Professional Documents

Culture Documents

Ashaka PulseJet Presentation

Ashaka PulseJet Presentation

Uploaded by

Mega Purnama ZainalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ashaka PulseJet Presentation

Ashaka PulseJet Presentation

Uploaded by

Mega Purnama ZainalCopyright:

Available Formats

Pulse Jet Dust Collector

Bag Filters

Pulse Jet Dust Collector

Pulse Jet Dust Collector

Why dust collectors?

Bag Filter Training Ashaka / 16/01/16 - 2

Pulse Jet Dust Collector

Why dust collectors?

Process Dust Collectors

Air Slide Dust Collectors

Bucket Elevator Dust Collectors

FK Pump feed hopper Dust Collectors

Silo Dust Collectors

Clinker Cooler Dust Collectors

Bag Filter Training Ashaka / 16/01/16 - 3

Pulse Jet Dust Collector

Why dust collectors?

To separate solid particulate matter from a gas

stream in order to maintain environmental

compliance

In most cement manufacturing applications, the

Dust Collector returns solid particulate matter back

to the operation for further processing

Bag Filter Training Ashaka / 16/01/16 - 4

Pulse Jet Dust Collector

Why dust collectors?

......and because DUST is also Money

(, $ or )

Bag Filter Training Ashaka / 16/01/16 - 5

Pulse Jet Dust Collector

Dust Collectors

Expansion chambers

Cyclones

Multi-cyclones

Sand filters

Scrubers

Fabric filters

Cartridge

ESP

Bag Filter Training Ashaka / 16/01/16 - 6

Pulse Jet Dust Collector

Fabric filters

Bag filters: three types according the

cleaning system

1. Shaker

2. Air reverse

3. Pulso jet

Bag Filter Training Ashaka / 16/01/16 - 7

Pulse Jet Dust Collector

Bag filter: shaker cleaning system

Particulate is collected on the inside surface of

the bag. The dust-laden gas enters through the

dirty side (inlet) of the collector and flows up

through the bag.

Tensioning assembly

Clamps

Bag Filter Training Ashaka / 16/01/16 - 8

Pulse Jet Dust Collector

Bag filter: reverse air

Additional

fan create

reverse air flow to

blow the bags and the

cake

is

dislodged.

Compartments need to

be isolated.

Bag Filter Training Ashaka / 16/01/16 - 9

Pulse Jet Dust Collector

Bag filter: pulso jet cleaning system

Blowpipe

Induced

Secondary

Pulse

Tube Sheet

Snap Band

Venturi

Cage

Shockwave

Normal flow

Dust

Bag Filter Training Ashaka / 16/01/16 - 10

Pulse Jet Dust Collector

Bag filter: pulso jet cleaning system

Bag Filter Training Ashaka / 16/01/16 - 11

Pulse Jet Dust Collector

PJBF Components

Dust Collector Intake

Deflector, Diffuser, or

Baffle Assembly

Dirty Air Chamber

Airlock

Filter Bag

Cage

Venturi

Tubesheet

Bag Filter Training Ashaka / 16/01/16 - 12

Pulse Jet Dust Collector

PJBF Components (contd)

Pulse Control System

Compressed Air Supply

Manifold

Solenoid Valve

Diaphragm Valve

Blow Down

Clean Air Chamber

Dust Collector Exhaust

Differential Pressure Indicator

Bag Filter Training Ashaka / 16/01/16 - 13

Pulse Jet Dust Collector

PJBF Components: Cleaning system

The essential parts:

C.A. manifold (14)

Pneumatic valves (13)

Solenoid valves box (8)

Air tube (7 / 19)

The airtight system between

ramps and body filter (detail B)

Air tube (compressed air

distributors) plus nozzles (5 / 6)

Bag Filter Training Ashaka / 16/01/16 - 14

Pulse Jet Dust Collector

PJBF Components: Manifold

C.A. Manifold

Bag Filter Training Ashaka / 16/01/16 - 15

Pulse Jet Dust Collector

PJBF Components

Manifold

+

Pulse valves

+

Expansion joint

Clean air chamber

+

Air pipes

Bag Filter Training Ashaka / 16/01/16 - 16

Pulse Jet Dust Collector

PJBF Components

Bag Filter Training Ashaka / 16/01/16 - 17

Pulse Jet Dust Collector

PJBF Components

Solenoide valve box

Bag Filter Training Ashaka / 16/01/16 - 18

Pulse Jet Dust Collector

PJBF Components: Tube sheet

Bag Filter Training Ashaka / 16/01/16 - 19

Pulse Jet Dust Collector

PJBF Components: Tube sheet

Up

Down

Bag Filter Training Ashaka / 16/01/16 - 20

Pulse Jet Dust Collector

PJBF Components

Bag

Venturi

Cage

Bag Filter Training Ashaka / 16/01/16 - 21

Pulse Jet Dust Collector

PJBF Components

Pulse valves

Solenoide valves

Bag Filter Training Ashaka / 16/01/16 - 22

Pulse Jet Dust Collector

Principle of Operation

System fan creates airflow thru Pulse Jet DC

Dust-laden gas enters thru inlet duct @ velocity x

Initial separation occurs as gas velocity slows due

to increase in volume as it enters dirty air chamber

(gas velocity decrease allows coarse material to fall

out of suspension)

Coarse material separation further enhanced by

inlet baffle/deflection plate that forces gas to make

abrupt change in direction in dirty air chamber

Bag Filter Training Ashaka / 16/01/16 - 23

Pulse Jet Dust Collector

Principle of Operation

Change in direction forces more coarse material to

fall out of suspension

Inlet baffle also serves to diffuse airflow evenly

throughout DC (ensures even wear on filter media)

Fine material left in suspension carried upward &

deposited on filter bag surface forms a cake on

bag surface

Bags cleaned regularly to maintain airflow done

by blast of compressed air injected thru venturi @

top opening of filter bag

Bag Filter Training Ashaka / 16/01/16 - 24

Pulse Jet Dust Collector

Principle of Operation

Roles of the venturi:

Increases velocity to enhance shock

wave created by compressed air pulse

Reduces filter bag abrasion by

directing compressed air blast to

center of filter bag

Create secondary induced draft from

clean air chamber helps fill bags with

air & enhances effect of shock wave

dramatically

improves

cleaning

efficiency

Bag Filter Training Ashaka / 16/01/16 - 25

Pulse Jet Dust Collector

Principle of Operation

Blast of compressed air stops normal flow of gases

in the bag & creates shock wave that travels down

inside of cage & back up

Shock wave removes agglomerated cake from

surface of the bag

Agglomerated material falls as a mass into bottom

of dirty air chamber by gravity

Superfine particles are re-entrained

Bag Filter Training Ashaka / 16/01/16 - 26

Pulse Jet Dust Collector

Principle of Operation

After passing thru filter media, clean gas stream

exits clean air chamber thru exhaust duct

Material collected in hopper is metered out by

some form of airlock or screw conveyors

Airlock @ material discharge acts as barrier

between flow of solids (material existing DC) &

false air (air trying to enter from hopper discharge

[in leakage])

Bag Filter Training Ashaka / 16/01/16 - 27

Pulse Jet Dust Collector

Principle of Operation

Bag Filter Training Ashaka / 16/01/16 - 28

Pulse Jet Dust Collector

Principle of Operation

Bag Filter Training Ashaka / 16/01/16 - 29

Pulse Jet Dust Collector

Principle of Operation

Bag Filter Training Ashaka / 16/01/16 - 30

Pulse Jet Dust Collector

Bag caking or P

The level of bag caking

is measured by the

filters

differential

pressure P between

the clean air chamber

and

the

dirty

air

chamber.

100 < P <150 mm WC

Bag Filter Training Ashaka / 16/01/16 - 31

Pulse Jet Dust Collector

Bag caking or P

100 < P <150 mm WC

Bag Filter Training Ashaka / 16/01/16 - 32

Pulse Jet Dust Collector

Optimum Cleaning Cycle

What is the importance of an optimum cleaning

cycle configuration?

Maintains rated airflow through the Dust Collector

at all times

Maintains stable dust return to the process

Optimizes the use of expensive compressed air

Ensures longest possible service life of the filter

media

Shortest possible time to recover pressure in manifold

Bag Filter Training Ashaka / 16/01/16 - 33

Pulse Jet Dust Collector

Optimum Cleaning Cycle

Pulsing system frequency, duration, and sequencing

The

pulsing system is used to control the firing

frequency and duration of the individual diaphragm

solenoid valves

Frequency is configured to maintain a stable DP

ensures a stable airflow through the Collector

The duration is adjusted to ensure optimum use of the

supplied compressed air

Bag Filter Training Ashaka / 16/01/16 - 34

Pulse Jet Dust Collector

Optimum Cleaning Cycle

Pulsing system frequency, duration, and sequencing

The

pulsing system is used to control the firing

frequency and duration of the individual diaphragm

solenoid valves

Frequency is configured to maintain a stable DP

ensures a stable airflow through the Collector

The duration is adjusted to ensure optimum use of the

supplied compressed air

Bag Filter Training Ashaka / 16/01/16 - 35

Pulse Jet Dust Collector

Optimum Cleaning Cycle

Frequency

Too

often Premature bag failure & high

energy

consumption

Too infrequent Large drops of material & unstable dust

returned to the process. Also creates instability in airflow

Bag Filter Training Ashaka / 16/01/16 - 36

Pulse Jet Dust Collector

Optimum Cleaning Cycle

Duration

Too long Waste of compressed air & increases header

pressures regain timing

Too short Shock wave not strong enough to remove filter

cake

Bag Filter Training Ashaka / 16/01/16 - 37

Pulse Jet Dust Collector

Optimum Cleaning Cycle

Sequencing

Never pulse two adjacent rows of bags one after the

other

Clean bags are the path of least resistance to airflow

through the Dust Collector

Pulsing an adjacent row -material released from one set

of bags, some of which will be deposited directly on the

surface of the adjacent clean row of bags

Pulse every other row as a minimum

Bag Filter Training Ashaka / 16/01/16 - 38

Pulse Jet Dust Collector

Optimum Cleaning Cycle

Pulse length: 50 ms

10s - 30s between pulses

Shortest possible time to

recover

manifold

pressure

in

Sequence 1,2,3 = Bad

Sequence 1,3,5 = Good

Never 2 adjacent rows

Bag Filter Training Ashaka / 16/01/16 - 39

Pulse Jet Dust Collector

Types of Pulsing Control

Timer Board Systems

Pulsing system runs continuously during operation

Defined frequency & duration

Bag Filter Training Ashaka / 16/01/16 - 40

Pulse Jet Dust Collector

Types of Pulsing Control

Local Pulse on Demand

System

Timer board cycle starts &

stops based on target

differential pressure

Bag Filter Training Ashaka / 16/01/16 - 41

Pulse Jet Dust Collector

Types of Pulsing Control

Programmable Logic Controllers (PLCs)

Computer controlled pulsing system capable of ondemand pulsing & greater sequencing flexibility

Bag Filter Training Ashaka / 16/01/16 - 42

Pulse Jet Dust Collector

Compressed air

Dry air

5 < P < 7 bars

Bag Filter Training Ashaka / 16/01/16 - 43

Pulse Jet Dust Collector

Engineering

Ducting system:

Gas speed from 16 m/s to 25 m/s

Filtering velocity:

From 1 m/min to 2 m/min

Also called air/cloth ratio

Velocity can:

V<300 fpm (1,5 m/s)

Bag Filter Training Ashaka / 16/01/16 - 44

Pulse Jet Dust Collector

Filter Media & Fabric Finishes

Conventional Depth Filtration

Relies on primary dust cake forming in cross-section of

filtration media

Secondary dust cake accumulates on outside of filtration

surface

Secondary dust cake removed during cleaning cycle

Over time, primary dust cake gets denser, reducing

permeability

Differential pressure increases steadily over life of filter

media

Bag Filter Training Ashaka / 16/01/16 - 45

Pulse Jet Dust Collector

Membrane Surface Filtration

Surface laminate applied directly to conventional filtration

fibre

Effective pore size much smaller than conventional depth

filtration media

Primary filter cake not required

Smooth surface released filter cake during cleaning cycle

Permeability recovers to almost original levels & no gradual

decrease in permeability over time

Consistently lower differential pressure across filter media,

less abrasion, increased airflow & filter life

Bag Filter Training Ashaka / 16/01/16 - 46

Pulse Jet Dust Collector

Filter Fabrics

Coarse Polyester

Felt:

deep penetration

Typical - polyester or glass

(high temp) felt

Allows particles to migrate

through over time & blind bag

Needs thick precoat, layer

Higher $$$ membranes like

Gore-Tex or teflon (PTFE)

Shallow penetration, lasts

Fine Membrane:

shallow penetration

longer before blinding

precoat not as critical

less pressure drop

Bag Filter Training Ashaka / 16/01/16 - 47

Pulse Jet Dust Collector

Filter Fabrics

Bag Filter Training Ashaka / 16/01/16 - 48

Pulse Jet Dust Collector

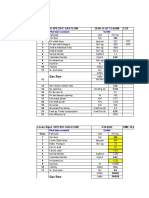

Fabric Comparison

Material

Max Op

Temp

Filtration

Abrasion

Cost

Polypropylene

76 C

Good

Excellent

Polyester

134 C

Excellent

Excellent

Acrylic

140 C

Good

Good

$$

Nomex

205 C

Good

Good

$$

Fibreglass

260 C

Fair

Fair

$$$

Bag Filter Training Ashaka / 16/01/16 - 49

Pulse Jet Dust Collector

Fabric Finishes Non-Fibreglass

Singe improves cake release

Glaze/Eggshell provides short-term improvement

for cake release, but may impede airflow

Silicone aids in initial dust cake development &

provides limited water repellency

Flame retardant retards combustibility, not flameproof; some water repellency, may impede airflow

Surface membrane improves fine particulate

capture, filtration efficiency, cake release & airflow

Bag Filter Training Ashaka / 16/01/16 - 50

Pulse Jet Dust Collector

Fabric Finishes - Fibreglass

Silicone, graphite, teflon protects glass yarn from

abrasion, adds lubricity

Acid resistant shields glass yarn from acid attack

Bag Filter Training Ashaka / 16/01/16 - 51

Pulse Jet Dust Collector

Positive Pressure Dust Collector

Uses

fan on dirty side of Dust

Collector to push dust-laden gas

through system

No pressure differential on casing &

sidewalls;

only

atmospheric

pressure

Less expensive than negative

pressure Dust Collector

Significantly more expensive to

operate & maintain than negative

pressure Dust Collector

Bag Filter Training Ashaka / 16/01/16 - 52

Pulse Jet Dust Collector

Negative Pressure Dust Collector

Uses fan on clean side of Dust Collector

to pull air through system

Filter streams contain high moisture,

corrosive gases & high concentrations of

abrasive dust

Structure must be re-inforced

Leakage contained inside Dust Collector

& emissions dont reach atmosphere

Wear on fan less than with positive

pressure Dust Collector

Bag Filter Training Ashaka / 16/01/16 - 53

Pulse Jet Dust Collector

Bag Break In

Bag conditioning agents used to develop optimum

primary dust cake within cross-section of conventional

depth filtration media

Conditioning or breaking in new DC bags can improve

Collector efficiency thru enhanced cake release & fine

particulate capture efficiency

Conditioning agents typically not required on surface

membrane filtration media due to lower porosity of

material enhancing particulate capture

Bag Filter Training Ashaka / 16/01/16 - 54

Pulse Jet Dust Collector

Bag Break In Procedure

Disable pulse control system or isolate compressed air

supply to manifold to isolate cleaning system

Operate fan at 75% of target airflow

Add conditioner

Start main process line

Operate normally, allow DP to reach 4-5 WC

Enable pulse control system or re-establish

compressed air supply to re-establish cleaning system

Monitor differential pressure until process line has

stabilized at normal

Bag Filter Training Ashaka / 16/01/16 - 55

Pulse Jet Dust Collector

Inspections

Running Inspection

Static Inspection

Bag Filter Training Ashaka / 16/01/16 - 56

Pulse Jet Dust Collector

Inspections: the filter

Bag Filter Training Ashaka / 16/01/16 - 57

Pulse Jet Dust Collector

Inspections: the support

Bag Filter Training Ashaka / 16/01/16 - 58

Pulse Jet Dust Collector

Inspections: Bearing supports

Bag Filter Training Ashaka / 16/01/16 - 59

Pulse Jet Dust Collector

Inspections: conveyors

Bag Filter Training Ashaka / 16/01/16 - 60

Pulse Jet Dust Collector

First level inspection

What

How

Noise (From Diaphragms)

Ear

Dust puffing (Walls)

See

Cleaning sequence

Ear

Drive/Bearings T

Touch

P (Between 4-6 w.c.)

See

V-belts

See, Nose

Fan vibrations

Ear, Touch

Guards

See

Inleaks (Doors, joints,housing, ducts)

Bag Filter Training Ashaka / 16/01/16 - 61

Pulse Jet Dust Collector

First level inspection

What

Stacker emissions

How

See

Check for cladding

Sequencial purging

Ear

Check A/C pressure gauges (5-7 bars)

See

Speed monitor

Dampers position

See

Bag Filter Training Ashaka / 16/01/16 - 62

Pulse Jet Dust Collector

Specific inspection

What

Torn bags

Blocked bags

Diaphragm damaged

Chambers

Bearings

Groken screw & flight

V-belts

Pulley status alignments

Air sluice/Double flap valves

Fan dampers

Fan impeller

Bag Filter Training Ashaka / 16/01/16 - 63

Pulse Jet Dust Collector

9. Troubleshooting

Reduced System Airflow

Bag Filter Training Ashaka / 16/01/16 - 64

Pulse Jet Dust Collector

Safety

Run cleaning mechanism 20 mins, fan off to clean filter

bags

Discharge all material from collection hopper

Shut off, blank & tag compressed air supply & relieve

pressure in header

Lock out electrical power on all rotating equipment

being serviced

Follow confined space entry procedures to the letter

If oxygen-deficient, purge with fresh air; secure or

remove doors; ensure safe working atmosphere

Bag Filter Training Ashaka / 16/01/16 - 65

Pulse Jet Dust Collector

Safety..

Cool internal before entering to avoid high internal

surface temps

Wear properly fitting respirator or dust mask when

working inside

Take extreme care when working inside tripping

hazards:

blow downs

perforated tubesheet

Bag Filter Training Ashaka / 16/01/16 - 66

Pulse Jet Dust Collector

ASHAKA

Before

After

Bag Filter Training Ashaka / 16/01/16 - 67

You might also like

- Quarter 3 - Module 1-W1&W2: Computer Systems Servicing (CSS)Document18 pagesQuarter 3 - Module 1-W1&W2: Computer Systems Servicing (CSS)AC Balio100% (5)

- Nozzle Ring Area of Raw MillDocument6 pagesNozzle Ring Area of Raw MillMohd Ali100% (7)

- (1.3) - Pyro Process Theory & Kiln System DesignDocument63 pages(1.3) - Pyro Process Theory & Kiln System DesignMuhammed Emami100% (1)

- 6) Fläkts FansSystem StagECC 2009Document82 pages6) Fläkts FansSystem StagECC 2009hmaza shakeelNo ratings yet

- OK MillDocument52 pagesOK MillYhaneNo ratings yet

- Check List Rotary Packer: Packing Plant General StatusDocument3 pagesCheck List Rotary Packer: Packing Plant General StatusTITUS YUSUF100% (1)

- RABH Vs Pulse Jet Bag FilterDocument1 pageRABH Vs Pulse Jet Bag FilterShuja Salim100% (1)

- Basic Criteria For Selection of Bag FilterDocument33 pagesBasic Criteria For Selection of Bag FilterMuhammadShoaib100% (3)

- Flame MomentumDocument30 pagesFlame MomentumSanth Raul100% (7)

- Muet 2006 To 2019 Past PapersDocument148 pagesMuet 2006 To 2019 Past PapersUmaid Ali Keerio100% (2)

- 6 Bag House BasicsDocument27 pages6 Bag House BasicsPANKAJ AGRAHARI100% (1)

- 10 BagHouseDocument32 pages10 BagHouseSrikant Ch100% (1)

- 3.1 Bag FiltersDocument12 pages3.1 Bag FiltersVishal100% (2)

- Welcome To All: Basics of Dedusting (Nuisance) FilterDocument109 pagesWelcome To All: Basics of Dedusting (Nuisance) Filterm_verma21100% (3)

- Kiln TrippingDocument13 pagesKiln Tripping7atemmohNo ratings yet

- Gebr. Pfeiffer Brochure Passion For Grinding enDocument28 pagesGebr. Pfeiffer Brochure Passion For Grinding enRollerJonnyNo ratings yet

- 09.00 Daniel Strohmeyer, Loesche GMBHDocument16 pages09.00 Daniel Strohmeyer, Loesche GMBHMohd Ali100% (1)

- VRM OperationsDocument35 pagesVRM OperationsJitendra Jangid100% (1)

- Grinding System and Circuit of VRM Process Data Plant DataDocument58 pagesGrinding System and Circuit of VRM Process Data Plant DataFasil Ayele67% (6)

- Doc VRM Measurements BATDocument15 pagesDoc VRM Measurements BATsaji kumar100% (1)

- Loesche Round Table VICATDocument20 pagesLoesche Round Table VICATrecaiNo ratings yet

- VRM Hydraulic SystemDocument2 pagesVRM Hydraulic SystemBhaskar Reddy100% (1)

- Fan Flow - CementDocument5 pagesFan Flow - CementharikrushnaNo ratings yet

- Proceedings Rev A English - Print ResDocument130 pagesProceedings Rev A English - Print ResRaúl Marcelo Veloz100% (1)

- V SK VSK: Focus On EfficiencyDocument8 pagesV SK VSK: Focus On EfficiencyGerman Gabriel Anaya VegaNo ratings yet

- Process GuidlinesDocument20 pagesProcess GuidlinesMKPashaPasha100% (4)

- Bag Filters Types, Working Principles & Daily Maintenance - INFINITY FOR CEMENT EQUIPMENT PDFDocument14 pagesBag Filters Types, Working Principles & Daily Maintenance - INFINITY FOR CEMENT EQUIPMENT PDFRICARDOALEXBORGES100% (2)

- VRM Heat and Mass BalanceDocument1 pageVRM Heat and Mass BalanceRajeshRockNo ratings yet

- VDZ Cement Manufacturing Course FlyerDocument4 pagesVDZ Cement Manufacturing Course FlyerfaheemqcNo ratings yet

- False AirDocument665 pagesFalse AirSantanu PachhalNo ratings yet

- High Efficiency Separators 3Document9 pagesHigh Efficiency Separators 3gldiasNo ratings yet

- Kiln Audit Training IntroductionDocument15 pagesKiln Audit Training IntroductionTamer Fathy100% (1)

- LoescheDocument35 pagesLoescheayaskant751001No ratings yet

- Cement Mill ReportDocument13 pagesCement Mill ReportYhaneNo ratings yet

- CoolersDocument297 pagesCoolersMUNNALURU UMAKANTHA RAONo ratings yet

- Diagnostic Study For Cement Mill OptimizationDocument9 pagesDiagnostic Study For Cement Mill OptimizationHilmy MuhammadNo ratings yet

- Questionnaire For Pyroprocessing ModificationDocument8 pagesQuestionnaire For Pyroprocessing ModificationVijay BhanNo ratings yet

- Operation TraianingDocument106 pagesOperation TraianingFurqan Shabbir100% (2)

- 04 Vertical Roller MillsDocument12 pages04 Vertical Roller MillsaktaserdincNo ratings yet

- Mini Plant Training Material: Air SlidesDocument28 pagesMini Plant Training Material: Air Slidesbulentbulut100% (2)

- Comparison Between Currently Applied Grinding TechnologiesDocument28 pagesComparison Between Currently Applied Grinding TechnologiesSai Sricharan Reddy100% (3)

- GGBFS Opeartion ManualDocument41 pagesGGBFS Opeartion ManualPushpendra Kumar KushwahaNo ratings yet

- 15th NCB Technical PaperDocument10 pages15th NCB Technical PaperSalah RomdaniNo ratings yet

- Fons Technology PDFDocument28 pagesFons Technology PDFBulent BULUTNo ratings yet

- Roller Press Classifier Circulation FactorDocument9 pagesRoller Press Classifier Circulation Factorshahid2995100% (1)

- Pyro Process Equipment PDFDocument114 pagesPyro Process Equipment PDFMohamedNo ratings yet

- Separation SBDocument50 pagesSeparation SBSuchismita Bhattacharya Bhaumik100% (4)

- Atox 20 Coal Mill Critical Interlock SheetDocument6 pagesAtox 20 Coal Mill Critical Interlock SheetValipireddy NagarjunNo ratings yet

- Unwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyDocument5 pagesUnwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyharyantoaditNo ratings yet

- Loesche - Loesche Cement Mills Concept Large CapacityDocument26 pagesLoesche - Loesche Cement Mills Concept Large Capacityphucdc095041No ratings yet

- VRM For ASECDocument77 pagesVRM For ASECHazem Hasan100% (5)

- Report On Cement MillDocument9 pagesReport On Cement MillYounas Khan100% (1)

- SOP-startup Shutdown and Operation of Raw MillDocument4 pagesSOP-startup Shutdown and Operation of Raw MillJCS100% (1)

- Performance Driven Maintenance Feb 52013Document25 pagesPerformance Driven Maintenance Feb 52013recaiNo ratings yet

- Improvement of Productivity Using Tromp Curve MeasDocument11 pagesImprovement of Productivity Using Tromp Curve MeasRachit Bansal BJ20099No ratings yet

- 411 Vertical Mills Operations - V1-0Document4 pages411 Vertical Mills Operations - V1-0Sai Sricharan Reddy83% (6)

- Raw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesDocument3 pagesRaw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesRamachandrarao MaddaliNo ratings yet

- Mill Fan Efficiency CalculationDocument8 pagesMill Fan Efficiency Calculationsam abusiNo ratings yet

- Bag FiltersDocument18 pagesBag FiltersMehmet C100% (2)

- Macam2 Cleaning FilterDocument3 pagesMacam2 Cleaning FilterperludownloadNo ratings yet

- Fabric Dust Collector SystemsDocument50 pagesFabric Dust Collector Systemsbreyes25100% (4)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- HCI 2008 Promo W SolutionDocument12 pagesHCI 2008 Promo W SolutionMichael CheeNo ratings yet

- Native Son Essay TopicsDocument7 pagesNative Son Essay TopicsafabioemwNo ratings yet

- Strength of Materialspretest Assignment1Document2 pagesStrength of Materialspretest Assignment1Nellai VprNo ratings yet

- Effective Phone and Door Scripts 0Document6 pagesEffective Phone and Door Scripts 0Kaso MuseNo ratings yet

- Free CV Template 31Document1 pageFree CV Template 31Aaron WilsonNo ratings yet

- Conceptual FrameworkDocument4 pagesConceptual FrameworkEustass KiddNo ratings yet

- VIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFDocument83 pagesVIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFOsamaAliMoussaNo ratings yet

- Unit Iv Secondary and Auxilary Motions 12Document3 pagesUnit Iv Secondary and Auxilary Motions 129043785763No ratings yet

- 10 Science NcertSolutions Chapter 8 ExercisesDocument4 pages10 Science NcertSolutions Chapter 8 ExercisesAnita GargNo ratings yet

- Hospice SynopsisDocument6 pagesHospice SynopsisPhalguna NaiduNo ratings yet

- Gcrouch@wsu - Edu Rmancini@wsu - Edu Andreakl@wsu - Edu: Groups/chem.345Document5 pagesGcrouch@wsu - Edu Rmancini@wsu - Edu Andreakl@wsu - Edu: Groups/chem.345Daniel McDermottNo ratings yet

- UntitledDocument5 pagesUntitledGerard Phoenix MaximoNo ratings yet

- Ericka Joyce O. Reynera: PERSONAL - INFORMATIONDocument2 pagesEricka Joyce O. Reynera: PERSONAL - INFORMATIONdead insideNo ratings yet

- Grade 7 Lesson: ReproductionDocument4 pagesGrade 7 Lesson: ReproductionJoedelyn Wagas100% (2)

- 9th Biology NotesDocument12 pages9th Biology Notesramaiz darNo ratings yet

- EN Subiecte Locala 19-20 GIMNAZIU 5-8 A-BDocument16 pagesEN Subiecte Locala 19-20 GIMNAZIU 5-8 A-BSpiridon AndreeaNo ratings yet

- Tera Spin PK-1500 Series PK-1600 40 Weighting Arms Jul-2018Document14 pagesTera Spin PK-1500 Series PK-1600 40 Weighting Arms Jul-2018deepakNo ratings yet

- Thrift Banks ActDocument25 pagesThrift Banks ActMadelle Pineda100% (1)

- CentrifugationDocument10 pagesCentrifugationBk FNo ratings yet

- Laboratorium Pengujian Teknik Sipil Universitas Bandar LampungDocument1 pageLaboratorium Pengujian Teknik Sipil Universitas Bandar LampungPanji OctaWirawanNo ratings yet

- Design of Stair CaseDocument2 pagesDesign of Stair Casepathan is khanNo ratings yet

- Cost FM Sample PaperDocument6 pagesCost FM Sample PapercacmacsNo ratings yet

- LC1D32M7: Product Data SheetDocument7 pagesLC1D32M7: Product Data SheetCHAHRHLHOHSNo ratings yet

- Shapes of NailsDocument14 pagesShapes of NailsIyannNo ratings yet

- Asset Accounting (J62) - Process DiagramsDocument8 pagesAsset Accounting (J62) - Process DiagramsMohammed Nawaz ShariffNo ratings yet

- Bolting Chart For Industrial FlangesDocument6 pagesBolting Chart For Industrial FlangesPritam JadhavNo ratings yet

- List of TradeMark Forms & Therein PDFDocument17 pagesList of TradeMark Forms & Therein PDFShreeneetRathiNo ratings yet

- Wider World 4 Grammar Presentation 1 4Document6 pagesWider World 4 Grammar Presentation 1 4veronika rugunNo ratings yet