Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

257 viewsNorthvale Steam Ejector Basics. 1

Northvale Steam Ejector Basics. 1

Uploaded by

eldwin_dj7216The document discusses eductors, which use a high velocity liquid jet to draw in and mix with a suction fluid. Eductors have no moving parts, are self-priming, and can lift or dilute fluids. They work by pressurized liquid entering a nozzle and generating a low pressure area to entrain the suction fluid. The mixed streams are then reconverted to pressure in a diffuser. Common eductor applications include pumping, mixing, aeration, dilution, and vacuum production. Design considerations include backpressure risks and needing a high motive pressure drop.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You might also like

- Client Name: XXX: Standard Operating ProcedureDocument6 pagesClient Name: XXX: Standard Operating ProcedureEra Enviro Solitions100% (2)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Manual P160Document11 pagesManual P160Jefril SiruNo ratings yet

- Jet MixingDocument5 pagesJet MixingSalman SheikhNo ratings yet

- ChokeDocument32 pagesChokerobertmikaNo ratings yet

- Experiment No. 1 Performance Test of Centrifugal PumpDocument24 pagesExperiment No. 1 Performance Test of Centrifugal PumpAli Requiso MahmudNo ratings yet

- Pressure Loss Experiment Gunt Hamburg HM 150.29Document2 pagesPressure Loss Experiment Gunt Hamburg HM 150.29eldwin_dj7216No ratings yet

- 37 - BQ WWTP 250 m3 - Project Pabrik Di Subang - Pt. Pelita Cengkareng PaperDocument3 pages37 - BQ WWTP 250 m3 - Project Pabrik Di Subang - Pt. Pelita Cengkareng PaperRully Ric Archt100% (1)

- Optimizing Purchasing Processes Saves 1 MillionDocument4 pagesOptimizing Purchasing Processes Saves 1 MillionMargara PerezNo ratings yet

- Liquid Jet EductorsDocument4 pagesLiquid Jet EductorsCookiemon100% (1)

- To Contain and To DeliverDocument5 pagesTo Contain and To DeliverMariel AbatayoNo ratings yet

- Vacuum System: Plant Engineer OleochemicalDocument55 pagesVacuum System: Plant Engineer OleochemicalMahendra Puguh100% (2)

- Tank EductorDocument3 pagesTank Eductorkonainglincho001No ratings yet

- Case Studies PDFDocument12 pagesCase Studies PDFDhruv BajpaiNo ratings yet

- Ejectors and EductorsDocument9 pagesEjectors and EductorsGanesan BalrajNo ratings yet

- 8.4 - Extraction and Washing Guide: OverviewDocument4 pages8.4 - Extraction and Washing Guide: OverviewDhruv PatelNo ratings yet

- Osmotic Methods of Liquid Food Concentration: Rinku Vithayathil REG - NO.2012412010Document22 pagesOsmotic Methods of Liquid Food Concentration: Rinku Vithayathil REG - NO.2012412010ervaishaliNo ratings yet

- Distillation (Part 2) : (DR.) Mirza Salman BaigDocument31 pagesDistillation (Part 2) : (DR.) Mirza Salman BaigSrđan TufegdžićNo ratings yet

- Pump Cavitation-Chemical EngineeringDocument1 pagePump Cavitation-Chemical EngineeringPavithiranNo ratings yet

- Cleaning Procedures DOW Filmtec Membranes LDocument7 pagesCleaning Procedures DOW Filmtec Membranes LAjay PatelNo ratings yet

- API冲洗方式 PDFDocument52 pagesAPI冲洗方式 PDF唐文义No ratings yet

- Pump - Suction Side System DesignDocument9 pagesPump - Suction Side System Designashumishra007100% (1)

- DEPC Treated Water RecipeDocument3 pagesDEPC Treated Water RecipeAnisam AbhiNo ratings yet

- Liquid Liquid ExtractionDocument25 pagesLiquid Liquid ExtractionAllensius Karelsta HarefaNo ratings yet

- Pervaporation Comes of Age: Reactions and SeparationsDocument7 pagesPervaporation Comes of Age: Reactions and SeparationsJUNIORNo ratings yet

- Manual P1000 PP - ALUDocument11 pagesManual P1000 PP - ALUJefril SiruNo ratings yet

- Core Sampling Recommended ProceduresDocument16 pagesCore Sampling Recommended ProceduresAgus Wahyu SetiawanNo ratings yet

- Solvent-Free Consolidation System Controls Proppant FlowbackDocument2 pagesSolvent-Free Consolidation System Controls Proppant Flowbackkumar abhishek singhNo ratings yet

- Tyco FoamDocument8 pagesTyco FoamAhrian BenaNo ratings yet

- Chapter 02Document62 pagesChapter 02Rushanth ChandraboseNo ratings yet

- Chap8 BioreactorDocument16 pagesChap8 Bioreactorprathaps1987No ratings yet

- Api 52Document3 pagesApi 52Sofiane HalimiNo ratings yet

- What Does Choke Valve MeanDocument5 pagesWhat Does Choke Valve MeanWael_Barakat_3179No ratings yet

- Chapter 02Document62 pagesChapter 02Rushanth ChandraboseNo ratings yet

- Evap and Crystal - QUICEDocument8 pagesEvap and Crystal - QUICERomel AlojadoNo ratings yet

- Pervaporation Introduction and ApplicationsDocument14 pagesPervaporation Introduction and ApplicationsAbdullah TasleemNo ratings yet

- Gear Pump Troubleshooting Guide 2Document12 pagesGear Pump Troubleshooting Guide 2tepu msosaNo ratings yet

- VAcuum Systems ComparisionDocument8 pagesVAcuum Systems ComparisionSANTOSHNo ratings yet

- Cleaning FT30 2005 pH13Document7 pagesCleaning FT30 2005 pH13gulfengsolutionsNo ratings yet

- Basic Knowledge About GC - Some Day You Need ThisDocument55 pagesBasic Knowledge About GC - Some Day You Need Thismn mustaffaNo ratings yet

- PHPA TestDocument2 pagesPHPA TestRagha RagNo ratings yet

- Distillation Column and ApplicationDocument59 pagesDistillation Column and ApplicationMahmoud HagagNo ratings yet

- Tank Mixing Eductors.: Features and SpecificationsDocument4 pagesTank Mixing Eductors.: Features and Specificationshoangvubui4632No ratings yet

- Cleaning and Disinfection Procedures For FILMTEC NF200 and NF270 ElementsDocument4 pagesCleaning and Disinfection Procedures For FILMTEC NF200 and NF270 ElementsgulfengsolutionsNo ratings yet

- K Brian & E RochaisDocument16 pagesK Brian & E RochaisLuigi Andrew MercadoNo ratings yet

- EjectorsDocument4 pagesEjectorsTirathBaxiNo ratings yet

- Maintenance and Troubleshooting of Oil Diffusion PumpsDocument5 pagesMaintenance and Troubleshooting of Oil Diffusion PumpsM Suraj KumarNo ratings yet

- 2Cl Adriano 2Cl Danao 2Cl DomalaonDocument14 pages2Cl Adriano 2Cl Danao 2Cl DomalaonclainNo ratings yet

- Evaporation & Evaporators: Prepared By:-Kuldeep BhattDocument26 pagesEvaporation & Evaporators: Prepared By:-Kuldeep BhattKuldeep BhattNo ratings yet

- Principles and Applications of Jet Aeration: Mixing Systems, IncDocument8 pagesPrinciples and Applications of Jet Aeration: Mixing Systems, IncRonaldo LeiteNo ratings yet

- Matachana - AP4 - Water Treatment System For Steriliser - User ManualDocument8 pagesMatachana - AP4 - Water Treatment System For Steriliser - User ManualWahidi AzaniNo ratings yet

- P700 Series MAXPUMP P65 Series: Diaphragm Pump Manual BookDocument9 pagesP700 Series MAXPUMP P65 Series: Diaphragm Pump Manual BookJefril SiruNo ratings yet

- Chapter 3 Low Expansion Foam SystemsDocument73 pagesChapter 3 Low Expansion Foam SystemsYusrizalNo ratings yet

- Self Priming PumpsxDocument3 pagesSelf Priming PumpsxFabio MiguelNo ratings yet

- Cleaning Membranes Elements - PD PDFDocument7 pagesCleaning Membranes Elements - PD PDFDaniel BolivarNo ratings yet

- Visual Encyclopedia of Chemical Engineering Adsorbers: About AdsorptionDocument26 pagesVisual Encyclopedia of Chemical Engineering Adsorbers: About AdsorptionVanNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- How Reverse Osmosis Works: A Look at Industrial ROFrom EverandHow Reverse Osmosis Works: A Look at Industrial RORating: 2.5 out of 5 stars2.5/5 (2)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersFrom EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersRating: 4.5 out of 5 stars4.5/5 (2)

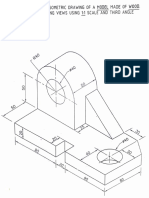

- Projection: Draw The Following Views Using 11 Scale and Third AngleDocument1 pageProjection: Draw The Following Views Using 11 Scale and Third Angleeldwin_dj7216No ratings yet

- Kaeser Compressors ASD 37 T - ME Dept OwnedDocument11 pagesKaeser Compressors ASD 37 T - ME Dept Ownedeldwin_dj7216100% (1)

- Comparison of Turbulence Models On 2D Backward Facing StepDocument16 pagesComparison of Turbulence Models On 2D Backward Facing Stepeldwin_dj7216No ratings yet

- GEA Steam-Jet-Vacuum-Pumps Brochure EN tcm11-22950 PDFDocument8 pagesGEA Steam-Jet-Vacuum-Pumps Brochure EN tcm11-22950 PDFeldwin_dj7216No ratings yet

- Lid Driven Cavity Flow OK Final EldwinDocument33 pagesLid Driven Cavity Flow OK Final Eldwineldwin_dj7216No ratings yet

- 2012 MIT KFUPM McGovern Ejector Efficiency PDFDocument12 pages2012 MIT KFUPM McGovern Ejector Efficiency PDFeldwin_dj7216No ratings yet

- ELDWIN Term Paper Boundary Layer Flow of A Nanofluid Over A Stretching SurfaceDocument15 pagesELDWIN Term Paper Boundary Layer Flow of A Nanofluid Over A Stretching Surfaceeldwin_dj7216No ratings yet

- Radiative Heat Transfer ProblemsDocument10 pagesRadiative Heat Transfer Problemseldwin_dj7216No ratings yet

- 2D Airfoil Meshing Tutorial in ICEM CFDDocument11 pages2D Airfoil Meshing Tutorial in ICEM CFDsvkindiaNo ratings yet

- Heat Transfer PHD Qualifying ExamDocument13 pagesHeat Transfer PHD Qualifying Exameldwin_dj7216No ratings yet

- JMST Journal EldwinDocument10 pagesJMST Journal Eldwineldwin_dj7216No ratings yet

- Mathematics Extension 2 HSC LevelDocument250 pagesMathematics Extension 2 HSC LevelkalstarNo ratings yet

- 2011 Sanjeeva - Ding - Ref - Stability of Nano Fluids in Quiescent and Shear Flow FieldsDocument6 pages2011 Sanjeeva - Ding - Ref - Stability of Nano Fluids in Quiescent and Shear Flow Fieldseldwin_dj7216No ratings yet

- Huawei OceanStor Dorado V6 All-Flash Storage Systems Pre-Sales Training....Document59 pagesHuawei OceanStor Dorado V6 All-Flash Storage Systems Pre-Sales Training....Wolf-Karsten Heintel100% (1)

- Man S20WDocument16 pagesMan S20WngocNo ratings yet

- New Generation in Pre-Heating TechnologyDocument16 pagesNew Generation in Pre-Heating TechnologymetudgnNo ratings yet

- Fisher Optimized Antisurge Control Valves: High Reliability To Meet World-Class Production DemandsDocument12 pagesFisher Optimized Antisurge Control Valves: High Reliability To Meet World-Class Production DemandsBeomHee LeeNo ratings yet

- Conexion en Power BuilderDocument252 pagesConexion en Power BuilderJuan Zem ZemNo ratings yet

- Poljoprivredni TraktoriDocument13 pagesPoljoprivredni TraktoriDražan MiloložaNo ratings yet

- Eardley Resume FinalDocument2 pagesEardley Resume Finalapi-298854508No ratings yet

- Cooling Water Systems FundamentalsDocument13 pagesCooling Water Systems FundamentalsAlfonso José García Laguna100% (3)

- Materiales BombasDocument132 pagesMateriales BombasCarlos JuárezNo ratings yet

- Combination Smoke and Heat Detector: Horing Lih Industrial Co., LTDDocument1 pageCombination Smoke and Heat Detector: Horing Lih Industrial Co., LTDIhsan OzzyNo ratings yet

- SUNTECH EN HiPower STP385S B60 WNH (MC4 385 365) 4G S3Document2 pagesSUNTECH EN HiPower STP385S B60 WNH (MC4 385 365) 4G S3Quốc Huy VũNo ratings yet

- Vertical Take Off and Landing Powerplant For AircraftsDocument5 pagesVertical Take Off and Landing Powerplant For AircraftsLiviu GiurcaNo ratings yet

- LSPB Trajectory Planning Design For The ModularDocument4 pagesLSPB Trajectory Planning Design For The ModularbasantsahuNo ratings yet

- Important: MMH Series Utility HeatersDocument2 pagesImportant: MMH Series Utility HeatersJames LoewenNo ratings yet

- A Discipline of TeamsDocument2 pagesA Discipline of TeamsAditya Bhat100% (1)

- CRD - c55 (1) Within Batch Uniformity FRSH ConcreteDocument6 pagesCRD - c55 (1) Within Batch Uniformity FRSH ConcreteKothiyal MukeshNo ratings yet

- The Best Way To Solve The World's Environmental Problems Is To Increase The Cost of Fuel. To What Extend Do You Agree or DisagreeDocument2 pagesThe Best Way To Solve The World's Environmental Problems Is To Increase The Cost of Fuel. To What Extend Do You Agree or DisagreeJagpreet Singh RandhawaNo ratings yet

- Un Esposo Conforme Al Corazon de Dios Spanish Edition by Jim George 0825412692Document5 pagesUn Esposo Conforme Al Corazon de Dios Spanish Edition by Jim George 0825412692Carlos Salgueiro VillarrealNo ratings yet

- UTC LM8560 Mos Ic: Digital Alarm ClockDocument9 pagesUTC LM8560 Mos Ic: Digital Alarm ClockAntonio De NobregaNo ratings yet

- Army Chemical Review #1 (2002)Document52 pagesArmy Chemical Review #1 (2002)Reid Kirby100% (1)

- Airbus AC A320 Jun2012Document607 pagesAirbus AC A320 Jun2012Rommel UparelaNo ratings yet

- F5 CW4 26 Nov 2012 AnswerDocument3 pagesF5 CW4 26 Nov 2012 AnswerLeo ChanNo ratings yet

- Success Story of TcsDocument8 pagesSuccess Story of TcsAjita TrivediNo ratings yet

- Static Metrics For CDocument3 pagesStatic Metrics For Cabhishek100% (1)

- Sugar Mill DrivesDocument8 pagesSugar Mill Drivessayyadmannan67% (3)

- Lecture19 150211 PDFDocument34 pagesLecture19 150211 PDFAbhishek SinghNo ratings yet

- 17mf023 Research Methodology LT P c3 0 0 3Document2 pages17mf023 Research Methodology LT P c3 0 0 3egspec.praveenNo ratings yet

- The PC Technicians Tune Up ManualDocument37 pagesThe PC Technicians Tune Up ManualJarvis Edwards100% (3)

Northvale Steam Ejector Basics. 1

Northvale Steam Ejector Basics. 1

Uploaded by

eldwin_dj72160 ratings0% found this document useful (0 votes)

257 views16 pagesThe document discusses eductors, which use a high velocity liquid jet to draw in and mix with a suction fluid. Eductors have no moving parts, are self-priming, and can lift or dilute fluids. They work by pressurized liquid entering a nozzle and generating a low pressure area to entrain the suction fluid. The mixed streams are then reconverted to pressure in a diffuser. Common eductor applications include pumping, mixing, aeration, dilution, and vacuum production. Design considerations include backpressure risks and needing a high motive pressure drop.

Original Description:

Original Title

Northvale-Steam-Ejector-Basics.-1.ppt

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses eductors, which use a high velocity liquid jet to draw in and mix with a suction fluid. Eductors have no moving parts, are self-priming, and can lift or dilute fluids. They work by pressurized liquid entering a nozzle and generating a low pressure area to entrain the suction fluid. The mixed streams are then reconverted to pressure in a diffuser. Common eductor applications include pumping, mixing, aeration, dilution, and vacuum production. Design considerations include backpressure risks and needing a high motive pressure drop.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

257 views16 pagesNorthvale Steam Ejector Basics. 1

Northvale Steam Ejector Basics. 1

Uploaded by

eldwin_dj7216The document discusses eductors, which use a high velocity liquid jet to draw in and mix with a suction fluid. Eductors have no moving parts, are self-priming, and can lift or dilute fluids. They work by pressurized liquid entering a nozzle and generating a low pressure area to entrain the suction fluid. The mixed streams are then reconverted to pressure in a diffuser. Common eductor applications include pumping, mixing, aeration, dilution, and vacuum production. Design considerations include backpressure risks and needing a high motive pressure drop.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 16

Northvale Korting Fluid Jet

Theory and Applications of Eductors

By

Patrick Belcher

Eductor Basics.-1

Pressurised liquid is fed, at normal pipeline

velocity, into the motive fluid connection. 1

Eductor Basics.-2

The motive fluid enters the nozzle and is sent into the

suction chamber as a high velocity, low pressure jet.

This generates a low pressure area in the chamber.

Eductor Basics.-3

The low pressure area entrains or draws in the

suction fluid.

Both streams are thoroughly mixed within the

turbulent area of the diffuser throat.

Eductor Basics.-4

In the outlet cone of the diffuser, the velocity of the mixed

stream is converted back to pressure energy

This enables the eductor to overcome a discharge head

which is higher than the suction head but lower than the

motive pressure.

Pumping

Maximum lift 8mwg

Lift affected by

specific Gravity

Performance is

dependent on motive

water pressure and

flow rate.

Vacuum Producing

Liquid or gas

Used for pump priming

Vessel evacuation

Fume Extraction

Aeration 1

Adds compressed air to water

Small bubbles promote solubility

Mixing throat increases intimacy between air

& fluid

Aeration 2

Uses atmospheric air.

Mixes tank contents

Aids flocculation

Mixing 1

Standard mixing

application.

3:1 mixing

No. of nozzles and

orientation depending

on tank shape.

Dilution 1

Can dilute and lift at

the same time.

Control dilution using

suction valve.

Risk of backflow if

discharge pressure too

high.

PTFE lined option

Dilution 2

Scheme for high dilution ratios.

Around the pump loop. Uses the pressure differential

between inlet & outlet of pump.

Does not create a permanent pressure loss in the pump

discharge line. Can be isolated when not required.

Additional mixing created by pump action.

Hopper Eductor

Used to

introduce

powders in

to liquid

stream

To make

lime

solution.

Eductor Benefits

No moving parts. Available in virtually

– Minimal Maintenance all materials

– Use in restricted space – Carbon Steel

– Suitable for hazardous – Stainless

zones

/316/304/Duplex

Can run with no – PTFE lined pipe

suction flow, or with

– Poly Propylene

entrained solids.

– UPVC

Self Priming

– ABS

– Ideal for intermittent

use – Hastelloy

Design Considerations.

High backpressure a problem => Backflow

to suction branch.

Requires a high pressure drop - Typical

discharge pressure < 0.5 Motive pressure.

Best designed for single motive operating

point. Adjust mixture by suction, not by

motive

Flow from bottom of tank could be of

benefit.

Eductor Uses

GAC/ Sand/Resin Dissolved air flotation

removal. Pumping

Dilution – Emptying pits and bunds

– Suction of concentrates Tank mixing

» Sulphuric Acid

» Caustic

System priming

» Brine

» Citric Acid

» Orthophosphoric acid

» Anti foaming agent

» Hypochlorite solution

You might also like

- Client Name: XXX: Standard Operating ProcedureDocument6 pagesClient Name: XXX: Standard Operating ProcedureEra Enviro Solitions100% (2)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Manual P160Document11 pagesManual P160Jefril SiruNo ratings yet

- Jet MixingDocument5 pagesJet MixingSalman SheikhNo ratings yet

- ChokeDocument32 pagesChokerobertmikaNo ratings yet

- Experiment No. 1 Performance Test of Centrifugal PumpDocument24 pagesExperiment No. 1 Performance Test of Centrifugal PumpAli Requiso MahmudNo ratings yet

- Pressure Loss Experiment Gunt Hamburg HM 150.29Document2 pagesPressure Loss Experiment Gunt Hamburg HM 150.29eldwin_dj7216No ratings yet

- 37 - BQ WWTP 250 m3 - Project Pabrik Di Subang - Pt. Pelita Cengkareng PaperDocument3 pages37 - BQ WWTP 250 m3 - Project Pabrik Di Subang - Pt. Pelita Cengkareng PaperRully Ric Archt100% (1)

- Optimizing Purchasing Processes Saves 1 MillionDocument4 pagesOptimizing Purchasing Processes Saves 1 MillionMargara PerezNo ratings yet

- Liquid Jet EductorsDocument4 pagesLiquid Jet EductorsCookiemon100% (1)

- To Contain and To DeliverDocument5 pagesTo Contain and To DeliverMariel AbatayoNo ratings yet

- Vacuum System: Plant Engineer OleochemicalDocument55 pagesVacuum System: Plant Engineer OleochemicalMahendra Puguh100% (2)

- Tank EductorDocument3 pagesTank Eductorkonainglincho001No ratings yet

- Case Studies PDFDocument12 pagesCase Studies PDFDhruv BajpaiNo ratings yet

- Ejectors and EductorsDocument9 pagesEjectors and EductorsGanesan BalrajNo ratings yet

- 8.4 - Extraction and Washing Guide: OverviewDocument4 pages8.4 - Extraction and Washing Guide: OverviewDhruv PatelNo ratings yet

- Osmotic Methods of Liquid Food Concentration: Rinku Vithayathil REG - NO.2012412010Document22 pagesOsmotic Methods of Liquid Food Concentration: Rinku Vithayathil REG - NO.2012412010ervaishaliNo ratings yet

- Distillation (Part 2) : (DR.) Mirza Salman BaigDocument31 pagesDistillation (Part 2) : (DR.) Mirza Salman BaigSrđan TufegdžićNo ratings yet

- Pump Cavitation-Chemical EngineeringDocument1 pagePump Cavitation-Chemical EngineeringPavithiranNo ratings yet

- Cleaning Procedures DOW Filmtec Membranes LDocument7 pagesCleaning Procedures DOW Filmtec Membranes LAjay PatelNo ratings yet

- API冲洗方式 PDFDocument52 pagesAPI冲洗方式 PDF唐文义No ratings yet

- Pump - Suction Side System DesignDocument9 pagesPump - Suction Side System Designashumishra007100% (1)

- DEPC Treated Water RecipeDocument3 pagesDEPC Treated Water RecipeAnisam AbhiNo ratings yet

- Liquid Liquid ExtractionDocument25 pagesLiquid Liquid ExtractionAllensius Karelsta HarefaNo ratings yet

- Pervaporation Comes of Age: Reactions and SeparationsDocument7 pagesPervaporation Comes of Age: Reactions and SeparationsJUNIORNo ratings yet

- Manual P1000 PP - ALUDocument11 pagesManual P1000 PP - ALUJefril SiruNo ratings yet

- Core Sampling Recommended ProceduresDocument16 pagesCore Sampling Recommended ProceduresAgus Wahyu SetiawanNo ratings yet

- Solvent-Free Consolidation System Controls Proppant FlowbackDocument2 pagesSolvent-Free Consolidation System Controls Proppant Flowbackkumar abhishek singhNo ratings yet

- Tyco FoamDocument8 pagesTyco FoamAhrian BenaNo ratings yet

- Chapter 02Document62 pagesChapter 02Rushanth ChandraboseNo ratings yet

- Chap8 BioreactorDocument16 pagesChap8 Bioreactorprathaps1987No ratings yet

- Api 52Document3 pagesApi 52Sofiane HalimiNo ratings yet

- What Does Choke Valve MeanDocument5 pagesWhat Does Choke Valve MeanWael_Barakat_3179No ratings yet

- Chapter 02Document62 pagesChapter 02Rushanth ChandraboseNo ratings yet

- Evap and Crystal - QUICEDocument8 pagesEvap and Crystal - QUICERomel AlojadoNo ratings yet

- Pervaporation Introduction and ApplicationsDocument14 pagesPervaporation Introduction and ApplicationsAbdullah TasleemNo ratings yet

- Gear Pump Troubleshooting Guide 2Document12 pagesGear Pump Troubleshooting Guide 2tepu msosaNo ratings yet

- VAcuum Systems ComparisionDocument8 pagesVAcuum Systems ComparisionSANTOSHNo ratings yet

- Cleaning FT30 2005 pH13Document7 pagesCleaning FT30 2005 pH13gulfengsolutionsNo ratings yet

- Basic Knowledge About GC - Some Day You Need ThisDocument55 pagesBasic Knowledge About GC - Some Day You Need Thismn mustaffaNo ratings yet

- PHPA TestDocument2 pagesPHPA TestRagha RagNo ratings yet

- Distillation Column and ApplicationDocument59 pagesDistillation Column and ApplicationMahmoud HagagNo ratings yet

- Tank Mixing Eductors.: Features and SpecificationsDocument4 pagesTank Mixing Eductors.: Features and Specificationshoangvubui4632No ratings yet

- Cleaning and Disinfection Procedures For FILMTEC NF200 and NF270 ElementsDocument4 pagesCleaning and Disinfection Procedures For FILMTEC NF200 and NF270 ElementsgulfengsolutionsNo ratings yet

- K Brian & E RochaisDocument16 pagesK Brian & E RochaisLuigi Andrew MercadoNo ratings yet

- EjectorsDocument4 pagesEjectorsTirathBaxiNo ratings yet

- Maintenance and Troubleshooting of Oil Diffusion PumpsDocument5 pagesMaintenance and Troubleshooting of Oil Diffusion PumpsM Suraj KumarNo ratings yet

- 2Cl Adriano 2Cl Danao 2Cl DomalaonDocument14 pages2Cl Adriano 2Cl Danao 2Cl DomalaonclainNo ratings yet

- Evaporation & Evaporators: Prepared By:-Kuldeep BhattDocument26 pagesEvaporation & Evaporators: Prepared By:-Kuldeep BhattKuldeep BhattNo ratings yet

- Principles and Applications of Jet Aeration: Mixing Systems, IncDocument8 pagesPrinciples and Applications of Jet Aeration: Mixing Systems, IncRonaldo LeiteNo ratings yet

- Matachana - AP4 - Water Treatment System For Steriliser - User ManualDocument8 pagesMatachana - AP4 - Water Treatment System For Steriliser - User ManualWahidi AzaniNo ratings yet

- P700 Series MAXPUMP P65 Series: Diaphragm Pump Manual BookDocument9 pagesP700 Series MAXPUMP P65 Series: Diaphragm Pump Manual BookJefril SiruNo ratings yet

- Chapter 3 Low Expansion Foam SystemsDocument73 pagesChapter 3 Low Expansion Foam SystemsYusrizalNo ratings yet

- Self Priming PumpsxDocument3 pagesSelf Priming PumpsxFabio MiguelNo ratings yet

- Cleaning Membranes Elements - PD PDFDocument7 pagesCleaning Membranes Elements - PD PDFDaniel BolivarNo ratings yet

- Visual Encyclopedia of Chemical Engineering Adsorbers: About AdsorptionDocument26 pagesVisual Encyclopedia of Chemical Engineering Adsorbers: About AdsorptionVanNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- How Reverse Osmosis Works: A Look at Industrial ROFrom EverandHow Reverse Osmosis Works: A Look at Industrial RORating: 2.5 out of 5 stars2.5/5 (2)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersFrom EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersRating: 4.5 out of 5 stars4.5/5 (2)

- Projection: Draw The Following Views Using 11 Scale and Third AngleDocument1 pageProjection: Draw The Following Views Using 11 Scale and Third Angleeldwin_dj7216No ratings yet

- Kaeser Compressors ASD 37 T - ME Dept OwnedDocument11 pagesKaeser Compressors ASD 37 T - ME Dept Ownedeldwin_dj7216100% (1)

- Comparison of Turbulence Models On 2D Backward Facing StepDocument16 pagesComparison of Turbulence Models On 2D Backward Facing Stepeldwin_dj7216No ratings yet

- GEA Steam-Jet-Vacuum-Pumps Brochure EN tcm11-22950 PDFDocument8 pagesGEA Steam-Jet-Vacuum-Pumps Brochure EN tcm11-22950 PDFeldwin_dj7216No ratings yet

- Lid Driven Cavity Flow OK Final EldwinDocument33 pagesLid Driven Cavity Flow OK Final Eldwineldwin_dj7216No ratings yet

- 2012 MIT KFUPM McGovern Ejector Efficiency PDFDocument12 pages2012 MIT KFUPM McGovern Ejector Efficiency PDFeldwin_dj7216No ratings yet

- ELDWIN Term Paper Boundary Layer Flow of A Nanofluid Over A Stretching SurfaceDocument15 pagesELDWIN Term Paper Boundary Layer Flow of A Nanofluid Over A Stretching Surfaceeldwin_dj7216No ratings yet

- Radiative Heat Transfer ProblemsDocument10 pagesRadiative Heat Transfer Problemseldwin_dj7216No ratings yet

- 2D Airfoil Meshing Tutorial in ICEM CFDDocument11 pages2D Airfoil Meshing Tutorial in ICEM CFDsvkindiaNo ratings yet

- Heat Transfer PHD Qualifying ExamDocument13 pagesHeat Transfer PHD Qualifying Exameldwin_dj7216No ratings yet

- JMST Journal EldwinDocument10 pagesJMST Journal Eldwineldwin_dj7216No ratings yet

- Mathematics Extension 2 HSC LevelDocument250 pagesMathematics Extension 2 HSC LevelkalstarNo ratings yet

- 2011 Sanjeeva - Ding - Ref - Stability of Nano Fluids in Quiescent and Shear Flow FieldsDocument6 pages2011 Sanjeeva - Ding - Ref - Stability of Nano Fluids in Quiescent and Shear Flow Fieldseldwin_dj7216No ratings yet

- Huawei OceanStor Dorado V6 All-Flash Storage Systems Pre-Sales Training....Document59 pagesHuawei OceanStor Dorado V6 All-Flash Storage Systems Pre-Sales Training....Wolf-Karsten Heintel100% (1)

- Man S20WDocument16 pagesMan S20WngocNo ratings yet

- New Generation in Pre-Heating TechnologyDocument16 pagesNew Generation in Pre-Heating TechnologymetudgnNo ratings yet

- Fisher Optimized Antisurge Control Valves: High Reliability To Meet World-Class Production DemandsDocument12 pagesFisher Optimized Antisurge Control Valves: High Reliability To Meet World-Class Production DemandsBeomHee LeeNo ratings yet

- Conexion en Power BuilderDocument252 pagesConexion en Power BuilderJuan Zem ZemNo ratings yet

- Poljoprivredni TraktoriDocument13 pagesPoljoprivredni TraktoriDražan MiloložaNo ratings yet

- Eardley Resume FinalDocument2 pagesEardley Resume Finalapi-298854508No ratings yet

- Cooling Water Systems FundamentalsDocument13 pagesCooling Water Systems FundamentalsAlfonso José García Laguna100% (3)

- Materiales BombasDocument132 pagesMateriales BombasCarlos JuárezNo ratings yet

- Combination Smoke and Heat Detector: Horing Lih Industrial Co., LTDDocument1 pageCombination Smoke and Heat Detector: Horing Lih Industrial Co., LTDIhsan OzzyNo ratings yet

- SUNTECH EN HiPower STP385S B60 WNH (MC4 385 365) 4G S3Document2 pagesSUNTECH EN HiPower STP385S B60 WNH (MC4 385 365) 4G S3Quốc Huy VũNo ratings yet

- Vertical Take Off and Landing Powerplant For AircraftsDocument5 pagesVertical Take Off and Landing Powerplant For AircraftsLiviu GiurcaNo ratings yet

- LSPB Trajectory Planning Design For The ModularDocument4 pagesLSPB Trajectory Planning Design For The ModularbasantsahuNo ratings yet

- Important: MMH Series Utility HeatersDocument2 pagesImportant: MMH Series Utility HeatersJames LoewenNo ratings yet

- A Discipline of TeamsDocument2 pagesA Discipline of TeamsAditya Bhat100% (1)

- CRD - c55 (1) Within Batch Uniformity FRSH ConcreteDocument6 pagesCRD - c55 (1) Within Batch Uniformity FRSH ConcreteKothiyal MukeshNo ratings yet

- The Best Way To Solve The World's Environmental Problems Is To Increase The Cost of Fuel. To What Extend Do You Agree or DisagreeDocument2 pagesThe Best Way To Solve The World's Environmental Problems Is To Increase The Cost of Fuel. To What Extend Do You Agree or DisagreeJagpreet Singh RandhawaNo ratings yet

- Un Esposo Conforme Al Corazon de Dios Spanish Edition by Jim George 0825412692Document5 pagesUn Esposo Conforme Al Corazon de Dios Spanish Edition by Jim George 0825412692Carlos Salgueiro VillarrealNo ratings yet

- UTC LM8560 Mos Ic: Digital Alarm ClockDocument9 pagesUTC LM8560 Mos Ic: Digital Alarm ClockAntonio De NobregaNo ratings yet

- Army Chemical Review #1 (2002)Document52 pagesArmy Chemical Review #1 (2002)Reid Kirby100% (1)

- Airbus AC A320 Jun2012Document607 pagesAirbus AC A320 Jun2012Rommel UparelaNo ratings yet

- F5 CW4 26 Nov 2012 AnswerDocument3 pagesF5 CW4 26 Nov 2012 AnswerLeo ChanNo ratings yet

- Success Story of TcsDocument8 pagesSuccess Story of TcsAjita TrivediNo ratings yet

- Static Metrics For CDocument3 pagesStatic Metrics For Cabhishek100% (1)

- Sugar Mill DrivesDocument8 pagesSugar Mill Drivessayyadmannan67% (3)

- Lecture19 150211 PDFDocument34 pagesLecture19 150211 PDFAbhishek SinghNo ratings yet

- 17mf023 Research Methodology LT P c3 0 0 3Document2 pages17mf023 Research Methodology LT P c3 0 0 3egspec.praveenNo ratings yet

- The PC Technicians Tune Up ManualDocument37 pagesThe PC Technicians Tune Up ManualJarvis Edwards100% (3)