Professional Documents

Culture Documents

Welding of P91

Welding of P91

Uploaded by

Shyam Sundar Gayen0 ratings0% found this document useful (0 votes)

124 views37 pagesThis presentation discusses the welding procedure of SA 335 P91 material. It begins by introducing P91 as the material of choice for high-temperature piping, which was developed to improve upon previous materials like X20. The presentation then covers edge preparation, fit-up, preheating, gas tungsten arc welding and shielded metal arc welding processes, post-weld heat treatment, and cooling rates for P91 welds. Proper welding of P91 requires careful control of variables like temperature and shielding gas to achieve high quality welds suitable for high-temperature piping applications.

Original Description:

P 91

Original Title

139281555-Welding-of-P91

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis presentation discusses the welding procedure of SA 335 P91 material. It begins by introducing P91 as the material of choice for high-temperature piping, which was developed to improve upon previous materials like X20. The presentation then covers edge preparation, fit-up, preheating, gas tungsten arc welding and shielded metal arc welding processes, post-weld heat treatment, and cooling rates for P91 welds. Proper welding of P91 requires careful control of variables like temperature and shielding gas to achieve high quality welds suitable for high-temperature piping applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

124 views37 pagesWelding of P91

Welding of P91

Uploaded by

Shyam Sundar GayenThis presentation discusses the welding procedure of SA 335 P91 material. It begins by introducing P91 as the material of choice for high-temperature piping, which was developed to improve upon previous materials like X20. The presentation then covers edge preparation, fit-up, preheating, gas tungsten arc welding and shielded metal arc welding processes, post-weld heat treatment, and cooling rates for P91 welds. Proper welding of P91 requires careful control of variables like temperature and shielding gas to achieve high quality welds suitable for high-temperature piping applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 37

A Presentation

on

Welding procedure of SA 335 P91 Material

Presented by

Siddhartha Sankar Bharali

Assistant Engineer

Emp Code : M6B194

Siddhartha Sankar Bharali

M6B194 1

WELDING BASE MATERIALS

P.No Group Common Tubes Pipes

No. Name

P1 1 Carbon Steels SA192 SA106GRB

P1 2 Carbon Steels SA210GRC SA106GRC

P3 1 Carbon-Moly SA209T1 SA335P1

Steels

P3 1 ½Cr½Mo SA213T2 SA335P2

Steels

P4 1Cr½Mo/ SA213T12/ SA335P12/

1¼Cr½Mo SA213T11 SA335P11

Steels

P5A 1 2¼Cr1Mo SA213T22 SA335P22

Steels

P5B 2 9Cr1MoV SA213T91 SA335P91

Steels

Siddhartha Sankar Bharali

M6B194 2

HIGH TEMPERATURE STEAM

PIPING MATERIAL BEFORE P91

Material used for high

temperature piping before the

use of P91 was X20.

Composition of P91 Composition of X20

9 Cr 1MoV 12 Cr 1Mo 1/4V

Siddhartha Sankar Bharali

M6B194 3

BREIF HISTORY OF X20

X20 was introduced in the 1950s in Germany and used in steam lines

operating at temperatures of 530 0C and higher for power generating sets of

150MW and more.

X20 material was first used in India for high-temperature steam piping

around 1970.

The use of X20 allowed wall thickness reductions of about 50%. These

reductions resulted in easier handling; less energy needed for preheating

and postweld heat treatment , faster start-up and shutdown of the unit.

However, two factors limited its use:

- The extreme care needed for its fabrication and welding.

- Its noninclusion in the American Society of Mechanical

Engineers (ASME).

Siddhartha Sankar Bharali

M6B194 4

INTRODUCTION OF A NEW

MATERIAL:P91

U.S. had been trying to develop a new material since the

middle 1970s to bridge the gap between ferritic P22 and

austenitic steels with respect to creep rupture strength for high-

temperature service from 540 to 600 0C.

As a result of these developmental efforts, a new material,

designated P91, was introduced in the U.S. in the 1980s by Oak

Ridge National Laboratory.

It has very high strength at elevated temperatures and good

fabrication properties. These features have made P91 the

material of choice for high-temperature steam piping.

Siddhartha Sankar Bharali

M6B194 5

P91 DETAILS

P NO. COMPOSITION FILLER USED ELECTRODE

P 5A GR 2 9 Cr 1 MoV 90 S- B9 E9018- B9

Siddhartha Sankar Bharali

M6B194 6

SA 335 P91 welding steps

Edge

preparation GTAW SMAW Cooling

& fit up

Purging Preheating PWHT Soaking

Siddhartha Sankar Bharali

M6B194 7

EDGE PREPARATION & FIT-UP

Cutting of P-91 material shall be done by band saw /

hacksaw / machining / grinding only. Edge preparation

(EP) shall be done only by machining.

The weld fit-up shall be carried out properly to ensure

proper alignment and root gap . Neither tack welds nor

bridge piece shall be used to secure alignment. Partial root

weld of minimum 20mm length by GTAW and fit-up by a

clamping arrangement is recommended. Use of site

manufactured clamps for fit up is acceptable .

Siddhartha Sankar Bharali

M6B194 8

The fit-up shall be as per drawing. Root gap shall be 2 to 4

mm; root mismatch shall be within 1-mm.

Siddhartha Sankar Bharali

M6B194 9

ELECTRODE NOMENCLATURE

Prefix ‘E’ : Arc Welding Electrode

First two or three digits : Strenght in ksi

For example : E-90xx is 90ksi

Second last digit: Welding position

For example : E-xx1x = All positions

: E-xx2x = Horizontal and Flat

: E-xx3x = Flat

Last digit : E-xxx1: Type of Coating and other Characteristics

For example : E-xxx3 = Rutile Coated

: E-xxx8 = Basic Coated (Low hydrogen)

Suffix ‘A-1,B-2,B-3 etc.’ : Alloying Element

For example : E-xxxx A-1 = 0.5Mo

: E-xxxx B-2 = 1.25Cr & 0.5Mo

: E-xxxx B-3 = 2.25Cr & 1.0Mo

Siddhartha Sankar Bharali

M6B194 10

PURGING

Reason for purging

It is generally carried out on the backside of the weld to

eliminate oxygen and other atmospheric gases from mixing

with hot metal.

Oxygen have a stronge tendency to combine with hot metal

which will lead to the formation of thin films of oxide layers on

the weld surface. It prevents the joining of two pieces by

welding.

Argon is commonly used as purging gas.

Siddhartha Sankar Bharali

M6B194 11

WHY ARGON ?

Argon is chemically inert, heavy, monatomic gas available in

large quantity at reasonable cost.

Argon is used for shielding and backing purpose.

Siddhartha Sankar Bharali

M6B194 12

ARRANGEMENT FOR PURGING

Siddhartha Sankar Bharali

M6B194 13

Purging Details

Purging should be start from inside of the pipe when root

temperature reaches 2200C .

Adequate amount of Argon should be purged in the root area.

Minimum pre-flushing time for purging before the start of

welding is 5 min irrespective of pipe thickness.

The min flow rate to be maintained during purging is 10-26

litres/min. For shielding during GTAW welding, flow rate is 8-

14 litres/min.

Siddhartha Sankar Bharali

M6B194 14

PREHEATING

Prior to the start of

preheating the surface should

be clean from oil, grease and

dirt.

Preheating temperature

should be maintained at

2200C.

Siddhartha Sankar Bharali

M6B194 15

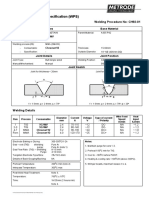

WELD PREHEAT & PWHT FOR PIPES(OD>102mm)

P No. of Thickness Butt Weld

Material (mm)

Preheat °C PWHT °C

P1 Gr 1 & ≤ 19 NIL NIL

SA106 > 19≤ 25 NIL 595- 625

Gr C

> 25 ≤ 75 150 595- 625

> 75 150 595- 625

P1 Gr 2 & ≤ 19 Nil Nil

SA 106 > 9≤ 19 Nil 620-650

Gr C

> 19 150 620-650

P4 Gr 1 ≤ 75 125 640- 670

> 75 150 640- 670

P5 A 150 680- 750

Siddhartha Sankar Bharali

M6B194 16

Contd.

P No. of Material Thickness Butt Weld

(mm)

Preheat °C PWHT °C

P5B Gr2 All 220 750-770

+

P5B Gr2

P5B Gr2 All 220 730- 760

+

P5 A

Siddhartha Sankar Bharali

M6B194 17

Preheating Methods

3 common methods of preheating:

Electrical resistance heating.

Induction heating.

Oxy- acetylene heating.

Siddhartha Sankar Bharali

M6B194 18

GTAW WELDING PROCESS

Siddhartha Sankar Bharali

M6B194 19

TIG WELGING BENIFITS

Superior weld quality.

Precise control of welding variables.

Free of spatter.

Low Distortion.

Weld can be made with or without filler material.

Siddhartha Sankar Bharali

M6B194 20

SMAW WELDING PROCESS

Siddhartha Sankar Bharali

M6B194 21

POST WELD HEAT TREATMENT (PWHT)

The method shall be by locally heating a circumferential band

including the entire weld and adjacent area of base metal, by

induction or electrical resistance heating.

Siddhartha Sankar Bharali

M6B194 22

DETAILS OF PWHT

PWHT temperature for P91 : (760±10)0 C

Soaking time : 2.5 minutes/ mm of weld thickness

subjected to minimum of two hours.

Siddhartha Sankar Bharali

M6B194 23

HEATING & COOLING RATES

Thickness of Material Maximum Heating Rate Maximum Cooling

Above 300°C Rate Upto 300°C

≤25 mm 220°C/hour 220°C/hour

> 25 ≤ 50 mm 110°C/hour 110°C/hour

> 50 ≤ 75 mm 75°C/hour 75°C/hour

> 75mm 55°C/hour 55°C/hour

Siddhartha Sankar Bharali

M6B194 24

GRAPHICAL REPRESENTATION OF SA 335 P91

WELDING PROCRESS

Siddhartha Sankar Bharali

M6B194 25

SL NO OPERATION TEMPERATURE RATE OF COOLING/

HEATING

1 PREHEAT 220 100

2 WELDING BY 220-350

GTAW/ SMAW

3 COOLING 80-100 100

4 HOLDING AT 80-100 FOR MIN 1 HR . HOLDING SHALL CONTINUE TILL

THE START OF PWHT

5 HEATING TO PWHT 760 +/- 10

6 SOAKING at PWHT 760 +/- 10 at 2MIN /

mm

7 COOLING COOLING TO 350

8 COOLING COOLING TO ROOM

TEMPERATURE

Siddhartha Sankar Bharali

M6B194 26

PREVENTIVE MEASURES DURING POWER

FAILURE

No interruption is allowed during welding & PWHT.

Following alternative arrangements should be made

available:

Diesel generator for power supply.

Gas burner arrangement for maintaining temperature.

Siddhartha Sankar Bharali

M6B194 27

PREVENTIVE MEASURES OF POWER

FAILURE DURING PREHEATING

Siddhartha Sankar Bharali

M6B194 28

PREVENTIVE MEASURES OF POWER

FAILURE DURING GTAW/SMAW

Gas burner arrangement is used to maintain the

temperature at 80 to 100°C up to a length of 50 mm on

either side from weld centre line along the complete

circumference of the pipe.

Root welding shall be continued after power is restored

and preheating temperature is raised to 220°C.

Siddhartha Sankar Bharali

M6B194 29

Siddhartha Sankar Bharali

M6B194 30

PREVENTIVE MEASURES OF POWER

FAILURE DURING PWHT HEATING CYCLE

During post weld heat treatment; The following shall be

followed:

During heating cycle : the whole operation to be repeated

from the beginning.

During soaking : Heat treat (soak) subsequently for the

entire duration. (complete period)

During cooling (above 350°C ) : Reheat to soaking

temperature and cool at the required rate.

* Temp should not be allowed to fall below 80 to 100°C. Gas

burner arrangement shall be used to maintain the temperature.

Siddhartha Sankar Bharali

M6B194 31

Siddhartha Sankar Bharali

M6B194 32

PREVENTIVE MEASURES OF POWER

FAILURE DURING PWHT SOAKING CYCLE

Siddhartha Sankar Bharali

M6B194 33

Do’s and Don’t’s during P91 welding

Do’s

Cutting by Band saw/Hack saw/Machining .

Pipes Edge Preparation by machining. Machining shall be

done without excessive pressure to prevent heating up of

pipe.

Adequate Argon Gas should be ensured for complete

purging of air inside the pipe before starting GTAW root

welding.

Preheating to 220°C minimum before GTAW root

welding.

Siddhartha Sankar Bharali

M6B194 34

Contd.

Argon purging should be continued until the GTAW root

welding followed by minimum two filler passes of SMAW,

is completed.

GTAW wires are kept in absolutely clean condition and

free from oil , rust, etc.

SMAW electrodes are baked to proper temperature.

Interpass temperature should be less than 350°C.

Argon purging arrangements should be removed after

welding.

Siddhartha Sankar Bharali

M6B194 35

Contd.

Don'ts

No Tack welding or Bridge piece welding is permitted.

Argon purging is continued till the completion of GTAW

root welding and two layers of SMAW.

Oxy-Acetylene flame cutting is avoided.

Do not allow moisture, rain, water, cold wind, cold draft

etc. to come in contact with the weld zone or heating zone

during the entire cycle from preheat to PWHT.

Use unidentified TIG wires or electrodes is not permitted.

Siddhartha Sankar Bharali

M6B194 36

THANK YOU

Siddhartha Sankar Bharali

M6B194 37

You might also like

- Asme CCase 1987-2Document2 pagesAsme CCase 1987-2ADAMJSRAONo ratings yet

- BGAS Qustins-1Document40 pagesBGAS Qustins-1Shyam Sundar GayenNo ratings yet

- PWHT, HT, Igc, MawpDocument40 pagesPWHT, HT, Igc, Mawpsachinshirnath100% (1)

- Sa515 GR 70 and Sa516 GR 70 t2776 PDFDocument3 pagesSa515 GR 70 and Sa516 GR 70 t2776 PDFvtbkNo ratings yet

- P91 Literature BOHLERDocument11 pagesP91 Literature BOHLERclaude.bouillot3566No ratings yet

- P3TF49 - S3 BorescopeDocument12 pagesP3TF49 - S3 BorescopeRajesh KannanNo ratings yet

- Standart Cina Untuk WeldingDocument52 pagesStandart Cina Untuk Weldingandristy90No ratings yet

- P Numbers: Grouping of Base Metals For Qualification (No. 1Document5 pagesP Numbers: Grouping of Base Metals For Qualification (No. 1Lim DongseopNo ratings yet

- P91 Welding and PWHT ProcedureDocument4 pagesP91 Welding and PWHT ProcedureHatem Ragab100% (2)

- Hot Tap Welding ParametersDocument7 pagesHot Tap Welding ParametersSiva RamNo ratings yet

- CCUG P91 Fabrication Guidelines Dave Buzza-1Document22 pagesCCUG P91 Fabrication Guidelines Dave Buzza-1Ranjith KumarNo ratings yet

- Asme Section I: Section - Iii Code ExtractionDocument3 pagesAsme Section I: Section - Iii Code ExtractionReadersmo100% (1)

- Pveng: Vessel With Large Opening Pve Sample VesselDocument1 pagePveng: Vessel With Large Opening Pve Sample VesselSivateja NallamothuNo ratings yet

- 331 Heat Treatment: ASME B31.3-2012Document4 pages331 Heat Treatment: ASME B31.3-2012Stephen RajNo ratings yet

- Welding Procedure Specification: Wps NoDocument1 pageWelding Procedure Specification: Wps NoLipika Gayen100% (1)

- Hot Tap Daily Welding Report 1Document1 pageHot Tap Daily Welding Report 1Jamal BakhtNo ratings yet

- Bohler Welding Thermalpower - ENGDocument24 pagesBohler Welding Thermalpower - ENGghostinshellNo ratings yet

- National Iranian Gas Company IGAT 5 Gas Compressor Stations: 602-106-TSH-VD-015 Rev. 0 PWHT ProcedureDocument9 pagesNational Iranian Gas Company IGAT 5 Gas Compressor Stations: 602-106-TSH-VD-015 Rev. 0 PWHT ProcedurewiNo ratings yet

- Soal CswipDocument1 pageSoal Cswipakun jeparaNo ratings yet

- Catalog 1 PDFDocument19 pagesCatalog 1 PDFtoto-gmbhNo ratings yet

- Material Comparison Tables (ASTM KS, JIS, DIN, BS, NBN, NF, UNI)Document12 pagesMaterial Comparison Tables (ASTM KS, JIS, DIN, BS, NBN, NF, UNI)mihailspiridonNo ratings yet

- Bill of Material - Globe Valve - Model 3000Document1 pageBill of Material - Globe Valve - Model 3000RAVIKIRAN BARDENo ratings yet

- Field Joint of Cement-Lined PipeDocument16 pagesField Joint of Cement-Lined Pipeahugandkiss77071No ratings yet

- Spec Grade Number Symbol Number Symbol Asme (Astm) KS JISDocument50 pagesSpec Grade Number Symbol Number Symbol Asme (Astm) KS JISVinay TrivediNo ratings yet

- Defects in Seamless TubesDocument4 pagesDefects in Seamless TubesAgniva DuttaNo ratings yet

- Minimum Number of Thermocouples-Local PWHTDocument5 pagesMinimum Number of Thermocouples-Local PWHTPradip Goswami100% (1)

- Purchase Spec. For Tubes (Sa213 TP321)Document5 pagesPurchase Spec. For Tubes (Sa213 TP321)Daison PaulNo ratings yet

- Roc-Master Swivel Ring Flange DatasheetDocument4 pagesRoc-Master Swivel Ring Flange DatasheetlunloonNo ratings yet

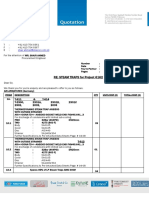

- Corporation.: Unpriced QuotationDocument12 pagesCorporation.: Unpriced QuotationavaisharmaNo ratings yet

- Sa 387Document29 pagesSa 387Ali VarmazyarNo ratings yet

- GTL WPSDocument6 pagesGTL WPSYoucef ChorfaNo ratings yet

- 13cr Martensitic Stainless Steel PQR and Wps ReviewDocument1 page13cr Martensitic Stainless Steel PQR and Wps Reviewenels77No ratings yet

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- EHB en File 9.7.3 Equivalent ASME en MaterialsDocument3 pagesEHB en File 9.7.3 Equivalent ASME en MaterialsRamuAlagappanNo ratings yet

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- EN10025 S235JR Steel PlateDocument2 pagesEN10025 S235JR Steel PlateNader NabilNo ratings yet

- Welding & SR Requirements - Pressure Parts - BoilerDocument7 pagesWelding & SR Requirements - Pressure Parts - BoilerNavneet SinghNo ratings yet

- Welding Repair ProcdureDocument16 pagesWelding Repair Procdureprem nautiyal100% (1)

- WPS Qualify To DNV-OS-C401 - SampleDocument12 pagesWPS Qualify To DNV-OS-C401 - SampleBien NguyenDuyNo ratings yet

- Chemical CompositionDocument1 pageChemical CompositionfrusdtNo ratings yet

- Equivalent ASME en MaterialsDocument3 pagesEquivalent ASME en MaterialsChee WeiNo ratings yet

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFDocument12 pages253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulNo ratings yet

- Er 100 S 1Document1 pageEr 100 S 1Oliver Quezada Inostroza100% (1)

- ASME 9 - CalculatorDocument2 pagesASME 9 - CalculatorEmel Besir100% (1)

- Saipem Wps ListDocument2 pagesSaipem Wps ListookaNo ratings yet

- Method Statement For Derrick Structure00Document3 pagesMethod Statement For Derrick Structure00khaled saeed100% (1)

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Welding of P91Document37 pagesWelding of P91nishant361100% (4)

- 09 - Replication&Met Evaluation PDFDocument61 pages09 - Replication&Met Evaluation PDFSACHIN PETKARNo ratings yet

- Special GadsketsDocument6 pagesSpecial GadsketshufuentsNo ratings yet

- R1-Ff-Bhadra Dam-30mt Hoist - Under Sluice Gate - r1Document15 pagesR1-Ff-Bhadra Dam-30mt Hoist - Under Sluice Gate - r1ajwalNo ratings yet

- Itb - PPT Final Matl Idf Workshop PT - Ip 21-23 Agst 2019Document113 pagesItb - PPT Final Matl Idf Workshop PT - Ip 21-23 Agst 2019Rizqi PriatnaNo ratings yet

- 12Cr Stats WeldingDocument27 pages12Cr Stats WeldingMark JohnsonNo ratings yet

- Threading Inserts and GradesDocument3 pagesThreading Inserts and GradeskarthikeyanNo ratings yet

- PGS SSWG Data-SheetDocument5 pagesPGS SSWG Data-Sheetazeem bilalNo ratings yet

- Trim Number Chart API ValveDocument2 pagesTrim Number Chart API ValveJuliusMaximus12No ratings yet

- FC142K1006PK-77 Traps-6162Document4 pagesFC142K1006PK-77 Traps-6162khan103No ratings yet

- item8-LNT NiCro60.20Document1 pageitem8-LNT NiCro60.20VVan TanNo ratings yet

- GK-Catalogue_Updated-22-sep-21Document10 pagesGK-Catalogue_Updated-22-sep-21mvb 012No ratings yet

- Kevinsteel SA 1210Document4 pagesKevinsteel SA 1210meisamNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Pipe Insulation: Qa / QC FormDocument1 pagePipe Insulation: Qa / QC FormShyam Sundar GayenNo ratings yet

- Painting Specificatin For Old Stack: Paint RAL D.F.T Area M 2 Theoretical Spreading RATE M 2/lit Consumption (Lit)Document2 pagesPainting Specificatin For Old Stack: Paint RAL D.F.T Area M 2 Theoretical Spreading RATE M 2/lit Consumption (Lit)Shyam Sundar GayenNo ratings yet

- 1.1.SCOPE: General 1Document1 page1.1.SCOPE: General 1Shyam Sundar GayenNo ratings yet

- Ultrasonic Examination Report (UT) : Report No: Location: ProjectDocument2 pagesUltrasonic Examination Report (UT) : Report No: Location: ProjectShyam Sundar GayenNo ratings yet

- Colour Code For Piping Material Colour Code For Piping MaterialDocument5 pagesColour Code For Piping Material Colour Code For Piping MaterialShyam Sundar GayenNo ratings yet

- Overseas Assignments: Assignments Abroad Times, Mumbai, Wednesday, June 06, 2018Document2 pagesOverseas Assignments: Assignments Abroad Times, Mumbai, Wednesday, June 06, 2018Shyam Sundar GayenNo ratings yet

- Ride On Tech: Students Worldwide CanDocument4 pagesRide On Tech: Students Worldwide CanShyam Sundar GayenNo ratings yet

- BGAS 2 Questions-1 PDFDocument33 pagesBGAS 2 Questions-1 PDFShyam Sundar Gayen100% (1)

- SAIC-A-2006 Rev 7Document5 pagesSAIC-A-2006 Rev 7Shyam Sundar GayenNo ratings yet

- Visual Inspection Report: Remarks After Repairs Before Repairs Type of Defect Part NoDocument2 pagesVisual Inspection Report: Remarks After Repairs Before Repairs Type of Defect Part NoShyam Sundar GayenNo ratings yet

- Overseas Assignments: Assignments Abroad Times, Mumbai, Wednesday, May 30, 2018Document2 pagesOverseas Assignments: Assignments Abroad Times, Mumbai, Wednesday, May 30, 2018Shyam Sundar GayenNo ratings yet

- Clad Handling ProcedureDocument1 pageClad Handling ProcedureShyam Sundar GayenNo ratings yet

- PT VariousDocument159 pagesPT VariousShyam Sundar GayenNo ratings yet

- New Doc 2018-03-01Document1 pageNew Doc 2018-03-01Shyam Sundar GayenNo ratings yet

- Visual ExamDocument22 pagesVisual ExamShyam Sundar Gayen100% (1)

- PT PracticalDocument40 pagesPT PracticalShyam Sundar GayenNo ratings yet

- ITB-spc For Tape Coating For UG Piping PDFDocument15 pagesITB-spc For Tape Coating For UG Piping PDFShyam Sundar GayenNo ratings yet

- MPT Training CoursesDocument156 pagesMPT Training CoursesShyam Sundar GayenNo ratings yet

- Advance of UtDocument50 pagesAdvance of UtShyam Sundar GayenNo ratings yet

- Magnetic Particle TestingDocument30 pagesMagnetic Particle TestingShyam Sundar GayenNo ratings yet

- Standardized Techniques of Manual Ultrasonic ExaminationDocument16 pagesStandardized Techniques of Manual Ultrasonic ExaminationShyam Sundar GayenNo ratings yet

- Ultrasonic DefinationDocument46 pagesUltrasonic DefinationShyam Sundar GayenNo ratings yet

- Failure of Chauras BridgeDocument8 pagesFailure of Chauras BridgeRitesh ChaurasiaNo ratings yet

- PNC00004 PDFDocument9 pagesPNC00004 PDFRaymundo Maldonado AlvarezNo ratings yet

- Spring Security Ui 3.0.0.M2Document47 pagesSpring Security Ui 3.0.0.M2LUIS QUINTANILLANo ratings yet

- Current and VoltageDocument1 pageCurrent and VoltageSuresh SenanayakeNo ratings yet

- EMEADocument74 pagesEMEAsohaibmuzaffar007No ratings yet

- Photography Techniques (Intermediate)Document43 pagesPhotography Techniques (Intermediate)Truc Nguyen100% (2)

- TOP SAP PP Training in Chandigarh & Mohali at GB Training & Placement CenterDocument3 pagesTOP SAP PP Training in Chandigarh & Mohali at GB Training & Placement CenterswayamNo ratings yet

- Identity in A Technological SocietyDocument6 pagesIdentity in A Technological SocietyRodrigo Sanz50% (2)

- GEARS March 2015 45RFE PDFDocument84 pagesGEARS March 2015 45RFE PDFManuel AmayaNo ratings yet

- Pegaclsa74v1 ADocument5 pagesPegaclsa74v1 AKumariNo ratings yet

- Bill of Quantity F G H (B2 Column 22F Slab) Include Form Work, Exclude Concrete and Rebar (Conventional Form Work)Document2 pagesBill of Quantity F G H (B2 Column 22F Slab) Include Form Work, Exclude Concrete and Rebar (Conventional Form Work)Phanint NgounNo ratings yet

- SQL IQDocument6 pagesSQL IQmahendranjanaNo ratings yet

- Hydraulic Calculation For FFDocument2 pagesHydraulic Calculation For FFUday KumarNo ratings yet

- 5th Grade Fact and Opinion Lesson PlanDocument10 pages5th Grade Fact and Opinion Lesson Planapi-433430734No ratings yet

- Economics Project Rubric 2016-17Document2 pagesEconomics Project Rubric 2016-17api-322597467No ratings yet

- Tme 601Document14 pagesTme 601dearsaswatNo ratings yet

- Chapter 8 Steam PipingDocument14 pagesChapter 8 Steam PipingDak Serik100% (2)

- NATIONAL TESTING AGENCY JEE (Main) Session - 3Document7 pagesNATIONAL TESTING AGENCY JEE (Main) Session - 3SouravNo ratings yet

- Dubai - The First City On The Blockchain: Case StudyDocument20 pagesDubai - The First City On The Blockchain: Case Studyk2mahenNo ratings yet

- Ten3 PDFDocument3 pagesTen3 PDFDan TranNo ratings yet

- GVP Module II Pharmacovigilance System Master File Rev 2 - en PDFDocument20 pagesGVP Module II Pharmacovigilance System Master File Rev 2 - en PDFBipin Bhagath.LNo ratings yet

- Welding Procedure - A - PDFDocument60 pagesWelding Procedure - A - PDFMade Agus BudiarthaNo ratings yet

- CATALOGO Gea T Smart Butterfly Valves Catalog Tcm38 13853Document94 pagesCATALOGO Gea T Smart Butterfly Valves Catalog Tcm38 13853Matheus Vinicius SilvaNo ratings yet

- PS-06 IC's SpecificationDocument2 pagesPS-06 IC's SpecificationYogesh KumarNo ratings yet

- Rhodoline 642 PDFDocument2 pagesRhodoline 642 PDFhemya7No ratings yet

- Differential Evolution: A Handbook For Global Permutation-Based Combinatorial OptimizationDocument225 pagesDifferential Evolution: A Handbook For Global Permutation-Based Combinatorial OptimizationDaniel NunesNo ratings yet

- Activiti User GuideDocument305 pagesActiviti User GuideyogaarsaNo ratings yet

- 14 References PDFDocument23 pages14 References PDFAgim KarajNo ratings yet

- Diffusers - OverviewDocument2 pagesDiffusers - OverviewMelvin SanchezNo ratings yet