Professional Documents

Culture Documents

Ventilatoren Zement en

Ventilatoren Zement en

Uploaded by

Fran JimenezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ventilatoren Zement en

Ventilatoren Zement en

Uploaded by

Fran JimenezCopyright:

Available Formats

Industrial fans

Winfried Koch 06.12.2012 1

Industrial fans

Preheater

Winfried Koch 06.12.2012 2

Industrial fans

S1 Preheater Area / Kiln Exhaust Gas Fan

Single- and double-inlet centrifugal fans for preheater systems in the cement

industry

with specially developed blade systems on which there are no or only slight dust

deposits

with throttle or speed regulation

installation (preferably) on raised foundation or vibration-isolated

heat-resistant and wear-protected (rare)

Winfried Koch 06.12.2012 3

Industrial fans

S1 Preheater Area / Kiln Exhaust Gas Fan

Single-inlet centrifugal fan for preheater systems in the cement industry

Winfried Koch 06.12.2012 4

Industrial fans

S1 Preheater Area / Kiln Exhaust Gas Fan

Double-inlet centrifugal fan for preheater systems in the cement industry

Winfried Koch 06.12.2012 5

Industrial fans

S1 Preheater Area / Kiln Exhaust Gas Fan

Single- and double-inlet centrifugals fan for preheater systems in the cement

industry

Performance Data

Flow volume: up to 1,000,000 m/h

Static pressure difference: c. 7,000 Pa (sometimes higher)

at operating temperature: 350 400 C

Mechanical design: up to 450 C 500 C

(momentarily up to 550 C)

Winfried Koch 06.12.2012 6

Industrial fans

S1 Preheater Area / Kiln Exhaust Gas Fan

Extract from the Reference List (from 2001)

Humboldt Wedag India Pvt. Ltd. Project JP Himachal Cement, India

Fan DHRV 40B-1600/K, V = 486,000 m/h, differential pressure 7,857 Pa,

temperature 260 C, 993 rpm, output 1,600 kW, impeller-D2 = 3,020 mm

Rohrdorfer Zement, Rohrdorf/Germany

Fan DHRV 45B-2000/K, V = 894,000 m/h, differential pressure 9,116 Pa,

temperature 425 C, 993 rpm, output 3,150 kW, impeller-D2 = 3,480 mm

F. L. Smidth A/S, Valby/DK, Project Shahrekord, Iran

Fan DHRV 45B-1800/K, V = 739,080 m/h, differential pressure 7,654 Pa,

temperature 283 C, 990 rpm, output 2,300 kW, impeller-D2 = 3,200 mm

PSP Engineering A. S., Prerov/CZ, Project Sepahan Cement, Iran

Fan DHRV 40B-1800/K, V = 832,830 m/h, differential pressure 8,777 Pa,

temperature 350 C, 990 rpm, output 2,800 kW, impeller-D2 = 3,640 mm

Polysius AG, Beckum/D, Project YAMAVER 5, Saudi Arabia

Fan DHRV 45B-1800/K, V = 882,000 m/h, differential pressure 8,517 Pa,

temperature 450 C, 990 rpm, output 3,080 kW, impeller-D2 = 3,220 mm

Winfried Koch 06.12.2012 7

Industrial fans

S1 Preheater Area / Kiln Exhaust Gas Fan

Venti Oelde Know-how

Design idling drive

Special bearing design

Blade geometry (to counteract caking)

Wear protection is rarely used

Material selection

Special flange connections between shaft and impeller

Venti Oelde fulfills the specifications of plant constructors/operators such as

Polysius

Winfried Koch 06.12.2012 8

Industrial fans

S1 Preheater Area / Kiln Exhaust Gas Fan

Production

Winfried Koch 06.12.2012 9

Industrial fans

S1 Preheater Area / Kiln Exhaust Gas Fan

Wear protection

Wear protection material S690QL, 5 mm thick

Winfried Koch 06.12.2012 10

Industrial fans

S1 Preheater Area / Kiln Exhaust Gas Fan

Wear protection

Winfried Koch 06.12.2012 11

Industrial fans

Kiln area

Winfried Koch 06.12.2012 12

Industrial fans

S2 Kiln area

Rotary kiln shell cooling

as axial flow fan

with special nozzle system

mobile (rails, rollers)

low noise (possible with silencer)

flow volume up to 30,000 m/h ball race cooling

per fan

up to 25 axial-flow fans are used

per kiln

as centrifugal fan (rare) mobile/pivotable

fixed installation / pivotable

Winfried Koch 06.12.2012 13

Industrial fans

S2 Kiln area

Rotary kiln shell cooling

movable on profiles / pivotable

Winfried Koch 06.12.2012 14

Industrial fans

S2 Kiln area / Kiln gas exhaust fan

Extract from reference list for rotary kiln shell cooling

Customer Project name Country Year

Polysius SONGIFA Vietnam 2003

Polysius TAHLOFA Vietnam 2003

Polysius YAMAVER Saudi Arabia 2005

Polysius EASTVER Saudi Arabia 2004

Lafarge Factory Wssingen Germany 2004

IHI QASSIM Saudi Arabia 2005

Winfried Koch 06.12.2012 15

Industrial fans

S2 Kiln area

Burner Fans

for primary air

for high pressure

up to 350 (400) mbar

flow volume up to 20,000 m/h

inlet temperature up to 40 C

single- and double-stage

supplied as complete unit

fan with start-up/regulating

damper

inlet silencer

silencing enclosure

Winfried Koch 06.12.2012 16

Industrial fans

S2 Kiln area

Burner fans (double-stage)

inlet flow measuring nozzle

1st stage 2nd stage

inlet

silencer

start-up/

regulating damper

actuator for

damper regulation vibration dampers

Winfried Koch 06.12.2012 17

Industrial fans

S2 Kiln area

Burner fans (single-stage)

Winfried Koch 06.12.2012 18

Industrial fans

S2 Kiln area

Extract from reference list for burner fans

F. L. Smidth, Valby/DK, Project Tonasa

Fan ZHRV 28-315/M, V = 10,742 m/h, total pressure 27,099 Pa,

temperature 30 C, 2,980 rpm, motor output 110 kW, impeller- 844 mm

Heracles Cement, Lykovrissi/GR, Project Halkis Evia

Fan HV-ZM 250-224, V = 7,300 m/h, total pressure 27,699 Pa,

temperature 20 C, 2,980 rpm, motor output 90 kW, impeller- 885 mm

F. L. Smidth, Valby/DK, Project Cessa Metapan

Fan ZHRV 31-280/M, V = 7,151 m/h, total pressure 26,572 Pa,

temperature 25 C, 3,560 rpm, motor output 84 kW, impeller- 701 mm

F. L. Smidth, Valby/DK, Project Khan

Fan ZHRV 31-315/M, V = 10,900 m/h, total pressure 26,697 Pa,

temperature 30 C, 2,980 rpm, motor output 132 kW, impeller- 839 mm

APO Cement, Naga/Cebu, Project Philippines

Fan ZHRV 45S-450/M, V = 19,800 m/h, total pressure 27,165 Pa,

temperature 20 C, 3,560 rpm, motor output 200/224 kW, impeller- 759 mm

Winfried Koch 06.12.2012 19

Industrial fans

Cooler

Winfried Koch 06.12.2012 20

Industrial fans

S3 Cooler area

Centrifugal fans for clinker cooler dust

collection system

single-and double-inlet centrifugal

fans

with suitable wear protection

speed control or throttle regulation

behind cyclone-separator

behind filter

flow volume up to 1,600,000 m/h

temperature up to 270 C

Impeller EP fan

(mechanical c. 350 C operation)

Winfried Koch 06.12.2012 21

Industrial fans

S3 Cooler area

Centrifugal fans for clinker cooler dust collection system

Fan behind ESP

Winfried Koch 06.12.2012 22

Industrial fans

S3 Cooler area

Extract from reference list for centrifugal fans for clinker cooler dust

collection system

China Building-Material Ind., Project Bestway/Pakistan

Fan DHRV 63 S-2000/K, V = 740,000 m/h, differential pressure 2,119 Pa,

temperature 250 C, 740 rpm, output 630 kW, impeller-D2 = 2,575 mm

F. L. Smidth Airtech A/S, Valby/DK, Project Benue Cement Co., Nigeria

Fan DHRV 63 S-1600/K, V = 385,200 m/h, differential pressure 1,586 Pa,

temperature 310 C, 740 rpm, output 250 kW, impeller-D2 = 2,140 mm

Kawasaki Heavy Industries/Japan, Project Turmenistan, Kelete

Fan HRV 63 S-2000/K, V = 342,000 m/h, differential pressure 4,052 Pa,

temperature 120 C, 745 rpm, output 457 kW, impeller-D2 = 2,700 mm

Gorazdze Cement, Opole/PL, Project Gorazdze

Fan DHRV 56 S-2000/K, V = 703,184 m/h, differential pressure 4,050 Pa,

temperature 245 C, 745 rpm, output 1,350 kW, impeller-D2 = 2,980 mm

Winfried Koch 06.12.2012 23

Industrial fans

S3 Cooler area

Venti Oelde Know-how

Wear protection solutions

Fan behind ESP Fan behind cyclone-separator

Winfried Koch 06.12.2012 24

Industrial fans

S3 Cooler area

Venti Oelde Know-how

Wear protection solutions

Wear protection on blade and Wear protection on blade inside

impeller centerplate Sodokay 900

Corodur 61

Winfried Koch 06.12.2012 25

Industrial fans

S3 Cooler area

Centrifugal fans as cooler fans for clinker cooler plants

with inlet flow measuring nozzle

with silencer

with inlet guide vane and speed control

motor output up to 355 kW

drive through coupling or v-belt drive (normally overhung impeller mounting)

up to 10 fans on each cooler side

Winfried Koch 06.12.2012 26

Industrial fans

S3 Cooler area

Centrifugal fans as cooler fans for clinker cooler plants

Winfried Koch 06.12.2012 27

Industrial fans

S3 Cooler area

Centrifugal fans as cooler fans for clinker cooler plants

Winfried Koch 06.12.2012 28

Industrial fans

S3 Cooler area

Extract from reference list centrifugal fans as cooler fans

Project Country

HIDMUE Bahrain

PALMAFA Mexico

GILANFA Iran

SABZEFA Iran

ARDFA Iran

IRSAB Iran

THALOFA Vietnam

PICO TRUNCADO Argentina

Winfried Koch 06.12.2012 29

Industrial fans

S3 Cooler area

Venti Oelde Know-how

low-noise installation

robust design

complete unit silencer with inlet flow measuring nozzle fan

Winfried Koch 06.12.2012 30

Industrial fans

Coal grinding plant

Winfried Koch 06.12.2012 31

Industrial fans

S4 Coal grinding plants

Special centrifugal fans for coal grinding

plants (rare in Europe)

with high-quality wear protection

designed to be pressure-shock-

resistant up to 3 bar pressure, 4 bar

absolute

with inlet guide vane and speed control

explosion-proof design (see example

1 and 2)

generally single-inlet machines

flow volume up to 300,000 m/h

static pressure difference up to

150 mbar

temperature c. 100 C

Winfried Koch 06.12.2012 32

Industrial fans

S4 Coal grinding plants

Venti Oelde Know-how

special wear protection

special pressure-shock-resistant design

Winfried Koch 06.12.2012 33

Industrial fans

S4 Coal grinding plants

High-performance centrifugal fans as

filter fans for coal grinding plants

with inlet guide vane and throttle

regulation or speed control

generally single-inlet machines

explosion-proof (ATEX) construction

Winfried Koch 06.12.2012 34

Industrial fans

S4 Coal grinding plants

Winfried Koch 06.12.2012 35

Industrial fans

S4 Coal grinding plants

Winfried Koch 06.12.2012 36

Industrial fans

S4 Coal grinding plants

Extract from reference list for centrifugal fans for coal grinding plants

Heidelberger Technology Center, Project Lehigh Portland Cement

Fan HRV 40-1400/K, V = 237,325 m/h, differential pressure 13,720 Pa,

temperature 89 C, 1,180 rpm, output 1,200 kW, impeller-D2 = 2.700 mm

Loesche GmbH, Dsseldorf/D, Project Saloniki Coal/GR

Fan HRV 45 S-1000/K, V = 116,000 m/h, differential pressure 10,470 Pa,

temperature 93 C, 1,480 rpm, output 450 kW, impeller-D2 = 1,900 mm

Fans in Coal Grinding Plants at:

Beocim, Serbia

Salonit Anhovo, Slovenia

Hope Cement, Great Britain

Winfried Koch 06.12.2012 37

Industrial fans

Cement grinding plant

Winfried Koch 06.12.2012 38

Industrial fans

S5 Cement grinding plant

Separator fans

special design

single- and double-inlet

throttle damper and speed control

regulation

special wear protection

flow volume up to 320,000 m/h

dust load up to 60 g/Sm

Winfried Koch 06.12.2012 39

Industrial fans

S5 Cement grinding plant

More than 300 separator circulating air fans have been supplied by Venti Oelde!

Extract from reference list of separator fans

Heidelberger Technology Center, Project Lehigh Portland Cement

Fan HRV 56 N-1800/K, V = 314,608 m/h, differential pressure 8,930 Pa,

temperature 0 C, 890 rpm, output 1,100 kW, impeller-D2 = 2,670 mm

F. L. Smidth Airtech A/S, Valby/DK, Project Shahroud, Iran

Fan HRV 50-1400/K, V = 173,160 m/h, differential pressure 4,540 Pa,

temperature 93 C, 990 rpm, output 327 kW, impeller-D2 = 2,280 mm

F. L. Smidth Airtech A/S, Valby/DK, Project Shahroud, Iran

Fan HRV 56 S-1600/K, V = 207,360 m/h, differential pressure 4,477 Pa,

temperature 105 C, 990 rpm, output 350 kW, impeller-D2 = 2,350 mm

F. L. Smidth Airtech A/S, Valby/DK, Project Fars Firouzkuh, Iran

Fan HRV 50-1400/K, V = 177,120 m/h, differential pressure 4,440 Pa,

temperature 94 C, 990 rpm, output 315 kW, impeller-D2 = 2,310 mm

Winfried Koch 06.12.2012 40

Industrial fans

S5 Cement grinding plant

Venti Oelde know-how

special wear protection

regulating devices with wear protection

useful life guarantee for wear protection for familiar processes

Winfried Koch 06.12.2012 41

Industrial fans

S5 Cement grinding plant

High-efficiency centrifugal fans as ESP fans

throttle damper and speed control

regulation

single- and double-inlet fans

Winfried Koch 06.12.2012 42

Industrial fans

Raw meal drying plant

Winfried Koch 06.12.2012 43

Industrial fans

S6 Raw meal drying plants

Centrifugal fans, single- and double-

inlet, for raw meal drying plants

(downstream of cyclone-separators)

designed for high dust loads

wear-protected

Centrifugal fans for ball mills and

roller mills

generally throttle regulating (also

speed control)

flow volume up to 1,000,000 m/h

static pressure difference c. 100 mbar

at 95 C

Winfried Koch 06.12.2012 44

Industrial fans

S6 Raw meal drying plants

Extract from reference list

Heidelberger Technology Center, Project Lehigh Portland Cement/USA

Fan DHRV 56 S-2500/K, V = 1,279,074 m/h, differential pressure 14,082 Pa,

temperature 83,5 C, 890 rpm, output 6,500 kW, impeller-D2 = 3,700 mm

Polysius AG, Beckum/D, Project Songifa/Vietnam

Fan DHRV 50-1800/K, V = 700,000 m/h, differential pressure 9,680 Pa,

temperature 90 C, 990 rpm, output 2,500 kW, impeller-D2 = 2,890 mm

Rohrdorfer Zement, Rohrdorf/D

Fan DHRV 45 S-1600/K, V = 485,000 m/h, differential pressure 9,651 Pa,

temperature 90 C, 993 rpm, output 2,000 kW, impeller-D2 = 2,810 mm

China Building Material Ind., Project Bestway/Pakistan

Fan DHRV 50-2000/K, V = 900,000 m/h, differential pressure 12,592 Pa,

temperature 90 C, 990 rpm, output 4,500 kW, impeller-D2 = 3,280 mm

Gebr. Pfeiffer, Kaiserslautern/D, Project Kerman Momtazan/Iran

Fan DHRV 50-2000/K, V = 880,000 m/h, differential pressure 9,990 Pa,

temperature 90 C, 980 rpm, output 3,500 kW, impeller-D2 = 3,260 mm

Winfried Koch 06.12.2012 45

Industrial fans

S6 Raw meal drying plants

Venti Oelde know-how

wear protection

high peripheral speed with high

mechanical load

Winfried Koch 06.12.2012 46

Industrial fans

S6 Raw meal drying plants

Centrifugal fans behind filter raw meal discharge air

Winfried Koch 06.12.2012 47

Industrial fans

S7 Other applications

high-pressure fans for pneumatic

material handling plants and silo

ventilating systems including

accessories such as filter

high-efficiency centrifugal fans for

dust collection plants

bypass fans, etc.

Winfried Koch 06.12.2012 48

Industrial fans

S8 Service

performance upgrading on existing fans

solving wear problems

cleaning during operation

teleservice (monitoring during operation)

Winfried Koch 06.12.2012 49

You might also like

- MERTEC Refactory Castables & Anchors - Binder 2011Document100 pagesMERTEC Refactory Castables & Anchors - Binder 2011jagrutNo ratings yet

- 2015 ICC Concrete Manual WorkbookDocument204 pages2015 ICC Concrete Manual Workbookdavid espinalNo ratings yet

- 010 Rotary ValveDocument1 page010 Rotary ValveBülent BulutNo ratings yet

- 22 ATC ARA DebottleneckingDocument15 pages22 ATC ARA DebottleneckingmkpqNo ratings yet

- Running Insp Sheet NewDocument20 pagesRunning Insp Sheet NewSafrin SangiaNo ratings yet

- 503 SNCR NOx and SNCRDocument11 pages503 SNCR NOx and SNCRvũ minh tâmNo ratings yet

- Helical Gearbox InstallationDocument8 pagesHelical Gearbox InstallationKUNALJAYNo ratings yet

- PR RFR P10-25 v1-0 How To Ensure Safety Under Refractory RoofsDocument7 pagesPR RFR P10-25 v1-0 How To Ensure Safety Under Refractory RoofsJuan Nacimba NacimbaNo ratings yet

- 03 MPT Introduction - Basics of VRM Process - R1Document20 pages03 MPT Introduction - Basics of VRM Process - R1Camilo CamposNo ratings yet

- Course 3 - Clinker Production: 3.7 FuelsDocument26 pagesCourse 3 - Clinker Production: 3.7 FuelsAVcheerNo ratings yet

- VDZ ActivityReport07 09Document140 pagesVDZ ActivityReport07 09jorge_acosta_112100% (1)

- Ultrasonic Test of Kiln ShellDocument5 pagesUltrasonic Test of Kiln ShellaansewuNo ratings yet

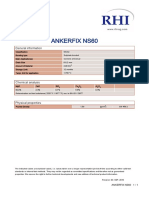

- Ankerfix NS60Document1 pageAnkerfix NS60mahreza189No ratings yet

- PM WNCC - Sep. 2019 OM Monthly ReportDocument6 pagesPM WNCC - Sep. 2019 OM Monthly ReportMahmoud HanafyNo ratings yet

- Quality Plan TemplateDocument2 pagesQuality Plan Templateapi-3850616100% (3)

- Fuchs Lubritech Group: DIN EN ISO 9001:2000Document54 pagesFuchs Lubritech Group: DIN EN ISO 9001:2000Hassan HamiNo ratings yet

- Mayor ShutdownDocument121 pagesMayor ShutdownIrshad HussainNo ratings yet

- Burner 1Document12 pagesBurner 1mkpqNo ratings yet

- Training PODFA: Overview of The Pyroprocessing ComponentsDocument50 pagesTraining PODFA: Overview of The Pyroprocessing ComponentsДен СтаднікNo ratings yet

- Topic 3 - Clinker Production: VDZ Online CoursesDocument52 pagesTopic 3 - Clinker Production: VDZ Online CoursesAVcheer100% (1)

- Per Banding An Desain Fls Pfister FeederDocument5 pagesPer Banding An Desain Fls Pfister Feederde_chemenx2540No ratings yet

- Catalytic Activated Ceramic Dust Filter For Removal of Dust NOx Dioxin and VOCs 2006Document5 pagesCatalytic Activated Ceramic Dust Filter For Removal of Dust NOx Dioxin and VOCs 2006Joseph RileyNo ratings yet

- MBT CalculatorDocument2 pagesMBT Calculatorsempatik721100% (1)

- How To Remove Scrap Materials From A Ball Mill CircuitDocument5 pagesHow To Remove Scrap Materials From A Ball Mill Circuitsafwat hassanNo ratings yet

- FIMSUP Double Rows Graphite Sealing For Rotary KilnDocument4 pagesFIMSUP Double Rows Graphite Sealing For Rotary KilnFurqan ShabbirNo ratings yet

- Vertical Mills 2008 - V2-0Document45 pagesVertical Mills 2008 - V2-0Mujahid BalochNo ratings yet

- Pre-Heater & Kiln InspectionDocument6 pagesPre-Heater & Kiln InspectionAtiq Ur RehmanNo ratings yet

- Medicion de Flujo de Solidos Por ImpactoDocument47 pagesMedicion de Flujo de Solidos Por ImpactogfautopackNo ratings yet

- Plant Process Audits2 PDFDocument38 pagesPlant Process Audits2 PDFvilas bollabathiniNo ratings yet

- Cement Plant VIPDocument51 pagesCement Plant VIPengr kazamNo ratings yet

- HASLE Datasheet OverviewDocument2 pagesHASLE Datasheet OverviewkINGNo ratings yet

- Design Guide For Air Slide PDFDocument2 pagesDesign Guide For Air Slide PDFAhmedRizk100% (1)

- Co2, H2Document101 pagesCo2, H2zohaib ul hassanNo ratings yet

- VDZ Cement Manufacturing Course FlyerDocument4 pagesVDZ Cement Manufacturing Course FlyerfaheemqcNo ratings yet

- Kiln Shell CoolingDocument4 pagesKiln Shell CoolingjmpbarrosNo ratings yet

- Alanco: Pulse Jet Filter Operation and Maintenance ManualDocument24 pagesAlanco: Pulse Jet Filter Operation and Maintenance ManualJahir Herrera DiazNo ratings yet

- FLS OM KPI Handbook Work 2012 Version 7 PDFDocument37 pagesFLS OM KPI Handbook Work 2012 Version 7 PDFTARNo ratings yet

- Performance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement PlantDocument8 pagesPerformance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement PlantSohail AhmedNo ratings yet

- Cement ProcessDocument9 pagesCement ProcessMob Morphling KurustienNo ratings yet

- 11A MER Basics On VRM Hydraulics R3Document22 pages11A MER Basics On VRM Hydraulics R3Camilo CamposNo ratings yet

- Cement Industry en PDFDocument12 pagesCement Industry en PDFzzhrhfvlNo ratings yet

- SOx Emmissions Absortion FLSDocument14 pagesSOx Emmissions Absortion FLSMartha Carolina Gomez MartinezNo ratings yet

- V6 EngineeringDocument252 pagesV6 Engineeringcrengifo1726No ratings yet

- Chapter 1 Final A5 Edit PDFDocument10 pagesChapter 1 Final A5 Edit PDFkINGNo ratings yet

- Pre Calci NerDocument61 pagesPre Calci NerLe HoangNo ratings yet

- Bulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropDocument2 pagesBulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropSivaram KrishnamoorthyNo ratings yet

- 31 MER VRM Inspections - Rev JSJ 120507Document45 pages31 MER VRM Inspections - Rev JSJ 120507Camilo CamposNo ratings yet

- Bogiflex KGD20 - For PlantDocument13 pagesBogiflex KGD20 - For PlantAnonymous PVXBGg9TNo ratings yet

- European Certification of Cement - The Ce-Mark: Th. PhilippouDocument38 pagesEuropean Certification of Cement - The Ce-Mark: Th. Philippoudoxa mariaNo ratings yet

- ITECA - On Line Quality Control Instrumentation For The Cement Industry PDFDocument55 pagesITECA - On Line Quality Control Instrumentation For The Cement Industry PDFawfahaddadinNo ratings yet

- Donk in Turbo CompressorsDocument16 pagesDonk in Turbo CompressorsLeon SanchezNo ratings yet

- 3011 Pittsburgh Pulverized Coal - 1213Document3 pages3011 Pittsburgh Pulverized Coal - 1213abdullah amanullah100% (1)

- Kiln Tires Repair SolutionDocument12 pagesKiln Tires Repair SolutionDương Quang KhánhNo ratings yet

- CEN/TC 51 Business Plan Date: 2015-04-21Document11 pagesCEN/TC 51 Business Plan Date: 2015-04-21Oyebola Akin-Delu0% (1)

- Mustekham 2 Coal HSLM 400-23Document207 pagesMustekham 2 Coal HSLM 400-23babarNo ratings yet

- Preheater Modifications BrochureDocument9 pagesPreheater Modifications BrochureKailash NathNo ratings yet

- CM2 AXIAL TEST Aug2014Document1 pageCM2 AXIAL TEST Aug2014Junaid Mazhar100% (1)

- FLSmidth SF Cooler UpgradeDocument2 pagesFLSmidth SF Cooler UpgradeMohammed AbdoNo ratings yet

- 12 Air Cooled Screw Chiller PresentationDocument48 pages12 Air Cooled Screw Chiller PresentationLeed EN100% (3)

- (1403-1C1312) Air Cooled Chillers 50Hz 20131216Document39 pages(1403-1C1312) Air Cooled Chillers 50Hz 20131216stefan_c_petreNo ratings yet

- Air Cooled Chillers 50Hz 20131203Document39 pagesAir Cooled Chillers 50Hz 20131203Dragos PicuNo ratings yet

- Operational Excellence Consulting LLC: "We Are What We Repeatedly Do. Excellence, Then, Is Not An Act, But A Habit."Document45 pagesOperational Excellence Consulting LLC: "We Are What We Repeatedly Do. Excellence, Then, Is Not An Act, But A Habit."Fran JimenezNo ratings yet

- The Next Generation of Internal Auditors The Fight For TalentDocument38 pagesThe Next Generation of Internal Auditors The Fight For TalentFran JimenezNo ratings yet

- TPM ConceptDocument18 pagesTPM ConceptFran JimenezNo ratings yet

- Barriers in TPM Implementation in Industries PDFDocument6 pagesBarriers in TPM Implementation in Industries PDFFran JimenezNo ratings yet

- El Rol Del Planeador de MantenimientoDocument2 pagesEl Rol Del Planeador de MantenimientoFran JimenezNo ratings yet

- Lubrication PDFDocument123 pagesLubrication PDFFran JimenezNo ratings yet

- Introduction To TPMDocument31 pagesIntroduction To TPMFran JimenezNo ratings yet

- 8th Maintenance Forum Presentation FinalDocument31 pages8th Maintenance Forum Presentation FinalFran JimenezNo ratings yet

- Reliability and Maintenance (RAM) : The Path To World-Class PerformanceDocument27 pagesReliability and Maintenance (RAM) : The Path To World-Class PerformanceFran JimenezNo ratings yet

- Goodman Screw Conveyor PDFDocument9 pagesGoodman Screw Conveyor PDFFran JimenezNo ratings yet

- Cement Grinding OptimizationDocument9 pagesCement Grinding OptimizationFran JimenezNo ratings yet

- Troubleshooting Screw ConveyorDocument5 pagesTroubleshooting Screw ConveyorFran JimenezNo ratings yet

- CTQ VocDocument9 pagesCTQ VocFran JimenezNo ratings yet

- SIPOCDocument7 pagesSIPOCFran JimenezNo ratings yet

- Prioritisation Matrix: Weighted Method For Option ReductionDocument7 pagesPrioritisation Matrix: Weighted Method For Option ReductionFran JimenezNo ratings yet

- Basic Project ManagementDocument17 pagesBasic Project ManagementFran JimenezNo ratings yet

- Structure by Engr. Enghoy With AnswersDocument15 pagesStructure by Engr. Enghoy With AnswersRuby MagsinoNo ratings yet

- Reducing The Environmental Impact of Concrete: Concrete Can Be Durable and Environmentally FriendlyDocument6 pagesReducing The Environmental Impact of Concrete: Concrete Can Be Durable and Environmentally FriendlyAniruddha TaraleNo ratings yet

- 00 SOR (RR) 2019-20 - 26-08-2019 Final 28.07.2019Document147 pages00 SOR (RR) 2019-20 - 26-08-2019 Final 28.07.2019Debashish Dey100% (1)

- Batimix Admixtures Solution PDFDocument3 pagesBatimix Admixtures Solution PDFkevin cosnerNo ratings yet

- Indore Stadium KavityDocument18 pagesIndore Stadium KavityD.V.Srinivasa RaoNo ratings yet

- Rotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationDocument1 pageRotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationVijay Bhan83% (6)

- Concrete Mix Design - (Part 1 & Part 2) PPT7Document39 pagesConcrete Mix Design - (Part 1 & Part 2) PPT7JuliaNo ratings yet

- Sulphate Attack and Ettringite Formation in The Lime and Cement Stabilized Marine Clays PDFDocument27 pagesSulphate Attack and Ettringite Formation in The Lime and Cement Stabilized Marine Clays PDFmarcoNo ratings yet

- Parametric Studies of Cement Production ProcesseDocument17 pagesParametric Studies of Cement Production ProcesseJ OHN BOSCONo ratings yet

- VICONDocument6 pagesVICONBukhori TamamNo ratings yet

- CC Road With DrainsDocument80 pagesCC Road With DrainsRajendra Prasad GubbalaNo ratings yet

- Creep in ConcreteDocument26 pagesCreep in ConcreteheminNo ratings yet

- AdmixturesDocument35 pagesAdmixturessachin.meenaNo ratings yet

- 01 - Development of Synthetic Aggregate Using off-ASTM Specification Ashes - 2013Document8 pages01 - Development of Synthetic Aggregate Using off-ASTM Specification Ashes - 2013TRAN Viet CuongNo ratings yet

- Chemical Inventory ListDocument21 pagesChemical Inventory ListsanjeevNo ratings yet

- SRSMES Presentation MovieDocument28 pagesSRSMES Presentation MovieKhan Ahmed MuradNo ratings yet

- Final Investigatory Project Paper 2014Document17 pagesFinal Investigatory Project Paper 2014api-24900091150% (6)

- Uses of CementDocument4 pagesUses of CementNaveen BansalNo ratings yet

- Minefill 2020-21Document450 pagesMinefill 2020-21ManuSachin100% (1)

- Work Method Statement For Ceramic Floor Tiling.Document4 pagesWork Method Statement For Ceramic Floor Tiling.lidea580% (5)

- Project: Esic Hospital Campus at Joka Boq For External Storm Water Drainage (RCC Pipe) SystemDocument3 pagesProject: Esic Hospital Campus at Joka Boq For External Storm Water Drainage (RCC Pipe) Systemyamanta_rajNo ratings yet

- 2.method Statement Plastering WorkDocument8 pages2.method Statement Plastering WorksochealaoNo ratings yet

- Belite Cement As An Ecological Alternative To Portland Cement - A ReviewDocument8 pagesBelite Cement As An Ecological Alternative To Portland Cement - A Reviewjulian casanovaNo ratings yet

- Various Angle Used in Conveyor Belt DesignDocument11 pagesVarious Angle Used in Conveyor Belt DesignprashantNo ratings yet

- Crown CementDocument24 pagesCrown Cementsajal sazzadNo ratings yet

- TDS - Glenium 110 UN PDFDocument3 pagesTDS - Glenium 110 UN PDFAlexi ALfred H. TagoNo ratings yet

- Synopsis of ACC LTDDocument5 pagesSynopsis of ACC LTDakki_6551No ratings yet

- M40 With Fly AshDocument1 pageM40 With Fly Ashscribdfree anytimeNo ratings yet

- Wang, Et Al (2018)Document14 pagesWang, Et Al (2018)Juliianiitha MaldonadoNo ratings yet