKPashaPasha100% (1)

- Running Insp Sheet NewDocument20 pagesRunning Insp Sheet NewSafrin SangiaNo ratings yet

- Upgradation of Kiln System To Enhance Productivity and Reduce Energy ConsumptionDocument38 pagesUpgradation of Kiln System To Enhance Productivity and Reduce Energy ConsumptionRavindranath BheemisettyNo ratings yet

- Holderbank: Binder 1 Materials Technology IDocument2 pagesHolderbank: Binder 1 Materials Technology IlatiefNo ratings yet

- Performing A Cement Plant Operations AuditDocument6 pagesPerforming A Cement Plant Operations AuditJa Phe TiNo ratings yet

- Electrical Energy Module Final Draft 20Document161 pagesElectrical Energy Module Final Draft 20Safrin SangiaNo ratings yet

- Performance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement PlantDocument8 pagesPerformance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement PlantSohail AhmedNo ratings yet

- 36 - Process Characteristics of Clinker and Cement Production - Cluster Workshop Hamburg 2107 - 10 - 26 - PresentedDocument30 pages36 - Process Characteristics of Clinker and Cement Production - Cluster Workshop Hamburg 2107 - 10 - 26 - PresentedIrshad Hussain100% (1)

- Silo 9 Boulders Investigation ReportDocument20 pagesSilo 9 Boulders Investigation ReportWaka OngetiNo ratings yet

- PS05 - PS ReportsDocument9 pagesPS05 - PS Reportssaji kumarNo ratings yet

- Thermal Ennergy SavingsDocument13 pagesThermal Ennergy SavingsSalud Y Sucesos100% (1)

- Better Grinding Systems: Figure 1: DeglomeratorDocument5 pagesBetter Grinding Systems: Figure 1: DeglomeratorSrikanth Mankala100% (1)

- KilnOpBasics - ManufProcess OverviewDocument31 pagesKilnOpBasics - ManufProcess Overviewmustaf100% (1)

- Guidelines COPROCEM LowDocument136 pagesGuidelines COPROCEM LowDekeukelaere Anne100% (1)

- KPI Handbook V9-2017Document42 pagesKPI Handbook V9-2017Neimar HahmeierNo ratings yet

- Cement Process Engineering Vade Mecum: 2. StatisticsDocument15 pagesCement Process Engineering Vade Mecum: 2. StatisticsVictorAndresMillaSalazarNo ratings yet

- Main BurnerDocument2 pagesMain BurnerSatish Kumar100% (1)

- Cem Train-21 SamplingDocument7 pagesCem Train-21 SamplingmohamedredaNo ratings yet

- Cement Processing Hol CimDocument1 pageCement Processing Hol CimShailesh RaneNo ratings yet

- 30 Reduction in Energy by Cooler Modification With IKN Pendulum CoolerDocument26 pages30 Reduction in Energy by Cooler Modification With IKN Pendulum CoolerBülent BulutNo ratings yet

- Loesche Grinding Plants For Coal GasificationDocument45 pagesLoesche Grinding Plants For Coal GasificationMaxim Polevoy100% (1)

- Kiln Audit Training IntroductionDocument15 pagesKiln Audit Training IntroductionTamer Fathy100% (1)

- FormulaDocument60 pagesFormulaYhaneNo ratings yet

- Guidelines For Solid FuelsDocument81 pagesGuidelines For Solid Fuelsjorge1947No ratings yet

- Inspection Report For Raw Mill's Internal Parts.: ObjectiveDocument3 pagesInspection Report For Raw Mill's Internal Parts.: ObjectiveMahmoud HanafyNo ratings yet

- Bogiflex KGD20 - For PlantDocument13 pagesBogiflex KGD20 - For PlantAnonymous PVXBGg9TNo ratings yet

- 441 GC & EspDocument6 pages441 GC & EspMKPashaPashaNo ratings yet

- Combustion CalculationesDocument3 pagesCombustion CalculationesSatish KumarNo ratings yet

- KHD Pyroclon EnglDocument4 pagesKHD Pyroclon Englkresimir.mikoc9765100% (1)

- Introduction of Bag Filters Constructional FeaturesDocument32 pagesIntroduction of Bag Filters Constructional FeaturesTin NguyenNo ratings yet

- Cement Plant Key Performance Indicators PDFDocument32 pagesCement Plant Key Performance Indicators PDFmanikandan RNo ratings yet

- Line II KPI 02-07-2021Document27 pagesLine II KPI 02-07-2021Raahi NoorNo ratings yet

- Combustion Engineering: Technical Development Program For Process Performance EngineersDocument36 pagesCombustion Engineering: Technical Development Program For Process Performance Engineersvikubhardwaj9224100% (1)

- Cement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 3.3 - ExerciseDocument1 pageCement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 3.3 - ExerciseElwathig BakhietNo ratings yet

- Qdoc - Tips - Proceedings English CompleterevbDocument217 pagesQdoc - Tips - Proceedings English CompleterevbThanhluan Nguyen100% (1)

- Kiln Stopped Due To BBS LeakageDocument8 pagesKiln Stopped Due To BBS LeakageSafrin SangiaNo ratings yet

- Mcr-T1: Raw Material BasisDocument1 pageMcr-T1: Raw Material Basismahreza189No ratings yet

- Thermal & Chemical - Kilb 2015Document37 pagesThermal & Chemical - Kilb 2015Moud SaklyNo ratings yet

- Book 6 Cement KilnsDocument24 pagesBook 6 Cement KilnsPrabakaran BaskaranNo ratings yet

- Kiln Inlet Risk AssessmentDocument2 pagesKiln Inlet Risk AssessmentmunatsiNo ratings yet

- TechManual Commercial CDDocument244 pagesTechManual Commercial CDWei Jia WenNo ratings yet

- Unitherm MAS-SW Gas Burner Staff-Training (Compatibility Mode)Document42 pagesUnitherm MAS-SW Gas Burner Staff-Training (Compatibility Mode)Nael88% (8)

- Classification Separation Exercise2.5.2Document2 pagesClassification Separation Exercise2.5.2Mohammed AbdoNo ratings yet

- Instruction For Filling Up The Form-Sb & Keeping Records and Information For Verification ProcessDocument57 pagesInstruction For Filling Up The Form-Sb & Keeping Records and Information For Verification ProcessBùi Hắc HảiNo ratings yet

- Opening PPE Course 2008Document7 pagesOpening PPE Course 2008vikubhardwaj9224No ratings yet

- Coolers SystemDocument69 pagesCoolers SystemM.IBRAHEEM100% (1)

- Oin Ops Chem 003 Recommendations On Online InstrumentsDocument9 pagesOin Ops Chem 003 Recommendations On Online InstrumentsraniNo ratings yet

- 45-R1 Indoor & Outdoor Unit & Installation Accessories (Samsung)Document155 pages45-R1 Indoor & Outdoor Unit & Installation Accessories (Samsung)ridNo ratings yet

- Reverse Osmosis Plant Capacity 25 LPH RO PlantDocument9 pagesReverse Osmosis Plant Capacity 25 LPH RO PlantsanjeevNo ratings yet

- 8115165rrev1 PDFDocument17 pages8115165rrev1 PDFpguosNo ratings yet

- Unloading by TrucksDocument2 pagesUnloading by Truckssaji kumarNo ratings yet

- Sop For Operation of EotDocument2 pagesSop For Operation of Eotsaji kumarNo ratings yet

- TASK - Clinker - Loading - in - RakeDocument2 pagesTASK - Clinker - Loading - in - Rakesaji kumarNo ratings yet

- Dammurage Study FormatDocument2 pagesDammurage Study Formatsaji kumarNo ratings yet

- Heo Operator: Token Empolyee Name Mobile Number DOZAR/Loader Clain ShellDocument6 pagesHeo Operator: Token Empolyee Name Mobile Number DOZAR/Loader Clain Shellsaji kumarNo ratings yet

- Invoice Was Made, With Weight of Clinker by Difference of Gross Weight and Tare WeightDocument1 pageInvoice Was Made, With Weight of Clinker by Difference of Gross Weight and Tare Weightsaji kumarNo ratings yet

- North - PV Var - Summary LK MarDocument3 pagesNorth - PV Var - Summary LK Marsaji kumarNo ratings yet

- Pre Installation Lab Requirements: (For Arl XRF 9900 Intellipower Series Spectrometer - 1200W)Document3 pagesPre Installation Lab Requirements: (For Arl XRF 9900 Intellipower Series Spectrometer - 1200W)saji kumarNo ratings yet

- 1.microscopy - Glass Content in Slag SOPDocument1 page1.microscopy - Glass Content in Slag SOPsaji kumarNo ratings yet

- Standard Operating Procedures 1Document1 pageStandard Operating Procedures 1saji kumarNo ratings yet

- Compliance Checklist - PlantDocument36 pagesCompliance Checklist - Plantsaji kumarNo ratings yet

- 1.1 Program KymoreDocument2 pages1.1 Program Kymoresaji kumarNo ratings yet

- SOP - 22 - Preparation of Activated GypsumDocument2 pagesSOP - 22 - Preparation of Activated Gypsumsaji kumarNo ratings yet

- Ot SlipDocument1 pageOt Slipsaji kumarNo ratings yet

- B K Singh Sot Dec06Document1 pageB K Singh Sot Dec06saji kumarNo ratings yet

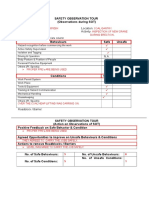

- M.P.Singh & B.K.Singh Coal Mill CCR 27/03/06 Mill Operation: Observer's Name: Location: Date: ActivityDocument2 pagesM.P.Singh & B.K.Singh Coal Mill CCR 27/03/06 Mill Operation: Observer's Name: Location: Date: Activitysaji kumarNo ratings yet

- Visit To DelhiDocument11 pagesVisit To Delhisaji kumarNo ratings yet

- Please Tick in Appropriate Column: Roadblock / BarrierDocument1 pagePlease Tick in Appropriate Column: Roadblock / Barriersaji kumarNo ratings yet

- BH15/SN23 BH15/SN30Document17 pagesBH15/SN23 BH15/SN30saji kumarNo ratings yet

- Procurement Process Guide V 5.0 - Final CompressedDocument114 pagesProcurement Process Guide V 5.0 - Final Compressedsaji kumar100% (1)

- Mines Bore Hole Sample Analysis Test Results (Durg)Document4 pagesMines Bore Hole Sample Analysis Test Results (Durg)saji kumarNo ratings yet

- Chapter 3a Geometry of CrystalsDocument72 pagesChapter 3a Geometry of Crystalssaji kumar100% (1)

- Jeld WenDocument1 pageJeld WenGg36No ratings yet

- Shop Windows 10 Professional Product Key With Lifetime Legitimacy Onlinekielj PDFDocument2 pagesShop Windows 10 Professional Product Key With Lifetime Legitimacy Onlinekielj PDFneedsoap6No ratings yet

- Package CTT': R Topics DocumentedDocument20 pagesPackage CTT': R Topics DocumentedSan Ban CastroNo ratings yet

- Mcqs On Analog Modulation (Am FM) Am Radio Limits The Upper Modulating Frequency To 5 Khz. This Results in ADocument18 pagesMcqs On Analog Modulation (Am FM) Am Radio Limits The Upper Modulating Frequency To 5 Khz. This Results in AZynNo ratings yet

- Microsoft Official Course: Deploying and Managing Windows Server 2012Document38 pagesMicrosoft Official Course: Deploying and Managing Windows Server 2012Adela Milea100% (1)

- AKX00022 WebDocument3 pagesAKX00022 WebShaik Arif BashaNo ratings yet

- OJT in WiproDocument8 pagesOJT in Wiproneha91npNo ratings yet

- Resume FinalDocument2 pagesResume FinalYoulah Mae Ybañez-PactolNo ratings yet

- Week 2 AssignmentDocument5 pagesWeek 2 AssignmentIkram Ullah Kakar50% (4)

- PanasonicDocument55 pagesPanasonicHuy TranNo ratings yet

- Practical Assignments For PHP Programming (PART-A)Document4 pagesPractical Assignments For PHP Programming (PART-A)dishanthpatel242No ratings yet

- Winplot TutorialDocument16 pagesWinplot TutorialRicardo MoGaNo ratings yet

- Redemption Form: 身为 Abbott Share & Care World (ASCW) 会员的我也核准 Abbott 透露我的个人资料*给指定的第三方以提供给 我额外的增值服务。Document2 pagesRedemption Form: 身为 Abbott Share & Care World (ASCW) 会员的我也核准 Abbott 透露我的个人资料*给指定的第三方以提供给 我额外的增值服务。nadhilah saffini100% (1)

- Data Warehousing and Data MiningDocument31 pagesData Warehousing and Data Miningpratyush0501No ratings yet

- Dual Band Butterfly Planar Antenna For WLAN ApplicationsDocument3 pagesDual Band Butterfly Planar Antenna For WLAN ApplicationsJuliana RedNo ratings yet

- Permutations & Combinations (Question Paper)Document4 pagesPermutations & Combinations (Question Paper)Abhinav RVNo ratings yet

- SAP - PP - Configurations XDocument5 pagesSAP - PP - Configurations XCamran KhanNo ratings yet

- CV - Vilma Tafilica 2Document2 pagesCV - Vilma Tafilica 2Vilma TafilicaNo ratings yet

- Hostel Warden CodesDocument74 pagesHostel Warden CodesgovardhanNo ratings yet

- APQPDocument4 pagesAPQPAmit Kumar SharmaNo ratings yet

- The Golden Technology Group - GTGDocument2 pagesThe Golden Technology Group - GTGDisco DancerNo ratings yet

- Tutorial 3Document11 pagesTutorial 3Gabriel MakNo ratings yet

- APM9926/C: Features ApplicationsDocument11 pagesAPM9926/C: Features ApplicationsMorteza BaratzadehNo ratings yet

- OmniTom Brochure 1-NL5000-100rev00Document8 pagesOmniTom Brochure 1-NL5000-100rev00david.fireNo ratings yet

- Service Manual: DEH-P450MPDocument76 pagesService Manual: DEH-P450MPTeddy KhantNo ratings yet

- An Automated Approach To Driving Assistance and Accident DetectionDocument3 pagesAn Automated Approach To Driving Assistance and Accident DetectionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- BRK232Document20 pagesBRK232wciscatoNo ratings yet

- Scandence: QR Code Based Attendance Management SystemDocument11 pagesScandence: QR Code Based Attendance Management SystemKaustubh SawantNo ratings yet

- Data Science Motivational LetterDocument2 pagesData Science Motivational LetterAli FaramarzNo ratings yet

- TreasuryDM1 2 MainDocument2 pagesTreasuryDM1 2 MainbalasukNo ratings yet

LK-XRF XRD Presentation

LK-XRF XRD Presentation

Uploaded by

saji kumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LK-XRF XRD Presentation

LK-XRF XRD Presentation

Uploaded by

saji kumarCopyright:

Available Formats

Sampling - XRD/XRF Course preparation

Participants name :

Dinesh Purohit

(Manager QA)

Lakheri Cement Works

Venue Maddukarrai Cement Works

Date -

Holcim Group Support Ltd 2010

XRF situation in Lakheri

Equipment Details

Equipment

Range

Existing

Parameter

XRF KV

0-30 (+/- 0.1)

30

XRF MA

0-40(+/- 0.1)

40

MDP Speed

10000-28000

27000

MDP Temp

15-60 deg C

20-30 deg C

0-8 Pa

2-6.5 Pa

400-4500

1900-2150

Spectrometer

Pressure (Vacuum)

Sec Water Resistively

* Check up of equipments as per ICS Instrument Status

Holcim Group Support Ltd 2010

10-03-08

Preparation XRD

XRF situation in Lakheri (Cont)

Equipment maintenance/Lab conditions

Internal- When soft maintenance like cartridge change and other smaller

job

External When Major s break down due to hardware & software

problem .

We control and monitor XRF KV, XRF MA, MDP Speed , Spectrometer

pressure ,Sec Water receptivity, P10 Gas cylinder pressure and flow

No Environment problems related to laboratory conditions

Room Temp maintained 20-22 deg C

Analysis control

We use press pallet as well as calibration standard press pallet in drift

correction

When analysis became out of tolerance (permissible limit) or addition/

deletion of New calibration standard - Drift Correction Method

Almost they are System sample with wide rage but some standard sample

like HOT Meal is synthetic.

Holcim Group Support Ltd 2010

10-03-08

Preparation XRD

XRF situation in Lakheri (cont.)

Supplier support

Service contract

service contract include only AMC twice in year and guarantee spares replacement(if required )

01 year service contract

Cost - 2,65,000 INR.

The supplier rate for service is good.

Specific issues for discussion with the supplier

Minimize break down time.

Critical spares availability in Indian counterpart.

One Maintance engg HQ should be at Jaipur/ Bhopal.

Supplier should trained at least Two instrument engg so that they can be able to follow the

service engg on phone and able to resolve cassette stucked in transmission problem & can

able to change FPC window and minimize XRF break down time.

Make more easy calibration procedure.

Water cartridge replacement alarm should give sufficient for replacement.

The serious and/or frequent problems are Hardware related problem generated XRF shut down

min. 1 month per year.

We faced many Hardware failures Related To Power supply system , and vacuum system,

Gonio Amplifier break down no any problem related to source, crystals & detectors.

Two times Software related problem Stopped XRF functions for 07 days .

Water pump failure , more noise and no new warrantee pump receive.

Instrument remain stopped for 07 week

Holcim Group Support Ltd 2010

10-03-08

Preparation XRD

XRD situation in Lakheri (Cont)

Preparation of Samples

Using same press pallet for XRD and XRF.

Before preparation of press pallet we ensure that powder should Below 63 microns size.

And results obtained of such press pallet again confirmed by our calibration standard

powder ,which was already analyzed at Techport, Thane.

Free lime analysis

free lime determined by calibration method only

free lime determined by XRD, cross checked by acid alkali titration once per shift

and some time much difference observed between them.

We need training of XRD to know

clinker phase with minimum and regular variation with bouge calculation.

XRD give absolute Free lime because some time wide variation observed

XRD and wet analysis.

XRD should give Quartz concentration.

XRD should explain portlandite, gypsum phase in clinker.

XRD should give information of alkali sulphate.

XRD should give important mineral present in Limestone.

Holcim Group Support Ltd 2010

between

10-03-08

Preparation XRD

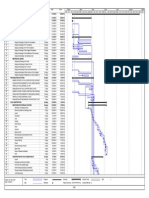

XRF breakdown details

From (Date)

To (Date)

No. Of

days

Reason

25.04.2008

Tripp with alarms 8195,8237& 8222 than

change De Ionized cartage

28.07.08

30.07.2008

18.08.2008

21.08.2008

XRF tripped & automatically restart

Card of x ray generator Is faulty

Continuous

25.09.2008

02.10.2008

Need to change GENEX

Continuous

23.10.2008

25.10.2008

GENEX (S703683T) 1.2 KW, 60 KV

replaced

26.07.2009

28.07.2009

03

General Maintenance

23.08.2009

29.08.2009

07

De Ionized cartage Change

Holcim Group Support Ltd 2010

03

KV too high or too low

10-03-08

Preparation XRD

XRF breakdown details

8

02.09.2009

04.09.2009

Cassette is not coming, stuck in side the tank

09.09.2009

15.09.2009

Concentration analysis program not working

10

21.09.2009

23.09.2009

Cassette is not coming, stuck in side the tank

12

1.12.2009

03.12.2010

Free CaO note analyzed (XRD System not

configured , Found Results abnormal

13

09.07.2010

12.07.2010

Mg,Na,Ba & Ti Found Results abnormal

(found F FIFO - full alarm) change S

703424 MUX Pre amplifier card)

14

31.07.2010

11.08.2010

12

Water pump found jam, change water pump

,Replacement of Preamplifier (MUX) for

Goniometer , Si mono channel is not working

15

08.10.2010

15.10.2010

Sample Not analyzed, molecular Pump frequently

tripped, than increase temp. of pump

Holcim Group Support Ltd 2010

10-03-08

Preparation XRD

Specific problems or success stories

Almost we are not so comfort because of

5 time break down of hardware like- Genex, mono 2 failure, MDP Pump,

water Pump replaced after one and half year of reporting.

Some time service engg. reach at site after 7-10 day of information.

Software for calibration is not user friendly because during task same entry

were fill in three time .

There were no sufficient time Before alarm to replace de ionizing water

cartridge and within half hour water cartridge became useless

Holcim Group Support Ltd 2010

10-03-08

Preparation XRD

Thank You

Holcim Group Support Ltd 2010

10-03-08

Preparation XRD

You might also like

- Cement Class NoteDocument19 pagesCement Class NoteEstiak AhmedNo ratings yet

- FLSmidth - Cement Training Catalogue 2018 PDFDocument12 pagesFLSmidth - Cement Training Catalogue 2018 PDFbertawan bastiarNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Cement GrindingDocument102 pagesCement GrindingSatish Kumar100% (1)

- New Hardware Grinding Aid - ECOFORDocument5 pagesNew Hardware Grinding Aid - ECOFORlovjnxNo ratings yet

- Cement Process Engineering Vade-Mecum: 1. MathematicsDocument7 pagesCement Process Engineering Vade-Mecum: 1. MathematicsTamer FathyNo ratings yet

- Cpb-Sem2011-P11-Axial Sampling and Tromp CurveDocument54 pagesCpb-Sem2011-P11-Axial Sampling and Tromp Curvechibssa alemayehu100% (1)

- Lafarge Cement Optimization SolutionDocument2 pagesLafarge Cement Optimization SolutionRaja Shannmugam100% (1)

- Cooling Cement Clinker Exercise2.3.4Document2 pagesCooling Cement Clinker Exercise2.3.4Mohammed AbdoNo ratings yet

- Safety PauseDocument4 pagesSafety PauseSafrin SangiaNo ratings yet

- 04 MillingDocument21 pages04 MillingMKPashaPasha100% (1)

- Running Insp Sheet NewDocument20 pagesRunning Insp Sheet NewSafrin SangiaNo ratings yet

- Upgradation of Kiln System To Enhance Productivity and Reduce Energy ConsumptionDocument38 pagesUpgradation of Kiln System To Enhance Productivity and Reduce Energy ConsumptionRavindranath BheemisettyNo ratings yet

- Holderbank: Binder 1 Materials Technology IDocument2 pagesHolderbank: Binder 1 Materials Technology IlatiefNo ratings yet

- Performing A Cement Plant Operations AuditDocument6 pagesPerforming A Cement Plant Operations AuditJa Phe TiNo ratings yet

- Electrical Energy Module Final Draft 20Document161 pagesElectrical Energy Module Final Draft 20Safrin SangiaNo ratings yet

- Performance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement PlantDocument8 pagesPerformance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement PlantSohail AhmedNo ratings yet

- 36 - Process Characteristics of Clinker and Cement Production - Cluster Workshop Hamburg 2107 - 10 - 26 - PresentedDocument30 pages36 - Process Characteristics of Clinker and Cement Production - Cluster Workshop Hamburg 2107 - 10 - 26 - PresentedIrshad Hussain100% (1)

- Silo 9 Boulders Investigation ReportDocument20 pagesSilo 9 Boulders Investigation ReportWaka OngetiNo ratings yet

- PS05 - PS ReportsDocument9 pagesPS05 - PS Reportssaji kumarNo ratings yet

- Thermal Ennergy SavingsDocument13 pagesThermal Ennergy SavingsSalud Y Sucesos100% (1)

- Better Grinding Systems: Figure 1: DeglomeratorDocument5 pagesBetter Grinding Systems: Figure 1: DeglomeratorSrikanth Mankala100% (1)

- KilnOpBasics - ManufProcess OverviewDocument31 pagesKilnOpBasics - ManufProcess Overviewmustaf100% (1)

- Guidelines COPROCEM LowDocument136 pagesGuidelines COPROCEM LowDekeukelaere Anne100% (1)

- KPI Handbook V9-2017Document42 pagesKPI Handbook V9-2017Neimar HahmeierNo ratings yet

- Cement Process Engineering Vade Mecum: 2. StatisticsDocument15 pagesCement Process Engineering Vade Mecum: 2. StatisticsVictorAndresMillaSalazarNo ratings yet

- Main BurnerDocument2 pagesMain BurnerSatish Kumar100% (1)

- Cem Train-21 SamplingDocument7 pagesCem Train-21 SamplingmohamedredaNo ratings yet

- Cement Processing Hol CimDocument1 pageCement Processing Hol CimShailesh RaneNo ratings yet

- 30 Reduction in Energy by Cooler Modification With IKN Pendulum CoolerDocument26 pages30 Reduction in Energy by Cooler Modification With IKN Pendulum CoolerBülent BulutNo ratings yet

- Loesche Grinding Plants For Coal GasificationDocument45 pagesLoesche Grinding Plants For Coal GasificationMaxim Polevoy100% (1)

- Kiln Audit Training IntroductionDocument15 pagesKiln Audit Training IntroductionTamer Fathy100% (1)

- FormulaDocument60 pagesFormulaYhaneNo ratings yet

- Guidelines For Solid FuelsDocument81 pagesGuidelines For Solid Fuelsjorge1947No ratings yet

- Inspection Report For Raw Mill's Internal Parts.: ObjectiveDocument3 pagesInspection Report For Raw Mill's Internal Parts.: ObjectiveMahmoud HanafyNo ratings yet

- Bogiflex KGD20 - For PlantDocument13 pagesBogiflex KGD20 - For PlantAnonymous PVXBGg9TNo ratings yet

- 441 GC & EspDocument6 pages441 GC & EspMKPashaPashaNo ratings yet

- Combustion CalculationesDocument3 pagesCombustion CalculationesSatish KumarNo ratings yet

- KHD Pyroclon EnglDocument4 pagesKHD Pyroclon Englkresimir.mikoc9765100% (1)

- Introduction of Bag Filters Constructional FeaturesDocument32 pagesIntroduction of Bag Filters Constructional FeaturesTin NguyenNo ratings yet

- Cement Plant Key Performance Indicators PDFDocument32 pagesCement Plant Key Performance Indicators PDFmanikandan RNo ratings yet

- Line II KPI 02-07-2021Document27 pagesLine II KPI 02-07-2021Raahi NoorNo ratings yet

- Combustion Engineering: Technical Development Program For Process Performance EngineersDocument36 pagesCombustion Engineering: Technical Development Program For Process Performance Engineersvikubhardwaj9224100% (1)

- Cement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 3.3 - ExerciseDocument1 pageCement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 3.3 - ExerciseElwathig BakhietNo ratings yet

- Qdoc - Tips - Proceedings English CompleterevbDocument217 pagesQdoc - Tips - Proceedings English CompleterevbThanhluan Nguyen100% (1)

- Kiln Stopped Due To BBS LeakageDocument8 pagesKiln Stopped Due To BBS LeakageSafrin SangiaNo ratings yet

- Mcr-T1: Raw Material BasisDocument1 pageMcr-T1: Raw Material Basismahreza189No ratings yet

- Thermal & Chemical - Kilb 2015Document37 pagesThermal & Chemical - Kilb 2015Moud SaklyNo ratings yet

- Book 6 Cement KilnsDocument24 pagesBook 6 Cement KilnsPrabakaran BaskaranNo ratings yet

- Kiln Inlet Risk AssessmentDocument2 pagesKiln Inlet Risk AssessmentmunatsiNo ratings yet

- TechManual Commercial CDDocument244 pagesTechManual Commercial CDWei Jia WenNo ratings yet

- Unitherm MAS-SW Gas Burner Staff-Training (Compatibility Mode)Document42 pagesUnitherm MAS-SW Gas Burner Staff-Training (Compatibility Mode)Nael88% (8)

- Classification Separation Exercise2.5.2Document2 pagesClassification Separation Exercise2.5.2Mohammed AbdoNo ratings yet

- Instruction For Filling Up The Form-Sb & Keeping Records and Information For Verification ProcessDocument57 pagesInstruction For Filling Up The Form-Sb & Keeping Records and Information For Verification ProcessBùi Hắc HảiNo ratings yet

- Opening PPE Course 2008Document7 pagesOpening PPE Course 2008vikubhardwaj9224No ratings yet

- Coolers SystemDocument69 pagesCoolers SystemM.IBRAHEEM100% (1)

- Oin Ops Chem 003 Recommendations On Online InstrumentsDocument9 pagesOin Ops Chem 003 Recommendations On Online InstrumentsraniNo ratings yet

- 45-R1 Indoor & Outdoor Unit & Installation Accessories (Samsung)Document155 pages45-R1 Indoor & Outdoor Unit & Installation Accessories (Samsung)ridNo ratings yet

- Reverse Osmosis Plant Capacity 25 LPH RO PlantDocument9 pagesReverse Osmosis Plant Capacity 25 LPH RO PlantsanjeevNo ratings yet

- 8115165rrev1 PDFDocument17 pages8115165rrev1 PDFpguosNo ratings yet

- Unloading by TrucksDocument2 pagesUnloading by Truckssaji kumarNo ratings yet

- Sop For Operation of EotDocument2 pagesSop For Operation of Eotsaji kumarNo ratings yet

- TASK - Clinker - Loading - in - RakeDocument2 pagesTASK - Clinker - Loading - in - Rakesaji kumarNo ratings yet

- Dammurage Study FormatDocument2 pagesDammurage Study Formatsaji kumarNo ratings yet

- Heo Operator: Token Empolyee Name Mobile Number DOZAR/Loader Clain ShellDocument6 pagesHeo Operator: Token Empolyee Name Mobile Number DOZAR/Loader Clain Shellsaji kumarNo ratings yet

- Invoice Was Made, With Weight of Clinker by Difference of Gross Weight and Tare WeightDocument1 pageInvoice Was Made, With Weight of Clinker by Difference of Gross Weight and Tare Weightsaji kumarNo ratings yet

- North - PV Var - Summary LK MarDocument3 pagesNorth - PV Var - Summary LK Marsaji kumarNo ratings yet

- Pre Installation Lab Requirements: (For Arl XRF 9900 Intellipower Series Spectrometer - 1200W)Document3 pagesPre Installation Lab Requirements: (For Arl XRF 9900 Intellipower Series Spectrometer - 1200W)saji kumarNo ratings yet

- 1.microscopy - Glass Content in Slag SOPDocument1 page1.microscopy - Glass Content in Slag SOPsaji kumarNo ratings yet

- Standard Operating Procedures 1Document1 pageStandard Operating Procedures 1saji kumarNo ratings yet

- Compliance Checklist - PlantDocument36 pagesCompliance Checklist - Plantsaji kumarNo ratings yet

- 1.1 Program KymoreDocument2 pages1.1 Program Kymoresaji kumarNo ratings yet

- SOP - 22 - Preparation of Activated GypsumDocument2 pagesSOP - 22 - Preparation of Activated Gypsumsaji kumarNo ratings yet

- Ot SlipDocument1 pageOt Slipsaji kumarNo ratings yet

- B K Singh Sot Dec06Document1 pageB K Singh Sot Dec06saji kumarNo ratings yet

- M.P.Singh & B.K.Singh Coal Mill CCR 27/03/06 Mill Operation: Observer's Name: Location: Date: ActivityDocument2 pagesM.P.Singh & B.K.Singh Coal Mill CCR 27/03/06 Mill Operation: Observer's Name: Location: Date: Activitysaji kumarNo ratings yet

- Visit To DelhiDocument11 pagesVisit To Delhisaji kumarNo ratings yet

- Please Tick in Appropriate Column: Roadblock / BarrierDocument1 pagePlease Tick in Appropriate Column: Roadblock / Barriersaji kumarNo ratings yet

- BH15/SN23 BH15/SN30Document17 pagesBH15/SN23 BH15/SN30saji kumarNo ratings yet

- Procurement Process Guide V 5.0 - Final CompressedDocument114 pagesProcurement Process Guide V 5.0 - Final Compressedsaji kumar100% (1)

- Mines Bore Hole Sample Analysis Test Results (Durg)Document4 pagesMines Bore Hole Sample Analysis Test Results (Durg)saji kumarNo ratings yet

- Chapter 3a Geometry of CrystalsDocument72 pagesChapter 3a Geometry of Crystalssaji kumar100% (1)

- Jeld WenDocument1 pageJeld WenGg36No ratings yet

- Shop Windows 10 Professional Product Key With Lifetime Legitimacy Onlinekielj PDFDocument2 pagesShop Windows 10 Professional Product Key With Lifetime Legitimacy Onlinekielj PDFneedsoap6No ratings yet

- Package CTT': R Topics DocumentedDocument20 pagesPackage CTT': R Topics DocumentedSan Ban CastroNo ratings yet

- Mcqs On Analog Modulation (Am FM) Am Radio Limits The Upper Modulating Frequency To 5 Khz. This Results in ADocument18 pagesMcqs On Analog Modulation (Am FM) Am Radio Limits The Upper Modulating Frequency To 5 Khz. This Results in AZynNo ratings yet

- Microsoft Official Course: Deploying and Managing Windows Server 2012Document38 pagesMicrosoft Official Course: Deploying and Managing Windows Server 2012Adela Milea100% (1)

- AKX00022 WebDocument3 pagesAKX00022 WebShaik Arif BashaNo ratings yet

- OJT in WiproDocument8 pagesOJT in Wiproneha91npNo ratings yet

- Resume FinalDocument2 pagesResume FinalYoulah Mae Ybañez-PactolNo ratings yet

- Week 2 AssignmentDocument5 pagesWeek 2 AssignmentIkram Ullah Kakar50% (4)

- PanasonicDocument55 pagesPanasonicHuy TranNo ratings yet

- Practical Assignments For PHP Programming (PART-A)Document4 pagesPractical Assignments For PHP Programming (PART-A)dishanthpatel242No ratings yet

- Winplot TutorialDocument16 pagesWinplot TutorialRicardo MoGaNo ratings yet

- Redemption Form: 身为 Abbott Share & Care World (ASCW) 会员的我也核准 Abbott 透露我的个人资料*给指定的第三方以提供给 我额外的增值服务。Document2 pagesRedemption Form: 身为 Abbott Share & Care World (ASCW) 会员的我也核准 Abbott 透露我的个人资料*给指定的第三方以提供给 我额外的增值服务。nadhilah saffini100% (1)

- Data Warehousing and Data MiningDocument31 pagesData Warehousing and Data Miningpratyush0501No ratings yet

- Dual Band Butterfly Planar Antenna For WLAN ApplicationsDocument3 pagesDual Band Butterfly Planar Antenna For WLAN ApplicationsJuliana RedNo ratings yet

- Permutations & Combinations (Question Paper)Document4 pagesPermutations & Combinations (Question Paper)Abhinav RVNo ratings yet

- SAP - PP - Configurations XDocument5 pagesSAP - PP - Configurations XCamran KhanNo ratings yet

- CV - Vilma Tafilica 2Document2 pagesCV - Vilma Tafilica 2Vilma TafilicaNo ratings yet

- Hostel Warden CodesDocument74 pagesHostel Warden CodesgovardhanNo ratings yet

- APQPDocument4 pagesAPQPAmit Kumar SharmaNo ratings yet

- The Golden Technology Group - GTGDocument2 pagesThe Golden Technology Group - GTGDisco DancerNo ratings yet

- Tutorial 3Document11 pagesTutorial 3Gabriel MakNo ratings yet

- APM9926/C: Features ApplicationsDocument11 pagesAPM9926/C: Features ApplicationsMorteza BaratzadehNo ratings yet

- OmniTom Brochure 1-NL5000-100rev00Document8 pagesOmniTom Brochure 1-NL5000-100rev00david.fireNo ratings yet

- Service Manual: DEH-P450MPDocument76 pagesService Manual: DEH-P450MPTeddy KhantNo ratings yet

- An Automated Approach To Driving Assistance and Accident DetectionDocument3 pagesAn Automated Approach To Driving Assistance and Accident DetectionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- BRK232Document20 pagesBRK232wciscatoNo ratings yet

- Scandence: QR Code Based Attendance Management SystemDocument11 pagesScandence: QR Code Based Attendance Management SystemKaustubh SawantNo ratings yet

- Data Science Motivational LetterDocument2 pagesData Science Motivational LetterAli FaramarzNo ratings yet

- TreasuryDM1 2 MainDocument2 pagesTreasuryDM1 2 MainbalasukNo ratings yet