Professional Documents

Culture Documents

CSWIP Practical Plate Exe 2007

CSWIP Practical Plate Exe 2007

Uploaded by

Walid SaadaniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CSWIP Practical Plate Exe 2007

CSWIP Practical Plate Exe 2007

Uploaded by

Walid SaadaniCopyright:

Available Formats

CSWIP 3.

1 Welding Inspection

Practical Plate Inspection

TWI Training & Examination

Services

Course Reference WIS 5

THIS

D AT U M

EDGE

22 Lack of sidewall

fusion

87

Arc Strike

241

Undercut smooth

30 1.5 max

236

4mm.

153

Name:

[Block capitals] Mr. I C Plenty

12-14mm

Centreline

Poor

Code/Specification used: TWI 09-09-03

B

crack 40

2mm

3mm in 50mm

Welding position: Flat /PA

length or scale on the plate surface

230

Gas pore

1.5

Page 1 of 3

51

FROM

NOTES:

Slag

inclusion

Length & thickness of

Welding process

EXAMPLE PLA

Signature: I C

M E AS U R E

WELD FACE

D AT U M

EDGE

128

3mm

Page 2 of 3

2mm

10

EXAMPLE PL

B

Root

concavity 2

deep

Lack of root

20Fusion

247

4mm.

Incomplete

root 50

penetration

on plate surface

n height :

alignment:

istortion:

THIS

NOTES:

FROM

23

M E AS U R E

WELD ROOT

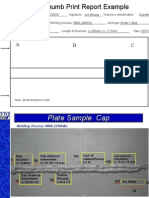

Plate Sample 6F Cap

Welding Process MMA (SMAW)

Mechanical

Damage

?

Lack of Sidewall fusion

Poor Toe Blend

Crater pipe

Lack of Sidewall Fusion + Incomplete Filled Groove

Tack Weld

Note: Arc strikes require blending and crack detection

Arc

Strikes

Plate Sample 6F Root

Welding Process MMA (SMAW)

?

Arc Strikes

Poor Stop/Start + Lack of Root

Penetration + Crater Pipe

? Damage +

? Mechanical

Lack of Root Fusion

Lack of Root Fusion

?

Blow Hole

Lack of

Root

Fusion

Lack of

Root

Fusion

Arc Strikes

Arc Strikes

Note: Arc strikes require blending and crack detection

Any Questions

You might also like

- 2-CSWIP Practical Plate ExamplesDocument31 pages2-CSWIP Practical Plate Examplesvibinkumars@gmail.com100% (42)

- CSWIP Welding Inspection Notes and QuestionsDocument132 pagesCSWIP Welding Inspection Notes and QuestionsfahreezNo ratings yet

- TWI Training CSWIP 3.1 Pipe 01 (Complete)Document8 pagesTWI Training CSWIP 3.1 Pipe 01 (Complete)Suli HartoNo ratings yet

- CSWIP Welding Inspection Plate Section PracticalDocument31 pagesCSWIP Welding Inspection Plate Section PracticalManoj Balla100% (4)

- 24B-Pactical Pipe Inspection 2006Document13 pages24B-Pactical Pipe Inspection 2006Khalid Perwez90% (10)

- CSWIP Practical Plate AnswersDocument31 pagesCSWIP Practical Plate AnswersSha Zha100% (1)

- CSWIP WIS 5 General Quiz: TWI Training & Examination ServicesDocument62 pagesCSWIP WIS 5 General Quiz: TWI Training & Examination Serviceshaoues23No ratings yet

- B. The Amount of Time The Electrode Is Being UsedDocument4 pagesB. The Amount of Time The Electrode Is Being UsedSolomon AttaNo ratings yet

- CSWIP WIS 5 General Quiz: TWI Training & Examination ServicesDocument63 pagesCSWIP WIS 5 General Quiz: TWI Training & Examination Serviceshaoues23No ratings yet

- 'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Document36 pages'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Vinoth KannanNo ratings yet

- MCQS .... CSWIP Questions and AnswersDocument67 pagesMCQS .... CSWIP Questions and AnswersAli Kashif100% (1)

- Cswip QuestioDocument15 pagesCswip Questioniminkp123100% (1)

- Weld Joint Geometry - Welding and NDE SymbolsDocument124 pagesWeld Joint Geometry - Welding and NDE Symbolstuvu100% (1)

- General Question Paper 1Document5 pagesGeneral Question Paper 1indusampathNo ratings yet

- CSWIP 3.2 - AppendixDocument51 pagesCSWIP 3.2 - AppendixRujal Maldini100% (1)

- Cswip 3.1 Welding Inspector - Multiple Choice Question, Dec 7, 2007Document18 pagesCswip 3.1 Welding Inspector - Multiple Choice Question, Dec 7, 2007Nagaya PushpaharaDoss50% (2)

- Morning Day 4 QuestionsDocument62 pagesMorning Day 4 Questionshaoues23No ratings yet

- CSWIP WIS 5 General Quiz: TWI Training & Examination ServicesDocument62 pagesCSWIP WIS 5 General Quiz: TWI Training & Examination Serviceshaoues23100% (1)

- Afternoon Quiz Set 3Document64 pagesAfternoon Quiz Set 3Anonymous 5iv0i3cZ100% (1)

- 4 - 0 MC Destructive TestingDocument23 pages4 - 0 MC Destructive TestingRidho KurniawanNo ratings yet

- Cswip Appendix 02 Plate Report and QuestionsDocument48 pagesCswip Appendix 02 Plate Report and QuestionsNsidibe Michael Etim100% (1)

- Cswip 3.1 QU MSR WI 4 05Document8 pagesCswip 3.1 QU MSR WI 4 05Luan Nguyen100% (3)

- Day 1 AnswersDocument31 pagesDay 1 Answershaoues23100% (2)

- Wis 5 Eoca AnswersDocument34 pagesWis 5 Eoca AnswersAli ClubistNo ratings yet

- Final Assesment Multiple Choice Question Cswip Welding Inspector Course Mfy Oo4 All Question To Be AttemptedDocument4 pagesFinal Assesment Multiple Choice Question Cswip Welding Inspector Course Mfy Oo4 All Question To Be AttemptedLe TuanNo ratings yet

- WIS5 - Appendix 2Document86 pagesWIS5 - Appendix 2Reza Fakhrizal100% (1)

- Twi - Welding Inspection - SteelsDocument209 pagesTwi - Welding Inspection - Steelsenels77No ratings yet

- Paper 1Document6 pagesPaper 1Umaibalan100% (1)

- Module 1 Welding Inspection and CertificationDocument16 pagesModule 1 Welding Inspection and CertificationMiki JaksicNo ratings yet

- 'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Document36 pages'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Veeralekshmanan KumarNo ratings yet

- Cswip 3 1 Macro PDFDocument36 pagesCswip 3 1 Macro PDFtheNo ratings yet

- Appendix English 2016Document180 pagesAppendix English 2016Adil Hasanov100% (1)

- Cswip 3.1 (Welding Inspector) Multiple Choice QuestionsDocument18 pagesCswip 3.1 (Welding Inspector) Multiple Choice QuestionsRajkumar ANo ratings yet

- CSWIP Set QuestionDocument13 pagesCSWIP Set QuestionMuhammad Hannan100% (2)

- Exam 9 Version 1 Tech@General-1Document15 pagesExam 9 Version 1 Tech@General-1Mebri ArdiantoniNo ratings yet

- CSWIP Practice Multi Chopice NotesDocument32 pagesCSWIP Practice Multi Chopice NotesAnonymous kIrNuh100% (1)

- Weld and Base Metal DiscontinuitiesDocument69 pagesWeld and Base Metal Discontinuitiestuvu0% (1)

- Questions Cswip 3.11.1Document11 pagesQuestions Cswip 3.11.1Ralph Laurence Parungao100% (1)

- WI 01 - Introduction To WI ModuleDocument14 pagesWI 01 - Introduction To WI ModuledayalramNo ratings yet

- Cswip Appendix 03 Pipe Reports and QuestionsDocument42 pagesCswip Appendix 03 Pipe Reports and QuestionsNsidibe Michael EtimNo ratings yet

- Cswip QA/answerDocument6 pagesCswip QA/answerJoseph PeterNo ratings yet

- Day 2 Questions: TWI Training & Examination ServicesDocument62 pagesDay 2 Questions: TWI Training & Examination Serviceshaoues230% (1)

- Iws Materials and Their Behaviour PDFDocument282 pagesIws Materials and Their Behaviour PDFkatfy1No ratings yet

- General 2Document4 pagesGeneral 2Sobia KalsoomNo ratings yet

- TWI CSWIP 3.1 Wis 5 Welding Inspection: World Centre For Materials Joining TechnologyDocument26 pagesTWI CSWIP 3.1 Wis 5 Welding Inspection: World Centre For Materials Joining TechnologyDanem HalasNo ratings yet

- CSWIP 3.1 Study NotesDocument11 pagesCSWIP 3.1 Study Notesmuhammadazhar50% (2)

- Practical Plate InspectionDocument8 pagesPractical Plate InspectionMohd Effiezool Yaser100% (1)

- TWI CSWIP 3.1 Wis 5 Welding Inspection Practical Visual Inspection of Pipe WeldsDocument11 pagesTWI CSWIP 3.1 Wis 5 Welding Inspection Practical Visual Inspection of Pipe WeldsJohn DareNo ratings yet

- Practical Plate AnswersDocument31 pagesPractical Plate Answersdaimahesh93% (15)

- Practical Visual Inspection of WeldsDocument40 pagesPractical Visual Inspection of WeldsAmit Sharma100% (1)

- Practical Plate - Pipe InspectionDocument10 pagesPractical Plate - Pipe InspectionPratheep ShansNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesdhasdjNo ratings yet

- CSWIP 3 1 PracticalDocument4 pagesCSWIP 3 1 PracticalAhmed Al-Emarah100% (1)

- PQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0Document12 pagesPQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0rodwellbNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEDocument18 pagesAcceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEEngineersEDGE CoimbatoreNo ratings yet

- NDT-Acceptance Various CodesDocument17 pagesNDT-Acceptance Various CodesShanmuga NavaneethanNo ratings yet

- CSWIP Welding Inspection Plate Section PracticalDocument31 pagesCSWIP Welding Inspection Plate Section PracticalLuan Nguyen86% (21)

- 3g Fcaw Wps for TrainingDocument3 pages3g Fcaw Wps for Trainingaleem.chenothNo ratings yet

- Plate Thumb Print Report ExampleDocument4 pagesPlate Thumb Print Report ExampleAnuradha SivakumarNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesMidhun K Chandrabose96% (25)