Professional Documents

Culture Documents

Melting of Metals: Cupola Furnace

Melting of Metals: Cupola Furnace

Uploaded by

Rahul RaiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Melting of Metals: Cupola Furnace

Melting of Metals: Cupola Furnace

Uploaded by

Rahul RaiCopyright:

Available Formats

MELTING OF METALS

CUPOLA FURNACE

Cupola furnace

A cupola furnace is a vertical cylindrical

furnace used for melting only cast iron.

cupola furnace consists of a cylindrical steel

shell lined with a refractory material like

firebrick and clay.

The height of the Cupola Furnace may range

from 20 - 35 feet, while its diameter ranges

from 10 - 15 inch.

Cupola Furnace is open at the both its top

and bottom initially.

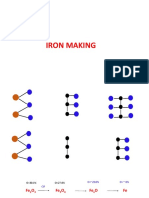

The charge used in cupola furnace consists

of alternate layers of coke, flux and metal

(iron).

These three components are continuously

built into the cupola furnace. The most

commonly used iron - to - coke ratio is 8:1.

The flux may be limestone (CaCO3),

fluorspar, sodium carbonate or calcium

carbide. Limestone is the commonly

employed flux.

The total weight of the flux will be

approximately 1/5th the weight of the coke

charge.

Various zones of Cupola

Well zone

Well zone is the portion situated between the

rammed sand bottom and just below the bottom

edge of the tuyeres. The molten metal is

occupied in this zone.

Combustion Zone

The combustion zone or oxidizing zone is

situated normally 15-30 cm from the bottom

edge of the tuyeres. It is in this zone where rapid

combustion of coke takes place due to which a

lot of heat is generated in the furnace. The

temperature in this zone varies from 1550 C

1850 C

Reducing Zone

In this zone, some of the hot CO2 gas moving

upward through the hot coke gets reduced to

CO. In other words, reduction of CO 2 to CO

occurs in this zone. Due to the reducing

atmosphere, the charge is protected from

oxidation. The reaction taking place in this zone

is given by:

CO2+C (coke)

2CO Heat

Melting Zone

The metal starts melting in this zone and trickles

down through the coke bed to the well zone. The

molten iron while passing down through the

reducing zone picks up carbon and the reaction

is given by: 3Fe+2CO

Fe3C+ CO2

Preheating zone

The portion occupied from the top surface

of the melting zone to the charging door is

called Preheating zone. The hot gases

rising upwards from the combustion and

reducing zone gives its heat to the charge

before passing out of the furnace. Thus,

the charge is preheated before descending

downwards.

Crucible furnace

You might also like

- Energy Optimizing FurnaceDocument4 pagesEnergy Optimizing Furnacesourajpatel100% (2)

- Cupola FurnaceDocument23 pagesCupola Furnacesayan halder100% (1)

- Pig Iron - Blast Furnace RouteDocument3 pagesPig Iron - Blast Furnace RouteRaden Pambudi PratamaNo ratings yet

- Ironmaking and Steelmaking Theory and PracticeDocument9 pagesIronmaking and Steelmaking Theory and PracticeRasul BzNo ratings yet

- Lecture-4-Intro. To Melting Furnaces-Lecture NotesDocument43 pagesLecture-4-Intro. To Melting Furnaces-Lecture NotesManchi MaheetNo ratings yet

- Iron Making PPT 1Document35 pagesIron Making PPT 1SHUBHAM VERMANo ratings yet

- 1 Introduction of The Blast Furnace ProcessDocument9 pages1 Introduction of The Blast Furnace Processhemant patilNo ratings yet

- CupolaDocument5 pagesCupolaRajan Goyal100% (2)

- Meltingfurnace 170728094222Document31 pagesMeltingfurnace 170728094222Ninfa LansangNo ratings yet

- Foundry PracticeDocument58 pagesFoundry PracticetrishNo ratings yet

- What Is Furnace ?Document21 pagesWhat Is Furnace ?BARUN BIKASH DENo ratings yet

- Present Indian Steel Making Practice and Its Scenario: Introduction: WHAT IS STEEL?Document10 pagesPresent Indian Steel Making Practice and Its Scenario: Introduction: WHAT IS STEEL?SarbajitManna100% (1)

- BF SlagDocument9 pagesBF SlagSuresh BabuNo ratings yet

- Blast Furnace Year 10Document10 pagesBlast Furnace Year 10Sapan KansaraNo ratings yet

- What Is SteelDocument10 pagesWhat Is SteelKristo Ver TamposNo ratings yet

- How's Steel Manufactured?: Raw Materials For IronmakingDocument6 pagesHow's Steel Manufactured?: Raw Materials For IronmakingUpendra93No ratings yet

- Steel Processing in Energy Optimizing Furnace: 4.1 Preparation of EofDocument8 pagesSteel Processing in Energy Optimizing Furnace: 4.1 Preparation of EofRitesh KumarNo ratings yet

- BF Alkali ProblemDocument6 pagesBF Alkali ProblemSuresh BabuNo ratings yet

- Lump Ore Characteristics and Their Impact On Blast Furnace OperationDocument7 pagesLump Ore Characteristics and Their Impact On Blast Furnace Operationalvaroaac4100% (1)

- S K HazraDocument6 pagesS K HazraRicky MenonNo ratings yet

- Iron Making Lecture 3 & 4Document38 pagesIron Making Lecture 3 & 4ganesh.patel37188No ratings yet

- 12.4 Ferroalloy ProductionDocument20 pages12.4 Ferroalloy ProductionMuhammad Kamran BhattiNo ratings yet

- Developments in Blast Furnace Process Control at Port Kembla BaseDocument13 pagesDevelopments in Blast Furnace Process Control at Port Kembla BaseBinod Kumar PadhiNo ratings yet

- The Blast FurnaceDocument17 pagesThe Blast FurnaceAnonymous mRBbdopMKfNo ratings yet

- Electric Arc Furnace Injection System For OxygenDocument7 pagesElectric Arc Furnace Injection System For OxygenIcilma LiraNo ratings yet

- Abnormality Prediction During Furnace Operation (C) Rev1Document35 pagesAbnormality Prediction During Furnace Operation (C) Rev1Shauvik Roy100% (1)

- Mini Blast FurnaceDocument8 pagesMini Blast FurnaceSantosh UpadhyayNo ratings yet

- Metallurgical Coke and ManufactureDocument9 pagesMetallurgical Coke and ManufactureThomasNo ratings yet

- A Critical Analysis ON Tap Hole by Abhik ChakrabortyDocument24 pagesA Critical Analysis ON Tap Hole by Abhik Chakrabortyravish8888No ratings yet

- Understanding Blast Furnace Hearth Wall Temperatures To Support Operational/Maintenance DecisionsDocument8 pagesUnderstanding Blast Furnace Hearth Wall Temperatures To Support Operational/Maintenance DecisionsJJNo ratings yet

- Study of Blast Furnace Cooling StaveDocument7 pagesStudy of Blast Furnace Cooling StavecaapasaNo ratings yet

- Furnace Proper FinalDocument49 pagesFurnace Proper FinalPrateek SinghNo ratings yet

- Iron Making2Document54 pagesIron Making2richa_msmeNo ratings yet

- Stamp Charging TechnologyDocument6 pagesStamp Charging Technologypramod_try100% (1)

- BSSL Blow-In Plan r1 PDFDocument37 pagesBSSL Blow-In Plan r1 PDFROWHEIT100% (1)

- Steel: by A S M Fahad Hossain Assistant Professor Department of Civil Engineering, AUSTDocument23 pagesSteel: by A S M Fahad Hossain Assistant Professor Department of Civil Engineering, AUSTMahadi HasanNo ratings yet

- Effect of Nut Coke On The Performance of The Ironmaking Blast Furnace Qingshi SongDocument159 pagesEffect of Nut Coke On The Performance of The Ironmaking Blast Furnace Qingshi SongGaurav SrivastavaNo ratings yet

- Cupola FurnaceDocument32 pagesCupola Furnaceadelina ednandaNo ratings yet

- Anal - Coal M.coke27.3Document37 pagesAnal - Coal M.coke27.3MadhavanIceNo ratings yet

- A Review On Stamped Charging of CoalsDocument31 pagesA Review On Stamped Charging of CoalsJorge MadiasNo ratings yet

- Bee - Hive Metallurgical CokeDocument4 pagesBee - Hive Metallurgical Coke124swadeshiNo ratings yet

- Concepts of Electric Arc Furnace Fume ControlDocument5 pagesConcepts of Electric Arc Furnace Fume ControlAshutosh SinghNo ratings yet

- Mathematical Modelling of A Cupola FurnaceDocument2 pagesMathematical Modelling of A Cupola FurnaceLokesh DahiyaNo ratings yet

- Corex GyanDocument104 pagesCorex Gyanrohitbhat2345No ratings yet

- Unit 4 v3 PDFDocument12 pagesUnit 4 v3 PDFCh RajuNo ratings yet

- Manufacture of Metallurgical CokeDocument18 pagesManufacture of Metallurgical CokeAravind GNo ratings yet

- Iron Making PPT Notes 2Document49 pagesIron Making PPT Notes 2SHUBHAM VERMANo ratings yet

- NPTELDocument587 pagesNPTELSk BeheraNo ratings yet

- State of The Art and Future of The Blast FurnaceDocument16 pagesState of The Art and Future of The Blast Furnacesaibal_silNo ratings yet

- Operation Manual FurnaceDocument21 pagesOperation Manual FurnaceAshutosh SinghNo ratings yet

- A Study On The Productivity of Sinter PlantDocument9 pagesA Study On The Productivity of Sinter Plantpavan619100% (1)

- Factors Affecting Silicomanganese Production Using Manganese Rich Slag in The ChargeDocument3 pagesFactors Affecting Silicomanganese Production Using Manganese Rich Slag in The ChargePushkar KhannaNo ratings yet

- Reverberatory Furnace: By: Walid Khalid AbdulkaderDocument9 pagesReverberatory Furnace: By: Walid Khalid Abdulkaderanon_665535262No ratings yet

- Desulphurization by Slag TreatmentDocument22 pagesDesulphurization by Slag TreatmentanandvinaygeraNo ratings yet

- Decreasing Blast Furnace Process Costs at Iscor Long ProductsDocument6 pagesDecreasing Blast Furnace Process Costs at Iscor Long ProductsPaul VermeulenNo ratings yet

- Session-1-Introduction and Coke MakingDocument51 pagesSession-1-Introduction and Coke MakingHeroNo ratings yet

- Blow in Essar 15.2.10Document18 pagesBlow in Essar 15.2.10TheleapInoblivionNo ratings yet

- December 2010: All Relevant Disclosures and Certifications BeginDocument36 pagesDecember 2010: All Relevant Disclosures and Certifications Beginbryan_porterNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- EconomyDocument4 pagesEconomyRahul RaiNo ratings yet

- The Basics of The Investment Casting ProcessDocument2 pagesThe Basics of The Investment Casting ProcessRahul RaiNo ratings yet

- CastingDocument4 pagesCastingRahul RaiNo ratings yet

- The Basics of The Investment Casting ProcessDocument2 pagesThe Basics of The Investment Casting ProcessRahul RaiNo ratings yet