Professional Documents

Culture Documents

1 Prolific Systems & Technologies (PVT) LTD

1 Prolific Systems & Technologies (PVT) LTD

Uploaded by

vijay kumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Prolific Systems & Technologies (PVT) LTD

1 Prolific Systems & Technologies (PVT) LTD

Uploaded by

vijay kumarCopyright:

Available Formats

Prolific Systems & Technologies Pvt Ltd

Prolific Systems & Technologies (Pvt) Ltd 1

ALIGNMENT

What do you mean by alignment

The process of adjusting parts so that they

are in proper relative position with respect to

each other.

Prolific Systems & Technologies (Pvt)

2

Ltd

WHY ALIGNMENT

50% of all machinery problems are caused by machinery

misalignment, the cost of which equates to not merely

damaged components and down-time, but also increased

power consumption and degradation of product quality.

Every year the industry spends a tremendously large

amount of money unnecessarily.

Prolific Systems & Technologies (Pvt)

3

Ltd

ALIGNMENT

In virtually every industry rotating machinery plays a vital role

Motors, pumps, conveyors - Critical to all machine

performance is the alignment of their drive shafts

So measuring how accurately they are aligned and how

much you need to correct them is vital information

Prolific Systems & Technologies (Pvt) Ltd 4

WHAT IS COUPLING ALIGNMENT?

Coupling alignment

is shaft alignment.

If the shafts are

aligned, the

couplings will

normally go along for

the ride.

WHAT IS SHAFT ALIGNMENT

Shaft alignment is the process to align two

or more shafts with each other to within a

tolerated margin.

It is an absolute requirement for machinery

before the machinery is put in service.

Prolific Systems & Technologies (Pvt)

6

Ltd

SHAFT ALIGNMENT

Shaft alignment of rotating equipment is the major

activity in maintenance of the equipment, one has to

concentrate upon

Misalignment of shaft contributes to

Reduced life of the equipments parts.

Premature failure of the equipment, resulting in

breakdown of machinery, causing production loss.

Prolific Systems & Technologies (Pvt)

7

Ltd

WHY ALIGNMENT

When the shaft of two rotator machines

are directly coupled via a flexible coupling,

Any misalignment between their

centerlines of rotation can result in

vibration and additional loads depending

on their severity, can produce premature

wear, or even catastrophic failure of

bearings, seals, the coupling itself, and

other machine components

Prolific Systems & Technologies (Pvt)

8

Ltd

WHY ALIGNMENT

Misalignment has long been recognized as

one of the leading causes of machinery

damage, and has been responsible for huge

economic losses.

The more misalignment, the greater the

rate of wear, likelihood of premature failure,

and loss of efficiency of the machine.

Moreover, misaligned machines absorb

more energy and consume more power.

Prolific Systems & Technologies (Pvt) Ltd 9

TYPES OF COUPLINGS

Rigid usually must Flexible uses one or

be aligned to very more elements to

close tolerances. connect the shafts.

Think of it as solidly Mechanical

bolting one shaft to Elastomeric

another. Metallic

These can tolerate

slightly more

misalignment, thermal

changes, and shock.

Prolific Systems & Technologies (Pvt)

10

Ltd

SHAFT ALIGNMENT (METHODS)

STRAIGHT EDGE METHOD DIAL METHOD- RIM AND FACE

REVERSE DIAL METHOD LASER METHOD

Prolific Systems & Technologies (Pvt)

11

Ltd

Every shaft, bent or straight, rotates about

an axis that forms a straight line

Prolific Systems & Technologies (Pvt)

12

Ltd

ALIGNMENT

The issue is quantification of the alignment

quality and determination of allowable deviation

the so called alignment tolerance.

We define misalignment by visualizing the shaft

centerlines of rotation as two straight lines in

space.

The trick is to get them to coincide so as to form

one straight line. If they dont, then there must

exist either offset misalignment or angular

misalignment or a combination of both.

Prolific Systems & Technologies (Pvt)

13

Ltd

CO-LINEARITY

Shafts in this same straight line are

considered co-linear, or in the same

straight line

Prolific Systems & Technologies (Pvt) Ltd 14

TYPES OF MISALIGNMENT

Offset, or Parallel the Angular the shafts are not

shafts are parallel to in the same plane, which

each other, but are not causes a difference in

co-planar, or in the same measurement between

plane. This can be both measurements made 180

vertical and horizontal. degrees opposite on the

coupling faces.

Its almost always a combination of both!

Prolific Systems & Technologies (Pvt) Ltd 15

TYPES OF MISALIGNMENT ( OFFSET)

Prolific Systems & Technologies (Pvt)

16

Ltd

ANGULAR MISALIGNMENT

Prolific Systems & Technologies (Pvt)

17

Ltd

MEASUREMENT CONVENTIONS

Offset or Parallel

Misalignment is

measured in thousandths

of an inch (0.000), also

called mils.

Angular Misalignment

is measured in

thousandths of an inch

(0.000), or mils, per inch

of coupling diameter.

Prolific Systems & Technologies (Pvt)

18

Ltd

PRE-ALIGNMENT STEPS

15 minutes or so of preparation time can save

you hours, and lots of money, in alignment costs

It can also save you a lot of unnecessary work

The following slides list some of the most

common errors made both before, and during,

shaft alignment

Prolific Systems & Technologies (Pvt)

19

Ltd

Error #1

ASSUMPTIONS AND THE LACK OF

OBSERVATION

Prolific Systems & Technologies (Pvt)

20

Ltd

Example

Prolific Systems & Technologies (Pvt)

21

Ltd

ASSUMPTIONS

NEVER ASSUME ITS LOCKED AND TAGGED!

Dont assume its aligned correctly, even if you did it the last

time.

Can the shafts be rotated together? Can they be rotated

individually? You may have to modify your alignment

technique.

Is there a soft foot issue? Check and minimize before

alignment.

Is there going to be thermal growth? How much? Which

direction? Is it going to get hotter, or colder?

Prolific Systems & Technologies (Pvt)

22

Ltd

ASSUMPTIONS

Is the coupling insert worn? Does it need

replacement?

Is there adequate spacing between the shafts?

Between couplings?

Has pipe strain been minimized?

Is the pump assembly sitting on isolators? Are they

functioning properly?

Is the pump assembly sitting on an inertia block? Is

it properly affixed to the floor?

Prolific Systems & Technologies (Pvt)

23

Ltd

ASSUMPTIONS

Do you notice any cracks in the floor around the

base? Can you feel vibration in the floor?

Does the coupling insert have excessive backlash?

Are the coupling flanges tight to the shaft?

Are set screws and bolts tight?

Are keys in place?

Prolific Systems & Technologies (Pvt)

24

Ltd

ASSUMPTIONS

Are the hubs concentric? You may be able to align an

eccentric hub, but may cause vibration, and make you look

bad, if you miss it.

Does the coupling guard clear the coupling?

How clean is the area?

Soft foot is not limited to just under the motor feet. It can

happen between a riser and frame, and between a frame and a

floor.

Are there jack bolts? Are they screwed tight to the motor?

Prolific Systems & Technologies (Pvt)

25

Ltd

Error #2

You do not know what your

alignment target, or tolerance, is

Prolific Systems & Technologies (Pvt)

26

Ltd

ALIGNMENT TARGETS

DONT GO BY THE COUPLING MANUFACTURERS

TOLERANCE!

The coupling manufacturers tolerance is based upon

the amount of misalignment the coupling will tolerate,

NOT what the bearings and seals will tolerate!

Think of it like a rubber band.

Prolific Systems & Technologies (Pvt)

27

Ltd

ALIGNMENT TOLERANCES

Alignment tolerances are

based on many things,

including:

Coupling type

Running speed

Company guidelines

Most alignment tool

VibrAligns tolerance manufacturers also have

table tolerances. Consult your

Engineering department, or

your alignment tool

representative, for more

information.

Prolific Systems & Technologies (Pvt)

28

Ltd

THERMAL GROWTH TARGETS

Machines that operate at a considerably hotter or

colder condition than the ambient room temperature

should be thermally compensated. They will grow

or shrink as they heat up, or cool off

Prolific Systems & Technologies (Pvt)

29

Ltd

THE MACHINE MANUFACTURERS

SPECS ARE A GOOD PLACE TO START

But, the machine manufacturer probably does not know:

The exact temperature of the driver and driven

machines

Ventilation quality or cooling effects

Piping strain influences

Piping thermal changes

COEFFICIENT OF THERMAL EXPANSION

If you cant

remember this chart,

remember this:

1 foot of steel get

100 degrees hotter, it

grows about 8 mils

( 0.008)

Prolific Systems & Technologies (Pvt)

31

Ltd

HOWEVER, THIS IS NOT A MAGIC FORMULA!

Machines do not usually heat or cool at the exact same

temperature top to bottom.

You need to find a mean, or average temperature of the

machine from the centerline of the shaft, to the bottom

of the foot.

Prolific Systems & Technologies (Pvt)

32

Ltd

THE BEST WAY TO KNOW THERMAL GROWTH

CHANGES

is to measure them yourself.

Measure the machine in the cold condition, and pre-

set it to the manufacturers recommendations.

Re-measure in the hot condition, if possible.

Some lasers can do this calculation for you, or you

can simply plot it on paper.

In addition, some laser alignment tool manufacturers

sell equipment that allow you to measure the

thermal changes.

Prolific Systems & Technologies (Pvt)

33

Ltd

Error #3

NOT CORRECTING FOR SOFT FOOT

Soft foot

Soft foot occurs when Soft foot is caused by deformed

machine feet do not rest machine base plates or by deformed

flatly on the machine base machine feet

Soft foot can be offset, angular, or both

Prolific Systems & Technologies (Pvt)

34

Ltd

ERROR #4

NOT KNOWING WHEN TO SAY WHEN

When the machine is aligned to within your alignment

tolerance, you are done

Dont try to get it all the way to zero

You may cause more problems than you correct

AND, you will certainly waste time

Prolific Systems & Technologies (Pvt)

35

Ltd

ERROR #5

NOT ROUGHING IN

Straightedge, flashlight, feeler gauges, taper gauge,

outside caliper, etc

Prolific Systems & Technologies (Pvt)

36

Ltd

A QUICK COMMENT ON SHIMS

Try to use a maximum of 4 or less shims under each foot. Its

not always possible, but try to minimize the number of shims

per foot

Use pre-cut stainless steel shims

You cant cut them for less than you can buy them

When you insert shims under the foot, slide them all the way in,

then back them out , so the bolt threads dont bend them

Dont reuse painted, or badly bent shims

Be careful. A 0.003 shim can cut you like a knife. Trust me on

this one!

Keep them neat

Prolific Systems & Technologies (Pvt)

37

Ltd

ERROR #6

NOT CONTROLLING BACKLASH OR

UNWANTED MOVEMENT

Some alignment systems are sensitive to backlash

or play in the coupling. Not only lasers, but

indicators can be misread due to backlash,

especially if there is any eccentricity in the coupling

Beware of bumping your indicators or laser detectors

Beware of any binding or tightness in the machines

as they are rotated

Prolific Systems & Technologies (Pvt)

38

Ltd

ERROR #7

INCORRECT SEQUENCE OF MOVES

Always correct vertical misalignment first.

Once the vertical (top to bottom, up and down)

is corrected, you can theoretically move the

machine side to side as far as it will go,

without changing the vertical alignment.

Then, correct misalignment in the horizontal

plane (side to side).

Prolific Systems & Technologies (Pvt)

39

Ltd

NOW WERE READY TO ALIGN!

Prolific Systems & Technologies (Pvt)

40

Ltd

YOU GOT TO MAKE THE RIGHT

MOVES!

Prolific Systems & Technologies (Pvt)

41

Ltd

Regardless of the method you use,

alignment needs to be done in four steps

Prolific Systems & Technologies (Pvt)

42

Ltd

ANGULAR MISALIGNMENT IN THE VERTICAL PLANE

Side View

Prolific Systems & Technologies (Pvt)

43

Ltd

PARALLEL OFFSET IN THE VERTICAL PLANE

Side View

Prolific Systems & Technologies (Pvt)

44

Ltd

ANGULAR MISALIGNMENT IN THE HORIZONTAL PLANE

Top View

Prolific Systems & Technologies (Pvt)

45

Ltd

PARALLEL OFFSET IN THE HORIZONTAL PLANE

Top View

Prolific Systems & Technologies (Pvt)

46

Ltd

THATS THE WAY ITS SUPPOSED TO

HAPPEN!

Prolific Systems & Technologies (Pvt)

47

Ltd

SO WHAT DO WE DO IF IT DOESNT?

Check for soft foot.

Check for bolt or base bound condition.

Check to make sure you havent bumped or moved

your alignment tools

Check for coupling backlash.

Check for excessive vibration in the area

Re-measure, and see if your results are repeatable.

Prolific Systems & Technologies (Pvt)

48

Ltd

TRICKS OF THE TRADE

A straightedge, an outside caliper, a Starrett taper gauge,

and a flashlight are good roughing-in tools.

A can of compressed air, like those used for cleaning

electronics, is good to clean dirt out from under motor feet.

A 0-1 micrometer is great for measuring the thickness of

shim stacks.

When aligning, excessive backlash can be compensated

with a few rounds of duct tape.

Two dial indicator magnetic bases make great stops to rest

the laser tool or indicator brackets at the 3 and 9 oclock

positions. It gives you an extra set of hands.

Prolific Systems & Technologies (Pvt)

49

Ltd

ALIGNMENT IN BELT DRIVE SYSTEM

Proper Alignment can increase belt drive

performance.

Misalignment is one of the most common causes

of premature belt failure.

Depending on its severity, misalignment can

gradually reduce belt performance by increasing

wear and fatigue Or It can destroy a belt in a

matter of hours or days.

Prolific Systems & Technologies (Pvt)

50

Ltd

TYPES OF ALIGNMENT

Basically, any degree of misalignment, angular or parallel, will

decrease the normal service life of a belt drive

Angular misalignment results in

accelerated belt/sheave wear and

potential belt stability problems

with individual V-belts.

Uneven belt and cord loading,

results in unequal load sharing

within multiple belt drives, and can

lead to premature failure

Gates Corporation Power

Transmission Product Application

engineers caution that angular

misalignment has a severe effect

on the performance of

synchronous belt drives

Prolific Systems & Technologies (Pvt)

51

Ltd

PARALLEL MISALIGNMENT

Parallel misalignment also

results in accelerated

belt/sheave wear and potential

belt stability problems with

individual V-belts. Uneven belt

and cord loading is not as

significant a concern as in

angular misalignment

However, parallel misalignment

is typically more of a concern

with V belts than with

synchronous belts This is

because V-belts run in fixed

grooves and cannot free float

between flanges, as

synchronous belts can, to a

limited degree

Prolific Systems & Technologies (Pvt)

52

Ltd

MEASURE MISALIGNMENT

Prolific Systems & Technologies (Pvt)

53

Ltd

MEASURE OF MISALIGNMENT

When preparing to measure parallel misalignment, the

maintenance technician must first verify that the

edges of both sheaves and sprockets are of equal

thickness, or quantify the difference in thickness

It is important to align the sheave grooves or

sprocket faces directly in line with one another, rather

than just the outside surfaces of the sheaves or

sprockets (flanges)

It may be necessary to mount sheaves or sprockets

with the outside surfaces offset with respect to one

another in order to properly align the grooves or

sprocket faces

Prolific Systems & Technologies (Pvt)

54

Ltd

MEASURE OF MISALIGNMENT

Sprocket flanges should also be inspected to be sure

that they run true. A bent flange could result in

erroneous measurements if the laser tool or

straightedge rests against the outside edge of the

damaged flange during the inspection process

To determine how much misalignment is acceptable

and at what point it becomes excessive, the

alignment must first be measured, quantified, and

then compared to the belt manufacturer's

recommendations for the particular type of belt

These recommendations can be found in drive

design manuals

Prolific Systems & Technologies (Pvt)

55

Ltd

MEASURING MISALIGNMENT

Misalignment can either be quantified mathematically,

or be compared to some general rules of thumb for

quicker and easier results

While using a straight edge to project the plane of the

outside face of sheave or sprocket #1 with respect to

sheave or sprocket #2, angular misalignment can be

quantified as the difference in clearance between the

straightedge and the outside surface of the sheave or

sprocket #2 across the diameter

Prolific Systems & Technologies (Pvt)

56

Ltd

MEASURING THE MISALIGNMENT

(ANGULAR MISALIGNMENT)

Prolific Systems & Technologies (Pvt)

57

Ltd

MEASURE OF MISALIGNMENT

(PARALLEL MISALIGNMENT)

Prolific Systems & Technologies (Pvt)

58

Ltd

MEASUREMENT OF MISALIGNMENT

The angle of parallel misalignment can be

quantified as the difference in clearance

between the straightedge and the outer

surfaces of the two sheaves or sprockets

across the separation distance

Prolific Systems & Technologies (Pvt)

59

Ltd

ALLOWABLE MISALIGNMENT

The total allowable misalignment

recommended for V-belts, in general, is

1/2-degree

While individual V-belts are known to be

capable of handling greater amounts of

misalignment before becoming unstable

Maintaining the misalignment to within 1/2-

degree will maximize belt life

Prolific Systems & Technologies (Pvt)

60

Ltd

ALLOWABLE MISALIGNMENT

The total amount of misalignment

recommended for synchronous, urethane 60-

degree belts (Polyflex), and poly-V belts

(Micro-V) is 1/4-degree

These drives are less tolerant of

misalignment than conventional V-belt drives,

and must be aligned more accurately

Prolific Systems & Technologies (Pvt)

61

Ltd

MEASUREMENT OF BELT

MISALIGNMENT

When determining if a V-type drive system is

aligned within these recommendations, the

angular and parallel misalignment must both be

measured and quantified individually and then

Added together

The total sum of angular and parallel

misalignment can then be compared to the belt

manufacturer's recommendations for the particular

type of drive.

Prolific Systems & Technologies (Pvt)

62

Ltd

RULE OF THUMB

Maintenance technicians may not always find it

practical or possible to accurately calculate the total

misalignment in a system while determining if it is in

acceptable alignment

It is also difficult to visualize small fractions of an

angle such as 1/2 and 1/4 degrees

These can be more clearly illustrated with the following

rules of thumb:

For V-belt drives:

1/2-degree angle = approximately 1/10-inch per foot of

distance travelled

For synchronous, 60-degree angle, and V-ribbed

drives:

1/4-degree angle = approximately 1/16-inch per foot of

distance travelled

Prolific Systems & Technologies (Pvt)

63

Ltd

IMPORTANT TIPS

Misalignment can be an obstacle for satisfactory

synchronous and V-belt drive performance

In many cases, it is not easily detectable in complex

drive applications. Maintenance technicians should

also check related components, such as brackets and

platforms, for proper design and placement.

These parts must be strong enough to withstand the

peak forces exerted by the belt drive without bending

or flexing

Prolific Systems & Technologies (Pvt)

64

Ltd

THANK YOU

Prolific Systems & Technologies (Pvt)

65

Ltd

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Caja Mazda 6 Fnr5Document54 pagesCaja Mazda 6 Fnr5Allison VR100% (6)

- Theatrical Rigging System Design GuideDocument32 pagesTheatrical Rigging System Design GuideVõ Quang KiệtNo ratings yet

- Pre-Alignment: How 15 Minutes Can Save You: Prolific Systems & Technologies PVT LTDDocument89 pagesPre-Alignment: How 15 Minutes Can Save You: Prolific Systems & Technologies PVT LTDTushar RanjanSahu100% (1)

- Introduction To Machinery Alignment: Advanced Consulting For TechnologiesDocument63 pagesIntroduction To Machinery Alignment: Advanced Consulting For TechnologiesDamir Vucicic100% (1)

- A Practical Guide To Shaft AlignmentDocument63 pagesA Practical Guide To Shaft AlignmentJustin CoyNo ratings yet

- Ludeca-A Practical Guide To Shaft Alignment PDFDocument0 pagesLudeca-A Practical Guide To Shaft Alignment PDFDelfinsh100% (1)

- RP Alignment Rev0 26.03.2007Document40 pagesRP Alignment Rev0 26.03.2007Dhanish KumarNo ratings yet

- Machine Installation - Shaft AlignmentDocument17 pagesMachine Installation - Shaft AlignmentD.b. Tampubolon100% (1)

- Misalignment: Advanced Consulting For TechnologiesDocument59 pagesMisalignment: Advanced Consulting For TechnologiesMohamed MusaNo ratings yet

- Why Alignment 8 Page Brochure Ali 9.100!02!10 GDocument8 pagesWhy Alignment 8 Page Brochure Ali 9.100!02!10 GAlejandro Jimenez FuentesNo ratings yet

- 6 Steps To Shaft Alignment PDFDocument18 pages6 Steps To Shaft Alignment PDFAhmed SaifeldinNo ratings yet

- Alignment Basics, Part Two: Ask ExpertsDocument2 pagesAlignment Basics, Part Two: Ask ExpertsFabian GarciaNo ratings yet

- 12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd 1670395912933Document8 pages12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd 1670395912933YhaneNo ratings yet

- Shaft Alignment Is A Profitable Form of Preventative MaintenanceDocument1 pageShaft Alignment Is A Profitable Form of Preventative MaintenancebelenyeriruelNo ratings yet

- Onsite Balancing and Analysis: ShaftsDocument3 pagesOnsite Balancing and Analysis: ShaftsAmmarNo ratings yet

- Alignment TolerancesDocument7 pagesAlignment TolerancesFarhan MalekNo ratings yet

- 12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd - 1670396292436Document8 pages12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd - 1670396292436YhaneNo ratings yet

- 11443FR TKSA ShaftAlignmentTools UnlockedDocument8 pages11443FR TKSA ShaftAlignmentTools UnlockedRobertoVianaCardosoNo ratings yet

- Alignment For Engineers - OGSDocument128 pagesAlignment For Engineers - OGSAhmed Abdelwahab100% (3)

- Alignment Pitfalls - How To Identify and Eliminate Them: "Can I Successfully Align The Machine?"Document6 pagesAlignment Pitfalls - How To Identify and Eliminate Them: "Can I Successfully Align The Machine?"Erika Ramos QuezadaNo ratings yet

- Conveyor Gearbox Failure Analysis #Document6 pagesConveyor Gearbox Failure Analysis #Satyam MadameNo ratings yet

- Aligment Methods-Act 20161120Document95 pagesAligment Methods-Act 20161120Mohamed MusaNo ratings yet

- Benefits Shaft AlignmentDocument4 pagesBenefits Shaft AlignmentCarolina PBNo ratings yet

- Afc Shaft Allignment Training PDFDocument142 pagesAfc Shaft Allignment Training PDFAbdelhameed YehiaNo ratings yet

- Importance Motor Shaft Motor Systemts4 PDFDocument2 pagesImportance Motor Shaft Motor Systemts4 PDFFrandika PrimayogaNo ratings yet

- How To Align Machines - OASIS Alignment ServicesDocument2 pagesHow To Align Machines - OASIS Alignment ServicesSivananthaa MurtheeNo ratings yet

- AlignmentDocument6 pagesAlignmentShams TabrezNo ratings yet

- Laser Shaft Alignment: Report No:1Document36 pagesLaser Shaft Alignment: Report No:1Mahmoud Morsy AboualiNo ratings yet

- SKF Shaft Alignment ProcedureDocument25 pagesSKF Shaft Alignment Procedurevijay kumarNo ratings yet

- Ludeca - A Practical Guide To Pulley Alignment PDFDocument13 pagesLudeca - A Practical Guide To Pulley Alignment PDFAlberto BalvinNo ratings yet

- Seminar ReportDocument22 pagesSeminar Reportअंकुर कांचनNo ratings yet

- Theatrical Rigging System Design Guide: Revised 2012Document31 pagesTheatrical Rigging System Design Guide: Revised 2012ajsniffNo ratings yet

- Backlashvs LostMotion PDFDocument4 pagesBacklashvs LostMotion PDFjeyaselvanmNo ratings yet

- Gregg Schwartz 507-438-6703: ISO 18436-2 & ASNT Vibration Condition Monitoring CertificationsDocument7 pagesGregg Schwartz 507-438-6703: ISO 18436-2 & ASNT Vibration Condition Monitoring CertificationsGerardo RosalesNo ratings yet

- Bearing Failure AnalysisDocument26 pagesBearing Failure AnalysisengrsurifNo ratings yet

- Rotor Dynamic Modelling As A Powerful Support Tool For Vibration Analysis On Large Turbomachinery - Murilo CamisãoDocument7 pagesRotor Dynamic Modelling As A Powerful Support Tool For Vibration Analysis On Large Turbomachinery - Murilo Camisãojoao batista alvesNo ratings yet

- Assembly - July 2017Document76 pagesAssembly - July 2017Varun KumarNo ratings yet

- Effect of Coupling Types On Rotor VibrationDocument14 pagesEffect of Coupling Types On Rotor VibrationMarwa BouslemaNo ratings yet

- Alignment Basics - Part OneDocument2 pagesAlignment Basics - Part Oneamigoeres7337No ratings yet

- Mainline Operations Ebook - Rigging Lab AcademyDocument33 pagesMainline Operations Ebook - Rigging Lab AcademyAlan Morais100% (1)

- Levelling and ALIGNINGDocument7 pagesLevelling and ALIGNINGThe Gamers ZoneNo ratings yet

- Alignment GuideDocument180 pagesAlignment GuideKSMNo ratings yet

- Single Idler Belt Scale: Instruction Manual PL-319 January 2001Document21 pagesSingle Idler Belt Scale: Instruction Manual PL-319 January 2001Julisa LombardoNo ratings yet

- Alignment Systems Products and Services Overview DOC 01.400 05-09-13 enDocument12 pagesAlignment Systems Products and Services Overview DOC 01.400 05-09-13 enSikasep TeaNo ratings yet

- Five Basic Errors in Shaft AlignmentDocument9 pagesFive Basic Errors in Shaft AlignmentTomy lee youngNo ratings yet

- CouplingDocument3 pagesCouplingjlellisNo ratings yet

- Shaft Alignment On PumpsDocument1 pageShaft Alignment On PumpsTuanbk NguyenNo ratings yet

- Management Guide To AlignmentDocument3 pagesManagement Guide To Alignmentjonalthan1987No ratings yet

- Dynamic Movement White Paper: Vibralign, Inc. 530G Southlake BLVD Richmond, Va 232326 804.379.2250Document0 pagesDynamic Movement White Paper: Vibralign, Inc. 530G Southlake BLVD Richmond, Va 232326 804.379.2250SreenivasNo ratings yet

- 5-Coll and Coll ExchangeDocument24 pages5-Coll and Coll ExchangeRogerio CastroNo ratings yet

- 2008 09 LORD BalancingDocument20 pages2008 09 LORD BalancingMiguelOliveira1No ratings yet

- Shop Balancing of Turbomachinery Rotors by John N: Mechanical Equipment TechnologistDocument4 pagesShop Balancing of Turbomachinery Rotors by John N: Mechanical Equipment Technologistjuancgr77No ratings yet

- Diferencial Meritor - Com Porquinho - Sem Bomba PDFDocument126 pagesDiferencial Meritor - Com Porquinho - Sem Bomba PDFClovis SantosNo ratings yet

- Robot Mechanisms and Mechanical Devices IllustratedFrom EverandRobot Mechanisms and Mechanical Devices IllustratedRating: 4 out of 5 stars4/5 (1)

- Performance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisFrom EverandPerformance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisNo ratings yet

- Err System Config FailedDocument2 pagesErr System Config Failedvijay kumarNo ratings yet

- Perf fw02 Apollo PerfDocument3 pagesPerf fw02 Apollo Perfvijay kumarNo ratings yet

- ERR SYSTEM CONFIG FAILED v1Document2 pagesERR SYSTEM CONFIG FAILED v1vijay kumarNo ratings yet

- ESXI Qualification Test PlanDocument2 pagesESXI Qualification Test Planvijay kumarNo ratings yet

- New Batches Info: Core Java ContentDocument3 pagesNew Batches Info: Core Java Contentvijay kumarNo ratings yet

- Upgrade Component Report 10.1.21.26Document1 pageUpgrade Component Report 10.1.21.26vijay kumarNo ratings yet

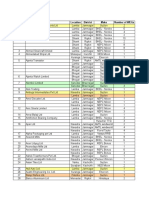

- Rapid TablesDocument27 pagesRapid Tablesvijay kumarNo ratings yet

- SVT Deployment ManagerDocument252 pagesSVT Deployment Managervijay kumarNo ratings yet

- VMware Vsphere 6Document1 pageVMware Vsphere 6vijay kumarNo ratings yet

- New Batches Info: Blueprism ContentDocument4 pagesNew Batches Info: Blueprism Contentvijay kumarNo ratings yet

- Company Certificate RammiDocument1 pageCompany Certificate Rammivijay kumarNo ratings yet

- B UCSM GUI Storage Management Guide 3 1 Chapter 010101Document16 pagesB UCSM GUI Storage Management Guide 3 1 Chapter 010101vijay kumarNo ratings yet

- Babji Cuurriculumvtiae - 2 (1) BajiDocument2 pagesBabji Cuurriculumvtiae - 2 (1) Bajivijay kumarNo ratings yet

- Company Certificate RammiDocument1 pageCompany Certificate Rammivijay kumarNo ratings yet

- Renaissance Calculating Tools: John NapierDocument2 pagesRenaissance Calculating Tools: John Napiervijay kumarNo ratings yet

- Ambico Engg. PVT LTDDocument2 pagesAmbico Engg. PVT LTDvijay kumarNo ratings yet

- Leadership: Peyton InvestmentsDocument2 pagesLeadership: Peyton Investmentsvijay kumarNo ratings yet

- The Ramco Cements LimitedDocument35 pagesThe Ramco Cements Limitedvijay kumar50% (2)

- First Computing Device: Babbage's Difference EngineDocument3 pagesFirst Computing Device: Babbage's Difference Enginevijay kumarNo ratings yet

- Etymology: Dictionary States That The Use of The Term To Mean "Calculating Machine" (Of Any Type) Is From 1897."Document1 pageEtymology: Dictionary States That The Use of The Term To Mean "Calculating Machine" (Of Any Type) Is From 1897."vijay kumarNo ratings yet

- Yugi Resume 1Document4 pagesYugi Resume 1vijay kumarNo ratings yet

- GrgreerhDocument1 pageGrgreerhvijay kumarNo ratings yet

- Transistors: Bipolar Junction TransistorDocument3 pagesTransistors: Bipolar Junction Transistorvijay kumarNo ratings yet

- Non Drawal CertificateDocument1 pageNon Drawal Certificatevijay kumar100% (3)

- RC - No:1958/RMSA/2017 DT: 05.2017Document1 pageRC - No:1958/RMSA/2017 DT: 05.2017vijay kumarNo ratings yet

- Suanpan: The Chinese (算盘) (the number represented on this abacus is 6,302,715,408)Document2 pagesSuanpan: The Chinese (算盘) (the number represented on this abacus is 6,302,715,408)vijay kumarNo ratings yet

- Value LabsDocument19 pagesValue Labsvijay kumarNo ratings yet

- Vilas V. Sardeshpande: HR ProfessionalDocument4 pagesVilas V. Sardeshpande: HR Professionalvijay kumarNo ratings yet

- Head Master: Rupees Fifty Five Thousand Five Hundred and Eighty Three OnlyDocument10 pagesHead Master: Rupees Fifty Five Thousand Five Hundred and Eighty Three Onlyvijay kumarNo ratings yet

- Tubing and Fittings Quick Reference (Metric and Inch) - WebDocument9 pagesTubing and Fittings Quick Reference (Metric and Inch) - WebRajkumar MudaliarNo ratings yet

- Service BUlletin 300036KDocument4 pagesService BUlletin 300036KMuhammad ShadabNo ratings yet

- Project ProposalDocument4 pagesProject Proposalapi-318375436No ratings yet

- Akun Sikelim Kabupaten BanyuasinDocument6 pagesAkun Sikelim Kabupaten BanyuasinSri AgustinaNo ratings yet

- Welcome: Rashtriya Ispat Nigam LimitedDocument44 pagesWelcome: Rashtriya Ispat Nigam Limitedbhujakhia_748657110No ratings yet

- ACCX-KITCHENHOODS SPMDocument36 pagesACCX-KITCHENHOODS SPMDavina FristantryNo ratings yet

- Integrating Cyber Threat Intelligence Using Classic Intel Techniques Elias Fox and Michael NorkusDocument22 pagesIntegrating Cyber Threat Intelligence Using Classic Intel Techniques Elias Fox and Michael NorkusDanny Espiritu ZarateNo ratings yet

- 22) Window Sections PDFDocument33 pages22) Window Sections PDFUvvj Raju100% (1)

- BCP Technical & Operating DataDocument24 pagesBCP Technical & Operating DataKrishnan SanthanarajNo ratings yet

- Employee Welfare Facilities Project ReportDocument119 pagesEmployee Welfare Facilities Project ReportBabasab Patil (Karrisatte)100% (2)

- 3.1 Day 3 - TESS VHF Training - Standard Radio Procedures and CallsignsDocument30 pages3.1 Day 3 - TESS VHF Training - Standard Radio Procedures and CallsignsOgunjimi Taofiki AdebisiNo ratings yet

- Ac 7 PDFDocument146 pagesAc 7 PDFMohammed Al-hewaimel100% (1)

- SP 07271130Document166 pagesSP 07271130kam_chan_syd7562No ratings yet

- 033 BOD IncubatorDocument4 pages033 BOD Incubatorbhavna sharmaNo ratings yet

- Sine Wavefor FormulaDocument158 pagesSine Wavefor FormulanmguravNo ratings yet

- PTT (Eran15.1 Draft A)Document108 pagesPTT (Eran15.1 Draft A)Denmark WilsonNo ratings yet

- BSBPMG516 - Assessment Task 1 UltimateDocument8 pagesBSBPMG516 - Assessment Task 1 Ultimatepancho070690No ratings yet

- West Auctions-Catalog PDFDocument4 pagesWest Auctions-Catalog PDFbelchior alvaroNo ratings yet

- Data Sheet, Gad, Sizing Calculation, Terminal Arrangement, Support Details of Bus Duct For New IntakeDocument2 pagesData Sheet, Gad, Sizing Calculation, Terminal Arrangement, Support Details of Bus Duct For New IntakeBasabRajNo ratings yet

- X2ED94JWNJUGOK0C13ALQG6BWSQNESDocument44 pagesX2ED94JWNJUGOK0C13ALQG6BWSQNESPrashantsutharNo ratings yet

- Curriculum Vitae PDFDocument1 pageCurriculum Vitae PDFhafid anggitoNo ratings yet

- 8259 Programmable Interrupt..Document3 pages8259 Programmable Interrupt..DiegoGuzmanNo ratings yet

- Disquietude Jan10Document3 pagesDisquietude Jan10chenamberNo ratings yet

- Coal Flotation-Technical ReviewDocument3 pagesCoal Flotation-Technical Reviewrajeevup2004No ratings yet

- Service Manual Ricoh Aficio 470wDocument231 pagesService Manual Ricoh Aficio 470wsangNo ratings yet

- BT - Temp13583 - Big-19 - 21 (Birac)Document12 pagesBT - Temp13583 - Big-19 - 21 (Birac)shaliniNo ratings yet

- Mobile Phone ArtDocument21 pagesMobile Phone ArtMhyrell Tolentino AgustinNo ratings yet

- Floyd The Science of Electronics: Digital 1e Multiple ChoiceDocument7 pagesFloyd The Science of Electronics: Digital 1e Multiple ChoiceVince CentenoNo ratings yet

- Nissens' Water-Cooled Charge Air CoolerDocument8 pagesNissens' Water-Cooled Charge Air CoolerMoisés SolisNo ratings yet