Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

211 viewsVibration Diagnostic Chart1

Vibration Diagnostic Chart1

Uploaded by

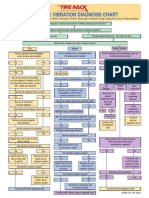

Anand KumarThis document contains vibration data from a single stage, 8 bladed machine with two bearings. It lists various frequencies detected from the machine including the rotating speed, bearing defect frequencies, blade passing frequency, and rotational orders. It also includes a vibration diagnostic chart that outlines common vibration signatures, root causes, and recommended corrections for issues relating to rotors, bearings, gears, motors, belts, and other mechanical components.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You might also like

- Yamaha XVZ1300 TF (L) Royal Star 99 Service Manual ENG by MosueDocument501 pagesYamaha XVZ1300 TF (L) Royal Star 99 Service Manual ENG by Mosuejtalarek100% (5)

- Proven Method For Specifying Both Six Spectral Alarm Bands As Well As Narrowband Alarm EnvelopesDocument4 pagesProven Method For Specifying Both Six Spectral Alarm Bands As Well As Narrowband Alarm EnvelopesVILLANUEVA_DANIEL2064No ratings yet

- Machine Design Project Report UNITENDocument58 pagesMachine Design Project Report UNITENSyafiq Fauzi100% (4)

- ISO 10064-6-2009 Code of Inspection Practice - Part 6 Bevel Gear Measurement Methods (Đo Bánh Răng Côn)Document42 pagesISO 10064-6-2009 Code of Inspection Practice - Part 6 Bevel Gear Measurement Methods (Đo Bánh Răng Côn)Màu Đen Cuộc Sống100% (1)

- Vibration Diagnostic ChartDocument49 pagesVibration Diagnostic Chartujepadounk100% (2)

- AKAI GX Reel To Reel RecorderDocument11 pagesAKAI GX Reel To Reel RecorderRoger CalvertNo ratings yet

- NSK Ball ScrewsDocument307 pagesNSK Ball ScrewsmostafaNo ratings yet

- 5MT Manual Trans & DiffDocument82 pages5MT Manual Trans & DiffghotimeNo ratings yet

- Vibrations in A Francis Turbine A Case StudyDocument4 pagesVibrations in A Francis Turbine A Case Studybukit_guestNo ratings yet

- Adre BrochureDocument12 pagesAdre BrochurenuesteNo ratings yet

- Diagnostic Techniques For Vibration Analysis of BearingsDocument9 pagesDiagnostic Techniques For Vibration Analysis of BearingsMohd Asiren Mohd Sharif100% (1)

- ISO Vibration Analysis Certification Exam Cat I Part 3 Signal Processing Ali M Al-ShurafaDocument1 pageISO Vibration Analysis Certification Exam Cat I Part 3 Signal Processing Ali M Al-ShurafaMohammed Kamel Tony100% (1)

- Phase Analysis: Making Vibration Analysis Easier: SearchDocument4 pagesPhase Analysis: Making Vibration Analysis Easier: Searchdillipsh123No ratings yet

- Time Waveform AnalysisDocument26 pagesTime Waveform AnalysisSurika Martalina100% (1)

- ORBIT AnalysisDocument4 pagesORBIT AnalysisManoj Paneri100% (1)

- Condition Monitoring of Centrifugal Blower Using Vibration Analysis PDFDocument10 pagesCondition Monitoring of Centrifugal Blower Using Vibration Analysis PDFJose PradoNo ratings yet

- Introduction To PeakvueDocument55 pagesIntroduction To PeakvuesebastianNo ratings yet

- Effective Use of Statistical Models To Establish and Update Vibration AlarmDocument11 pagesEffective Use of Statistical Models To Establish and Update Vibration AlarmMohammadreza GalebanNo ratings yet

- Vibration Analysis - Center of Electrical MachinesDocument12 pagesVibration Analysis - Center of Electrical MachinesmortezaNo ratings yet

- NTN Bearing Bpfo&BpfiDocument61 pagesNTN Bearing Bpfo&BpfishantanusamajdarNo ratings yet

- Detect Machinery Faults by Using Peak VueDocument13 pagesDetect Machinery Faults by Using Peak VueHarold Alconz100% (2)

- Phase MeasurementDocument5 pagesPhase Measurementuak107080No ratings yet

- Vibration Analysis Reports of RM ChemicalsDocument25 pagesVibration Analysis Reports of RM ChemicalsAnant Jain100% (2)

- Transient Speed Vibration Analysis: Insights Into Machinery BehaviorDocument47 pagesTransient Speed Vibration Analysis: Insights Into Machinery Behaviorpeach5No ratings yet

- Vibration Analysis For GearsDocument5 pagesVibration Analysis For GearsJaime Berry100% (1)

- 5 Successful Predictive Vibrations - March - 2012Document28 pages5 Successful Predictive Vibrations - March - 2012jorgemegok1860No ratings yet

- Order Analysis ToolkitDocument16 pagesOrder Analysis ToolkitManuel Enrique Salas FernándezNo ratings yet

- REDUCTION of The SKI SLOPE EFFECTDocument8 pagesREDUCTION of The SKI SLOPE EFFECTEnzo MarquesNo ratings yet

- Predict-Mobius Training BrochureDocument7 pagesPredict-Mobius Training BrochurefaisalNo ratings yet

- Vibration Assessment QuizDocument2 pagesVibration Assessment QuizJose Luis RattiaNo ratings yet

- Vibration AnalysisDocument22 pagesVibration Analysisvenkat chakNo ratings yet

- Introduction To PeakvueDocument55 pagesIntroduction To PeakvueAhmed Nazeem100% (4)

- 3 - Simon MillsDocument35 pages3 - Simon MillsRajesh PotluriNo ratings yet

- An Introduction To Time Waveform AnalysisDocument17 pagesAn Introduction To Time Waveform AnalysisBassemNo ratings yet

- Vibration Analysis For Reciprocating CompressorsDocument48 pagesVibration Analysis For Reciprocating CompressorsJose PradoNo ratings yet

- 10 Components of A Successful Vibration Program 2Document5 pages10 Components of A Successful Vibration Program 2allmcbeallNo ratings yet

- Advanced Vibration AnalysisDocument24 pagesAdvanced Vibration AnalysisM Hamza NadeemNo ratings yet

- Rotordynamic Stability Case StudiesDocument9 pagesRotordynamic Stability Case StudiesYong LiNo ratings yet

- Vibration MathDocument4 pagesVibration Mathyianisr5990No ratings yet

- Welcome To Modal Testing and Analysis: From Brüel & KjærDocument20 pagesWelcome To Modal Testing and Analysis: From Brüel & KjærAhmed AymanNo ratings yet

- CSIemersonDocument49 pagesCSIemersonMuhammad Haroon100% (1)

- Vibration TestDocument16 pagesVibration TestSACHIN A. MORENo ratings yet

- Vibration ChartDocument1 pageVibration Chartairframer1981No ratings yet

- BalancingDocument138 pagesBalancingJeinnerCastroNo ratings yet

- AMPLITUDE MODULATION Versus BEATSDocument5 pagesAMPLITUDE MODULATION Versus BEATSHaitham YoussefNo ratings yet

- Autocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookDocument8 pagesAutocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookLe Thanh Hai100% (2)

- Advanced Turbomachinery Diagnostics - Online Course W2Document8 pagesAdvanced Turbomachinery Diagnostics - Online Course W2ali shetaNo ratings yet

- Vibration ISO Level 1 Module 2Document33 pagesVibration ISO Level 1 Module 2Shambhu Poddar100% (1)

- Low Frequency Vibration Analysis & Effects of AC CouplingDocument5 pagesLow Frequency Vibration Analysis & Effects of AC CouplingLasse HansenNo ratings yet

- Basic Vibration Analysis ?Document20 pagesBasic Vibration Analysis ?Avinash Kamuni100% (1)

- Rev.13 VibViewDocument466 pagesRev.13 VibViewdford8583No ratings yet

- Signature AnalysisDocument27 pagesSignature Analysisvinod kumarNo ratings yet

- 9 - Electrical FaultDocument24 pages9 - Electrical Faultmohamed ghoneemNo ratings yet

- Signature AnalysisDocument49 pagesSignature AnalysisVirgilio100% (1)

- Vibration Quick ReferenceDocument49 pagesVibration Quick Referencekeepmoshing2No ratings yet

- Aria VibrationDocument1 pageAria VibrationalxmaasNo ratings yet

- Vibration Diagnostics ChartDocument49 pagesVibration Diagnostics ChartHaitham Mohammad100% (1)

- Vibration Sources Identification GuideDocument1 pageVibration Sources Identification Guideridzim4638No ratings yet

- Vibration QuizDocument8 pagesVibration QuizJorge Gamarra TolentinoNo ratings yet

- Vibration Signature Analysis PROC - V18Document2 pagesVibration Signature Analysis PROC - V18ronfrendNo ratings yet

- Machinery Vibration DiagnosticsDocument22 pagesMachinery Vibration Diagnosticstonytayic100% (7)

- 05-Fault Analysis 4Document17 pages05-Fault Analysis 4Hatem Abdelrahman100% (1)

- Vibration Analysis ProcedureDocument26 pagesVibration Analysis ProcedureronfrendNo ratings yet

- DG1Document44 pagesDG1Anand Kumar100% (1)

- Basics of Vibration and Vibration MeasurementDocument38 pagesBasics of Vibration and Vibration MeasurementAnand Kumar100% (4)

- Ethanol As Gas Turbine FuelDocument2 pagesEthanol As Gas Turbine FuelAnand Kumar100% (1)

- Tsi FinalDocument41 pagesTsi FinalAnand KumarNo ratings yet

- Service ManualDocument21 pagesService Manualathalim1463No ratings yet

- Ajuste de 9A StrokerDocument2 pagesAjuste de 9A Strokergonzalo hernandez aguilarNo ratings yet

- Warning: Section 25 - Mechanical Front Axle - Chapter 1 10Document32 pagesWarning: Section 25 - Mechanical Front Axle - Chapter 1 10rodrigoNo ratings yet

- Class Test 4 & 5 Cams - Gears - Assignment Questions KomDocument10 pagesClass Test 4 & 5 Cams - Gears - Assignment Questions KomVenkateswar Reddy MallepallyNo ratings yet

- Front Drive AxleDocument19 pagesFront Drive AxleGeraldo Pozos VazquezNo ratings yet

- RSPD ServiceDocument58 pagesRSPD Service김진오No ratings yet

- Engineer'S Manual: SeriesDocument126 pagesEngineer'S Manual: SeriesAnonymous hMyP30F6mNo ratings yet

- Ese 2021: Prelims Exam: MechanicalDocument12 pagesEse 2021: Prelims Exam: MechanicalSheelendra kumarNo ratings yet

- United States Patent (10) Patent No.: US 9,080,720 B2Document16 pagesUnited States Patent (10) Patent No.: US 9,080,720 B2sfjhsakjfhNo ratings yet

- ODF-1 - Learning MaterialDocument52 pagesODF-1 - Learning MaterialAsmawi SanuddinNo ratings yet

- Design of Power Transmission SystemDocument67 pagesDesign of Power Transmission SystemVivek LevinNo ratings yet

- Cambio Arbol de LevasDocument12 pagesCambio Arbol de LevasgenaroNo ratings yet

- KISSsoft 2019 Tutorial 16-The-Tolerance-For-The-External-Diameter-Of-The-WormDocument17 pagesKISSsoft 2019 Tutorial 16-The-Tolerance-For-The-External-Diameter-Of-The-WormNguyễnVănLăngNo ratings yet

- Kyosho Superten Fw04Document36 pagesKyosho Superten Fw04aascmdthlbaimpgtbiNo ratings yet

- Alinear Tambor HoistDocument13 pagesAlinear Tambor HoistFreud CutireNo ratings yet

- Dana Ring and Pinion PatternDocument2 pagesDana Ring and Pinion PatternMohammed gNo ratings yet

- Transmissiya HD 120Document95 pagesTransmissiya HD 120анджелаNo ratings yet

- Vol. IVDocument501 pagesVol. IVsvenkzNo ratings yet

- Fenner Keyless DrivesDocument56 pagesFenner Keyless DrivesroytamaltanuNo ratings yet

- Design and Function: Marine Transmissions Gearboxes, Drives, IPSDocument80 pagesDesign and Function: Marine Transmissions Gearboxes, Drives, IPSSON100% (1)

- Armado Caja Diferen YarisDocument3 pagesArmado Caja Diferen YarisDouglas DuarteNo ratings yet

- Introduction To MetrologyDocument55 pagesIntroduction To MetrologyVishnuPSVichuNo ratings yet

- Ball ScrewDocument4 pagesBall ScrewJohn BlackburnNo ratings yet

- Sliding Mode Controller Design For Controlling The Speed of A DC MotorDocument5 pagesSliding Mode Controller Design For Controlling The Speed of A DC Motorbokic88No ratings yet

- M & M MCQ QPDocument12 pagesM & M MCQ QPPrabin MahatoNo ratings yet

Vibration Diagnostic Chart1

Vibration Diagnostic Chart1

Uploaded by

Anand Kumar0 ratings0% found this document useful (0 votes)

211 views16 pagesThis document contains vibration data from a single stage, 8 bladed machine with two bearings. It lists various frequencies detected from the machine including the rotating speed, bearing defect frequencies, blade passing frequency, and rotational orders. It also includes a vibration diagnostic chart that outlines common vibration signatures, root causes, and recommended corrections for issues relating to rotors, bearings, gears, motors, belts, and other mechanical components.

Original Description:

vibration diagnostic chart

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains vibration data from a single stage, 8 bladed machine with two bearings. It lists various frequencies detected from the machine including the rotating speed, bearing defect frequencies, blade passing frequency, and rotational orders. It also includes a vibration diagnostic chart that outlines common vibration signatures, root causes, and recommended corrections for issues relating to rotors, bearings, gears, motors, belts, and other mechanical components.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

211 views16 pagesVibration Diagnostic Chart1

Vibration Diagnostic Chart1

Uploaded by

Anand KumarThis document contains vibration data from a single stage, 8 bladed machine with two bearings. It lists various frequencies detected from the machine including the rotating speed, bearing defect frequencies, blade passing frequency, and rotational orders. It also includes a vibration diagnostic chart that outlines common vibration signatures, root causes, and recommended corrections for issues relating to rotors, bearings, gears, motors, belts, and other mechanical components.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 16

Frequencies of Interest

Single stg, 8 bladed m/c, Brgs 22168 & 749, Flex Cplg. Speed-2940 rpm

Sr No

Description

Freq. (Hz)

Rotating Speed

49

Brg. 22168 (no of rollers 24,Roller dia

0.6,pitch dia 5.8)

Outer Race defect

263

Inner Race defect

324

Roller defect

117

Train defect

11

Bearing 749 (no of rollers 18, roller dia0.777,pitch dia-5.195)

Outer race defect

188

Inner race defect

253

Roller defect

80

Train defect

10

Rotational Orders (2X to 6X)

98,147,196,245,294

Blade passing (8X)

392

VIBRATION DIAGNOSTIC CHART

In phase, steady. Amplitude

speed sqd. Correction: one bal. wt.

in the plane of rotor CG.

Phase diff. 1800 Amplitude

speed sqd. Correction: bal. wts.

at least in two planes.

Phase Axial in phase, radial

unsteady.

VIBRATION DIAGNOSTIC CHART

Largest vib. at 1X of eccentric

component, direction thru centers

of two rotors. Horz. & vert phase

diff either oo or by 1800

High axial vib (1X Bent at cntr, 2X

bent at cplg.)

Axial phase diff. ~ 1800

Axial phase diff 1800 across cplg.

Normally high 1X,2X axial vib,

sometimes 3X

VIBRATION DIAGNOSTIC CHART

Radial phase diff 1800 across cplg.

2X vib often larger than 1X, severe

misalignment severe higher

harmonics upto 8X. Cplg type.

Will cause twisting motion. Axial

phase shift appx 1800 Top/Bott or

E/W. Correction: correct brg.

Installation.

Amplitude amplification

significant with speed. Phase 900

at resonance nearly 1800 when

passes thru.

VIBRATION DIAGNOSTIC CHART

MECHANICAL LOOSENESS

Type A : structural

weakness/looseness(m/c feet,

base plate, sole plate,

foundation. Loose fndn bolts,

grout deterioration), soft foot.

Vert phase diff. 1800 between

foot, base /base plate.

Type B : loose pillow blocks bolts/

brg pedestals/cracks in frame

structure.

Type C: Brg. Excessive

clearance, brg liner loose in cap,

loose impeller on shaf. Phase

unstable. Amplitude noticeably

different (radial 300 increments).

Subharmonic multiples at exactly

1/2X or 1/3X RPM.

VIBRATION DIAGNOSTIC CHART

Generates a similar

spectrum like Mech

looseness. A series of

freq often exciting one or

more resonances/

integer fractions

subharmonics(1/2X,1/3X

)

Advanced wear: upto

10X or 20X (in multiple of

1X).

Wiped: High vert

amlitude Vs Horz.

Excessive clearance;

high vibrn.

VIBRATION DIAGNOSTIC CHART

At 0.42 to 0.48 X

RPM,quite severe.

Inherently

unstable.

Lube oil

visc/pressure/exter

nal preload.

May occur if m/c

operated at or

above 2X rotor

critical freq. Oil film

may no longer

support. Whirl

speed will lock

onto rotor critical,

even with m/c

speed increase.

VIBRATION DIAGNOSTIC CHART

Stg 1: freq 20K to 60KHz.

Techniques: spike energy,

HFD, shock pulse. Spike

energy ~ 0.25gse.

Stg 2: brg component natural

freq appears (0.5 to 2KHz).

Side bands above or below to

natural freq also appear. Spike

energy ~ 0.5gse.

Stg 3: brg defect freq &

harmonics appears.sidebands

grow around. Spk energy ~

1gse or above. Visible wear.

Stg 4: Running spd harmonics

also grow. Brg. defect/

component natural freq begin

to disappear and replaced with

random high freq vibrn. Spk

energy will decrease, grow

significantly just prior to failure.

Ball & Roller Brg defects

For outer race defect F (Hz)= n/2(1-bd/pd cos)rpm

For inner race defect F (Hz)= n/2(1+bd/pd cos)rpm

For ball defect F(Hz) = pd/bd [1-(bd/pd cos)2]rpm

For train defect F(Hz)= (1-bd/pd cos)rpm

n= no of balls or rollers

bd= ball dia in mm

pd= pitch dia in mm

rpm= relative revns betn outer & inner race

= contact angle

VIBRATION DIAGNOSTIC CHART

A. For m/cs having blades/vanes.

Large ampld BPF if gap between

rotating vanes & stationary

diffuser not equal around. Also

due to wear rings seizure/ flow

disturbances in piping/ eccentric

placement.

B. In blowers /fans due to

pressure variations. Low freq

vibrn 50 to 2KCPM.

C. Random high freq vibrn

sometimes superimposed with

BPF harmonics. Sounds as if

gravels passing thru.

VIBRATION DIAGNOSTIC CHART

A. All peaks of low amplds.

Running speed sidebands around

GMF

B. Gear natural freq alongwith

running speed side bands. High

ampld sidebands around

GMF(though GMF may or may

not change), when wear is

noticeable.

C. Perform analysis at maximum

operating load. High GMF with

low sidebands, no gear natural

freq. No problem.

VIBRATION DIAGNOSTIC CHART

D. Eccentr/backlash/non-parallel

shaft: (GMF + sidebands) high

ampld. The sidebands freq will

determine the problematic gear.

Improper backlash: excites also

gear natural freq with 1X

sidebands. GMF ampld will reduce

with load increase.

E. Second order or higher GMF

harmonics + sidebands at 1X.

Ampld at 2X, 3X GMF higher

than 1XGMF.

F. High ampld 1XRPM of

concerned gear+ gear natural

freq + sidebands at 1XRPM. Best

detected in time domain.

G. High vibrn at low freq(<

600CPM). Maximum effect when

faulty pinion & gear teeth both

enter mesh at same time. Na =

number of unique assembly

VIBRATION DIAGNOSTIC CHART

A. Stator eccentricity: uneven air

gap: For induction motor 5%,

Synchronous motor 10%. Soft

foot, high vibrn at 2X line freq.

Loose Iron: due to support

weakness or looseness.

Shorted lamination: uneven

localized heating, shaft bow thus

thermally induced vibrn.

B. Pulsating vibrn between 2FL &

closest runnining speed

harmonics. Zoom facility

required to separate. Fp + Fp

sidebands around 2FL/1X. Fp. ~

20 to 120CPM.

C. High 1XRPM + Fp sidebands.

In addition cracked rotor bars will

show Fp side bands around 3X,

4X, 5XRPM.

Loose rotor bars: RBPF

alongwith 2FL sidebands and or

its harmonic. High 2XRBPF, low

1XRBPF.

VIBRATION DIAGNOSTIC CHART

D. Vibrn at 2FL + 1/3 FL sidebands

around 2FL. 2FL ampld may

exceed 25 mm/sec pk if left

uncorrected

E. Coil pass freq = No of stator

coils x RPM

No of stator coils = No of poles x

No of coils per pole

F. High ampld at speed controller

firing freq & harmonics ; if broken

field winding/ bad SCRs & loose

connection.

Loose / blown fuses & shorted

control cards will show high

ampld at 1X to 5X line freq. High

amplitude

VIBRATION DIAGNOSTIC CHART

A. 2 to 4 times belt freq. Often 2X

belt freq pk dominant. Ampld

unsteady, pulsing with either driver

or driven RPM.

On timing belt: wear/pulley

misalignmnt appears at timing belt

freq.

Belt freq = Pulley (RPM x pitch dia)

x / belt length

Timing belt freq = Pulley (RPM x

teeth)= belt freq x No. of belt teeth

B. Ratio of ampld of driver/ driven

: relative mass and frame

stiffness.

C. Ampld highest in line with the

belts.

VIBRATION DIAGNOSTIC CHART

D. Belt natural freq close to driver /

driven RPM. Can be altered by

either changing belt tension or

length.

Two closely spaced freq going

into and out of synchronisation.

The wideband spectrum shows

one pk pulsating up & down. Beat

freq . ~ 5 to 100 CPM

You might also like

- Yamaha XVZ1300 TF (L) Royal Star 99 Service Manual ENG by MosueDocument501 pagesYamaha XVZ1300 TF (L) Royal Star 99 Service Manual ENG by Mosuejtalarek100% (5)

- Proven Method For Specifying Both Six Spectral Alarm Bands As Well As Narrowband Alarm EnvelopesDocument4 pagesProven Method For Specifying Both Six Spectral Alarm Bands As Well As Narrowband Alarm EnvelopesVILLANUEVA_DANIEL2064No ratings yet

- Machine Design Project Report UNITENDocument58 pagesMachine Design Project Report UNITENSyafiq Fauzi100% (4)

- ISO 10064-6-2009 Code of Inspection Practice - Part 6 Bevel Gear Measurement Methods (Đo Bánh Răng Côn)Document42 pagesISO 10064-6-2009 Code of Inspection Practice - Part 6 Bevel Gear Measurement Methods (Đo Bánh Răng Côn)Màu Đen Cuộc Sống100% (1)

- Vibration Diagnostic ChartDocument49 pagesVibration Diagnostic Chartujepadounk100% (2)

- AKAI GX Reel To Reel RecorderDocument11 pagesAKAI GX Reel To Reel RecorderRoger CalvertNo ratings yet

- NSK Ball ScrewsDocument307 pagesNSK Ball ScrewsmostafaNo ratings yet

- 5MT Manual Trans & DiffDocument82 pages5MT Manual Trans & DiffghotimeNo ratings yet

- Vibrations in A Francis Turbine A Case StudyDocument4 pagesVibrations in A Francis Turbine A Case Studybukit_guestNo ratings yet

- Adre BrochureDocument12 pagesAdre BrochurenuesteNo ratings yet

- Diagnostic Techniques For Vibration Analysis of BearingsDocument9 pagesDiagnostic Techniques For Vibration Analysis of BearingsMohd Asiren Mohd Sharif100% (1)

- ISO Vibration Analysis Certification Exam Cat I Part 3 Signal Processing Ali M Al-ShurafaDocument1 pageISO Vibration Analysis Certification Exam Cat I Part 3 Signal Processing Ali M Al-ShurafaMohammed Kamel Tony100% (1)

- Phase Analysis: Making Vibration Analysis Easier: SearchDocument4 pagesPhase Analysis: Making Vibration Analysis Easier: Searchdillipsh123No ratings yet

- Time Waveform AnalysisDocument26 pagesTime Waveform AnalysisSurika Martalina100% (1)

- ORBIT AnalysisDocument4 pagesORBIT AnalysisManoj Paneri100% (1)

- Condition Monitoring of Centrifugal Blower Using Vibration Analysis PDFDocument10 pagesCondition Monitoring of Centrifugal Blower Using Vibration Analysis PDFJose PradoNo ratings yet

- Introduction To PeakvueDocument55 pagesIntroduction To PeakvuesebastianNo ratings yet

- Effective Use of Statistical Models To Establish and Update Vibration AlarmDocument11 pagesEffective Use of Statistical Models To Establish and Update Vibration AlarmMohammadreza GalebanNo ratings yet

- Vibration Analysis - Center of Electrical MachinesDocument12 pagesVibration Analysis - Center of Electrical MachinesmortezaNo ratings yet

- NTN Bearing Bpfo&BpfiDocument61 pagesNTN Bearing Bpfo&BpfishantanusamajdarNo ratings yet

- Detect Machinery Faults by Using Peak VueDocument13 pagesDetect Machinery Faults by Using Peak VueHarold Alconz100% (2)

- Phase MeasurementDocument5 pagesPhase Measurementuak107080No ratings yet

- Vibration Analysis Reports of RM ChemicalsDocument25 pagesVibration Analysis Reports of RM ChemicalsAnant Jain100% (2)

- Transient Speed Vibration Analysis: Insights Into Machinery BehaviorDocument47 pagesTransient Speed Vibration Analysis: Insights Into Machinery Behaviorpeach5No ratings yet

- Vibration Analysis For GearsDocument5 pagesVibration Analysis For GearsJaime Berry100% (1)

- 5 Successful Predictive Vibrations - March - 2012Document28 pages5 Successful Predictive Vibrations - March - 2012jorgemegok1860No ratings yet

- Order Analysis ToolkitDocument16 pagesOrder Analysis ToolkitManuel Enrique Salas FernándezNo ratings yet

- REDUCTION of The SKI SLOPE EFFECTDocument8 pagesREDUCTION of The SKI SLOPE EFFECTEnzo MarquesNo ratings yet

- Predict-Mobius Training BrochureDocument7 pagesPredict-Mobius Training BrochurefaisalNo ratings yet

- Vibration Assessment QuizDocument2 pagesVibration Assessment QuizJose Luis RattiaNo ratings yet

- Vibration AnalysisDocument22 pagesVibration Analysisvenkat chakNo ratings yet

- Introduction To PeakvueDocument55 pagesIntroduction To PeakvueAhmed Nazeem100% (4)

- 3 - Simon MillsDocument35 pages3 - Simon MillsRajesh PotluriNo ratings yet

- An Introduction To Time Waveform AnalysisDocument17 pagesAn Introduction To Time Waveform AnalysisBassemNo ratings yet

- Vibration Analysis For Reciprocating CompressorsDocument48 pagesVibration Analysis For Reciprocating CompressorsJose PradoNo ratings yet

- 10 Components of A Successful Vibration Program 2Document5 pages10 Components of A Successful Vibration Program 2allmcbeallNo ratings yet

- Advanced Vibration AnalysisDocument24 pagesAdvanced Vibration AnalysisM Hamza NadeemNo ratings yet

- Rotordynamic Stability Case StudiesDocument9 pagesRotordynamic Stability Case StudiesYong LiNo ratings yet

- Vibration MathDocument4 pagesVibration Mathyianisr5990No ratings yet

- Welcome To Modal Testing and Analysis: From Brüel & KjærDocument20 pagesWelcome To Modal Testing and Analysis: From Brüel & KjærAhmed AymanNo ratings yet

- CSIemersonDocument49 pagesCSIemersonMuhammad Haroon100% (1)

- Vibration TestDocument16 pagesVibration TestSACHIN A. MORENo ratings yet

- Vibration ChartDocument1 pageVibration Chartairframer1981No ratings yet

- BalancingDocument138 pagesBalancingJeinnerCastroNo ratings yet

- AMPLITUDE MODULATION Versus BEATSDocument5 pagesAMPLITUDE MODULATION Versus BEATSHaitham YoussefNo ratings yet

- Autocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookDocument8 pagesAutocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookLe Thanh Hai100% (2)

- Advanced Turbomachinery Diagnostics - Online Course W2Document8 pagesAdvanced Turbomachinery Diagnostics - Online Course W2ali shetaNo ratings yet

- Vibration ISO Level 1 Module 2Document33 pagesVibration ISO Level 1 Module 2Shambhu Poddar100% (1)

- Low Frequency Vibration Analysis & Effects of AC CouplingDocument5 pagesLow Frequency Vibration Analysis & Effects of AC CouplingLasse HansenNo ratings yet

- Basic Vibration Analysis ?Document20 pagesBasic Vibration Analysis ?Avinash Kamuni100% (1)

- Rev.13 VibViewDocument466 pagesRev.13 VibViewdford8583No ratings yet

- Signature AnalysisDocument27 pagesSignature Analysisvinod kumarNo ratings yet

- 9 - Electrical FaultDocument24 pages9 - Electrical Faultmohamed ghoneemNo ratings yet

- Signature AnalysisDocument49 pagesSignature AnalysisVirgilio100% (1)

- Vibration Quick ReferenceDocument49 pagesVibration Quick Referencekeepmoshing2No ratings yet

- Aria VibrationDocument1 pageAria VibrationalxmaasNo ratings yet

- Vibration Diagnostics ChartDocument49 pagesVibration Diagnostics ChartHaitham Mohammad100% (1)

- Vibration Sources Identification GuideDocument1 pageVibration Sources Identification Guideridzim4638No ratings yet

- Vibration QuizDocument8 pagesVibration QuizJorge Gamarra TolentinoNo ratings yet

- Vibration Signature Analysis PROC - V18Document2 pagesVibration Signature Analysis PROC - V18ronfrendNo ratings yet

- Machinery Vibration DiagnosticsDocument22 pagesMachinery Vibration Diagnosticstonytayic100% (7)

- 05-Fault Analysis 4Document17 pages05-Fault Analysis 4Hatem Abdelrahman100% (1)

- Vibration Analysis ProcedureDocument26 pagesVibration Analysis ProcedureronfrendNo ratings yet

- DG1Document44 pagesDG1Anand Kumar100% (1)

- Basics of Vibration and Vibration MeasurementDocument38 pagesBasics of Vibration and Vibration MeasurementAnand Kumar100% (4)

- Ethanol As Gas Turbine FuelDocument2 pagesEthanol As Gas Turbine FuelAnand Kumar100% (1)

- Tsi FinalDocument41 pagesTsi FinalAnand KumarNo ratings yet

- Service ManualDocument21 pagesService Manualathalim1463No ratings yet

- Ajuste de 9A StrokerDocument2 pagesAjuste de 9A Strokergonzalo hernandez aguilarNo ratings yet

- Warning: Section 25 - Mechanical Front Axle - Chapter 1 10Document32 pagesWarning: Section 25 - Mechanical Front Axle - Chapter 1 10rodrigoNo ratings yet

- Class Test 4 & 5 Cams - Gears - Assignment Questions KomDocument10 pagesClass Test 4 & 5 Cams - Gears - Assignment Questions KomVenkateswar Reddy MallepallyNo ratings yet

- Front Drive AxleDocument19 pagesFront Drive AxleGeraldo Pozos VazquezNo ratings yet

- RSPD ServiceDocument58 pagesRSPD Service김진오No ratings yet

- Engineer'S Manual: SeriesDocument126 pagesEngineer'S Manual: SeriesAnonymous hMyP30F6mNo ratings yet

- Ese 2021: Prelims Exam: MechanicalDocument12 pagesEse 2021: Prelims Exam: MechanicalSheelendra kumarNo ratings yet

- United States Patent (10) Patent No.: US 9,080,720 B2Document16 pagesUnited States Patent (10) Patent No.: US 9,080,720 B2sfjhsakjfhNo ratings yet

- ODF-1 - Learning MaterialDocument52 pagesODF-1 - Learning MaterialAsmawi SanuddinNo ratings yet

- Design of Power Transmission SystemDocument67 pagesDesign of Power Transmission SystemVivek LevinNo ratings yet

- Cambio Arbol de LevasDocument12 pagesCambio Arbol de LevasgenaroNo ratings yet

- KISSsoft 2019 Tutorial 16-The-Tolerance-For-The-External-Diameter-Of-The-WormDocument17 pagesKISSsoft 2019 Tutorial 16-The-Tolerance-For-The-External-Diameter-Of-The-WormNguyễnVănLăngNo ratings yet

- Kyosho Superten Fw04Document36 pagesKyosho Superten Fw04aascmdthlbaimpgtbiNo ratings yet

- Alinear Tambor HoistDocument13 pagesAlinear Tambor HoistFreud CutireNo ratings yet

- Dana Ring and Pinion PatternDocument2 pagesDana Ring and Pinion PatternMohammed gNo ratings yet

- Transmissiya HD 120Document95 pagesTransmissiya HD 120анджелаNo ratings yet

- Vol. IVDocument501 pagesVol. IVsvenkzNo ratings yet

- Fenner Keyless DrivesDocument56 pagesFenner Keyless DrivesroytamaltanuNo ratings yet

- Design and Function: Marine Transmissions Gearboxes, Drives, IPSDocument80 pagesDesign and Function: Marine Transmissions Gearboxes, Drives, IPSSON100% (1)

- Armado Caja Diferen YarisDocument3 pagesArmado Caja Diferen YarisDouglas DuarteNo ratings yet

- Introduction To MetrologyDocument55 pagesIntroduction To MetrologyVishnuPSVichuNo ratings yet

- Ball ScrewDocument4 pagesBall ScrewJohn BlackburnNo ratings yet

- Sliding Mode Controller Design For Controlling The Speed of A DC MotorDocument5 pagesSliding Mode Controller Design For Controlling The Speed of A DC Motorbokic88No ratings yet

- M & M MCQ QPDocument12 pagesM & M MCQ QPPrabin MahatoNo ratings yet