Professional Documents

Culture Documents

University of Washington: Dawg Sled

University of Washington: Dawg Sled

Uploaded by

alfin vandeniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

University of Washington: Dawg Sled

University of Washington: Dawg Sled

Uploaded by

alfin vandeniCopyright:

Available Formats

Dawg Sled

University of Washington

What powers our car? What stops our car?

Elon Musk once said that the problem with existing batteries is Iodine Clock

that they suck. If the CEO of Tesla Motors and SpaceX felt Hydrogen peroxide variation of the iodine clock reaction to

obligated to complain about batteries and found no dissent from stop our car.

his complaint, then it is obvious that batteries are the technology After a certain time the color of the solution will change to a

to improve. Currently, the best battery technology is geared dark blue.

towards lithium-ion batteries. A major problem with building In order to vary the time we have changed the hydrogen

lithium-ion batteries is the expense. The equipment and peroxide concentration.

materials needed to build lithium-ion batteries, including the The color change blocks light from an LED to a photoresistor,

need for additional safety features, is way over the budget of our the voltage change triggers a relay to disconnect the battery

basement laboratory. In the end, we decided upon building a from the motors.

custom 3-D printed dry cell battery as the energy source of our

car. This dry cell battery is commonly known as the zinc-carbon

battery, but more accurately described as a zinc-manganese Materials for our iodine clock

battery. Mixture A

Starch, Sodium thiosulfate, Potassium iodide, Water

Battery Uniqueness Mixture B

Although the zinc-carbon battery chemistry is a throwback to the Sulfuric Acid, Hydrogen peroxide, Water

first commercially sold battery, we had implemented ways to

innovate this classic battery further. The carbon anode used for Figure 2: Initial design of car with 3-D printed body.

this battery is recycled carbon fiber scraps from a materials Reaction for the iodine clock

science research lab on UW campus. For the battery cell First Reaction

compartments we employed a customized flat cell design and 3- H2O2 + 3I + 2H+ I3- + 2H2O

D printed the casings in the most efficient manner. After the Generates triiodine ions

battery cell sandwich is assembled, each cell are connected in Second Reaction

series and then attached to the electric motor, powering our car. 2S2O32 + I3- S4O6 + 3I-

This reaction is faster than reaction one and is the rate

determining step.

Materials to make our zinc-carbon battery Third Reaction

Anode (negative terminal) I3- + starch Starch-I5- complex + I

Zinc plate After all the thiosulfate ions have been consumed by reaction 2,

Cathode (positive terminal) the triiodide ions react with the starch to form the starch-

Manganese dioxide, ammonium chloride, zinc chloride, pentaiodide complex. This product is what gives the solution the

graphite powder dark blue color.

Carbon fiber as the carbon anode

Flat cell compartments (3-D printed)

PLA (polylactic acid) filament Environmental, Health, and Safety

Emission free vehicle!

Waste is easily disposed of properly to UW EH&S.

Zinc-carbon battery total chemical reaction Battery stack is contained within a 3D printed, sealed plastic

Zn(s) + 2MnO2(s) + 2NH4Cl(aq) Mn2O3(s) + Zn(NH3)2Cl2 (aq) casing.

+ H2O(l) Figure 3: The car body group working on assembling the car. High pressures, gaseous emissions, and ignition sources are

avoided using the battery system.

All members wore lab safety goggles and nitrile gloves while

working in the lab.

Members underwent UW EH&S trainings for managing

laboratory chemicals, fire extinguisher operation and the

Globally Harmonized Systems.

Acknowledgements

The Chem-E-Car Club would like to give thanks to UW Department

of Chemical Engineering for providing us the funds and space to

pursue our project. We would especially like to thank department

chair Franois Baneyx and our club advisor Professor Stuart Adler.

Figure 4: All members of the ChemE Car club, including our advisor

Stuart Adler.

Figure 1: Measuring electric potential of our prototype batteries.

You might also like

- DeNora - Amit SoralDocument29 pagesDeNora - Amit SoralshrutikesavanNo ratings yet

- Spear LithiumionchemistriesDocument18 pagesSpear LithiumionchemistrieskcpatnaikNo ratings yet

- Building Chemistry Lab Chapter 10 PDFDocument5 pagesBuilding Chemistry Lab Chapter 10 PDFJesha LibreaNo ratings yet

- Poe Ans4th PT3Document3 pagesPoe Ans4th PT3AmierainNo ratings yet

- (An Autonomous Institution Under VTU, Belgaum) : "Batteries-Nickel Based, Sodium Based, Lithium Based Batteries"Document16 pages(An Autonomous Institution Under VTU, Belgaum) : "Batteries-Nickel Based, Sodium Based, Lithium Based Batteries"Manoj ManuNo ratings yet

- Rechargeablebatteriesreport Dev 160926110353Document24 pagesRechargeablebatteriesreport Dev 160926110353Sudhanshu sekhar PadhiNo ratings yet

- Batteries and Fuel Cells PDFDocument23 pagesBatteries and Fuel Cells PDFHidden NameNo ratings yet

- Battery Overview: Dr. P.J.BansodDocument43 pagesBattery Overview: Dr. P.J.BansodmayurNo ratings yet

- 00960a PDFDocument20 pages00960a PDFrosaNo ratings yet

- Ch-7 Electricity and Chemistry (Electrolysis)Document13 pagesCh-7 Electricity and Chemistry (Electrolysis)daveymilan36No ratings yet

- LAB103 Experiment of Lithium Ion BatteryDocument6 pagesLAB103 Experiment of Lithium Ion BatteryZhuoya ZhangNo ratings yet

- Electrochemical Power Sources: BatteriesDocument31 pagesElectrochemical Power Sources: BatteriessudhaNo ratings yet

- Dr. Nalini G Sundaram Materials Science DivisionDocument63 pagesDr. Nalini G Sundaram Materials Science Divisionlinni123No ratings yet

- MT30001 Materials Engineering (30001)Document38 pagesMT30001 Materials Engineering (30001)Rajesh MundaryNo ratings yet

- Cathodic Protection Applications of Sacrificial AnodeDocument7 pagesCathodic Protection Applications of Sacrificial AnodeSurya PrakashNo ratings yet

- BATTERIES1Document16 pagesBATTERIES1anieshNo ratings yet

- Flow Batteries For Grid-Scale Energy Storage: Joep PijpersDocument16 pagesFlow Batteries For Grid-Scale Energy Storage: Joep Pijpers周学龙No ratings yet

- Battery TechnologyDocument60 pagesBattery TechnologyKasinathan MuniandiNo ratings yet

- AMCO Saft India LTD: WelcomesDocument56 pagesAMCO Saft India LTD: WelcomesM Abu SayedNo ratings yet

- Commercial Galvanic Cells: BatteriesDocument9 pagesCommercial Galvanic Cells: BatteriesKamalpreet SinghNo ratings yet

- Fuel CellDocument20 pagesFuel Cellram kishor singh100% (1)

- Hoja de Seguridad PilasDocument13 pagesHoja de Seguridad PilasOlimpio Moya EstelaNo ratings yet

- Battery Power Webinar V0Document27 pagesBattery Power Webinar V0Dipti GahlotNo ratings yet

- Lab Report 4 (ALCANTARA - BSEE-1D)Document3 pagesLab Report 4 (ALCANTARA - BSEE-1D)Lawrence Abram AlcantaraNo ratings yet

- Lab Report 4 (Alcantara - Bsee-1d)Document3 pagesLab Report 4 (Alcantara - Bsee-1d)Lawrence Abram AlcantaraNo ratings yet

- Course1B LeggDocument31 pagesCourse1B LeggLe LanNo ratings yet

- Module 4Document41 pagesModule 4Anshu MalikNo ratings yet

- New Materials For and Challenges in Lithium Ion Battery ResearchDocument66 pagesNew Materials For and Challenges in Lithium Ion Battery ResearchPankaj MauryaNo ratings yet

- Why Lithium Ion Batteries FailDocument28 pagesWhy Lithium Ion Batteries Failanand.tvsmNo ratings yet

- Battery Characteristics and Lechlanche CellDocument19 pagesBattery Characteristics and Lechlanche Celldhandapani dhanalakshmiNo ratings yet

- Comparison of Batteries Used in Electrical Vehicles: (A Review)Document5 pagesComparison of Batteries Used in Electrical Vehicles: (A Review)pierre abreu mackleine100% (1)

- Sodium Ionbattery 16 02 2023Document22 pagesSodium Ionbattery 16 02 2023venugopalan srinivasanNo ratings yet

- Module 4Document49 pagesModule 4Ankit YadavNo ratings yet

- NETZSCH Article How To Uniformly Disperse Nanoparticles 05 2010Document3 pagesNETZSCH Article How To Uniformly Disperse Nanoparticles 05 2010Khamis KhamisNo ratings yet

- 2017 PosterDocument1 page2017 PostertilamisuNo ratings yet

- Alexander Cross & Catherine Moran: Energy Dense Metal Air Batteries: Tomorrow'S Power Source?Document1 pageAlexander Cross & Catherine Moran: Energy Dense Metal Air Batteries: Tomorrow'S Power Source?Vikas MishraNo ratings yet

- EE8451, EE6303 Linear Integrated Circuits and Applications LICA - 2 Marks With Answers 2Document47 pagesEE8451, EE6303 Linear Integrated Circuits and Applications LICA - 2 Marks With Answers 2manoj kumarNo ratings yet

- LIE600 Lecture 2Document46 pagesLIE600 Lecture 2balajibalasubramanian91No ratings yet

- Ev Batteries BasicDocument66 pagesEv Batteries BasicmahammadsalmanmechNo ratings yet

- Quantum Dot Based Photonic Devices: Muhammad UsmanDocument34 pagesQuantum Dot Based Photonic Devices: Muhammad UsmanNoctis CallumNo ratings yet

- Batteries Fuel Cell ElectrolysisDocument15 pagesBatteries Fuel Cell Electrolysisaljon lindayaoNo ratings yet

- Batteries and Corrosion-IDocument39 pagesBatteries and Corrosion-IRavi KumarNo ratings yet

- Ch10 Solid StateDocument30 pagesCh10 Solid StateKrish VeniNo ratings yet

- Alkaline Battery-2016Document4 pagesAlkaline Battery-2016ZerotheoryNo ratings yet

- Alkaline Application ManualDocument14 pagesAlkaline Application ManualFred BohnNo ratings yet

- Air BatteriesDocument32 pagesAir Batteriescharlie scienceNo ratings yet

- Supercapacitors 6th Lecture 1 PDFDocument16 pagesSupercapacitors 6th Lecture 1 PDFSiddarthNo ratings yet

- Principleofna Ionbaterries 160420154603Document25 pagesPrincipleofna Ionbaterries 160420154603venugopalan srinivasanNo ratings yet

- Introduction To Electrodeionization: Jeff Tate Agape Water Solutions, IncDocument26 pagesIntroduction To Electrodeionization: Jeff Tate Agape Water Solutions, Incsagor sagorNo ratings yet

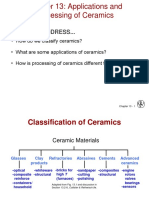

- Chapter 13 - Applications and Processing of CeramicsDocument26 pagesChapter 13 - Applications and Processing of CeramicsAngelino PimentelNo ratings yet

- Karkuzhali 2020Document8 pagesKarkuzhali 2020G P ROHTIHNo ratings yet

- Nature and Properties of MaterialsDocument22 pagesNature and Properties of MaterialsAvi AlokNo ratings yet

- Carbon ZincDocument5 pagesCarbon ZincJessa Mae LabasanNo ratings yet

- Chem 131 Lesson 8Document5 pagesChem 131 Lesson 8Denampo Ivan MikhaelNo ratings yet

- CP 3Document93 pagesCP 3MAHMOUD MOHAMEDNo ratings yet

- Presentation Types Batteries PPT 1516085460 20707Document37 pagesPresentation Types Batteries PPT 1516085460 20707Shivam Kumar Yadav Sky100% (2)

- Batteries 162Document28 pagesBatteries 162Galaxy LeeNo ratings yet

- Acsaem 1c01029Document8 pagesAcsaem 1c01029Rishabh KumarNo ratings yet

- IST - Ni BatteriesDocument13 pagesIST - Ni Batteries19-801 Bhargav SreeramuluNo ratings yet

- Ceramic and GlassDocument27 pagesCeramic and Glasskautsar muafaNo ratings yet

- On Solar Hydrogen and NanotechnologyFrom EverandOn Solar Hydrogen and NanotechnologyLionel VayssieresNo ratings yet

- MATERI 2 Water Treatment Plant and LaboratoriumDocument15 pagesMATERI 2 Water Treatment Plant and LaboratoriumNur Ali SaidNo ratings yet

- Valsartan FrmulationsDocument1 pageValsartan Frmulationsiloveit52252No ratings yet

- Digunakan Dalam Baterai Untuk Kalkulator, Jam, Kamera, Alat Pacu Jantung, Bahancampuran Logam, Sintesis Senyawa Organik Dan Aplikasi NuklirDocument8 pagesDigunakan Dalam Baterai Untuk Kalkulator, Jam, Kamera, Alat Pacu Jantung, Bahancampuran Logam, Sintesis Senyawa Organik Dan Aplikasi NuklirAzariNo ratings yet

- Practice Book of Chemistry For Jee MainDocument15 pagesPractice Book of Chemistry For Jee MainLuis AndersonNo ratings yet

- Copper Alloys in Ingot Form: Standard Specification ForDocument12 pagesCopper Alloys in Ingot Form: Standard Specification ForFierro Huerta Guillermo IsraelNo ratings yet

- Chiu Shun International Co.,Ltd (Henry - Taiwan)Document3 pagesChiu Shun International Co.,Ltd (Henry - Taiwan)Thêu PhạmNo ratings yet

- P Block Elements NotesDocument12 pagesP Block Elements NotesBanu MNo ratings yet

- 03 - Ingredient Analysis Table 2012 EditionDocument4 pages03 - Ingredient Analysis Table 2012 EditionnorwayerNo ratings yet

- A Hydrometallurgical Process For The Separation and Recovery of AntimonyDocument7 pagesA Hydrometallurgical Process For The Separation and Recovery of AntimonyPauloValdiviesoNo ratings yet

- Concept of Atomic Number Led To The Synthesis of New Elements in The LaboratoryDocument36 pagesConcept of Atomic Number Led To The Synthesis of New Elements in The LaboratoryMizuki YamizakiNo ratings yet

- Conti-Trapetsiruuvit: Solutions For Power TransmissionDocument72 pagesConti-Trapetsiruuvit: Solutions For Power TransmissionJoe TrumpNo ratings yet

- ProposalDocument9 pagesProposalZubair AshrafNo ratings yet

- 2018 Nutritional Monitoring BookDocument118 pages2018 Nutritional Monitoring BookrubenNo ratings yet

- ID Potensi Sebaran Limbah Merkuri PertambanDocument11 pagesID Potensi Sebaran Limbah Merkuri PertambanHaryadi StNo ratings yet

- Periodic Classification of Elements MCQsDocument4 pagesPeriodic Classification of Elements MCQsSomeone 123No ratings yet

- Acids, Alkalis and Titrations 2 QPDocument12 pagesAcids, Alkalis and Titrations 2 QPD SNo ratings yet

- Is Matter Around Us PureDocument16 pagesIs Matter Around Us PureGiridhar RagavasimhanNo ratings yet

- Gravity of MaterialsDocument1 pageGravity of Materialsck19654840No ratings yet

- MSDS - Stainless Steel PTFE TapeDocument3 pagesMSDS - Stainless Steel PTFE TapeUtilities2No ratings yet

- A Comparison of Geometric Isomerism in Transition Metal ComplexesDocument5 pagesA Comparison of Geometric Isomerism in Transition Metal ComplexesDaniel RodmanNo ratings yet

- Astm hk40 Chemical Composition Astm hk40 Mechanica 2 PDFDocument2 pagesAstm hk40 Chemical Composition Astm hk40 Mechanica 2 PDFprashant mishraNo ratings yet

- Fire Clay Composition & PropertiesDocument4 pagesFire Clay Composition & PropertiestaghdirimNo ratings yet

- Applications of Coordination Complexes in IndustryDocument4 pagesApplications of Coordination Complexes in IndustryAnonymous bPaX80xp4100% (3)

- Chem21 02 PBL Is PDFDocument5 pagesChem21 02 PBL Is PDFjay jayNo ratings yet

- Atomic Structure - Subatomic Particles WSDocument1 pageAtomic Structure - Subatomic Particles WSDenise AcunaNo ratings yet

- Concrete Testing With Chloride & Sulphates Tests - Sussex Rope AccessDocument3 pagesConcrete Testing With Chloride & Sulphates Tests - Sussex Rope AccessPritha DasNo ratings yet

- 10 Science NcertSolutions Chapter 5 ExercisesDocument4 pages10 Science NcertSolutions Chapter 5 ExercisesContacts nilNo ratings yet

- Lime PDFDocument30 pagesLime PDFManish Rawat100% (1)

- Claim and Ref of BenfotiamineDocument4 pagesClaim and Ref of BenfotiamineKanji PatelNo ratings yet