Professional Documents

Culture Documents

MNS-SG - Technical Presentation 2013

MNS-SG - Technical Presentation 2013

Uploaded by

Jorge Luis Mallqui BarbaranCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MNS-SG - Technical Presentation 2013

MNS-SG - Technical Presentation 2013

Uploaded by

Jorge Luis Mallqui BarbaranCopyright:

Available Formats

29th 30th October 2013, Rodrigo Morales

MNS Systems Workshop 2013

MNS-SG Technical Description

MNS-SG

Arc Flash

Industry Standards/Markets

Arc Resistant Features

Equipment Ratings

Mechanical Overview

Electrical Overview

Arc Flash Mitigation

Arc Mitigation

BU 3101 Low Voltage Systems

9/6/17 | Slide 2

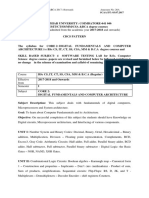

Industry Standards

MNS-SG Switchgear is designed, tested, and constructed to meet/exceed these standards:

UL 1558 Metal-Enclosed Low Voltage Power Circuit Breaker Switchgear

ANSI C37.20.1 IEEE Standard for Metal-Enclosed Low Voltage Power Circuit Breaker

Switchgear

ANSI C37.20.7 ---- IEEE Guide for Testing Metal-Enclosed Switchgear Rated Up to 38kv

for Internal Arcing Faults

ANSI C37.50 Test Procedure for Low Voltage AC Power Circuit Breakers Used in

Enclosures

ANSI C37.51 Conformance Testing of Metal-Enclosed Low Voltage AC Power Circuit

Breaker Switchgear Assemblies

Seismic Qualification to IBC-2009 and ASCE7-10

Emax Circuit Breaker is designed, tested, and constructed to meet/exceed these standards:

ANSI C37.13 Low Voltage AC Power Circuit Breakers Used in Enclosures

ANSI C37.16 Preferred Ratings, Related Requirements, and Application for Low Voltage Power

Circuit Breakers and AC Power Circuit Protectors

ANSI C37.17 Trip Devices for AC and General Purpose DC Low-Voltage Power Circuit Breakers

UL1066 Low Voltage AC and DC Power Circuit Breakers Used in Enclosures

BU 3101 Low Voltage Systems

9/6/17 | Slide 3

Market Segments

The MNS-SG is designed to meet the most

stringent industry requirements in the

following markets:

Oil and Gas

Mining and Metals

Utilities

Utility and co-generation

Steel Mill

Pharmaceutical

Waste Water Oil and gas

Semiconductor Manufacturing

Power Generation

Food and Beverage

Aerospace

Critical Power and Data Centers

Industrial facilities

Pulp and Paper

BU 3101 Low Voltage Systems

9/6/17 | Slide 4

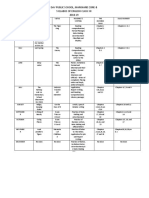

Equipment Ratings

Rated continuous current 1600, 2000, 3200, 4000A, 5000A

Rated tested maximum voltage (Arc Resistant) 254Vac, 508Vac

Rated voltage (Arc Resistant) 240Vac, 480Vac

Rated tested maximum voltage (Non Arc Resistant) 254Vac, 508Vac, 635Vac

Rated voltage (Non Arc Resistant) 240Vac, 480Vac, 600Vac

Phases 3 phase 3 wire, 3 phase 4 wire

Neutral (when required on 4Wire Systems) 100% rated

Frequency 60 Hz

Short circuit current withstand at 480Vac up to 100ka

Short circuit current withstand at 600Vac Non Arc up to 85kA

Resistant

Bus Bracing up to 100ka @ 480v, up to 85ka @ 600V

Enclosure Rating (Arc Resistant) NEMA 1

Enclosure Rating (Non Arc Resistant) NEMA 1 (with and without Gasketing)

Seismic Ratings IBC2009, ASCE7-10

BU 3101 Low Voltage Systems

9/6/17 | Slide 5

Mechanical Overview

Roof Flaps

Rear Ventilation Flaps

BU 3101 Low Voltage Systems

9/6/17 | Slide 6

Mechanical Overview-Dimensions

Width- 23.6 (600mm), 27.6 (700mm,

31.5 (800mm), 39.4 (1000mm)

Depth- 70.87 (1800mm)

Height-

Arc-Resistant (top of chimney)

96.1 (2439.7mm)

Arc-Resistant w/overhead lifting

device 99.4 (2524mm)

Arc-Resistant (top of plenum)

122.1 (3100.5mm)

BU 3101 Low Voltage Systems

9/6/17 | Slide 7

Mechanical Overview- Frame

Heavy duty Galvanized C Channel Steel Profile used for all framing

structure

Exterior sheet metal is 12 or 14 Gauge Galvanized Painted Steel

Interior parts are 11 to 14 Gauge Galvanized Steel or Glastic

BU 3101 Low Voltage Systems

9/6/17 | Slide 8

Mechanical Overview- Roof Chimney

Roof chimney flaps automatically open to safely exhaust pressure

and gasses independent of the arc origination point inside the

switchgear

BU 3101 Low Voltage Systems

9/6/17 | Slide 9

Mechanical Overview- Rear Flaps

Design uses Rear Flaps for:

Additional ventilation for Thermal Cooling

Automatically seals gases and pressure inside the equipment during Arc Fault

Operator Safety by channeling the gasses away from outside enclosure

Additional protection of operation and surrounding equipment during Arc Fault

Flaps can be opened/closed from the outside of the equipment

BU 3101 Low Voltage Systems

9/6/17 | Slide 10

Mechanical Overview- Door Mechanisms

Enhanced (3) point latches are provided on front

Optional Rear Door

doors as standard

Mechanism

Top/Bottom horizontal wireways have 180 degree

locking latching mechanism

Optional rear doors have (3) point latching

mechanism

Front Door Mechanism

BU 3101 Low Voltage Systems

9/6/17 | Slide 11

Mechanical Overview- Floor Plate

Floor plate is 14 Gauge Galvanized Steel construction

Floor plate with Control Conduit cover Floor plate with Power Conduit cover

BU 3101 Low Voltage Systems

9/6/17 | Slide 12

Mechanical Overview- Bus Compartment

Bus phasing is N A B C top to bottom

Main distribution bus ampacity is up to 5000A with bus bracing up to 100kA

Vertical distribution bus ampacity is up to 5000A with bus bracing up to 100kA

Non-insulated bus is silver plated with optional tin-plating available

Main bus Splice Plate that slides into final assembly position

BU 3101 Low Voltage Systems

9/6/17 | Slide 13

Mechanical Overview-Cable Compartment

Mechanical and Compression Lugs

Available

BU 3101 Low Voltage Systems

9/6/17 | Slide 14

Mechanical Overview- Barriers

Galvanized Steel and Glastic Barriers

separating Main Bus compartment

from cable compartment

Vertical Galvanized Steel Barriers

separating cable compartment

sections

BU 3101 Low Voltage Systems

9/6/17 | Slide 15

Mechanical Overview- Grounding

Ground bus bar is available with silver,

tin, bare plating

Door Ground Strap

BU 3101 Low Voltage Systems

9/6/17 | Slide 16

Mechanical Overview- Plenum

The optional plenum collects and contains the

exhaust pressure and gasses for safe

channeling to a designated area

The direction of the outlet flap can be

specified by the customer

BU 3101 Low Voltage Systems

9/6/17 | Slide 17

Electrical Overview- Wiring

As a standard, all control wiring is #14 AWG SIS

Control wire for current transformers is #10 AWG SIS

Potential transformers are #12 AWG

BU 3101 Low Voltage Systems

9/6/17 | Slide 18

Electrical Overview- Wireway

Wireway are location at the top, bottom

and vertically within a section

The top wireway is 4 (100mm) high

The bottom wireway is 6 (150mm) high

Wireway doors are hinged and secured

with quarter-turn latches

Pic of vertical wireway

BU 3101 Low Voltage Systems

9/6/17 | Slide 19

Electrical Overview- Emax Power Circuit Breaker

1. Trademark, size of CB

2. Trip unit

3. PB for manual opening

4. PB for manual closing

5. Lever to manually charge

closing spring

6. Label with electrical

characteristics

7. Mechanical device to signal

CB open O and Closed I

8. Signal for springs charged

or discharged

9. Mechanical indication of trip

10. Key lock in open position

11. Key lock and padlock in

racking-in, racking-out position

12. Racking-in, racking-out device

13. Terminal box

14. Sliding contacts

15. CB position indicator

BU 3101 Low Voltage Systems

9/6/17 | Slide 20

Electrical Overview- Emax Cradle

1 Sheet steel supporting structure

2 Single Grounding pilers mounted on the

left for E1, E2, and E3 double grounding

pilers for E4 and E6

3 Automatic Safety shutters

4 Terminal support base

5 Terminals

6 Contacts signaling that the circuit breaker

is connected, isolated for test, racked-out

7 Sliding contacts

8 Padlock device for safety shutters

9 Fixing points (4 for E1, E2, E3, and 6 for

E4, E6)

BU 3101 Low Voltage Systems

9/6/17 | Slide 21

Electrical Overview- Emax Trip Units

PR121

Protection Features Only

PR122

Protection Features

LCD Display

Current Measurement

Contact Wear

Communications option

PR123

PR122 Features

Harmonic Measurements

Communications option

BU 3101 Low Voltage Systems

9/6/17 | Slide 22

Electrical Overview- Instrumentation

Indicating Lights

Volt, amp, and watt meters

Control switches

Multifunction Metering

Solid-state Relays

Surge Protectors

Test Switches

BU 3101 Low Voltage Systems

9/6/17 | Slide 23

Electrical Overview- Transfer Scheme

Main-Tie-Main transfer

scheme (open transition)

Relay controlled

Kirk Key Interlock

BU 3101 Low Voltage Systems

9/6/17 | Slide 24

Electrical Overview- Communications

Modbus (Standard)

Profibus

DeviceNet

Ethernet

BU 3101 Low Voltage Systems

9/6/17 | Slide 25

Arc Mitigation

Maintenance Switch

Provides option to dial

down to a lower

instantaneous setting on

trip unit for performing

instantaneous

REA Relay Arc Flash System

Detects an arc anywhere in

the bus compartment and

cable compartment utilizing

long-fiber sensor system,

tripping upstream main

breaker in order to provide

minimal damage to

equipment

BU 3101 Low Voltage Systems

9/6/17 | Slide 26

Arc Mitigation

Infrared Windows

IR cameras are used for thermal

scanning of connections

Minimizes the exposure to live

conductors

Quantity and location of the IR

windows are dependent breaker

stacking arrangement

BU 3101 Low Voltage Systems

9/6/17 | Slide 27

Local solutions

Low Voltage Switchgear must common Integrations

GE Multilin Relays (C60s , SR750, SR 760 , PQM II, Multilin F35..)

High Resistance Grounding systems (post glover, Startcoetc..)

MNS-MCC and MNS-SG Bus Transition Sections

Customized coupling bus sections

Customized Bus duct incoming

Customized Transfer Schemes

Many more

BU 3101 Low Voltage Systems

9/6/17 | Slide 28

BU 3101 Low Voltage Systems

9/6/17 | Slide 29

You might also like

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- Manual Lava Louça CCR200 - MDIK80-00 LIVRETO PDFDocument132 pagesManual Lava Louça CCR200 - MDIK80-00 LIVRETO PDFJulyanorigoniNo ratings yet

- Maxsb PresentationDocument41 pagesMaxsb PresentationjaneshkumarNo ratings yet

- 2TDC490003 MNS-SG NON AR Guideform Specification Rev. ADocument15 pages2TDC490003 MNS-SG NON AR Guideform Specification Rev. ALokesh BabuNo ratings yet

- ABB IEC LV SwitchgearDocument48 pagesABB IEC LV Switchgearomh129100% (1)

- Low Voltage Metal Enclosed Drawout Arc Resistant Switchgear: MNS-SG Guideform SpecificationDocument16 pagesLow Voltage Metal Enclosed Drawout Arc Resistant Switchgear: MNS-SG Guideform SpecificationCharles RobiansyahNo ratings yet

- Square D Power-Zone III SwitchgearDocument40 pagesSquare D Power-Zone III SwitchgeardameddyNo ratings yet

- GIS Arrester PDFDocument0 pagesGIS Arrester PDFMrC03No ratings yet

- Brochure ANSIDocument40 pagesBrochure ANSIDaniel PalaciosNo ratings yet

- SCO1603PMB: Make Before Break Changeover Switch External Handle 160A 3P Catalogue NoDocument2 pagesSCO1603PMB: Make Before Break Changeover Switch External Handle 160A 3P Catalogue Norahim sNo ratings yet

- Amted399086en (Web)Document180 pagesAmted399086en (Web)aleksandaralNo ratings yet

- Low Voltage Metal Enclosed Drawout Arc Resistant Switchgear: MNS-SG Guideform SpecificationDocument16 pagesLow Voltage Metal Enclosed Drawout Arc Resistant Switchgear: MNS-SG Guideform SpecificationSanj PandeyNo ratings yet

- Cable Accessories: Systems, IncDocument4 pagesCable Accessories: Systems, IncLuis MurilloNo ratings yet

- CIGRE-Over Head Line Fault LocatorDocument13 pagesCIGRE-Over Head Line Fault LocatorcontenteeeNo ratings yet

- LineTrapsAir Core, Dry TypeDocument8 pagesLineTrapsAir Core, Dry TypeSINU0607IITEEENo ratings yet

- Okken Solution GuideDocument26 pagesOkken Solution GuideShailesh ChettyNo ratings yet

- Major ProjectDocument30 pagesMajor ProjectRakesh YadavNo ratings yet

- BTB - Technical Catalogue AC ContactorDocument30 pagesBTB - Technical Catalogue AC ContactorGiau Ngoc HoangNo ratings yet

- LV Catalog ENGDocument11 pagesLV Catalog ENGAbd KHEMIRINo ratings yet

- HTLS (HPC) IEEMA Seminar BrianWareingDocument69 pagesHTLS (HPC) IEEMA Seminar BrianWareingJose ValdiviesoNo ratings yet

- 15KW On Grid Roof Top HP STATIONDocument7 pages15KW On Grid Roof Top HP STATIONAjayNo ratings yet

- SBS-N Red Ed2Document4 pagesSBS-N Red Ed2Bhageerathi SahuNo ratings yet

- Mcs Miniature Contactors Selection Guide: The Miniature Modular Control System Small in Dimensions - Big in PerformanceDocument36 pagesMcs Miniature Contactors Selection Guide: The Miniature Modular Control System Small in Dimensions - Big in PerformanceRichard WiltsieNo ratings yet

- Bus Duct Trunking SystemDocument15 pagesBus Duct Trunking SystemmahmoudNo ratings yet

- Low Voltage Switchgear: Maxsg SpecificationsDocument18 pagesLow Voltage Switchgear: Maxsg SpecificationssuvarnapreyasNo ratings yet

- CA326GB1103Document6 pagesCA326GB1103karunamcsNo ratings yet

- 130405-BuJ Vakuum Generatorschalter EN PDFDocument12 pages130405-BuJ Vakuum Generatorschalter EN PDFStephen BridgesNo ratings yet

- An Overview of Gas Insulated SubstationDocument30 pagesAn Overview of Gas Insulated SubstationHaripriya PalemNo ratings yet

- Apresentação Unisec AbbDocument76 pagesApresentação Unisec AbbAnd Web100% (1)

- Katko Switches Technical Information AllDocument10 pagesKatko Switches Technical Information AllSanishka NiroshanNo ratings yet

- ACTOM MV GMA - SingleDocument4 pagesACTOM MV GMA - SingleDevon Antony HeuerNo ratings yet

- Cortacircuito NCX 7 y 15 KVDocument2 pagesCortacircuito NCX 7 y 15 KVMilton MhNo ratings yet

- 6000 BR 1205Document40 pages6000 BR 1205Carlos BenavidesNo ratings yet

- CBR Technical Description in Eng 01-2010Document16 pagesCBR Technical Description in Eng 01-2010james_vaughnanNo ratings yet

- Siemens: Presentation ON Substation DesignDocument43 pagesSiemens: Presentation ON Substation DesignSatyaNo ratings yet

- Ring Main Unit - 8DJH STDocument8 pagesRing Main Unit - 8DJH STaayushNo ratings yet

- 242pmi90 2GNM110092Document12 pages242pmi90 2GNM110092Pao PawNo ratings yet

- Technical Specifications of Transformers: Applicable Codes and Standards For TransformersDocument5 pagesTechnical Specifications of Transformers: Applicable Codes and Standards For TransformersNnaabyendu SahaNo ratings yet

- Do You Remember Electromechanical RelaysDocument78 pagesDo You Remember Electromechanical RelaysRajesh BoddunaNo ratings yet

- 1VGA671005 - UniGear ZVC LeafletDocument2 pages1VGA671005 - UniGear ZVC LeafletHoumanNo ratings yet

- PBC 6200Document53 pagesPBC 6200YousufaLi Moiz HussainNo ratings yet

- DatasheetDocument3 pagesDatasheetTanyaradzwa MoyoNo ratings yet

- Surge Arresters GuideDocument116 pagesSurge Arresters GuideSudharsan SD100% (1)

- National Electrical Manufacturers Association (NEMA) Collection ListDocument14 pagesNational Electrical Manufacturers Association (NEMA) Collection Listglee326100% (1)

- B3 - 206 - 2006-Substation Design Using Phase To Phase InsulationDocument9 pagesB3 - 206 - 2006-Substation Design Using Phase To Phase Insulationarmien edwardsNo ratings yet

- GTP Pix 12 Cico PDFDocument11 pagesGTP Pix 12 Cico PDFNishantha AriyadasaNo ratings yet

- CA Powercube PBF (En) B 1vcp000253 1201aDocument20 pagesCA Powercube PBF (En) B 1vcp000253 1201aPrashanth ChandrashekarNo ratings yet

- SENTRON Residual Current Protective Devices AFDDs Complete English 10 2014 201502111453105536Document50 pagesSENTRON Residual Current Protective Devices AFDDs Complete English 10 2014 201502111453105536Alvaro Coy H.No ratings yet

- Sub-Stations: Departmental of Electrical EngineeringDocument41 pagesSub-Stations: Departmental of Electrical EngineeringJAYESHNo ratings yet

- 22 - Catalouge For 11kV GISDocument8 pages22 - Catalouge For 11kV GISIRCON RAPDRP Electrical ProjectsNo ratings yet

- Ln25pro PDFDocument8 pagesLn25pro PDFNapoleón Ortíz CárdenasNo ratings yet

- Nycta Project R-50529: Prepared ForDocument46 pagesNycta Project R-50529: Prepared ForGlenn NewmarkNo ratings yet

- MoellerDocument39 pagesMoellerMilagros Arteaga GonzalezNo ratings yet

- Abb GCB Chapter 9Document9 pagesAbb GCB Chapter 9RagsNo ratings yet

- Cat - Capacitors For UPS-2011-Epcos PDFDocument6 pagesCat - Capacitors For UPS-2011-Epcos PDFAirton José FloresNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Basic Programming Simatic S7-300Document41 pagesBasic Programming Simatic S7-300Jaziel Cabral100% (1)

- A New High-Speed Foreign Fiber Detection System With Machine VisionDocument23 pagesA New High-Speed Foreign Fiber Detection System With Machine VisionijtrobinNo ratings yet

- Power Swing BlockingDocument1 pagePower Swing BlockingAbdul RahmanNo ratings yet

- SciCan Statim 2000 S, G4 Autoclave - Service ManualDocument275 pagesSciCan Statim 2000 S, G4 Autoclave - Service ManualXat DeviceNo ratings yet

- Pennbuying, Dual Motor Driver L298 PDFDocument11 pagesPennbuying, Dual Motor Driver L298 PDFbaymax love spideyNo ratings yet

- Horizontal Deep Freezer Manufacturer Tanco Lab ProductsDocument2 pagesHorizontal Deep Freezer Manufacturer Tanco Lab ProductsTanco Lab ProductsNo ratings yet

- Class Exercise: Motor Protection: Prot405 - Exercise - Motorprotectionexercise - R4 1Document13 pagesClass Exercise: Motor Protection: Prot405 - Exercise - Motorprotectionexercise - R4 1polNo ratings yet

- D3W001CNKWDocument2 pagesD3W001CNKWRamon GonzalezNo ratings yet

- Rhotex - 320 IX28005 EDocument2 pagesRhotex - 320 IX28005 ESatish ShettyNo ratings yet

- Product List: Type Part Number Specification Power Supply RemarksDocument6 pagesProduct List: Type Part Number Specification Power Supply RemarkszorcarNo ratings yet

- FlowMon Catalogue 2 PDFDocument12 pagesFlowMon Catalogue 2 PDFsimbamikeNo ratings yet

- Toshiba Qosmio f40 f45Document278 pagesToshiba Qosmio f40 f45Francisco StankeviciusNo ratings yet

- Dav Public School, Jharkhand Zone-B Syllabus of English Class Xii 2018-19Document21 pagesDav Public School, Jharkhand Zone-B Syllabus of English Class Xii 2018-19Nishita SinhaNo ratings yet

- Computer 1718Document3 pagesComputer 1718Moorthy GaccsNo ratings yet

- Cvmk2: Three-Phase Power Analyzer, Assembly On Panel or Din RailDocument2 pagesCvmk2: Three-Phase Power Analyzer, Assembly On Panel or Din RailRodrigo PardoNo ratings yet

- Chapter Five: Memory InterfacingDocument15 pagesChapter Five: Memory Interfacingoumer beshirNo ratings yet

- Motorola HT820Document2 pagesMotorola HT820tennis5luvNo ratings yet

- Polymetron Silca Analyzer PDFDocument4 pagesPolymetron Silca Analyzer PDFJibin JacobNo ratings yet

- 3699 FU Tiller 105 105 NG20Document18 pages3699 FU Tiller 105 105 NG20Nabeel MohammedNo ratings yet

- MSE 310 - Part3 - (Student) - FilledDocument22 pagesMSE 310 - Part3 - (Student) - FilledaaaNo ratings yet

- CD Changer RetrofitDocument2 pagesCD Changer RetrofitsacaetanoNo ratings yet

- Cs2100 12 Basic DatapathDocument50 pagesCs2100 12 Basic DatapathamandaNo ratings yet

- Seminar ReportDocument26 pagesSeminar ReportPranita K50% (2)

- Fiche Technique 6w3Document1 pageFiche Technique 6w3sady keleNo ratings yet

- Samsung PDFDocument24 pagesSamsung PDFsandi123inNo ratings yet

- Your Home Deserves A Treat: HBL Installment Plan On 0% Mark-UpDocument10 pagesYour Home Deserves A Treat: HBL Installment Plan On 0% Mark-UpHamza ShaniNo ratings yet

- A Compact Hilbert Curve Fractal Antenna On Metamaterial Using CSRRDocument6 pagesA Compact Hilbert Curve Fractal Antenna On Metamaterial Using CSRRfahmiNo ratings yet

- Chapter 5Document13 pagesChapter 5chibssa alemayehuNo ratings yet

- WGC 090 - 1401 Specifications ENGDocument2 pagesWGC 090 - 1401 Specifications ENGEmerson BatistaNo ratings yet