Professional Documents

Culture Documents

Sustainable Design Through The: 12 Principles of Green Engineering

Sustainable Design Through The: 12 Principles of Green Engineering

Uploaded by

andysm04Copyright:

Available Formats

You might also like

- NAPLEX NoteDocument58 pagesNAPLEX Notebapimirab654100% (1)

- Business Plan Security CompanyDocument27 pagesBusiness Plan Security CompanyJiji100% (3)

- Excavation Inspection HSE ChecklistDocument3 pagesExcavation Inspection HSE ChecklistSarfraz RandhawaNo ratings yet

- Terms of ReferenceDocument2 pagesTerms of ReferenceRahul VermaNo ratings yet

- Green Engineering: Create, Enhance and SustainDocument22 pagesGreen Engineering: Create, Enhance and Sustainnandan akNo ratings yet

- Green Engineering: Create, Enhance and SustainDocument23 pagesGreen Engineering: Create, Enhance and Sustainnandan akNo ratings yet

- Green EngineeringDocument22 pagesGreen EngineeringJozel IluminNo ratings yet

- Evaluation of Design Alternatives of End-of-Life Products Under Stochastic Yields in Multiple PeriodsDocument13 pagesEvaluation of Design Alternatives of End-of-Life Products Under Stochastic Yields in Multiple Periodsakshatgupta100% (1)

- Chapter-VIII: Green Engineering and Built EnvironmentDocument3 pagesChapter-VIII: Green Engineering and Built EnvironmentRojan PradhanNo ratings yet

- Advanced Green TechnologiesDocument7 pagesAdvanced Green TechnologiesIsha MeshramNo ratings yet

- Unit 3 Lecture 11Document6 pagesUnit 3 Lecture 11Girish RakeshNo ratings yet

- CHAPTER 2 p6-10Document4 pagesCHAPTER 2 p6-10Kirk Gwapo SilvaNo ratings yet

- Implementation of Green Chemistry Principles in Circular EconomyDocument17 pagesImplementation of Green Chemistry Principles in Circular EconomyFive GemNo ratings yet

- Presentation 2Document21 pagesPresentation 2Kandagatla KamalNo ratings yet

- Design For Disassembly GuidelinesDocument8 pagesDesign For Disassembly GuidelinesMalvika KulkarniNo ratings yet

- Industrial EcologyDocument6 pagesIndustrial Ecologyarmaghanqadir9No ratings yet

- Green EngineeringDocument27 pagesGreen EngineeringpikaNo ratings yet

- Innovation ManagementDocument3 pagesInnovation ManagementThird Eye PicturesNo ratings yet

- Unit2 EMDocument8 pagesUnit2 EMmukeshchauhan65040No ratings yet

- Obligatory Reading 1Document12 pagesObligatory Reading 1Dani ValleroNo ratings yet

- Design For The EnvironmentDocument52 pagesDesign For The EnvironmentDeborah catherineNo ratings yet

- Design For Disassembly Criteria in EUDocument12 pagesDesign For Disassembly Criteria in EUAslı KAYANo ratings yet

- Sustainability Part 2 - UMDocument43 pagesSustainability Part 2 - UMJared AngNo ratings yet

- CHEG 5165 - Process Integration and Pinch AnalysisDocument52 pagesCHEG 5165 - Process Integration and Pinch AnalysisSurafelNo ratings yet

- Lecture 24 (26.10.23)Document55 pagesLecture 24 (26.10.23)Rishit GuptaNo ratings yet

- Lecture 24 (26.10.23)Document55 pagesLecture 24 (26.10.23)gshaurya994No ratings yet

- 12 Principles ExamplesDocument9 pages12 Principles ExamplesGels GenovaNo ratings yet

- Sustainable Design of Material Handling EquipmentDocument9 pagesSustainable Design of Material Handling EquipmentPRATHAMESH KERKARNo ratings yet

- Green ChemistryDocument55 pagesGreen Chemistryapoorvbhai73No ratings yet

- Lecture 6 - Design For Environment (DfE) SE Jan 2020Document29 pagesLecture 6 - Design For Environment (DfE) SE Jan 2020DINONo ratings yet

- ADBHB-Eco Industrial Park - Ch1IntroDocument17 pagesADBHB-Eco Industrial Park - Ch1Introchuotlac2605No ratings yet

- 111 Ijmperdjun2019111Document18 pages111 Ijmperdjun2019111TJPRC PublicationsNo ratings yet

- Based On High-Level ParallelsDocument14 pagesBased On High-Level ParallelsShubham GoelNo ratings yet

- Sustainable Manufacturing Through Application of Reconfigurable and Intelligent Systems in Production Processes: A System PerspectiveDocument13 pagesSustainable Manufacturing Through Application of Reconfigurable and Intelligent Systems in Production Processes: A System Perspectivenikhilchari7896No ratings yet

- Chapter Two: General Design ConsiderationsDocument27 pagesChapter Two: General Design ConsiderationsTeddy Ekubay GNo ratings yet

- Mechanical Life Cycle Handbook Good Environmental Design and Manufacturing by Mahendra S. HundalDocument679 pagesMechanical Life Cycle Handbook Good Environmental Design and Manufacturing by Mahendra S. HundalJúlio RezendeNo ratings yet

- J Jclepro 2016 10 130Document28 pagesJ Jclepro 2016 10 130jayeshmali193No ratings yet

- Using Quality Function Deployment For Technique Selection For Optimum Environmental Performance ImprovementDocument9 pagesUsing Quality Function Deployment For Technique Selection For Optimum Environmental Performance ImprovementMarvi HarsiNo ratings yet

- BB - Dr.newcomb - Confpro.96 DETC DTM 1516.1996Document12 pagesBB - Dr.newcomb - Confpro.96 DETC DTM 1516.1996df_campos3353No ratings yet

- Principles: Ethics of Green EngineeringDocument9 pagesPrinciples: Ethics of Green EngineeringMart Brevin BitonNo ratings yet

- Webinar Ce and MeDocument40 pagesWebinar Ce and MeFernando KatayamaNo ratings yet

- 19 - DFR - Systematic Integration of Design-For-Recycling Into Product Design (1995)Document8 pages19 - DFR - Systematic Integration of Design-For-Recycling Into Product Design (1995)Aleena KanwalNo ratings yet

- Operations Management Sustaina Chain Management 12th Edition 242Document1 pageOperations Management Sustaina Chain Management 12th Edition 242omer asgharNo ratings yet

- The Impact of Automotive Product Remanufacturing oDocument6 pagesThe Impact of Automotive Product Remanufacturing oTam Jun HuiNo ratings yet

- 1 s2.0 S2212827122006588 MainDocument6 pages1 s2.0 S2212827122006588 MainJ.C.VNo ratings yet

- PVPS Circular-EconomyDocument7 pagesPVPS Circular-Economysimaproindia4958No ratings yet

- OM AssignmentDocument11 pagesOM AssignmentHayat Nasir1281No ratings yet

- SLCA To Support Evaluation of Environmental Conscious Production Process Alternatives: An Industrial CaseDocument8 pagesSLCA To Support Evaluation of Environmental Conscious Production Process Alternatives: An Industrial Casefahri alNo ratings yet

- Creating By-Product Resource Exchanges: Strategies For Eco-Industrial ParksDocument9 pagesCreating By-Product Resource Exchanges: Strategies For Eco-Industrial ParksGuillermo Andres Fuentes BarreraNo ratings yet

- Green Technology and Enviromental SustainablilityDocument54 pagesGreen Technology and Enviromental SustainablilityAmirah SufianNo ratings yet

- 1994 - Compatibility Analysis of Product Design For Recyclability and ReuseDocument20 pages1994 - Compatibility Analysis of Product Design For Recyclability and ReuseEmanuel BalzanNo ratings yet

- Modularization in Chemical Processing: Special Section: Process IntensificationDocument9 pagesModularization in Chemical Processing: Special Section: Process IntensificationJohn AnthoniNo ratings yet

- Reduction Cost ManufactureDocument21 pagesReduction Cost ManufactureAnonymous d1Cgf1n9INo ratings yet

- Sciencedirect: Design and Manufacturing of A Sustainable PedelecDocument6 pagesSciencedirect: Design and Manufacturing of A Sustainable PedelecdfsalamancahNo ratings yet

- Approach of Green and Lean Manufacturing Study of The Small Industries in BangladeshDocument4 pagesApproach of Green and Lean Manufacturing Study of The Small Industries in BangladeshMunem ShahriarNo ratings yet

- Dell DfE Survey PaperDocument4 pagesDell DfE Survey Paperwb22f014aNo ratings yet

- Cadena de Suministro SostenibleDocument18 pagesCadena de Suministro SostenibleAleejandra VilleegasNo ratings yet

- Lieder 2017 Towards Circular Economy Implementation in ManufacDocument19 pagesLieder 2017 Towards Circular Economy Implementation in Manufacmukessh1995No ratings yet

- 266 Arun NambiarDocument6 pages266 Arun NambiarJen S. GallanoNo ratings yet

- OM AssignmentDocument11 pagesOM AssignmentYitayew AlehegnNo ratings yet

- Algorithms 17 00098 v2Document22 pagesAlgorithms 17 00098 v2jamel-shamsNo ratings yet

- Scor Model and The Green Supply ChainDocument4 pagesScor Model and The Green Supply ChainpmayaduqueNo ratings yet

- Journal of Manufacturing Systems: ReviewDocument8 pagesJournal of Manufacturing Systems: ReviewQuỳnh NguyễnNo ratings yet

- New Salary Scales Updated February 2023 NAC ExtendedDocument2 pagesNew Salary Scales Updated February 2023 NAC ExtendedIon NNo ratings yet

- S111 EN 12 Aluminium Standard Inclinometric CasingDocument4 pagesS111 EN 12 Aluminium Standard Inclinometric CasingIrwan DarmawanNo ratings yet

- Career at PrachayDocument15 pagesCareer at PrachayGirish LakhotiyaNo ratings yet

- Listado JM Motors Jun-2020Document291 pagesListado JM Motors Jun-2020OliverNo ratings yet

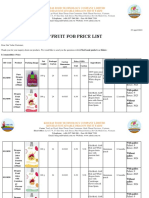

- Buenavista Central Elementary SchoolDocument2 pagesBuenavista Central Elementary Schoolanon_108827268No ratings yet

- The Impact of Incentives On The Performance of Employees in Public Sector: Case Study in Ministry of LaborDocument12 pagesThe Impact of Incentives On The Performance of Employees in Public Sector: Case Study in Ministry of LaborBaby SileshiNo ratings yet

- 217 Mod 03 Differential Locks (IC TF OP) 2-07-03Document6 pages217 Mod 03 Differential Locks (IC TF OP) 2-07-03arkhom1No ratings yet

- 1.kim Hai Fob Price List 2019 (New)Document6 pages1.kim Hai Fob Price List 2019 (New)Khanh QuocNo ratings yet

- Reducer: Sweat Reducer Hydraulic Concentric Eccentric ReducersDocument1 pageReducer: Sweat Reducer Hydraulic Concentric Eccentric ReducersMayur MandrekarNo ratings yet

- Sump Well-20 KL PDFDocument3 pagesSump Well-20 KL PDFvisali garikapatiNo ratings yet

- Integrated Mobility & Service Plan - TumakuruDocument20 pagesIntegrated Mobility & Service Plan - TumakuruVinay RajNo ratings yet

- Mukesh Yadav InsurnaceDocument3 pagesMukesh Yadav InsurnaceTriangle Tower ConstructionNo ratings yet

- ALKANSYADocument2 pagesALKANSYAkhiemonsNo ratings yet

- WL115 0117 PE4710 Water PipeDocument8 pagesWL115 0117 PE4710 Water PipeEdwin MariacaNo ratings yet

- Quiz 5 Chap 5 AnswerDocument4 pagesQuiz 5 Chap 5 AnswerPhương NgaNo ratings yet

- MelEye - CatalogDocument4 pagesMelEye - CatalogChinmay GhoshNo ratings yet

- Holiday Homework: FUN INDocument25 pagesHoliday Homework: FUN INSunita palNo ratings yet

- Gas Velocity CalculatorDocument5 pagesGas Velocity CalculatoresutjiadiNo ratings yet

- Class002 - 201200394-201000327-201000542Document46 pagesClass002 - 201200394-201000327-201000542api-286690957No ratings yet

- Bank of America Vs Phil Racing ClubDocument2 pagesBank of America Vs Phil Racing ClubMary Joyce Lacambra AquinoNo ratings yet

- Karhula - Model Z-Y100Z-2 - Manual.Document8 pagesKarhula - Model Z-Y100Z-2 - Manual.German ZuletaNo ratings yet

- Full Ebook of Lipidomics Methods and Protocols 2Nd Edition Sanjoy K Bhattacharya Editor Online PDF All ChapterDocument69 pagesFull Ebook of Lipidomics Methods and Protocols 2Nd Edition Sanjoy K Bhattacharya Editor Online PDF All Chapterandrewmolina926227100% (4)

- SOGA CH 2 - Transfer of Ownership Notes by Gyaani AcademyDocument5 pagesSOGA CH 2 - Transfer of Ownership Notes by Gyaani Academykjkapiljain510No ratings yet

- ChecklistDocument1 pageChecklistLarrytate15100% (2)

- Solvent-Based Separation and Recycling of Waste Plastics A ReviewDocument14 pagesSolvent-Based Separation and Recycling of Waste Plastics A ReviewChristhy Vanessa Ruiz MadroñeroNo ratings yet

- Tax Structure in IndiaDocument33 pagesTax Structure in IndiaVinayak Saxena100% (1)

Sustainable Design Through The: 12 Principles of Green Engineering

Sustainable Design Through The: 12 Principles of Green Engineering

Uploaded by

andysm04Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sustainable Design Through The: 12 Principles of Green Engineering

Sustainable Design Through The: 12 Principles of Green Engineering

Uploaded by

andysm04Copyright:

Available Formats

Sustainable Design through

the 12 Principles of Green

Engineering

Julie Beth Zimmerman, PhD

Office of Research and Development

United States Environmental Protection Agency

What is Green Engineering?

Design, discovery, and implementation

Molecules, products, processes, systems

Maximize Inherency

Maximize mass, energy, time, and space

efficiency

Goals of Principles of Green

Engineering

Provide a framework

Applicable

Effective

Appropriate

Apply across disciplines

Chemical, Civil, Environmental, Mechanical, Systems

Apply across scales of design

Molecular architecture to construct chemical compounds

Product architecture to create a cell phone

Urban architecture to build a city

How were the Principles of Green

Engineering developed?

Identify examples of successful engineering

that moves towards sustainability

Elucidate the underlying principle(s)

embedded in the examples.

See if the embedded principles are

applicable across scales and across

disciplines

various disciplines

various scales

even if not generally realized

How to think about Principles of

Green Engineering?

Not Rules, commandments, or natural laws.

Can be viewed as performance parameters

Need to be optimized

Need to be applied in context

Synergies

Trade-offs

Vary with innovation, creativity

Vary with culture, society

How to think about Principles of

Green Engineering? (cont.)

Often synergistic with traditional design

metrics.

Quality

Safety

Cost effective

Moving towards sustainability is a

performance goal.

Fundamental Issues in applying the

Principles of Green Engineering

Inherency

Life cycle foundation across all

principles.

Holistic or so-called systems

thinking should be applied to avoid

the unintended consequence of

doing the wrong things, but doing

them very well.

Applying the Principles of Green

Engineering:

Schematic of potential benefits vs. investments

re-define

the

problem

re-engineer

potential realized benefits

the system

optimize the

existing solution

(incrementalism)

investments (i.e., time, money, resources,energy)

The 12 Principles of Green

Engineering

Principle 1

Designers need to strive to ensure that all

material and energy inputs and outputs

are as inherently non-hazardous as

possible.

Principle 2

It is better to prevent waste than to treat

or clean up waste after it is formed.

Principle 2 (cont.)

End of pipe technologies

Containment systems for storage and

disposal

Expensive

Constant monitoring

Potential to fail

Principle 3

Separation and purification operations

should be a component of the design

framework.

Principle 3 (cont.)

Up-front design allows products to selfseparate using intrinsic physical/chemical

properties such as solubility, volatility, etc.

The catalyst is soluble in one of the reagents and remains soluble when

the other reagent is added. As the reaction goes on, and the product

builds up, the catalyst precipitates from the mixture as oil. This oil

liquid clathrateremains to be an active catalyst, as the reagents are

able to penetrate into it. When all the reagents are converted into

products, the oily catalyst turns into a sticky solid, which can be easily

separated and recycled.

"A Recyclable Catalyst that Precipitates at the End of the Reaction."

Dioumaev, VK, and RM Bullock. July 31, 2003. Nature 424(6948):530531

Principle 4

System components should be designed

to maximize mass, energy and temporal

efficiency.

Principle 4 (cont.)

Process intensification

Sophisticated actuator-control systems

Principle 5

System components should be output

pulled rather than input pushed through

the use of energy and materials.

(Le Chatliers Principle)

LeChatelier'sPrinciple

"If a system in equilibrium is subjected to a

stress the equilibrium will shift in the direction

which tends to relieve that stress."

Principle 5 (cont.)

Often drive a reaction or transformation to

completion by adding materials or energy.

A+B C+D

Similarly, a reaction can be pulled to

completion by removing the product without

adding materials or energy.

A+B C+D

Principle 5 (cont.)

Just in time manufacturing

Production is based on demand

eliminates waste due to overproduction and lowers warehousing

costs

supplies are closely monitored and quickly altered to meet

changing demands

small and accurate resupply deliveries must be made just as

they are needed

Principle 6

Embedded entropy and complexity must

be viewed as an investment when making

design choices on recycle, reuse or

beneficial disposition.

Principle 6 (cont.)

The amount of complexity built into a product

whether at the macro, micro, or molecular

scale is usually a function of resource

expenditures.

High complexity, low entropy reuse

Lower complexity value-conserving recycling where possible

or beneficial disposition

Natural systems can also be recognized as

having complexity

Principle 6 (cont.)

Case for modular, standardized, platformbased, upgradable design

Principle 7

Targeted durability, not immortality,

should be a design goal.

Principle 7 (cont.)

Products that last well beyond their useful

commercial life often result in environmental

problems ranging from solid waste to

persistence and bioaccumulation.

Repair and maintenance must also be

considered

Must balance targeted lifetime with durability

and robustness in anticipated operating

conditions.

Principle 7 (cont.)

Biodegradable plastics

Principle 8

Design for unnecessary capacity or capability

should be considered a design flaw. This

includes engineering one size fits all

solutions.

Principle 8 (cont.)

While product agility and product flexibility

can be desirable, the cost in terms of

materials and energy for unusable capacity

and capability can be high.

There is also a tendency to design for the

worst case scenario such that the same

product or process can be utilized regardless

of spatial or temporal conditions.

Principle 8 (cont.)

A single laundry detergent

formulation that is intended to

work anywhere in the US and

must be designed to work in

the most extreme hard water

conditions

Phosphates were added as builders to

remove hardness of water

Phosphates, by their high nutrient value,

can cause eutrophication in water bodies

Principle 9

Multi-component products should strive

for material unification to promote

disassembly and value retention.

(minimize material diversity)

Principle 9 (cont.)

Selected automobile designers are reducing

the number of plastics by developing different

forms of polymers to have new material

characteristics that improve ease of

disassembly and recyclability.

This technology is currently applied to the

design of multilayer components, such as

door and instrument panels.

Principle 9 (cont.)

For example, components can be produced using a

single material, such as metallocene polyolefins,

that are engineered to have the various and

necessary design properties.

Through the use of this monomaterial design

strategy, it is no longer necessary to disassemble

the door or instrument panel for recovery and

recycling

Principle 10

Design of processes and systems must

include integration and interconnectivity

with available energy and materials flows.

Principle 10 (cont.)

Principle 11

Performance metrics include designing

for performance in commercial after-life.

Principle 11 (cont.)

"When we reuse our products

much less recycle them we keep

our costs down significantly," says

Rob Fischmann, head of worldwide

recycling at Kodak. "The secondtime cost for these cameras is

essentially zero."

Principle 12

Design should be based on renewable and

readily available inputs.

Principle 12 (cont.)

With cooperative development from Mitsui

Chemicals Inc. and Cargill-Dow, LLC,

SANYO achieved the world's first bioplastic (polylactic acid) optical disc in

9/2003.

Use corn as base material to derive

polylactic acid with its optical property and

exact structure.

Roughly 85 corn kernels is needed to

make one disc and one ear of corn to

make 10 discs. The world corn production

is about 600 million tons, less than 0.1%

is needed to make 10 billion discs

(current annual worldwide demand).

In the end, Green Engineering

Principles

Create a universal language between

designers at all scales leading to

Inherent

Innovative

Integrated

Interdisciplinary

systematic designs that consider

environmental, economic, and social

criteria

the goal of sustainability.

For more information:

Dr. Julie Zimmerman, US EPA,

zimmerman.julie@epa.gov; +1 202 343 9689

Anastas, P. T.; Zimmerman, J. B., Design through the Twelve

Principles of Green Engineering. Environmental Science and

Technology, 37 (5): 94A-101A, 2003.

McDonough, W.; Braungart, M.; Anastas, P.T.; Zimmerman, J.B.

Applying the Principles of Green Engineering to Cradle-to-Cradle

Design. Environmental Science and Technology, 37 (23): 434A441A, 2003.

You might also like

- NAPLEX NoteDocument58 pagesNAPLEX Notebapimirab654100% (1)

- Business Plan Security CompanyDocument27 pagesBusiness Plan Security CompanyJiji100% (3)

- Excavation Inspection HSE ChecklistDocument3 pagesExcavation Inspection HSE ChecklistSarfraz RandhawaNo ratings yet

- Terms of ReferenceDocument2 pagesTerms of ReferenceRahul VermaNo ratings yet

- Green Engineering: Create, Enhance and SustainDocument22 pagesGreen Engineering: Create, Enhance and Sustainnandan akNo ratings yet

- Green Engineering: Create, Enhance and SustainDocument23 pagesGreen Engineering: Create, Enhance and Sustainnandan akNo ratings yet

- Green EngineeringDocument22 pagesGreen EngineeringJozel IluminNo ratings yet

- Evaluation of Design Alternatives of End-of-Life Products Under Stochastic Yields in Multiple PeriodsDocument13 pagesEvaluation of Design Alternatives of End-of-Life Products Under Stochastic Yields in Multiple Periodsakshatgupta100% (1)

- Chapter-VIII: Green Engineering and Built EnvironmentDocument3 pagesChapter-VIII: Green Engineering and Built EnvironmentRojan PradhanNo ratings yet

- Advanced Green TechnologiesDocument7 pagesAdvanced Green TechnologiesIsha MeshramNo ratings yet

- Unit 3 Lecture 11Document6 pagesUnit 3 Lecture 11Girish RakeshNo ratings yet

- CHAPTER 2 p6-10Document4 pagesCHAPTER 2 p6-10Kirk Gwapo SilvaNo ratings yet

- Implementation of Green Chemistry Principles in Circular EconomyDocument17 pagesImplementation of Green Chemistry Principles in Circular EconomyFive GemNo ratings yet

- Presentation 2Document21 pagesPresentation 2Kandagatla KamalNo ratings yet

- Design For Disassembly GuidelinesDocument8 pagesDesign For Disassembly GuidelinesMalvika KulkarniNo ratings yet

- Industrial EcologyDocument6 pagesIndustrial Ecologyarmaghanqadir9No ratings yet

- Green EngineeringDocument27 pagesGreen EngineeringpikaNo ratings yet

- Innovation ManagementDocument3 pagesInnovation ManagementThird Eye PicturesNo ratings yet

- Unit2 EMDocument8 pagesUnit2 EMmukeshchauhan65040No ratings yet

- Obligatory Reading 1Document12 pagesObligatory Reading 1Dani ValleroNo ratings yet

- Design For The EnvironmentDocument52 pagesDesign For The EnvironmentDeborah catherineNo ratings yet

- Design For Disassembly Criteria in EUDocument12 pagesDesign For Disassembly Criteria in EUAslı KAYANo ratings yet

- Sustainability Part 2 - UMDocument43 pagesSustainability Part 2 - UMJared AngNo ratings yet

- CHEG 5165 - Process Integration and Pinch AnalysisDocument52 pagesCHEG 5165 - Process Integration and Pinch AnalysisSurafelNo ratings yet

- Lecture 24 (26.10.23)Document55 pagesLecture 24 (26.10.23)Rishit GuptaNo ratings yet

- Lecture 24 (26.10.23)Document55 pagesLecture 24 (26.10.23)gshaurya994No ratings yet

- 12 Principles ExamplesDocument9 pages12 Principles ExamplesGels GenovaNo ratings yet

- Sustainable Design of Material Handling EquipmentDocument9 pagesSustainable Design of Material Handling EquipmentPRATHAMESH KERKARNo ratings yet

- Green ChemistryDocument55 pagesGreen Chemistryapoorvbhai73No ratings yet

- Lecture 6 - Design For Environment (DfE) SE Jan 2020Document29 pagesLecture 6 - Design For Environment (DfE) SE Jan 2020DINONo ratings yet

- ADBHB-Eco Industrial Park - Ch1IntroDocument17 pagesADBHB-Eco Industrial Park - Ch1Introchuotlac2605No ratings yet

- 111 Ijmperdjun2019111Document18 pages111 Ijmperdjun2019111TJPRC PublicationsNo ratings yet

- Based On High-Level ParallelsDocument14 pagesBased On High-Level ParallelsShubham GoelNo ratings yet

- Sustainable Manufacturing Through Application of Reconfigurable and Intelligent Systems in Production Processes: A System PerspectiveDocument13 pagesSustainable Manufacturing Through Application of Reconfigurable and Intelligent Systems in Production Processes: A System Perspectivenikhilchari7896No ratings yet

- Chapter Two: General Design ConsiderationsDocument27 pagesChapter Two: General Design ConsiderationsTeddy Ekubay GNo ratings yet

- Mechanical Life Cycle Handbook Good Environmental Design and Manufacturing by Mahendra S. HundalDocument679 pagesMechanical Life Cycle Handbook Good Environmental Design and Manufacturing by Mahendra S. HundalJúlio RezendeNo ratings yet

- J Jclepro 2016 10 130Document28 pagesJ Jclepro 2016 10 130jayeshmali193No ratings yet

- Using Quality Function Deployment For Technique Selection For Optimum Environmental Performance ImprovementDocument9 pagesUsing Quality Function Deployment For Technique Selection For Optimum Environmental Performance ImprovementMarvi HarsiNo ratings yet

- BB - Dr.newcomb - Confpro.96 DETC DTM 1516.1996Document12 pagesBB - Dr.newcomb - Confpro.96 DETC DTM 1516.1996df_campos3353No ratings yet

- Principles: Ethics of Green EngineeringDocument9 pagesPrinciples: Ethics of Green EngineeringMart Brevin BitonNo ratings yet

- Webinar Ce and MeDocument40 pagesWebinar Ce and MeFernando KatayamaNo ratings yet

- 19 - DFR - Systematic Integration of Design-For-Recycling Into Product Design (1995)Document8 pages19 - DFR - Systematic Integration of Design-For-Recycling Into Product Design (1995)Aleena KanwalNo ratings yet

- Operations Management Sustaina Chain Management 12th Edition 242Document1 pageOperations Management Sustaina Chain Management 12th Edition 242omer asgharNo ratings yet

- The Impact of Automotive Product Remanufacturing oDocument6 pagesThe Impact of Automotive Product Remanufacturing oTam Jun HuiNo ratings yet

- 1 s2.0 S2212827122006588 MainDocument6 pages1 s2.0 S2212827122006588 MainJ.C.VNo ratings yet

- PVPS Circular-EconomyDocument7 pagesPVPS Circular-Economysimaproindia4958No ratings yet

- OM AssignmentDocument11 pagesOM AssignmentHayat Nasir1281No ratings yet

- SLCA To Support Evaluation of Environmental Conscious Production Process Alternatives: An Industrial CaseDocument8 pagesSLCA To Support Evaluation of Environmental Conscious Production Process Alternatives: An Industrial Casefahri alNo ratings yet

- Creating By-Product Resource Exchanges: Strategies For Eco-Industrial ParksDocument9 pagesCreating By-Product Resource Exchanges: Strategies For Eco-Industrial ParksGuillermo Andres Fuentes BarreraNo ratings yet

- Green Technology and Enviromental SustainablilityDocument54 pagesGreen Technology and Enviromental SustainablilityAmirah SufianNo ratings yet

- 1994 - Compatibility Analysis of Product Design For Recyclability and ReuseDocument20 pages1994 - Compatibility Analysis of Product Design For Recyclability and ReuseEmanuel BalzanNo ratings yet

- Modularization in Chemical Processing: Special Section: Process IntensificationDocument9 pagesModularization in Chemical Processing: Special Section: Process IntensificationJohn AnthoniNo ratings yet

- Reduction Cost ManufactureDocument21 pagesReduction Cost ManufactureAnonymous d1Cgf1n9INo ratings yet

- Sciencedirect: Design and Manufacturing of A Sustainable PedelecDocument6 pagesSciencedirect: Design and Manufacturing of A Sustainable PedelecdfsalamancahNo ratings yet

- Approach of Green and Lean Manufacturing Study of The Small Industries in BangladeshDocument4 pagesApproach of Green and Lean Manufacturing Study of The Small Industries in BangladeshMunem ShahriarNo ratings yet

- Dell DfE Survey PaperDocument4 pagesDell DfE Survey Paperwb22f014aNo ratings yet

- Cadena de Suministro SostenibleDocument18 pagesCadena de Suministro SostenibleAleejandra VilleegasNo ratings yet

- Lieder 2017 Towards Circular Economy Implementation in ManufacDocument19 pagesLieder 2017 Towards Circular Economy Implementation in Manufacmukessh1995No ratings yet

- 266 Arun NambiarDocument6 pages266 Arun NambiarJen S. GallanoNo ratings yet

- OM AssignmentDocument11 pagesOM AssignmentYitayew AlehegnNo ratings yet

- Algorithms 17 00098 v2Document22 pagesAlgorithms 17 00098 v2jamel-shamsNo ratings yet

- Scor Model and The Green Supply ChainDocument4 pagesScor Model and The Green Supply ChainpmayaduqueNo ratings yet

- Journal of Manufacturing Systems: ReviewDocument8 pagesJournal of Manufacturing Systems: ReviewQuỳnh NguyễnNo ratings yet

- New Salary Scales Updated February 2023 NAC ExtendedDocument2 pagesNew Salary Scales Updated February 2023 NAC ExtendedIon NNo ratings yet

- S111 EN 12 Aluminium Standard Inclinometric CasingDocument4 pagesS111 EN 12 Aluminium Standard Inclinometric CasingIrwan DarmawanNo ratings yet

- Career at PrachayDocument15 pagesCareer at PrachayGirish LakhotiyaNo ratings yet

- Listado JM Motors Jun-2020Document291 pagesListado JM Motors Jun-2020OliverNo ratings yet

- Buenavista Central Elementary SchoolDocument2 pagesBuenavista Central Elementary Schoolanon_108827268No ratings yet

- The Impact of Incentives On The Performance of Employees in Public Sector: Case Study in Ministry of LaborDocument12 pagesThe Impact of Incentives On The Performance of Employees in Public Sector: Case Study in Ministry of LaborBaby SileshiNo ratings yet

- 217 Mod 03 Differential Locks (IC TF OP) 2-07-03Document6 pages217 Mod 03 Differential Locks (IC TF OP) 2-07-03arkhom1No ratings yet

- 1.kim Hai Fob Price List 2019 (New)Document6 pages1.kim Hai Fob Price List 2019 (New)Khanh QuocNo ratings yet

- Reducer: Sweat Reducer Hydraulic Concentric Eccentric ReducersDocument1 pageReducer: Sweat Reducer Hydraulic Concentric Eccentric ReducersMayur MandrekarNo ratings yet

- Sump Well-20 KL PDFDocument3 pagesSump Well-20 KL PDFvisali garikapatiNo ratings yet

- Integrated Mobility & Service Plan - TumakuruDocument20 pagesIntegrated Mobility & Service Plan - TumakuruVinay RajNo ratings yet

- Mukesh Yadav InsurnaceDocument3 pagesMukesh Yadav InsurnaceTriangle Tower ConstructionNo ratings yet

- ALKANSYADocument2 pagesALKANSYAkhiemonsNo ratings yet

- WL115 0117 PE4710 Water PipeDocument8 pagesWL115 0117 PE4710 Water PipeEdwin MariacaNo ratings yet

- Quiz 5 Chap 5 AnswerDocument4 pagesQuiz 5 Chap 5 AnswerPhương NgaNo ratings yet

- MelEye - CatalogDocument4 pagesMelEye - CatalogChinmay GhoshNo ratings yet

- Holiday Homework: FUN INDocument25 pagesHoliday Homework: FUN INSunita palNo ratings yet

- Gas Velocity CalculatorDocument5 pagesGas Velocity CalculatoresutjiadiNo ratings yet

- Class002 - 201200394-201000327-201000542Document46 pagesClass002 - 201200394-201000327-201000542api-286690957No ratings yet

- Bank of America Vs Phil Racing ClubDocument2 pagesBank of America Vs Phil Racing ClubMary Joyce Lacambra AquinoNo ratings yet

- Karhula - Model Z-Y100Z-2 - Manual.Document8 pagesKarhula - Model Z-Y100Z-2 - Manual.German ZuletaNo ratings yet

- Full Ebook of Lipidomics Methods and Protocols 2Nd Edition Sanjoy K Bhattacharya Editor Online PDF All ChapterDocument69 pagesFull Ebook of Lipidomics Methods and Protocols 2Nd Edition Sanjoy K Bhattacharya Editor Online PDF All Chapterandrewmolina926227100% (4)

- SOGA CH 2 - Transfer of Ownership Notes by Gyaani AcademyDocument5 pagesSOGA CH 2 - Transfer of Ownership Notes by Gyaani Academykjkapiljain510No ratings yet

- ChecklistDocument1 pageChecklistLarrytate15100% (2)

- Solvent-Based Separation and Recycling of Waste Plastics A ReviewDocument14 pagesSolvent-Based Separation and Recycling of Waste Plastics A ReviewChristhy Vanessa Ruiz MadroñeroNo ratings yet

- Tax Structure in IndiaDocument33 pagesTax Structure in IndiaVinayak Saxena100% (1)