Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

11 views1 Department of Mining Engineering

1 Department of Mining Engineering

Uploaded by

Yewuhalashet FisshaThe document discusses three main types of power systems used for machines: electrical, pneumatic, and hydraulic. The electrical power system uses a network to supply power to homes and industries from generators through transmission and distribution systems. Pneumatic systems use compressed air and pressure differentials to create movement, similar to hydraulics which use liquids instead of gases. Hydraulic systems are commonly used where large, precise forces are required, as seen in vehicles, construction equipment, and industrial machinery. Key differences are that pneumatic systems use compressed air while hydraulic systems use pressurized liquids like oil. Pneumatic systems generally have lower costs and simpler designs than hydraulic systems.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- Haven Taxi Cert - HAVCERTTX v8.9.5Document1 pageHaven Taxi Cert - HAVCERTTX v8.9.5Аудио книги на български Петко КостадиновNo ratings yet

- Actuators NotesDocument7 pagesActuators NotesNAAZNo ratings yet

- Can Crusher ReportDocument12 pagesCan Crusher ReportHarkirat SinghNo ratings yet

- Chapter 1 Part ADocument26 pagesChapter 1 Part AYip Tuck WaiNo ratings yet

- Fluid Power Systems Introduction To Fluid Power By: Nebyat YDocument30 pagesFluid Power Systems Introduction To Fluid Power By: Nebyat Yጃሎ ቲዩብ JALO TUBENo ratings yet

- Basic PneumaticsDocument48 pagesBasic Pneumaticszamir zakwanNo ratings yet

- Hydraulic and Pneumatic System, 4th Mechanical Dep. (1) - 1Document107 pagesHydraulic and Pneumatic System, 4th Mechanical Dep. (1) - 1Mina MagdyNo ratings yet

- ME416 LN 201617 Unit1Document66 pagesME416 LN 201617 Unit1rajkumarNo ratings yet

- 7 BTech Automation Lab ManualDocument48 pages7 BTech Automation Lab ManualA ABHISHEK MARSHALLNo ratings yet

- Chapter 1 Lecture 1Document23 pagesChapter 1 Lecture 1birhanubic23No ratings yet

- CH 1 FPSDocument55 pagesCH 1 FPSkidus tsegayeNo ratings yet

- Text BooksDocument114 pagesText BooksNarendra ChavdaNo ratings yet

- FPS Module 1Document28 pagesFPS Module 1RickNo ratings yet

- Ece006 Homework1Document12 pagesEce006 Homework1JHOZEFUS SABREDONo ratings yet

- Hydraulics Intro PDFDocument81 pagesHydraulics Intro PDFavinash babuNo ratings yet

- Fluid Power With Applications 7th Edition - Chapter 1Document53 pagesFluid Power With Applications 7th Edition - Chapter 1Nadeem AldwaimaNo ratings yet

- B.E Mech - Regulations 2010 Fluid Power Systems Smex1022Document18 pagesB.E Mech - Regulations 2010 Fluid Power Systems Smex1022yuvaraja sNo ratings yet

- Free-Samples - Amie - Chapters - Mining Pumps and Power Transmission-Sec-B-Mining-MachineryDocument27 pagesFree-Samples - Amie - Chapters - Mining Pumps and Power Transmission-Sec-B-Mining-MachineryAkash SinghNo ratings yet

- CH 3 Hydraulic SystemsDocument19 pagesCH 3 Hydraulic Systemsworkinehali92No ratings yet

- Applied Hydraulics and Pneumatics: RequiredDocument22 pagesApplied Hydraulics and Pneumatics: RequiredmuthupuviNo ratings yet

- Free Samples - Amie - Chapters - Mining Pumps and Power Transmission Sec B Mining MachineryDocument26 pagesFree Samples - Amie - Chapters - Mining Pumps and Power Transmission Sec B Mining MachineryNgatcha Ralain BryanNo ratings yet

- Auto Riveting MachineDocument28 pagesAuto Riveting MachineDeepak DaineNo ratings yet

- Hydraulics and PneumaticsDocument15 pagesHydraulics and Pneumaticsdivakarshettyas4029No ratings yet

- Physics Investigatory Project: Himesh Rajendran Xii A Roll Number - 17Document25 pagesPhysics Investigatory Project: Himesh Rajendran Xii A Roll Number - 17Himesh Rajendran50% (2)

- SYNOPSIS Hydraulic PressDocument10 pagesSYNOPSIS Hydraulic PressDIVYANSHI PHOTO STATENo ratings yet

- Pneumatic and Hydraulic DriveDocument14 pagesPneumatic and Hydraulic DriveswethaNo ratings yet

- Week 2 Pneumatics and HydraulicsDocument14 pagesWeek 2 Pneumatics and HydraulicsSarah Maravilla MañaraNo ratings yet

- 3.hydraulic Arm ProjecTDocument34 pages3.hydraulic Arm ProjecTManish Singh100% (1)

- Hydraulics LectureDocument20 pagesHydraulics Lecturee_manpreetNo ratings yet

- Fluid Power Control - NPTELDocument1,164 pagesFluid Power Control - NPTELSonal Power Unlimitd83% (6)

- Hydraulics 1Document6 pagesHydraulics 1Mereh MriNo ratings yet

- Pneumatics Vs HydraulicsDocument19 pagesPneumatics Vs HydraulicsGebBerhe100% (1)

- ME 407 M2 Ktuassist - inDocument39 pagesME 407 M2 Ktuassist - inAnirudh Madhav KakkadNo ratings yet

- Course Number: Me 433 Fluidics Fluidics 3 Credit Hour: PFMHBB R Prof. Mahbubur RazzaqueDocument11 pagesCourse Number: Me 433 Fluidics Fluidics 3 Credit Hour: PFMHBB R Prof. Mahbubur RazzaqueMuhammed RazzaqueNo ratings yet

- Hydraulic Arm ProjectDocument31 pagesHydraulic Arm Projectgsrawat123No ratings yet

- Hydraulic Arm ProjectDocument31 pagesHydraulic Arm ProjectGovind Rajput77% (22)

- Hydraulic CKT Colour CodeDocument10 pagesHydraulic CKT Colour CodepawargdNo ratings yet

- CAGIAir Compressor HPDocument30 pagesCAGIAir Compressor HPRobinson VasquezNo ratings yet

- How The Hydraulic Sistem WorkDocument11 pagesHow The Hydraulic Sistem WorkRianNo ratings yet

- How The Hydraulic Sistem WorkDocument11 pagesHow The Hydraulic Sistem WorkRianNo ratings yet

- CH - 1 Introduction To Pneumatics and Hydraulics SystemDocument60 pagesCH - 1 Introduction To Pneumatics and Hydraulics SystemEyasu demsewNo ratings yet

- Pneumatic JackDocument39 pagesPneumatic Jackvishnu kumarNo ratings yet

- Pneumatic Punching MachineDocument40 pagesPneumatic Punching MachineIlaya Raja67% (6)

- Ch3 Hydraulics - Slide MainDocument53 pagesCh3 Hydraulics - Slide Mainkabtamu mamoNo ratings yet

- PhysicsDocument8 pagesPhysicssharad chaudharyNo ratings yet

- Submitted byDocument62 pagesSubmitted byRameez AhmadNo ratings yet

- Design & Fabrication of Pneumatic Forging MachineDocument39 pagesDesign & Fabrication of Pneumatic Forging MachineDinesh KumarNo ratings yet

- Practicas Lorena (Autoguardado)Document24 pagesPracticas Lorena (Autoguardado)Alberto CamposNo ratings yet

- Fluid Power Part1Document101 pagesFluid Power Part1absolutebajwa100% (1)

- Difference Between Hyra and PneuDocument4 pagesDifference Between Hyra and PneuBurhoneySonNo ratings yet

- Introduction To Hydraulic and Pneumatic SystemsDocument10 pagesIntroduction To Hydraulic and Pneumatic SystemsAnkita AidNo ratings yet

- Final Report Hydro Milling ....Document29 pagesFinal Report Hydro Milling ....Ramjan ShidvankarNo ratings yet

- HYDRAULICS&PNEUMATICScontrol - diagram-AUTOMATION 1Document40 pagesHYDRAULICS&PNEUMATICScontrol - diagram-AUTOMATION 1Marlowe Cris MenceroNo ratings yet

- Chapter 1 Introduction To Fluid PowerDocument33 pagesChapter 1 Introduction To Fluid PowerSiraj Busse100% (4)

- Pneumatic Control SystemfinalDocument6 pagesPneumatic Control Systemfinalneo100% (1)

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerFrom Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerNo ratings yet

- Saba Stones ReportDocument33 pagesSaba Stones ReportYewuhalashet Fissha100% (1)

- Chapter Seven: Rock Breaking Mechanism and Blasting ApplicationDocument39 pagesChapter Seven: Rock Breaking Mechanism and Blasting ApplicationYewuhalashet FisshaNo ratings yet

- Work Sheet: Mining Engineering DepartmentDocument2 pagesWork Sheet: Mining Engineering DepartmentYewuhalashet FisshaNo ratings yet

- Underground Blasting: by Angesom.gDocument29 pagesUnderground Blasting: by Angesom.gYewuhalashet FisshaNo ratings yet

- Chapter 6Document50 pagesChapter 6Yewuhalashet FisshaNo ratings yet

- Aksum University School of Mines Department of Mining EngineeringDocument30 pagesAksum University School of Mines Department of Mining EngineeringYewuhalashet FisshaNo ratings yet

- Chapter Three: 1 Department of Mining EngineeringDocument24 pagesChapter Three: 1 Department of Mining EngineeringYewuhalashet FisshaNo ratings yet

- K-G-Y ResearchDocument39 pagesK-G-Y ResearchYewuhalashet FisshaNo ratings yet

- 2021 Audi A4 s4 78208Document304 pages2021 Audi A4 s4 78208Michael SørensenNo ratings yet

- 737-800 GolDocument17 pages737-800 GolFRANCISCO CINTORA COTA100% (3)

- Methods of LevelingDocument2 pagesMethods of LevelingWong WK0% (1)

- Data Parts Bazaar (16.04.03) FinalDocument72 pagesData Parts Bazaar (16.04.03) FinalLukman HakimNo ratings yet

- GEH-Steering Gear. UpdateDocument40 pagesGEH-Steering Gear. UpdateMohammed KaleemNo ratings yet

- 2020 Nissan 370z Brochure enDocument8 pages2020 Nissan 370z Brochure enSteven PentonNo ratings yet

- TransportationDocument18 pagesTransportationAbishank PalNo ratings yet

- VTC FH Brochure en ENpdfDocument36 pagesVTC FH Brochure en ENpdfKrzysztof MarzecNo ratings yet

- The Account of PigafettaDocument4 pagesThe Account of Pigafettajanellajoyce.malloNo ratings yet

- High Speed Ev New Car Quotation: Model Specification PictureDocument22 pagesHigh Speed Ev New Car Quotation: Model Specification PictureИса РозибаевNo ratings yet

- 0 Customs Manual CRBDocument11 pages0 Customs Manual CRBTanujLodhiNo ratings yet

- CDI SystemDocument6 pagesCDI Systemshivaram0% (1)

- Scania Catalogue 2015Document4 pagesScania Catalogue 2015Anita Miljkovic100% (1)

- Harley-Davidson Road King Police (EFI) Owner's ManualsDocument188 pagesHarley-Davidson Road King Police (EFI) Owner's ManualsCarlos NetoNo ratings yet

- How Elevator Is Made - Used, Parts, Dimensions, Structure, Machine, Design, Raw Materials PDFDocument4 pagesHow Elevator Is Made - Used, Parts, Dimensions, Structure, Machine, Design, Raw Materials PDFpersephoniseNo ratings yet

- Lounge Access List WorlDocument2 pagesLounge Access List WorlAditya ChauhanNo ratings yet

- Floating Storage and Regasification Unit (FSRU) : 26 January 2011 Oscar Spieler, Chief Executive OfficerDocument16 pagesFloating Storage and Regasification Unit (FSRU) : 26 January 2011 Oscar Spieler, Chief Executive Officercbmzo100% (1)

- Cartuchos FerroviáriosDocument8 pagesCartuchos Ferroviáriosfnahas_bhNo ratings yet

- Humanitarian AidDocument6 pagesHumanitarian AidHumair KhanNo ratings yet

- Handout-on-Network-Analysis 4Document10 pagesHandout-on-Network-Analysis 4Janine SalvioNo ratings yet

- Job Safety Analysis Forklift OperationsDocument2 pagesJob Safety Analysis Forklift Operationssufiyanshaikh50% (2)

- Yukon Gear 2012 Catalog PDFDocument104 pagesYukon Gear 2012 Catalog PDFxeron7126No ratings yet

- Flight International Magazine 1920-11-04 PDFDocument22 pagesFlight International Magazine 1920-11-04 PDFthais.tNo ratings yet

- Railway Fail-Safe Signalization and Interlocking Design Based On Automation Petri NetDocument5 pagesRailway Fail-Safe Signalization and Interlocking Design Based On Automation Petri NetmikeNo ratings yet

- Greater Downtown Kirkland Urban Center PlanDocument99 pagesGreater Downtown Kirkland Urban Center PlanThe UrbanistNo ratings yet

- Ivory Coast: Customs Regulations and Information For ImportsDocument2 pagesIvory Coast: Customs Regulations and Information For ImportsAziz SghayerNo ratings yet

- 8.Pms Monthly July 15 Lsa&FfaDocument10 pages8.Pms Monthly July 15 Lsa&FfaMuhammad Abdul WahidNo ratings yet

- A320/321 CHECKLIST: PreflightDocument3 pagesA320/321 CHECKLIST: PreflightErik AndreoniNo ratings yet

1 Department of Mining Engineering

1 Department of Mining Engineering

Uploaded by

Yewuhalashet Fissha0 ratings0% found this document useful (0 votes)

11 views18 pagesThe document discusses three main types of power systems used for machines: electrical, pneumatic, and hydraulic. The electrical power system uses a network to supply power to homes and industries from generators through transmission and distribution systems. Pneumatic systems use compressed air and pressure differentials to create movement, similar to hydraulics which use liquids instead of gases. Hydraulic systems are commonly used where large, precise forces are required, as seen in vehicles, construction equipment, and industrial machinery. Key differences are that pneumatic systems use compressed air while hydraulic systems use pressurized liquids like oil. Pneumatic systems generally have lower costs and simpler designs than hydraulic systems.

Original Description:

Original Title

Chapter=2.pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses three main types of power systems used for machines: electrical, pneumatic, and hydraulic. The electrical power system uses a network to supply power to homes and industries from generators through transmission and distribution systems. Pneumatic systems use compressed air and pressure differentials to create movement, similar to hydraulics which use liquids instead of gases. Hydraulic systems are commonly used where large, precise forces are required, as seen in vehicles, construction equipment, and industrial machinery. Key differences are that pneumatic systems use compressed air while hydraulic systems use pressurized liquids like oil. Pneumatic systems generally have lower costs and simpler designs than hydraulic systems.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

11 views18 pages1 Department of Mining Engineering

1 Department of Mining Engineering

Uploaded by

Yewuhalashet FisshaThe document discusses three main types of power systems used for machines: electrical, pneumatic, and hydraulic. The electrical power system uses a network to supply power to homes and industries from generators through transmission and distribution systems. Pneumatic systems use compressed air and pressure differentials to create movement, similar to hydraulics which use liquids instead of gases. Hydraulic systems are commonly used where large, precise forces are required, as seen in vehicles, construction equipment, and industrial machinery. Key differences are that pneumatic systems use compressed air while hydraulic systems use pressurized liquids like oil. Pneumatic systems generally have lower costs and simpler designs than hydraulic systems.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 18

Department of Mining Engineering 1

Power transmission is the movement of energy from its place of

generation to a location where it is applied to performing useful

work.

Power is defined formally as units of energy per unit time. OR

Power is the rate of energy generation or use, measured in Watts =

[Joules / sec].

Power systems used for machines are mainly Three types these are;

1.Electrical power system

2. Pneumatic Power System

3. Hydraulic Power system

Department of Mining Engineering 2

1.Electric power system: is a network of electrical components

used to supply, transmit and use electric power. An example of an

electric power system is the network that supplies a region's homes

and industry with power—for sizable regions, this power system is

known as the grid and can be broadly divided into the generators that

supply the power, the transmission system that carries the power from

the generating centers to the load centers and the distribution

system that feeds the power to nearby homes and industries.

The majority of these systems rely upon three-phase AC power—the

standard for large-scale power transmission and distribution across

the modern world.

Department of Mining Engineering 3

2.Pneumatic power system

Pneumatic : from the Greek (pneumn) for wind or breath.

Pneumatics is a type of power transmission that uses a gas ( in

our case, air) and pressure differential to create movement. Akin

to Hydraulics, but hydraulics use oil, water, or other fluids

instead of gases.

Pneumatic systems use air to transfer force from one point to

another. “Air is Compressible”

Compressible:

This describes whether it is possible to force an object into a

smaller space than it normally occupies. For example, a sponge

is compressible because it can be squeezed into a smaller size.

and “liquid is Incompressible”

ƒIncompressible:

The opposite to compressible. When a “squeezing” force is

applied to an object, it does not change to a smaller size. Liquid,

for example hydraulic fluid, possesses this physical property.

Department of Mining Engineering 4

Compressor

Driller Machine

Jack hammer

Fig.1. Examples of Pneumatic

Machines

Department of Mining Engineering 5

3.Hydraulic power system

Hydraulic: from the Greek words (hydra) for water and aulos for a pipe.

Hydraulic systems use liquid to transfer force from one point to another.

Hydraulic systems are commonly used where mechanisms require large forces

and precise control.

Examples: Include vehicle power steering and brakes, hydraulic jacks and

heavy earth moving machines.

Liquid is ideal for transferring a force from the control mechanism to the

mechanism doing the work. For example transferring force from the brake

pedal to the wheel brake in a car.

Uses of hydraulics power

Hydraulics plays an important role in many industries; there are a

lot of hydraulic applications in manufacturing, transportation, and

construction sectors. Hydraulics systems are used where large,

precise forces are required.

Department of Mining Engineering 6

Hydraulic power, also called Fluid Power, power

transmitted by the controlled circulation of

pressurized fluid, usually a water-soluble oil or

water–glycol mixture, to a motor that converts it into

a mechanical output capable of doing work on a load.

Hydraulic power systems have greater flexibility than

mechanical and electrical systems and can produce

more power than such systems of equal size. They

also provide rapid and accurate responses to controls.

As a result, hydraulic power systems are extensively

used in modern aircraft, automobiles, heavy industrial

machinery, and many kinds of machine tools.

Department of Mining Engineering 7

Back Hoe Machine Hydraulic Shovel

Front End Loader(FEL) Dumper

Fig.2. Examples of Hydraulic Machines

Department of Mining Engineering 8

Hydraulic and Pneumatic Motors

Pneumatic Power - Air-powered cylinders

• Compressed air

• Either stored on board or injected by a pump

• Produces linear motion through activation of cylinders

Hydraulic Power - Fluid (non-air)-powered cylinders

• Uncompressible fluid, most often oil.

• Requires a pump to generate the pressure and flow rate needed.

• Complex and difficult to build effectively, and costly.

Department of Mining Engineering 9

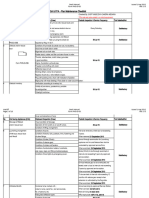

Table 1. Pneumatic and Hydraulic Difference

Department of Mining Engineering 10

Hydraulic and pneumatic power systems

Despite the immense capabilities of hydraulics presented in terms of moving

higher loads and in other industrial utilization, pneumatics are still in wide use

today.

Some applications and advantages of pneumatics in industry, Pneumatics is

study of mechanical motion caused by pressurized gases and how this motion can

be used to perform engineering tasks. Pneumatics is used mainly in mining and

general construction works. Pneumatic devices are used frequently in the

dentistry industry across the world. On the other hand, hydraulics means use of

pressurized fluids to execute a mechanical task. Hydraulics is frequently used in

the concepts of turbines, dams, and rivers.

Air brakes in buses, air compressors, compressed air engines,

jackhammers, and vacuum pumps are some of the most

commonly used types of mechanical equipment that are based on

pneumatics technology.

Department of Mining Engineering 11

Advantages of Pneumatics over Hydraulics

Like hydraulics, pneumatics is a type of

fluid power application where instead of

an incompressible liquid, pneumatics

employ gas in their system. Hydraulics

present certain advantages over

pneumatics, but in a given application,

pneumatic powered equipment is more

suitable, particularly in industries where

the factory units are plumbed for

compressed air.

Department of Mining Engineering 12

The air used in pneumatic devices is dried and

free from moisture so that it does not create any

problem to the internal parts of the system.

Moreover, to avoid corrosive actions, oil or

lubricants are added so that friction effects can be

reduced. Compressed air is used in most of the

machines and in some cases compressed carbon

dioxide is used. As most of the pneumatic devices

are air based, they have a less complicated design

and can be made of inexpensive material. Mass

production techniques can be adopted to produce

pneumatic systems, which not only save money

but save time too.

Department of Mining Engineering 13

Initial cost is less; hydraulics equipment cost as much as twice the

price of pneumatic equipment.

A pneumatic water treatment automation system reduces the costs

of installation and operation compared with conventional electrical

installations. For opening and closing of underwater valves,

pneumatic systems work well because they can sustain overload

pressure conditions.

Pneumatic actuators also have long life and perform well with

negligible maintenance requirement throughout their life cycle.

Very suitable for power transmission when distance of

transmission is more.

Department of Mining Engineering 14

The major disadvantage of pneumatic systems is that they

cannot be employed for tasks that require working

under high pressures. However, modern technology is

working on finding better solutions to this address this

problem so that heavy engineering tasks can be

executed using pneumatic devices. In order to execute

low scale engineering and mechanical tasks,

pneumatic devices would be the best suited and a

viable alternative over hydraulic systems.

Department of Mining Engineering 15

“ INDIVIDUAL ASSIGNMENT”

1.Explain briefly about the different

mechanical excavation machines applicable

for both surface and underground mining?

Department of Mining Engineering 16

Thank You

Department of Mining Engineering 17

Department of Mining Engineering 18

You might also like

- Haven Taxi Cert - HAVCERTTX v8.9.5Document1 pageHaven Taxi Cert - HAVCERTTX v8.9.5Аудио книги на български Петко КостадиновNo ratings yet

- Actuators NotesDocument7 pagesActuators NotesNAAZNo ratings yet

- Can Crusher ReportDocument12 pagesCan Crusher ReportHarkirat SinghNo ratings yet

- Chapter 1 Part ADocument26 pagesChapter 1 Part AYip Tuck WaiNo ratings yet

- Fluid Power Systems Introduction To Fluid Power By: Nebyat YDocument30 pagesFluid Power Systems Introduction To Fluid Power By: Nebyat Yጃሎ ቲዩብ JALO TUBENo ratings yet

- Basic PneumaticsDocument48 pagesBasic Pneumaticszamir zakwanNo ratings yet

- Hydraulic and Pneumatic System, 4th Mechanical Dep. (1) - 1Document107 pagesHydraulic and Pneumatic System, 4th Mechanical Dep. (1) - 1Mina MagdyNo ratings yet

- ME416 LN 201617 Unit1Document66 pagesME416 LN 201617 Unit1rajkumarNo ratings yet

- 7 BTech Automation Lab ManualDocument48 pages7 BTech Automation Lab ManualA ABHISHEK MARSHALLNo ratings yet

- Chapter 1 Lecture 1Document23 pagesChapter 1 Lecture 1birhanubic23No ratings yet

- CH 1 FPSDocument55 pagesCH 1 FPSkidus tsegayeNo ratings yet

- Text BooksDocument114 pagesText BooksNarendra ChavdaNo ratings yet

- FPS Module 1Document28 pagesFPS Module 1RickNo ratings yet

- Ece006 Homework1Document12 pagesEce006 Homework1JHOZEFUS SABREDONo ratings yet

- Hydraulics Intro PDFDocument81 pagesHydraulics Intro PDFavinash babuNo ratings yet

- Fluid Power With Applications 7th Edition - Chapter 1Document53 pagesFluid Power With Applications 7th Edition - Chapter 1Nadeem AldwaimaNo ratings yet

- B.E Mech - Regulations 2010 Fluid Power Systems Smex1022Document18 pagesB.E Mech - Regulations 2010 Fluid Power Systems Smex1022yuvaraja sNo ratings yet

- Free-Samples - Amie - Chapters - Mining Pumps and Power Transmission-Sec-B-Mining-MachineryDocument27 pagesFree-Samples - Amie - Chapters - Mining Pumps and Power Transmission-Sec-B-Mining-MachineryAkash SinghNo ratings yet

- CH 3 Hydraulic SystemsDocument19 pagesCH 3 Hydraulic Systemsworkinehali92No ratings yet

- Applied Hydraulics and Pneumatics: RequiredDocument22 pagesApplied Hydraulics and Pneumatics: RequiredmuthupuviNo ratings yet

- Free Samples - Amie - Chapters - Mining Pumps and Power Transmission Sec B Mining MachineryDocument26 pagesFree Samples - Amie - Chapters - Mining Pumps and Power Transmission Sec B Mining MachineryNgatcha Ralain BryanNo ratings yet

- Auto Riveting MachineDocument28 pagesAuto Riveting MachineDeepak DaineNo ratings yet

- Hydraulics and PneumaticsDocument15 pagesHydraulics and Pneumaticsdivakarshettyas4029No ratings yet

- Physics Investigatory Project: Himesh Rajendran Xii A Roll Number - 17Document25 pagesPhysics Investigatory Project: Himesh Rajendran Xii A Roll Number - 17Himesh Rajendran50% (2)

- SYNOPSIS Hydraulic PressDocument10 pagesSYNOPSIS Hydraulic PressDIVYANSHI PHOTO STATENo ratings yet

- Pneumatic and Hydraulic DriveDocument14 pagesPneumatic and Hydraulic DriveswethaNo ratings yet

- Week 2 Pneumatics and HydraulicsDocument14 pagesWeek 2 Pneumatics and HydraulicsSarah Maravilla MañaraNo ratings yet

- 3.hydraulic Arm ProjecTDocument34 pages3.hydraulic Arm ProjecTManish Singh100% (1)

- Hydraulics LectureDocument20 pagesHydraulics Lecturee_manpreetNo ratings yet

- Fluid Power Control - NPTELDocument1,164 pagesFluid Power Control - NPTELSonal Power Unlimitd83% (6)

- Hydraulics 1Document6 pagesHydraulics 1Mereh MriNo ratings yet

- Pneumatics Vs HydraulicsDocument19 pagesPneumatics Vs HydraulicsGebBerhe100% (1)

- ME 407 M2 Ktuassist - inDocument39 pagesME 407 M2 Ktuassist - inAnirudh Madhav KakkadNo ratings yet

- Course Number: Me 433 Fluidics Fluidics 3 Credit Hour: PFMHBB R Prof. Mahbubur RazzaqueDocument11 pagesCourse Number: Me 433 Fluidics Fluidics 3 Credit Hour: PFMHBB R Prof. Mahbubur RazzaqueMuhammed RazzaqueNo ratings yet

- Hydraulic Arm ProjectDocument31 pagesHydraulic Arm Projectgsrawat123No ratings yet

- Hydraulic Arm ProjectDocument31 pagesHydraulic Arm ProjectGovind Rajput77% (22)

- Hydraulic CKT Colour CodeDocument10 pagesHydraulic CKT Colour CodepawargdNo ratings yet

- CAGIAir Compressor HPDocument30 pagesCAGIAir Compressor HPRobinson VasquezNo ratings yet

- How The Hydraulic Sistem WorkDocument11 pagesHow The Hydraulic Sistem WorkRianNo ratings yet

- How The Hydraulic Sistem WorkDocument11 pagesHow The Hydraulic Sistem WorkRianNo ratings yet

- CH - 1 Introduction To Pneumatics and Hydraulics SystemDocument60 pagesCH - 1 Introduction To Pneumatics and Hydraulics SystemEyasu demsewNo ratings yet

- Pneumatic JackDocument39 pagesPneumatic Jackvishnu kumarNo ratings yet

- Pneumatic Punching MachineDocument40 pagesPneumatic Punching MachineIlaya Raja67% (6)

- Ch3 Hydraulics - Slide MainDocument53 pagesCh3 Hydraulics - Slide Mainkabtamu mamoNo ratings yet

- PhysicsDocument8 pagesPhysicssharad chaudharyNo ratings yet

- Submitted byDocument62 pagesSubmitted byRameez AhmadNo ratings yet

- Design & Fabrication of Pneumatic Forging MachineDocument39 pagesDesign & Fabrication of Pneumatic Forging MachineDinesh KumarNo ratings yet

- Practicas Lorena (Autoguardado)Document24 pagesPracticas Lorena (Autoguardado)Alberto CamposNo ratings yet

- Fluid Power Part1Document101 pagesFluid Power Part1absolutebajwa100% (1)

- Difference Between Hyra and PneuDocument4 pagesDifference Between Hyra and PneuBurhoneySonNo ratings yet

- Introduction To Hydraulic and Pneumatic SystemsDocument10 pagesIntroduction To Hydraulic and Pneumatic SystemsAnkita AidNo ratings yet

- Final Report Hydro Milling ....Document29 pagesFinal Report Hydro Milling ....Ramjan ShidvankarNo ratings yet

- HYDRAULICS&PNEUMATICScontrol - diagram-AUTOMATION 1Document40 pagesHYDRAULICS&PNEUMATICScontrol - diagram-AUTOMATION 1Marlowe Cris MenceroNo ratings yet

- Chapter 1 Introduction To Fluid PowerDocument33 pagesChapter 1 Introduction To Fluid PowerSiraj Busse100% (4)

- Pneumatic Control SystemfinalDocument6 pagesPneumatic Control Systemfinalneo100% (1)

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerFrom Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerNo ratings yet

- Saba Stones ReportDocument33 pagesSaba Stones ReportYewuhalashet Fissha100% (1)

- Chapter Seven: Rock Breaking Mechanism and Blasting ApplicationDocument39 pagesChapter Seven: Rock Breaking Mechanism and Blasting ApplicationYewuhalashet FisshaNo ratings yet

- Work Sheet: Mining Engineering DepartmentDocument2 pagesWork Sheet: Mining Engineering DepartmentYewuhalashet FisshaNo ratings yet

- Underground Blasting: by Angesom.gDocument29 pagesUnderground Blasting: by Angesom.gYewuhalashet FisshaNo ratings yet

- Chapter 6Document50 pagesChapter 6Yewuhalashet FisshaNo ratings yet

- Aksum University School of Mines Department of Mining EngineeringDocument30 pagesAksum University School of Mines Department of Mining EngineeringYewuhalashet FisshaNo ratings yet

- Chapter Three: 1 Department of Mining EngineeringDocument24 pagesChapter Three: 1 Department of Mining EngineeringYewuhalashet FisshaNo ratings yet

- K-G-Y ResearchDocument39 pagesK-G-Y ResearchYewuhalashet FisshaNo ratings yet

- 2021 Audi A4 s4 78208Document304 pages2021 Audi A4 s4 78208Michael SørensenNo ratings yet

- 737-800 GolDocument17 pages737-800 GolFRANCISCO CINTORA COTA100% (3)

- Methods of LevelingDocument2 pagesMethods of LevelingWong WK0% (1)

- Data Parts Bazaar (16.04.03) FinalDocument72 pagesData Parts Bazaar (16.04.03) FinalLukman HakimNo ratings yet

- GEH-Steering Gear. UpdateDocument40 pagesGEH-Steering Gear. UpdateMohammed KaleemNo ratings yet

- 2020 Nissan 370z Brochure enDocument8 pages2020 Nissan 370z Brochure enSteven PentonNo ratings yet

- TransportationDocument18 pagesTransportationAbishank PalNo ratings yet

- VTC FH Brochure en ENpdfDocument36 pagesVTC FH Brochure en ENpdfKrzysztof MarzecNo ratings yet

- The Account of PigafettaDocument4 pagesThe Account of Pigafettajanellajoyce.malloNo ratings yet

- High Speed Ev New Car Quotation: Model Specification PictureDocument22 pagesHigh Speed Ev New Car Quotation: Model Specification PictureИса РозибаевNo ratings yet

- 0 Customs Manual CRBDocument11 pages0 Customs Manual CRBTanujLodhiNo ratings yet

- CDI SystemDocument6 pagesCDI Systemshivaram0% (1)

- Scania Catalogue 2015Document4 pagesScania Catalogue 2015Anita Miljkovic100% (1)

- Harley-Davidson Road King Police (EFI) Owner's ManualsDocument188 pagesHarley-Davidson Road King Police (EFI) Owner's ManualsCarlos NetoNo ratings yet

- How Elevator Is Made - Used, Parts, Dimensions, Structure, Machine, Design, Raw Materials PDFDocument4 pagesHow Elevator Is Made - Used, Parts, Dimensions, Structure, Machine, Design, Raw Materials PDFpersephoniseNo ratings yet

- Lounge Access List WorlDocument2 pagesLounge Access List WorlAditya ChauhanNo ratings yet

- Floating Storage and Regasification Unit (FSRU) : 26 January 2011 Oscar Spieler, Chief Executive OfficerDocument16 pagesFloating Storage and Regasification Unit (FSRU) : 26 January 2011 Oscar Spieler, Chief Executive Officercbmzo100% (1)

- Cartuchos FerroviáriosDocument8 pagesCartuchos Ferroviáriosfnahas_bhNo ratings yet

- Humanitarian AidDocument6 pagesHumanitarian AidHumair KhanNo ratings yet

- Handout-on-Network-Analysis 4Document10 pagesHandout-on-Network-Analysis 4Janine SalvioNo ratings yet

- Job Safety Analysis Forklift OperationsDocument2 pagesJob Safety Analysis Forklift Operationssufiyanshaikh50% (2)

- Yukon Gear 2012 Catalog PDFDocument104 pagesYukon Gear 2012 Catalog PDFxeron7126No ratings yet

- Flight International Magazine 1920-11-04 PDFDocument22 pagesFlight International Magazine 1920-11-04 PDFthais.tNo ratings yet

- Railway Fail-Safe Signalization and Interlocking Design Based On Automation Petri NetDocument5 pagesRailway Fail-Safe Signalization and Interlocking Design Based On Automation Petri NetmikeNo ratings yet

- Greater Downtown Kirkland Urban Center PlanDocument99 pagesGreater Downtown Kirkland Urban Center PlanThe UrbanistNo ratings yet

- Ivory Coast: Customs Regulations and Information For ImportsDocument2 pagesIvory Coast: Customs Regulations and Information For ImportsAziz SghayerNo ratings yet

- 8.Pms Monthly July 15 Lsa&FfaDocument10 pages8.Pms Monthly July 15 Lsa&FfaMuhammad Abdul WahidNo ratings yet

- A320/321 CHECKLIST: PreflightDocument3 pagesA320/321 CHECKLIST: PreflightErik AndreoniNo ratings yet