Professional Documents

Culture Documents

Elastic and Plastic Deformation: - Metals Deform Both Elastically and Plastically

Elastic and Plastic Deformation: - Metals Deform Both Elastically and Plastically

Uploaded by

Harris DarCopyright:

Available Formats

You might also like

- Atm GuideDocument23 pagesAtm GuideGilbert Kamanzi100% (3)

- Diebold Atm Operator ManualDocument72 pagesDiebold Atm Operator ManualHarris Dar50% (2)

- Diebold Atm Operator ManualDocument4 pagesDiebold Atm Operator ManualHarris Dar0% (3)

- Diebold Atm Operator ManualDocument4 pagesDiebold Atm Operator ManualHarris Dar0% (3)

- GIA Colored Stones 8Document51 pagesGIA Colored Stones 8Judy Wallace Reed89% (9)

- Chapter 1 Solutions (Global Edition) : Prob. 1.1Document10 pagesChapter 1 Solutions (Global Edition) : Prob. 1.1靑山なつきNo ratings yet

- Solidification and Crystalline Imperfection Part 1Document25 pagesSolidification and Crystalline Imperfection Part 1Aiman MutallidNo ratings yet

- Dislocation TheoryDocument37 pagesDislocation TheoryAbbireddy Siva Ganesh100% (1)

- Introduction To Optical Mineralogy Willia - 59f150bd1723dd1e2af83188Document2 pagesIntroduction To Optical Mineralogy Willia - 59f150bd1723dd1e2af83188Bernhard ManurungNo ratings yet

- Blue Basic Concepts On Structure of SolidsDocument22 pagesBlue Basic Concepts On Structure of SolidsME011Mohsin BilalNo ratings yet

- Failure Mechanism of MatterDocument66 pagesFailure Mechanism of MatterSiva Kumar SalumuriNo ratings yet

- Lec3-Dislocation, Slip Systems and TwiningDocument32 pagesLec3-Dislocation, Slip Systems and Twiningsamurai7_77No ratings yet

- Elastic and Plastic Behaviour 2Document94 pagesElastic and Plastic Behaviour 2Anjana2893100% (1)

- Deformation & StrengthDocument35 pagesDeformation & StrengthcolorofstoneNo ratings yet

- Chap5 FinalDocument49 pagesChap5 Finalamanuelfitsum589No ratings yet

- Electronic Properties of Materials: Lecture - 3: Crystal DefectsDocument19 pagesElectronic Properties of Materials: Lecture - 3: Crystal DefectsKm. Rakibur RahmanNo ratings yet

- Material Deformations WorkshopDocument20 pagesMaterial Deformations WorkshopAman RajNo ratings yet

- Lec03 Plasticity P2Document35 pagesLec03 Plasticity P2Muna UnisaNo ratings yet

- Manufacturing Technology (ME361) Lecture 2: Shantanu BhattacharyaDocument21 pagesManufacturing Technology (ME361) Lecture 2: Shantanu BhattacharyaSahil SundaNo ratings yet

- Lecture 5 - Crystal Defects-Dislocations - 2 PDFDocument53 pagesLecture 5 - Crystal Defects-Dislocations - 2 PDFArpit Pradhan100% (1)

- Defects in Crystals PDFDocument31 pagesDefects in Crystals PDFChama9No ratings yet

- Engineering Materials-I: Chapter-4: Dislocations & Strengthening MechanismsDocument23 pagesEngineering Materials-I: Chapter-4: Dislocations & Strengthening MechanismsÇãłl Mê MęlkãNo ratings yet

- Material Deformations Workshop PDFDocument20 pagesMaterial Deformations Workshop PDFDimas SatriaNo ratings yet

- Manufacturing Processes (ME361) Lecture 3 and 4Document32 pagesManufacturing Processes (ME361) Lecture 3 and 4Randhir KyNo ratings yet

- Processing of Aerospace Materials Part I (ME772) : Crystal Structures, Imperfections, Slip and Strain Hardening in MetalsDocument19 pagesProcessing of Aerospace Materials Part I (ME772) : Crystal Structures, Imperfections, Slip and Strain Hardening in MetalsB RITHIKANo ratings yet

- Plastic Deformation, Flow Stress and FormabilityDocument35 pagesPlastic Deformation, Flow Stress and FormabilityAnna100% (2)

- Single Crystal Slip: Adapted From Fig. 7.9, Callister 7eDocument15 pagesSingle Crystal Slip: Adapted From Fig. 7.9, Callister 7eavenashaNo ratings yet

- EBT211 - Lecture 6 - Slip PDFDocument36 pagesEBT211 - Lecture 6 - Slip PDFSollehah SuhaimiNo ratings yet

- Elastic and Plastic BehaviourDocument94 pagesElastic and Plastic BehaviournavneeshvNo ratings yet

- ME 1022 Materials TechnologyDocument77 pagesME 1022 Materials TechnologyShubham PadwalNo ratings yet

- Manufacturing Processes (ME361) Lecture 25 and 27Document40 pagesManufacturing Processes (ME361) Lecture 25 and 27RandhirKumarNo ratings yet

- 1 - Deformation of Materials-1Document89 pages1 - Deformation of Materials-1Revanth MuralidharNo ratings yet

- Mechanical Behavior IIIDocument16 pagesMechanical Behavior IIIVidushi MakhijaNo ratings yet

- MM207 Group 11Document52 pagesMM207 Group 11nitharsunNo ratings yet

- Chap 6Document22 pagesChap 6api-3803993100% (1)

- Schmid's Law: Plastic Deformation (SLIP) in Polycrystalline MaterialsDocument3 pagesSchmid's Law: Plastic Deformation (SLIP) in Polycrystalline MaterialsyashvantNo ratings yet

- Twinning 1Document10 pagesTwinning 1AnjaniAkulaNo ratings yet

- Keanu Husein Material TestingDocument2 pagesKeanu Husein Material TestingKeanu MitchellNo ratings yet

- Closed-Book Practice-Ch 07 (2016!12!24)Document8 pagesClosed-Book Practice-Ch 07 (2016!12!24)JuanNo ratings yet

- DislocationsDocument11 pagesDislocationsraghcharashNo ratings yet

- Fracture Mechanics 1 EBB 334Document37 pagesFracture Mechanics 1 EBB 334Luiz CordeiroNo ratings yet

- Ipmem BookDocument55 pagesIpmem BookRamesh NayakNo ratings yet

- MS Module 3Document16 pagesMS Module 3Affan KhanNo ratings yet

- Solidification, Solid Solutions and Diffusion in SolidsDocument43 pagesSolidification, Solid Solutions and Diffusion in SolidsKelvin MugwagwaNo ratings yet

- 04 Plastic Deformation of Single Crystal-21-42Document22 pages04 Plastic Deformation of Single Crystal-21-42Aravind SomasundaramNo ratings yet

- Slip Systems and TwinningDocument33 pagesSlip Systems and TwinningAyush ShahNo ratings yet

- Basics of Physical Metallurgy MM 2107Document22 pagesBasics of Physical Metallurgy MM 2107srujan baluNo ratings yet

- Imperfections in Solid Materials - Ch4Document40 pagesImperfections in Solid Materials - Ch4aa454No ratings yet

- Ch. 2Document27 pagesCh. 2mhmdramdan.208200No ratings yet

- Mechanical Behavior IIDocument29 pagesMechanical Behavior IIVidushi MakhijaNo ratings yet

- 4 Deformation and Strengthening MechanismsDocument90 pages4 Deformation and Strengthening MechanismsSusheel SrinivasNo ratings yet

- Kuliah-6 MetFis2-Crystal InterfaceDocument59 pagesKuliah-6 MetFis2-Crystal InterfaceYusuf Bayu AjiNo ratings yet

- Kuliah-6 MetFis2-Crystal InterfaceDocument59 pagesKuliah-6 MetFis2-Crystal InterfaceYusuf Bayu AjiNo ratings yet

- DislocationMotion STR Recovery Ch7Document42 pagesDislocationMotion STR Recovery Ch7subodhcebNo ratings yet

- Imperfections in SolidsDocument50 pagesImperfections in Solidsavutu_kunduruNo ratings yet

- Single Crystal Slip: Adapted From Fig. 7.9, Callister 7eDocument15 pagesSingle Crystal Slip: Adapted From Fig. 7.9, Callister 7epriyabrata maharanaNo ratings yet

- Unit - I Lecture - 10 Slip Systems: Dr. K. Devendranath Ramkumar School of Mechanical & Building SciencesDocument21 pagesUnit - I Lecture - 10 Slip Systems: Dr. K. Devendranath Ramkumar School of Mechanical & Building SciencesyashvantNo ratings yet

- M2 Lec 1&2 - MmeDocument43 pagesM2 Lec 1&2 - MmeUsama ShameerNo ratings yet

- Chapter 04Document37 pagesChapter 04Husna MustafaNo ratings yet

- Crystal Defects: 1. Point Defects A. VacanciesDocument16 pagesCrystal Defects: 1. Point Defects A. VacanciesBlue_rabbit_2012No ratings yet

- Chapter 7 - Dislocations and Strengethening MechanismsDocument50 pagesChapter 7 - Dislocations and Strengethening MechanismsmikeengineeringNo ratings yet

- Dislocations: Basic ConceptsDocument27 pagesDislocations: Basic ConceptspavankcvsNo ratings yet

- 5.0.imperfections in SolidsDocument28 pages5.0.imperfections in SolidsBrian Quintero ArboledaNo ratings yet

- Crystal Defect.Document36 pagesCrystal Defect.Anand KumarNo ratings yet

- Machine Workshop: What I Have Done in My Visits To WorkshopDocument18 pagesMachine Workshop: What I Have Done in My Visits To WorkshopHarris DarNo ratings yet

- Scan ResultsDocument12 pagesScan ResultsHarris DarNo ratings yet

- Halliday's Function of Language Theory: Prof. Jamil AkhtarDocument11 pagesHalliday's Function of Language Theory: Prof. Jamil AkhtarHarris DarNo ratings yet

- WhitePaper CheckerDocument9 pagesWhitePaper CheckerHarris DarNo ratings yet

- MoniMax5100T Operator Manual V2Document279 pagesMoniMax5100T Operator Manual V2Harris DarNo ratings yet

- Iron Carbon Diagram 6Document15 pagesIron Carbon Diagram 6Harris DarNo ratings yet

- Course Outline BSC Mechanical Eng2015Document10 pagesCourse Outline BSC Mechanical Eng2015Harris DarNo ratings yet

- T4 MineralsDocument42 pagesT4 MineralsAra LimNo ratings yet

- Crystal StructuresDocument54 pagesCrystal StructuresyashvantNo ratings yet

- Lecture Notes - Physical Metallurgy - Materials Science and Engineering - MIT OpenCourseWareDocument3 pagesLecture Notes - Physical Metallurgy - Materials Science and Engineering - MIT OpenCourseWareSharek HasanNo ratings yet

- Weigner Seitz CellsDocument3 pagesWeigner Seitz CellsArooj MukarramNo ratings yet

- Chapter 5b Crystal Imperfections DislocationsDocument94 pagesChapter 5b Crystal Imperfections DislocationsSayantan DexNo ratings yet

- Metamorphism of Peltic RocksDocument13 pagesMetamorphism of Peltic RocksAvinash UpadhyayNo ratings yet

- Indogress AaaaaDocument12 pagesIndogress AaaaaMario Maharddhika SamkaraNo ratings yet

- Applied GeologyDocument826 pagesApplied GeologyJavier Vera100% (11)

- Solid State Physics 2 Edition/ Giuseppe Grosso: Geometrical Description of Crystals:Direct and Reciprocal LatticesDocument17 pagesSolid State Physics 2 Edition/ Giuseppe Grosso: Geometrical Description of Crystals:Direct and Reciprocal LatticesMia Kristina DamayantiNo ratings yet

- GLGY 471 - Lab 2: Earth Materials 1Document14 pagesGLGY 471 - Lab 2: Earth Materials 1Ayesha ANo ratings yet

- Research GemologistDocument3 pagesResearch Gemologistapi-78849285No ratings yet

- Ore Microscopy - Tanta Univ.Document52 pagesOre Microscopy - Tanta Univ.Edith FuentesNo ratings yet

- Guide To Optical Quartz Crystal: Left Handed Right HandedDocument1 pageGuide To Optical Quartz Crystal: Left Handed Right HandedPatParimiNo ratings yet

- Other Characteristics:: Name of Rock: Granite Type of Rock: IgneousDocument2 pagesOther Characteristics:: Name of Rock: Granite Type of Rock: IgneousKamal CENo ratings yet

- Phase Diagram: - Only Certain Compositions of Materials Are Allowed at ADocument16 pagesPhase Diagram: - Only Certain Compositions of Materials Are Allowed at AmailstonaikNo ratings yet

- G304 GE413 CrystallographyDocument2 pagesG304 GE413 CrystallographyDarwin Torres RojasNo ratings yet

- Solid State ChemistryDocument61 pagesSolid State ChemistrydhananjaylandgeNo ratings yet

- XRD Reading Material PDFDocument69 pagesXRD Reading Material PDFMith DongreNo ratings yet

- Star Ocean 2 - CustomizeDocument29 pagesStar Ocean 2 - CustomizeEduardoBugsNo ratings yet

- Mineral Resource and Ore Reserve Estimation: Second EditionDocument14 pagesMineral Resource and Ore Reserve Estimation: Second EditionRenzo YaringañoNo ratings yet

- Archangels CrystalsDocument2 pagesArchangels CrystalsSlavica Otovic100% (2)

- Craig Vaughan CHPTR 11 PDFDocument25 pagesCraig Vaughan CHPTR 11 PDFSharon BennyNo ratings yet

- Strunz Minerals (AA)Document227 pagesStrunz Minerals (AA)Abrianto AkuanNo ratings yet

- ch03 PDFDocument98 pagesch03 PDFMaha JanaNo ratings yet

- Sacred GeometryDocument8 pagesSacred GeometryMarie VictoireNo ratings yet

- 2C Crystalline and Noncrystalline MaterialsDocument8 pages2C Crystalline and Noncrystalline MaterialsAhmed AliNo ratings yet

- Critical Resolved Shear Stress - WikipediaDocument9 pagesCritical Resolved Shear Stress - WikipediaRaman dhimanNo ratings yet

Elastic and Plastic Deformation: - Metals Deform Both Elastically and Plastically

Elastic and Plastic Deformation: - Metals Deform Both Elastically and Plastically

Uploaded by

Harris DarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elastic and Plastic Deformation: - Metals Deform Both Elastically and Plastically

Elastic and Plastic Deformation: - Metals Deform Both Elastically and Plastically

Uploaded by

Harris DarCopyright:

Available Formats

Elastic And Plastic Deformation

• Metals deform both elastically and

plastically.

Elastic Deformation.

Plastic Deformation.

Deformation By Slip.

Deformation By Twinning.

Diff B/w Slip And Twinning.

Elastic deformation

• Elastic deformation takes place at low

stresses and has three main

characteristics, namely

• I) It is reversible .

• ii) Stress and strain are linearly

proportional to each other according to

Hook’s Law

• iii) It is usually small i.e < 1 % elastic

strain.

Plastic or permanent deformation

• Once the yield or flow stress has been

exceeded, plastic or permanent

deformation occurs.

• It take place by one of two simple

processes,

• I) Slip or glide

• ii) Twinning.

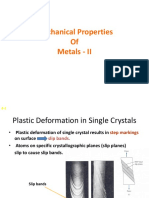

Deformation by Slip

• The usual method of plastic deformation in

metals is by

• Sliding a block of the crystal over one another

along definite crystallographic planes( slip

planes) in the specific slip direction, then

• A step is produced in the polished surface.

• When view a polished surface from the top

through a microscope, the step shows up as a

line , which is called as a slip line.

•Sliding a block of the

crystal over one another

along definite

crystallographic planes

( slip planes) in the

specific slip direction, then

•A step is produced in the

polished surface.

• When view a polished

surface from the top

through a microscope,

•The step shows up as a

line , which is called as a

slip line.

• Slip plane: is the plane of greatest atomic

density

• Slip direction: is the closet-packed

direction

• Slip system: Slip plane together with the

slip direction

• To prove that these slip directions lie in the

slip plane hu + kv + lw = 0 .

Face centered cubic Structure

• The four {111} octahedral planes are with

high atomic density.

• Three <110 > directions are the close-

packed direction.

• Therefore, the fcc lattice has 12 slip

system.

• Copper , Brass , aluminum are f.cc metals.

B.C.C Unit cell

Body centered cubic structure

• The {110} planes have the highest atomic

density in bcc structure, but they are not greatly

superior in this respect to {112} , {123} planes.

• However, in bcc structure four <111> directions

is closed packed direction in bcc structure.

• Slip in bcc metals is found to occur on the {110},

{112}, and {123} planes. Total twelve planes.

• Therefore, 48 possible slip system.

Hexagonal Closed-Packed metals

• Basal plane (0001) , only plane with high atomic

density in hcp structure.

• The axes<1120> , three closed packed

direction.

• Three Slip system in HCP structure.

• The limited number of slip systems is the reason

for the extreme orientation dependence and low

ductility in hcp metals.

Deformation by Twinning

• Deformation twinning is a process in which a

region of crystal undergoes a homogeneous

shear that produces the original crystal structure

in a new orientation.

• In the simplest case, this results in the atoms of

the original crystal (parent) and those of the

product crystal (twin) being mirror images of

each other by reflection in a composition plane.

• -The lattice strains needed to produced a twin

configuration in a crystal are small, so that the

amount of gross deformation that can be produced

by twinning is small.

• For example, the maximum extension which it is

possible to produced in a zinc crystal when entire

crystal is converted in to a twin on the plane {1012}

is only 7.39 percent.

• The important role of twining comes in plastic

deformation not from the strain produced by the

twinning process

• But from the fact that orientation changes resulting

from twinning may place a new slip systems in a

favourable orientation with respect to the stress axis

so that additional slip can take place.

• Thus, twinning is important in overall

deformation of metals with a low number of slip

systems, such as HCP metals.

• However it should be understood that only a

relatively small fraction of the total volume of a

crystal is oriented by twinning, and

• Therefore hcp metals will, in general, posses

less ductility than metals with a greater number

of slip systems.

• -Twinning occurs in a definite direction on a specific

crystallographic plane for each crystal structure.

• -Twinning stress is lower than the stress for slip and

occur at low temperatures or high stain rates.

• -The lattice strains needed to produce a twin

configuration in a crystal are small,

• so that the amount of gross deformation that can be

produced by twinning is small.

• -The important role of twining is to place a new slip

systems in a favorable orientation with respect to the

stress axis so that additional slip can take place.

Difference in Twinning compare to Slip

• -In slip orientation of the crystal above and below the slip

plane is the same after deformation.

-An orientation difference exist across the twin plane.

• -Slip is usually considered to occur in discrete multiples

of the atomic spacing.

-Movements are less than an atomic distance in twinning.

• -Slip occur on a relatively widely spread planes.

-Twining involve every atomic plane in the deformation.

• -There is a delay time of several milliseconds before a

slip band is formed.

-Twin can form in a time as short as few milli second.

You might also like

- Atm GuideDocument23 pagesAtm GuideGilbert Kamanzi100% (3)

- Diebold Atm Operator ManualDocument72 pagesDiebold Atm Operator ManualHarris Dar50% (2)

- Diebold Atm Operator ManualDocument4 pagesDiebold Atm Operator ManualHarris Dar0% (3)

- Diebold Atm Operator ManualDocument4 pagesDiebold Atm Operator ManualHarris Dar0% (3)

- GIA Colored Stones 8Document51 pagesGIA Colored Stones 8Judy Wallace Reed89% (9)

- Chapter 1 Solutions (Global Edition) : Prob. 1.1Document10 pagesChapter 1 Solutions (Global Edition) : Prob. 1.1靑山なつきNo ratings yet

- Solidification and Crystalline Imperfection Part 1Document25 pagesSolidification and Crystalline Imperfection Part 1Aiman MutallidNo ratings yet

- Dislocation TheoryDocument37 pagesDislocation TheoryAbbireddy Siva Ganesh100% (1)

- Introduction To Optical Mineralogy Willia - 59f150bd1723dd1e2af83188Document2 pagesIntroduction To Optical Mineralogy Willia - 59f150bd1723dd1e2af83188Bernhard ManurungNo ratings yet

- Blue Basic Concepts On Structure of SolidsDocument22 pagesBlue Basic Concepts On Structure of SolidsME011Mohsin BilalNo ratings yet

- Failure Mechanism of MatterDocument66 pagesFailure Mechanism of MatterSiva Kumar SalumuriNo ratings yet

- Lec3-Dislocation, Slip Systems and TwiningDocument32 pagesLec3-Dislocation, Slip Systems and Twiningsamurai7_77No ratings yet

- Elastic and Plastic Behaviour 2Document94 pagesElastic and Plastic Behaviour 2Anjana2893100% (1)

- Deformation & StrengthDocument35 pagesDeformation & StrengthcolorofstoneNo ratings yet

- Chap5 FinalDocument49 pagesChap5 Finalamanuelfitsum589No ratings yet

- Electronic Properties of Materials: Lecture - 3: Crystal DefectsDocument19 pagesElectronic Properties of Materials: Lecture - 3: Crystal DefectsKm. Rakibur RahmanNo ratings yet

- Material Deformations WorkshopDocument20 pagesMaterial Deformations WorkshopAman RajNo ratings yet

- Lec03 Plasticity P2Document35 pagesLec03 Plasticity P2Muna UnisaNo ratings yet

- Manufacturing Technology (ME361) Lecture 2: Shantanu BhattacharyaDocument21 pagesManufacturing Technology (ME361) Lecture 2: Shantanu BhattacharyaSahil SundaNo ratings yet

- Lecture 5 - Crystal Defects-Dislocations - 2 PDFDocument53 pagesLecture 5 - Crystal Defects-Dislocations - 2 PDFArpit Pradhan100% (1)

- Defects in Crystals PDFDocument31 pagesDefects in Crystals PDFChama9No ratings yet

- Engineering Materials-I: Chapter-4: Dislocations & Strengthening MechanismsDocument23 pagesEngineering Materials-I: Chapter-4: Dislocations & Strengthening MechanismsÇãłl Mê MęlkãNo ratings yet

- Material Deformations Workshop PDFDocument20 pagesMaterial Deformations Workshop PDFDimas SatriaNo ratings yet

- Manufacturing Processes (ME361) Lecture 3 and 4Document32 pagesManufacturing Processes (ME361) Lecture 3 and 4Randhir KyNo ratings yet

- Processing of Aerospace Materials Part I (ME772) : Crystal Structures, Imperfections, Slip and Strain Hardening in MetalsDocument19 pagesProcessing of Aerospace Materials Part I (ME772) : Crystal Structures, Imperfections, Slip and Strain Hardening in MetalsB RITHIKANo ratings yet

- Plastic Deformation, Flow Stress and FormabilityDocument35 pagesPlastic Deformation, Flow Stress and FormabilityAnna100% (2)

- Single Crystal Slip: Adapted From Fig. 7.9, Callister 7eDocument15 pagesSingle Crystal Slip: Adapted From Fig. 7.9, Callister 7eavenashaNo ratings yet

- EBT211 - Lecture 6 - Slip PDFDocument36 pagesEBT211 - Lecture 6 - Slip PDFSollehah SuhaimiNo ratings yet

- Elastic and Plastic BehaviourDocument94 pagesElastic and Plastic BehaviournavneeshvNo ratings yet

- ME 1022 Materials TechnologyDocument77 pagesME 1022 Materials TechnologyShubham PadwalNo ratings yet

- Manufacturing Processes (ME361) Lecture 25 and 27Document40 pagesManufacturing Processes (ME361) Lecture 25 and 27RandhirKumarNo ratings yet

- 1 - Deformation of Materials-1Document89 pages1 - Deformation of Materials-1Revanth MuralidharNo ratings yet

- Mechanical Behavior IIIDocument16 pagesMechanical Behavior IIIVidushi MakhijaNo ratings yet

- MM207 Group 11Document52 pagesMM207 Group 11nitharsunNo ratings yet

- Chap 6Document22 pagesChap 6api-3803993100% (1)

- Schmid's Law: Plastic Deformation (SLIP) in Polycrystalline MaterialsDocument3 pagesSchmid's Law: Plastic Deformation (SLIP) in Polycrystalline MaterialsyashvantNo ratings yet

- Twinning 1Document10 pagesTwinning 1AnjaniAkulaNo ratings yet

- Keanu Husein Material TestingDocument2 pagesKeanu Husein Material TestingKeanu MitchellNo ratings yet

- Closed-Book Practice-Ch 07 (2016!12!24)Document8 pagesClosed-Book Practice-Ch 07 (2016!12!24)JuanNo ratings yet

- DislocationsDocument11 pagesDislocationsraghcharashNo ratings yet

- Fracture Mechanics 1 EBB 334Document37 pagesFracture Mechanics 1 EBB 334Luiz CordeiroNo ratings yet

- Ipmem BookDocument55 pagesIpmem BookRamesh NayakNo ratings yet

- MS Module 3Document16 pagesMS Module 3Affan KhanNo ratings yet

- Solidification, Solid Solutions and Diffusion in SolidsDocument43 pagesSolidification, Solid Solutions and Diffusion in SolidsKelvin MugwagwaNo ratings yet

- 04 Plastic Deformation of Single Crystal-21-42Document22 pages04 Plastic Deformation of Single Crystal-21-42Aravind SomasundaramNo ratings yet

- Slip Systems and TwinningDocument33 pagesSlip Systems and TwinningAyush ShahNo ratings yet

- Basics of Physical Metallurgy MM 2107Document22 pagesBasics of Physical Metallurgy MM 2107srujan baluNo ratings yet

- Imperfections in Solid Materials - Ch4Document40 pagesImperfections in Solid Materials - Ch4aa454No ratings yet

- Ch. 2Document27 pagesCh. 2mhmdramdan.208200No ratings yet

- Mechanical Behavior IIDocument29 pagesMechanical Behavior IIVidushi MakhijaNo ratings yet

- 4 Deformation and Strengthening MechanismsDocument90 pages4 Deformation and Strengthening MechanismsSusheel SrinivasNo ratings yet

- Kuliah-6 MetFis2-Crystal InterfaceDocument59 pagesKuliah-6 MetFis2-Crystal InterfaceYusuf Bayu AjiNo ratings yet

- Kuliah-6 MetFis2-Crystal InterfaceDocument59 pagesKuliah-6 MetFis2-Crystal InterfaceYusuf Bayu AjiNo ratings yet

- DislocationMotion STR Recovery Ch7Document42 pagesDislocationMotion STR Recovery Ch7subodhcebNo ratings yet

- Imperfections in SolidsDocument50 pagesImperfections in Solidsavutu_kunduruNo ratings yet

- Single Crystal Slip: Adapted From Fig. 7.9, Callister 7eDocument15 pagesSingle Crystal Slip: Adapted From Fig. 7.9, Callister 7epriyabrata maharanaNo ratings yet

- Unit - I Lecture - 10 Slip Systems: Dr. K. Devendranath Ramkumar School of Mechanical & Building SciencesDocument21 pagesUnit - I Lecture - 10 Slip Systems: Dr. K. Devendranath Ramkumar School of Mechanical & Building SciencesyashvantNo ratings yet

- M2 Lec 1&2 - MmeDocument43 pagesM2 Lec 1&2 - MmeUsama ShameerNo ratings yet

- Chapter 04Document37 pagesChapter 04Husna MustafaNo ratings yet

- Crystal Defects: 1. Point Defects A. VacanciesDocument16 pagesCrystal Defects: 1. Point Defects A. VacanciesBlue_rabbit_2012No ratings yet

- Chapter 7 - Dislocations and Strengethening MechanismsDocument50 pagesChapter 7 - Dislocations and Strengethening MechanismsmikeengineeringNo ratings yet

- Dislocations: Basic ConceptsDocument27 pagesDislocations: Basic ConceptspavankcvsNo ratings yet

- 5.0.imperfections in SolidsDocument28 pages5.0.imperfections in SolidsBrian Quintero ArboledaNo ratings yet

- Crystal Defect.Document36 pagesCrystal Defect.Anand KumarNo ratings yet

- Machine Workshop: What I Have Done in My Visits To WorkshopDocument18 pagesMachine Workshop: What I Have Done in My Visits To WorkshopHarris DarNo ratings yet

- Scan ResultsDocument12 pagesScan ResultsHarris DarNo ratings yet

- Halliday's Function of Language Theory: Prof. Jamil AkhtarDocument11 pagesHalliday's Function of Language Theory: Prof. Jamil AkhtarHarris DarNo ratings yet

- WhitePaper CheckerDocument9 pagesWhitePaper CheckerHarris DarNo ratings yet

- MoniMax5100T Operator Manual V2Document279 pagesMoniMax5100T Operator Manual V2Harris DarNo ratings yet

- Iron Carbon Diagram 6Document15 pagesIron Carbon Diagram 6Harris DarNo ratings yet

- Course Outline BSC Mechanical Eng2015Document10 pagesCourse Outline BSC Mechanical Eng2015Harris DarNo ratings yet

- T4 MineralsDocument42 pagesT4 MineralsAra LimNo ratings yet

- Crystal StructuresDocument54 pagesCrystal StructuresyashvantNo ratings yet

- Lecture Notes - Physical Metallurgy - Materials Science and Engineering - MIT OpenCourseWareDocument3 pagesLecture Notes - Physical Metallurgy - Materials Science and Engineering - MIT OpenCourseWareSharek HasanNo ratings yet

- Weigner Seitz CellsDocument3 pagesWeigner Seitz CellsArooj MukarramNo ratings yet

- Chapter 5b Crystal Imperfections DislocationsDocument94 pagesChapter 5b Crystal Imperfections DislocationsSayantan DexNo ratings yet

- Metamorphism of Peltic RocksDocument13 pagesMetamorphism of Peltic RocksAvinash UpadhyayNo ratings yet

- Indogress AaaaaDocument12 pagesIndogress AaaaaMario Maharddhika SamkaraNo ratings yet

- Applied GeologyDocument826 pagesApplied GeologyJavier Vera100% (11)

- Solid State Physics 2 Edition/ Giuseppe Grosso: Geometrical Description of Crystals:Direct and Reciprocal LatticesDocument17 pagesSolid State Physics 2 Edition/ Giuseppe Grosso: Geometrical Description of Crystals:Direct and Reciprocal LatticesMia Kristina DamayantiNo ratings yet

- GLGY 471 - Lab 2: Earth Materials 1Document14 pagesGLGY 471 - Lab 2: Earth Materials 1Ayesha ANo ratings yet

- Research GemologistDocument3 pagesResearch Gemologistapi-78849285No ratings yet

- Ore Microscopy - Tanta Univ.Document52 pagesOre Microscopy - Tanta Univ.Edith FuentesNo ratings yet

- Guide To Optical Quartz Crystal: Left Handed Right HandedDocument1 pageGuide To Optical Quartz Crystal: Left Handed Right HandedPatParimiNo ratings yet

- Other Characteristics:: Name of Rock: Granite Type of Rock: IgneousDocument2 pagesOther Characteristics:: Name of Rock: Granite Type of Rock: IgneousKamal CENo ratings yet

- Phase Diagram: - Only Certain Compositions of Materials Are Allowed at ADocument16 pagesPhase Diagram: - Only Certain Compositions of Materials Are Allowed at AmailstonaikNo ratings yet

- G304 GE413 CrystallographyDocument2 pagesG304 GE413 CrystallographyDarwin Torres RojasNo ratings yet

- Solid State ChemistryDocument61 pagesSolid State ChemistrydhananjaylandgeNo ratings yet

- XRD Reading Material PDFDocument69 pagesXRD Reading Material PDFMith DongreNo ratings yet

- Star Ocean 2 - CustomizeDocument29 pagesStar Ocean 2 - CustomizeEduardoBugsNo ratings yet

- Mineral Resource and Ore Reserve Estimation: Second EditionDocument14 pagesMineral Resource and Ore Reserve Estimation: Second EditionRenzo YaringañoNo ratings yet

- Archangels CrystalsDocument2 pagesArchangels CrystalsSlavica Otovic100% (2)

- Craig Vaughan CHPTR 11 PDFDocument25 pagesCraig Vaughan CHPTR 11 PDFSharon BennyNo ratings yet

- Strunz Minerals (AA)Document227 pagesStrunz Minerals (AA)Abrianto AkuanNo ratings yet

- ch03 PDFDocument98 pagesch03 PDFMaha JanaNo ratings yet

- Sacred GeometryDocument8 pagesSacred GeometryMarie VictoireNo ratings yet

- 2C Crystalline and Noncrystalline MaterialsDocument8 pages2C Crystalline and Noncrystalline MaterialsAhmed AliNo ratings yet

- Critical Resolved Shear Stress - WikipediaDocument9 pagesCritical Resolved Shear Stress - WikipediaRaman dhimanNo ratings yet