Professional Documents

Culture Documents

Mechanical Seals Piping Plans API 628

Mechanical Seals Piping Plans API 628

Uploaded by

Pedro ViegasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Seals Piping Plans API 628

Mechanical Seals Piping Plans API 628

Uploaded by

Pedro ViegasCopyright:

Available Formats

Mechanical Seal Piping Plans

Single Seals Plans 01, 02, 11, 13, 14, 21, 23, 31, 32, 41

Dual Seals Plans 52, 53 A, 53 B, 53 C, 54

Quench Seals Plans 62, 65

Gas Seals Plans 72, 74, 75, 76

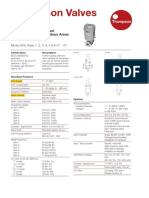

inlet

seal

end view

pressure flow control

indicator valve

temperature flow check

indicator valve

indicator from clean source,

(optional)

(optional) normally open

strainer

What

Seal flush from an external clean source.

Why

Seal chamber heat removal.

Process and solids removal from seal chamber.

Increase seal chamber pressure and fluid vapor margin.

Where

Dirty or contaminated fluids, paper pulp.

High temperature service.

Polymerizing and/or oxidizing fluids.

Preventative Maintenance

Use throat bushing sized to hold pressure or maintain flow velocity.

To restrict dirty process fluid, regulate injection flow rate.

To increase fluid vapor margin, regulate injection pressure.

Injection fluid must be compatible with process fluid.

Regularly monitor control system for closed valves or signs of plugging.

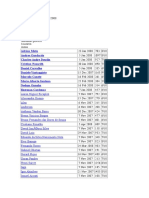

You might also like

- Bhs PDF en RDVDocument10 pagesBhs PDF en RDVolgiertNo ratings yet

- Nooter Eriksen HRSG AdvantagesDocument3 pagesNooter Eriksen HRSG Advantagesaliscribd46100% (2)

- Alignment CourseDocument167 pagesAlignment Coursedennis_packiaraj3063100% (22)

- CMMS Failure CodesDocument9 pagesCMMS Failure CodesPedro ViegasNo ratings yet

- HeDocument18 pagesHeRima MelatiNo ratings yet

- Bernoulli's Theory of FlightDocument24 pagesBernoulli's Theory of FlightABHISHEKNo ratings yet

- Lecture1 IntroDocument28 pagesLecture1 IntroSergio Fernández BlancoNo ratings yet

- PECATDocument23 pagesPECATichal_zaidanNo ratings yet

- Solid Particle Erosion and Mechanical DamageDocument5 pagesSolid Particle Erosion and Mechanical DamageCarlos ToscanoNo ratings yet

- 2.gas Turbine Operation, Maintenance & TroubleshootingDocument3 pages2.gas Turbine Operation, Maintenance & TroubleshootingMowaten Masry100% (1)

- Uk-Standard Asme Bladder AccumulatorDocument3 pagesUk-Standard Asme Bladder AccumulatorRamin SoadNo ratings yet

- MCO2 SP300 8011 SP2 8007 Operationmanual enDocument49 pagesMCO2 SP300 8011 SP2 8007 Operationmanual encengiz gunesNo ratings yet

- Trotec Speedy100 ManualDocument58 pagesTrotec Speedy100 ManualmanuelNo ratings yet

- GE Energy LM2500+ G4 Operation and Maintenance Manual: Water Wash System DescriptionDocument2 pagesGE Energy LM2500+ G4 Operation and Maintenance Manual: Water Wash System DescriptionAndrea Cupello100% (1)

- المستندDocument5 pagesالمستندMahdi HassanNo ratings yet

- Steam Turbine-Part III - Trip and Throttle ValveDocument7 pagesSteam Turbine-Part III - Trip and Throttle ValveAahmer Hasan100% (1)

- Centrifugal CompressorDocument14 pagesCentrifugal CompressorridanormaNo ratings yet

- February 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsDocument4 pagesFebruary 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsKarim MuhammedNo ratings yet

- GE Energy LM2500+ G4 Operation and Maintenance Manual: Hydraulic Start System DescriptionDocument5 pagesGE Energy LM2500+ G4 Operation and Maintenance Manual: Hydraulic Start System DescriptionAndrea Cupello100% (1)

- CCO New Moppet A4 Sales Sheet 100418Document2 pagesCCO New Moppet A4 Sales Sheet 100418Puja Ningrat WibowoNo ratings yet

- CenssorsDocument106 pagesCenssorsChandraSekaranBmNo ratings yet

- Governers FinalDocument52 pagesGoverners Finaldanish moinNo ratings yet

- 23 KKK TurbineDocument1 page23 KKK Turbineshoaib705No ratings yet

- AGV 50 Gas Turbine Fuel ValveDocument4 pagesAGV 50 Gas Turbine Fuel Valvehzq1eNo ratings yet

- Approved OilsDocument10 pagesApproved OilsDenis JimenezNo ratings yet

- Portfolio Vacuum ProcedureDocument2 pagesPortfolio Vacuum ProcedureAli SalmanNo ratings yet

- CombustionSystems RR DLE CourseAssignment 2e PDFDocument6 pagesCombustionSystems RR DLE CourseAssignment 2e PDFJarnodeJongNo ratings yet

- Hot Gas Path InspectionDocument54 pagesHot Gas Path InspectionMalik HatemNo ratings yet

- Mechanical Seal and Support System Considerations For Negative Temperature Hydrocarbon Services: NGL Processing and Ethylene Production FocusDocument21 pagesMechanical Seal and Support System Considerations For Negative Temperature Hydrocarbon Services: NGL Processing and Ethylene Production FocuspratapNo ratings yet

- Elliott Brush Ring Seals: Installation KitDocument2 pagesElliott Brush Ring Seals: Installation Kitfouzi gher100% (1)

- Dual Fuel Operation: Figure 1. Typical Fuel Transfer From Gas To Liquid Fuel SequenceDocument5 pagesDual Fuel Operation: Figure 1. Typical Fuel Transfer From Gas To Liquid Fuel SequenceDenis JimenezNo ratings yet

- ZJD Series Lubricant Oil Purifier 2020Document14 pagesZJD Series Lubricant Oil Purifier 2020Alex100% (1)

- Hydrocom: Experience Real Capacity Control and Energy SavingsDocument8 pagesHydrocom: Experience Real Capacity Control and Energy SavingsVignesh Dheenakumar100% (1)

- Dresser-Rand Group Inc - FinalDocument24 pagesDresser-Rand Group Inc - FinalMatt JonesNo ratings yet

- Boiler MaintenanceDocument5 pagesBoiler MaintenanceNicole FikingasNo ratings yet

- Pump Maintenance StandardDocument4 pagesPump Maintenance StandardNaing Min Htun100% (1)

- GE Energy LM2500+ G4 Operation and Maintenance Manual: Generator Lube Oil System DescriptionDocument4 pagesGE Energy LM2500+ G4 Operation and Maintenance Manual: Generator Lube Oil System DescriptionAndrea CupelloNo ratings yet

- Controlling Coupling Guard Leakage: Rotating Equipment/MaintenanceDocument3 pagesControlling Coupling Guard Leakage: Rotating Equipment/MaintenanceinterveiwNo ratings yet

- Gas Turbine Maintenance: Features To Enhance MaintenanceDocument22 pagesGas Turbine Maintenance: Features To Enhance MaintenanceThilagavathy SethuramahNo ratings yet

- Rikt71 Produkt e A4 Web Final PDFDocument6 pagesRikt71 Produkt e A4 Web Final PDFJaswindersingh BhatiaNo ratings yet

- Gas Engine Oil Analysis (Wear Check)Document2 pagesGas Engine Oil Analysis (Wear Check)anibal_rios_rivasNo ratings yet

- Generator Performance Plus PDFDocument4 pagesGenerator Performance Plus PDFkamal arabNo ratings yet

- How To Boost HRSG Performance and Increase Your Plant's Bottom LineDocument28 pagesHow To Boost HRSG Performance and Increase Your Plant's Bottom Lineabdulyunus_amir100% (1)

- Maxseal Direct Solenoid-Operated Control Valve For Hazardous Areas Ex EsDocument2 pagesMaxseal Direct Solenoid-Operated Control Valve For Hazardous Areas Ex EstariqNo ratings yet

- Gas Turbine GEK28143a PDFDocument10 pagesGas Turbine GEK28143a PDFSunario YapNo ratings yet

- Compressor Water Wash SystemDocument10 pagesCompressor Water Wash SystemCarlos GonzálezNo ratings yet

- Single-Stage Steam TurbinesDocument8 pagesSingle-Stage Steam Turbinesfouzi gherNo ratings yet

- Compressor Brochure A4 - SpreadsDocument27 pagesCompressor Brochure A4 - SpreadsIwan AbdurahmanNo ratings yet

- Flexible Coupling For Gas Turbine ApplicationsDocument10 pagesFlexible Coupling For Gas Turbine Applicationsherysyam1980No ratings yet

- D VipDocument6 pagesD VipClemente Rafael Marval EscalonaNo ratings yet

- Systems Description Lubricating Oil System For LM2000Document3 pagesSystems Description Lubricating Oil System For LM2000KALPUSHNo ratings yet

- Boiler Tube AssessmentDocument7 pagesBoiler Tube AssessmentNorman IskandarNo ratings yet

- Annual Outage Maintenence Check List - BFPTDocument8 pagesAnnual Outage Maintenence Check List - BFPTSamuelTrinandoNo ratings yet

- Fluitec ccs218 1310r1Document2 pagesFluitec ccs218 1310r1api-221802169No ratings yet

- Use of Cold Air Velocity Test (CAVT) To Locate Erosion Prone Zones in Pulverized Coal Fired Utility BoilerDocument5 pagesUse of Cold Air Velocity Test (CAVT) To Locate Erosion Prone Zones in Pulverized Coal Fired Utility BoilerVinoth KumarNo ratings yet

- Compressor Turbo-Air API a4-IRDocument12 pagesCompressor Turbo-Air API a4-IRMachineryengNo ratings yet

- Gas Turbine Heat Rate Versus EOHDocument2 pagesGas Turbine Heat Rate Versus EOHAbdulyunus Amir100% (3)

- LV05 - Routine Maintenance - Issue 1Document53 pagesLV05 - Routine Maintenance - Issue 1Đức Hòang100% (1)

- Machinery Lubrication November December 2017 PDFDocument89 pagesMachinery Lubrication November December 2017 PDFJorge Cuadros BlasNo ratings yet

- Effective Varnish Removal From Turbine Lubrication SystemsDocument9 pagesEffective Varnish Removal From Turbine Lubrication SystemsOsman AhmedNo ratings yet

- HRSGDocument9 pagesHRSGprasad5034100% (1)

- Asset Integrity Management A Complete Guide - 2020 EditionFrom EverandAsset Integrity Management A Complete Guide - 2020 EditionNo ratings yet

- An Insider's Guide To CMMS Functions, Selection and ImplementationDocument26 pagesAn Insider's Guide To CMMS Functions, Selection and ImplementationPedro ViegasNo ratings yet

- Dot Point Bar PowerPoint DiagramDocument1 pageDot Point Bar PowerPoint DiagramPedro ViegasNo ratings yet

- 7 Global Golden Rules of Safety - Rule 6 - Handling, Loading & Unloading of Loads Fall Hazards Work at Height - DraftDocument6 pages7 Global Golden Rules of Safety - Rule 6 - Handling, Loading & Unloading of Loads Fall Hazards Work at Height - DraftPedro ViegasNo ratings yet

- Enova - Pedro Insigths 2023Document5 pagesEnova - Pedro Insigths 2023Pedro ViegasNo ratings yet

- IR Checks of Conveyor Idler RollersDocument5 pagesIR Checks of Conveyor Idler RollersPedro ViegasNo ratings yet

- 7 Global Golden Rules of Safety - Rule 7 - Vehicles, Mobile Equipment & Workplace - DraftDocument11 pages7 Global Golden Rules of Safety - Rule 7 - Vehicles, Mobile Equipment & Workplace - DraftPedro ViegasNo ratings yet

- 7 Global Golden Rules of Safety - Rule 4 - Machinery & Rotary Part Protection - DraftDocument7 pages7 Global Golden Rules of Safety - Rule 4 - Machinery & Rotary Part Protection - DraftPedro ViegasNo ratings yet

- 7 Reasons To Do Laser AlignmentDocument8 pages7 Reasons To Do Laser AlignmentPedro ViegasNo ratings yet

- 7 Global Golden Rules of Safety - Rule 2 - Body Protection - DraftDocument6 pages7 Global Golden Rules of Safety - Rule 2 - Body Protection - DraftPedro ViegasNo ratings yet

- 7 Global Golden Rules of Safety - Rule 1 - Safety Priority - DraftDocument4 pages7 Global Golden Rules of Safety - Rule 1 - Safety Priority - DraftPedro ViegasNo ratings yet

- 7 Global Golden Rules of Safety - List of RulesDocument1 page7 Global Golden Rules of Safety - List of RulesPedro ViegasNo ratings yet

- 7 Global Golden Rules of Safety - Rule 5 - LOTO & Work Permit - DraftDocument5 pages7 Global Golden Rules of Safety - Rule 5 - LOTO & Work Permit - DraftPedro ViegasNo ratings yet

- Indicator MTBFDocument2 pagesIndicator MTBFPedro ViegasNo ratings yet

- 7 Global Golden Rules of Safety - Rule 3 - Safety Walks, Communication & Report - DraftDocument3 pages7 Global Golden Rules of Safety - Rule 3 - Safety Walks, Communication & Report - DraftPedro ViegasNo ratings yet

- 10 Ways To Reduce Reactive Maintenance: Ten Actions Worth ConsideringDocument4 pages10 Ways To Reduce Reactive Maintenance: Ten Actions Worth ConsideringPedro ViegasNo ratings yet

- Irregular English VerbsDocument1 pageIrregular English VerbsPedro ViegasNo ratings yet

- Spiral Freezer Gearbox FailuresDocument7 pagesSpiral Freezer Gearbox FailuresPedro ViegasNo ratings yet

- The Golden Rules of SafetyDocument11 pagesThe Golden Rules of SafetyPedro ViegasNo ratings yet

- 70 30 PhenomenonDocument2 pages70 30 PhenomenonPedro ViegasNo ratings yet

- (Name / Logo) : Internal Strengths Internal WeaknesssesDocument7 pages(Name / Logo) : Internal Strengths Internal WeaknesssesPedro ViegasNo ratings yet

- Backlog ManagementDocument3 pagesBacklog ManagementPedro ViegasNo ratings yet

- Signalling / Alarm and Interlock System Inspection RecordDocument1 pageSignalling / Alarm and Interlock System Inspection RecordPedro ViegasNo ratings yet

- Defining Maintenance Routes - Oracle Enterprise Asset ManagementDocument4 pagesDefining Maintenance Routes - Oracle Enterprise Asset ManagementPedro ViegasNo ratings yet

- Best Players FM2008Document2 pagesBest Players FM2008Pedro ViegasNo ratings yet

- Troubleshooting Guide: Asset Family Centrifugal Process PumpsDocument1 pageTroubleshooting Guide: Asset Family Centrifugal Process PumpsPedro ViegasNo ratings yet

- Flow of FluidSDocument53 pagesFlow of FluidSAbas AcmadNo ratings yet

- Unistrut Uniper Pipe Support SystemsDocument24 pagesUnistrut Uniper Pipe Support SystemsmolinachNo ratings yet

- Pompe IncendiuDocument3 pagesPompe IncendiuMilimilimanimo ManimanimilimoNo ratings yet

- DR Rola ME 362 Sheet 1Document4 pagesDR Rola ME 362 Sheet 1Keroles SabryNo ratings yet

- Design For Overpressure and Underpressure Protection: Slide Show Exit Slides With TextDocument81 pagesDesign For Overpressure and Underpressure Protection: Slide Show Exit Slides With TextMohamed FouadNo ratings yet

- Separator SizingDocument16 pagesSeparator SizingMichael J. BaneNo ratings yet

- Machinery Operating ManualDocument213 pagesMachinery Operating Manualbatizap batizapNo ratings yet

- A Simplified Approach To Water-Hammer Analysis PDFDocument0 pagesA Simplified Approach To Water-Hammer Analysis PDFbtjajadi100% (1)

- FLuid FlowDocument13 pagesFLuid FlowDuncoh DunNo ratings yet

- Index ApiDocument4 pagesIndex ApiAnand Prakash Sharma100% (1)

- Chapter 14 PumpDocument63 pagesChapter 14 PumpRoque MoronNo ratings yet

- RENOLIN ZAF MC Technical Report ENDocument6 pagesRENOLIN ZAF MC Technical Report ENFarhan TamjidNo ratings yet

- MITSUBISHI OUTLANDER 2007 SERVICE MANUAL Volume 1 2 3 Engine LubricationDocument6 pagesMITSUBISHI OUTLANDER 2007 SERVICE MANUAL Volume 1 2 3 Engine LubricationAlberto José Meta GoudinhoNo ratings yet

- Archimedes' PrincipleDocument4 pagesArchimedes' PrincipleJa Kov100% (1)

- Chapter 06 Pressure Losses in The Circulating SystemDocument22 pagesChapter 06 Pressure Losses in The Circulating SystemAbrar HassanNo ratings yet

- UltraChem Lubricants Product HandbookDocument222 pagesUltraChem Lubricants Product HandbookCao Quy NguyenNo ratings yet

- Steam Silencer DesignDocument3 pagesSteam Silencer DesignDaan Brenis100% (1)

- Drains On Engine Room MachineryDocument11 pagesDrains On Engine Room MachineryReeta SingjNo ratings yet

- Ian Coleen Estremera. Activity2 Fans and Blowers - IPEDocument4 pagesIan Coleen Estremera. Activity2 Fans and Blowers - IPEIan EstremeraNo ratings yet

- ME8694 HydraulicsandPneumaticsQuestionBank PDFDocument15 pagesME8694 HydraulicsandPneumaticsQuestionBank PDFVikram mNo ratings yet

- Experiment E 1Document12 pagesExperiment E 1RINA RINANo ratings yet

- Gas Turbine BasicsDocument52 pagesGas Turbine Basicsrahuldayal100% (3)

- Kod SizingDocument2 pagesKod SizingCan YıldırımNo ratings yet

- Micron S602 ECODocument4 pagesMicron S602 ECOTan Kang YaoNo ratings yet

- Terms Pipe LVL 4Document11 pagesTerms Pipe LVL 4Ange JayloNo ratings yet

- Types of PumpsDocument3 pagesTypes of PumpsKunal SinghNo ratings yet