Professional Documents

Culture Documents

Boring Tool

Boring Tool

Uploaded by

muneiah100%(1)100% found this document useful (1 vote)

443 views15 pagesThe document discusses different methods of boring operations. Boring involves enlarging existing holes using single-point cutting tools. It can be done on lathes or boring machines. Small holes are bored on lathes using forged solid tools or boring bars. Large jobs use horizontal boring machines which support heavy workpieces. Boring bars come in different types to machine long holes and are supported by the spindle, end columns, or fixtures. Boring heads mount multiple cutters for large diameter holes.

Original Description:

DESCRIPTION AND USE OF BORING TOOLS

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses different methods of boring operations. Boring involves enlarging existing holes using single-point cutting tools. It can be done on lathes or boring machines. Small holes are bored on lathes using forged solid tools or boring bars. Large jobs use horizontal boring machines which support heavy workpieces. Boring bars come in different types to machine long holes and are supported by the spindle, end columns, or fixtures. Boring heads mount multiple cutters for large diameter holes.

Copyright:

© All Rights Reserved

100%(1)100% found this document useful (1 vote)

443 views15 pagesBoring Tool

Boring Tool

Uploaded by

muneiahThe document discusses different methods of boring operations. Boring involves enlarging existing holes using single-point cutting tools. It can be done on lathes or boring machines. Small holes are bored on lathes using forged solid tools or boring bars. Large jobs use horizontal boring machines which support heavy workpieces. Boring bars come in different types to machine long holes and are supported by the spindle, end columns, or fixtures. Boring heads mount multiple cutters for large diameter holes.

Copyright:

© All Rights Reserved

You are on page 1of 15

BORING

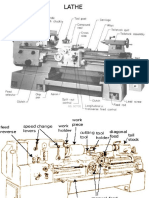

• The operation of boring differs from drilling is that it

implies the enlargement of an already existing hole.

• The operation of boring is usually performed by a single

point cutting tool.

• The hole can be due to previous drilling or produced in

casting or forging.

• Both through & blind holes can be bored either on a lathe

or on a boring machine tool.

• When small holes are to be bored particularly in small

jobs, which can be conveniently held in chucks or face

plates, the operation of boring can easily be done on

Centre lathe or capstan & turret lathes of medium in

size.

• For large & heavy jobs special boring machines are to be

used which makes the operation easy & efficient.

Horizontal boring machine

• In a horizontal boring machine, the work is

supported on a table which is stationary and the

tool revolves in a horizontal axis.

• The horizontal boring machine can perform

boring, reaming, turning, threading, facing,

milling, grooving, recessing and many other

operations with suitable tools.

• Work pieces which are heavy, irregular,

unsymmetrical or bulky can be conveniently held

and machined.

Boring tools & Bars

• The tools used in boring work are of mainly two

types:

Rotating type

Non-Rotating type

• Of the two types , the first kind is used when it is

inconvenient to rotate the work on account of it’s

awkward shape or similar other reasons.

• On the other type when the work is of such

nature that it can be conveniently rotated, the

second type is preferred

• Few common type of boring tools are:

Forged solid tools

Boring bars

Boring tools inserted teeth

Boring head or Center head

Forged solid tools:

• They provide probably, the quickest method of

boring in small jobs on centre, capstan and turret

lathes.

• They are generally forged out of tool steel and then

ground to correct angles.

• They are made in pairs, consisting of a rough and

finishing tool.

• These tools are held either in slide rest, turret head

or sometimes in tail stock.

• The work is held in a chuck or face plate and

revolved, the tool being fed into the job by moving

the slide rest, turret slide or in tail stock spindle.

Rough boring tool Finish boring tool

• Boring bars:

• when we have to machine long holes, boring bars

are commonly used.

• These bars are generally cylindrical in shape and

carry a slot to accommodate the tool bit.

• The commonly used types of boring bars are

• One has tool bit projecting in front of its end. It

used for boring blind holes.

• the second one carries a slot for fixing the bit at

some from the end of the bar.

• These boring bars are possible to held on a centre

lathe, turret lathe as well as on a boring machine.

• In case of a boring machine ordinary boring

operations are carried out with tools mounted on

a bar held in spindle having morse taper hole.

• The maximum diameter of the bar employed is

not more than the spindle diameter.

The different methods of supporting bars are

described below.

• Supported by spindle:

• For boring blind holes, bars are used to be

supported at the spindle end only. This type of

bar is called as stub bar.

• Supported by spindle & end column:

• while boring long open holes, boring bars are

supported at the spindle end and by a bearing

block at the other end mounted on the end

supporting column.

• This type of bar is called Line bar.

• Supported by the work piece: in some types of

work, the bar may be supported in the bored

holes of the work by bushings.

• This type of support takes much of setting time,

used in stray jobs where one or two similar

articles are machined

• Supported by boring fixtures:

• In mass production work boring jigs are used.

They locate, guide and support the bars at

intermediate points

• Boring bars are used for boring smaller diameter

holes.

• Boring head or cutter head: the boring heads

used for mounting cutters while machining large

diameter holes where a standard boring bar is

unsuitable due to smaller diameter.

• It consists of a circular body which can be keyed

to the boring bar at any desired position along it’s

length.

• Two or three square slots are made radially in the

body.

• Cutters are fitted in these slots and are secured in

position by means of setscrews.

A simple boring head

You might also like

- DR Lock Key ChartDocument4 pagesDR Lock Key Chartapek1No ratings yet

- Milling OperationsDocument4 pagesMilling Operationsinboxsweets100% (1)

- Slotting MachineDocument32 pagesSlotting Machinesanaashraf91% (11)

- 07-Pipe FittingsDocument1 page07-Pipe Fittingssopan kharcheNo ratings yet

- Module - 4 - Shaper, Planer, Slotter, Grinding MachinesDocument70 pagesModule - 4 - Shaper, Planer, Slotter, Grinding MachinesIrfan ShaikhNo ratings yet

- BORINGDocument4 pagesBORINGPandi VelanNo ratings yet

- Non Chip FormingDocument33 pagesNon Chip FormingNur AmirahNo ratings yet

- Drilling SRM UniviersityDocument27 pagesDrilling SRM UniviersityBhavin Desai100% (2)

- Lathe and Drilling MachinesDocument48 pagesLathe and Drilling MachinesMisga BekeleNo ratings yet

- Drill Press Text BookDocument138 pagesDrill Press Text BookKartik Sheth100% (1)

- Milling Report SampleDocument3 pagesMilling Report SampleAmanda LamNo ratings yet

- Machine Tools and Machining1Document62 pagesMachine Tools and Machining1Faisal MaqsoodNo ratings yet

- Name of The Experiment:: Study and Operation Bench Drilling MachineDocument5 pagesName of The Experiment:: Study and Operation Bench Drilling MachinemadNo ratings yet

- Unit 2 - Drilling 29Document41 pagesUnit 2 - Drilling 29normanjames966No ratings yet

- Lathe and Capstan & TurretDocument13 pagesLathe and Capstan & TurretNishit Parmar100% (1)

- Abrasive Jet and Water Jet Machining Mp2Document50 pagesAbrasive Jet and Water Jet Machining Mp2Drew LadlowNo ratings yet

- Different Shaper Machine Accessories and AttachementsDocument3 pagesDifferent Shaper Machine Accessories and AttachementsJaymark BebatNo ratings yet

- Unit 3a4 Sawing 180328125446Document29 pagesUnit 3a4 Sawing 180328125446Gilang RestuNo ratings yet

- Drill Jig Design Considerations - Drill Jig TypesDocument39 pagesDrill Jig Design Considerations - Drill Jig TypesJaime MontielNo ratings yet

- Lathe AccessoriesDocument4 pagesLathe AccessoriesBOT-X GAMING100% (1)

- BME Unit IV Machine ToolsDocument41 pagesBME Unit IV Machine ToolsArvind BhosaleNo ratings yet

- JJ104 Workshop Technology Chapter4 Twist DrillDocument52 pagesJJ104 Workshop Technology Chapter4 Twist DrillAh TiangNo ratings yet

- Tail Stock of LatheDocument7 pagesTail Stock of LatheKIÊN HOÀNG TRUNG100% (1)

- Finishing Operations Lec 4Document27 pagesFinishing Operations Lec 4AnnieMalik100% (1)

- Forging Operations: 1: DrawingDocument4 pagesForging Operations: 1: DrawingvijayakumarNo ratings yet

- An Introduction To Type of JigsDocument29 pagesAn Introduction To Type of JigsVanaja JadapalliNo ratings yet

- Chucks: Clamp Radial Symmetry Cylindrical Drill Bit Power Tool Bar Spindle LatheDocument14 pagesChucks: Clamp Radial Symmetry Cylindrical Drill Bit Power Tool Bar Spindle LatheIrtaza Husnain100% (1)

- Optimization of Grinding Cycle Time For End Mill ManufacturingDocument5 pagesOptimization of Grinding Cycle Time For End Mill ManufacturingIJARMATE100% (1)

- Shot Blasting Is A Rapid, Environment Friendly, CostDocument10 pagesShot Blasting Is A Rapid, Environment Friendly, CostSulfikar SalimNo ratings yet

- Grinding AssignmentDocument4 pagesGrinding AssignmentSyed Ashmal Hashmi100% (1)

- Gang DrillDocument41 pagesGang DrillManny SinghNo ratings yet

- Course File Jigs & FixturessDocument18 pagesCourse File Jigs & FixturessYogendra KumarNo ratings yet

- Split Cavity and Side CoreDocument29 pagesSplit Cavity and Side CoreShubham ChoudhariNo ratings yet

- 5 Grinding and Realated OperationsDocument23 pages5 Grinding and Realated OperationsSaiful IslamNo ratings yet

- Slotting MachineDocument30 pagesSlotting MachineUsman Zubair100% (1)

- TOOL DESIGN - Press Tool OperationDocument7 pagesTOOL DESIGN - Press Tool OperationAbinPGeorgeNo ratings yet

- Capstan & Turret LatheDocument18 pagesCapstan & Turret LatheNIKHIL CHIKATE50% (2)

- Work Holding DevicesDocument13 pagesWork Holding DevicesDerrick Maatla Moadi100% (1)

- Power Transmission: Belt Drives, Rope Drives, Chain Drives, Gear DrivesDocument27 pagesPower Transmission: Belt Drives, Rope Drives, Chain Drives, Gear DrivesAshwin AdithyaNo ratings yet

- MFT2 Lab 2Document48 pagesMFT2 Lab 2dellibabu509No ratings yet

- Study On Basic Lathe Machining: AIM: To Study The Construction Details and Working Principle of Basic MachiningDocument12 pagesStudy On Basic Lathe Machining: AIM: To Study The Construction Details and Working Principle of Basic Machininggirma workuNo ratings yet

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocument12 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaNo ratings yet

- Module II - GrindingDocument73 pagesModule II - GrindingHARI KRISHNANNo ratings yet

- Lathe: GS, SctceDocument48 pagesLathe: GS, SctceGouthamPrasad100% (2)

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocument20 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaNo ratings yet

- LatheDocument14 pagesLatheHimanshu ModiNo ratings yet

- Experiment No. 1: Study of Universal 3 Jaw Chuck Lathe MachineDocument5 pagesExperiment No. 1: Study of Universal 3 Jaw Chuck Lathe MachineHasnain AshrafNo ratings yet

- Computer Programming 1 - Jenny's OnlineDocument4 pagesComputer Programming 1 - Jenny's OnlineHiro GamerNo ratings yet

- Drilling MachineDocument30 pagesDrilling MachinePuneeth KumarNo ratings yet

- Jigs Fixtures QuizDocument1 pageJigs Fixtures QuizMalcolm DiamondNo ratings yet

- Drilling Machine & ReamersDocument42 pagesDrilling Machine & ReamersSomenath RahaNo ratings yet

- Which ToolDocument11 pagesWhich ToolJJ ROETSNo ratings yet

- Unit-4 MMDocument74 pagesUnit-4 MMRama SamyNo ratings yet

- Grinding MachinesDocument44 pagesGrinding MachinesPrashant Rao MeshramNo ratings yet

- PSG Data V BeltsDocument53 pagesPSG Data V BeltsAllen GeorgeNo ratings yet

- Micro Project: Sections of SolidsDocument13 pagesMicro Project: Sections of Solidsomkar digamabar sononeNo ratings yet

- Effect of Teaching Reaming Operation With Fabricated Woodwork Mini Lathe On Students' Achievement in Carpentry and Joinery in Technical Colleges in Rivers State NigeriaDocument6 pagesEffect of Teaching Reaming Operation With Fabricated Woodwork Mini Lathe On Students' Achievement in Carpentry and Joinery in Technical Colleges in Rivers State NigeriaEditor IJTSRDNo ratings yet

- Diamond and CBN WheelsDocument22 pagesDiamond and CBN WheelsM. Aguiar100% (1)

- Chisel NewDocument4 pagesChisel NewCornelius BillyNo ratings yet

- MillingDocument38 pagesMillingMahesh KumarNo ratings yet

- Drillingjig 181228111255Document15 pagesDrillingjig 181228111255Odlnayer AllebramNo ratings yet

- DrillingDocument71 pagesDrillingravi upadhyayNo ratings yet

- Sheet Metal Work, Bench Work and FittingDocument63 pagesSheet Metal Work, Bench Work and FittingSolcastic SoulNo ratings yet

- 3A - Centrifugal PumpDocument11 pages3A - Centrifugal PumpM Afuw MudhaffarNo ratings yet

- CH 05 AntitankDocument31 pagesCH 05 AntitankPGNo ratings yet

- Flight Management System (FMS)Document4 pagesFlight Management System (FMS)NITINNo ratings yet

- Manual de Peças Ricoh Duplicador jp730Document65 pagesManual de Peças Ricoh Duplicador jp730Fábio Henrique BarrosNo ratings yet

- Grinding & DrillingDocument11 pagesGrinding & DrillingRifki YolandNo ratings yet

- BallisticsDocument6 pagesBallisticsAntonette NavarroNo ratings yet

- Excel Lengkap Pabrik DMEDocument24 pagesExcel Lengkap Pabrik DMEwinaNo ratings yet

- Inventory: Warehouse PO No. Bin UOM Quantity Unit Price (S) Total Price (S)Document5 pagesInventory: Warehouse PO No. Bin UOM Quantity Unit Price (S) Total Price (S)Mohamed MusaNo ratings yet

- Import Item 15052023Document8 pagesImport Item 15052023Indah PhotoNo ratings yet

- Cub Cadet Parts Manual For Model Rzt42 Kohler 17aa5b4gDocument4 pagesCub Cadet Parts Manual For Model Rzt42 Kohler 17aa5b4gbryan100% (40)

- Lesson 1 Terminology and History - Forensic BallisticsDocument27 pagesLesson 1 Terminology and History - Forensic BallisticsEve LynnNo ratings yet

- 2016 Sac Latam Spec 60hz CPDocument76 pages2016 Sac Latam Spec 60hz CPJerges Gerardo Mamani SilvaNo ratings yet

- Mhda Hollow Ceiling AnchorDocument1 pageMhda Hollow Ceiling AnchorMohammed AnwarNo ratings yet

- Maestro Filtros 18-04-18Document11 pagesMaestro Filtros 18-04-18Jean Paul LoayzaNo ratings yet

- 148313Document59 pages148313K.n.TingNo ratings yet

- VARGUS - Gear Milling New - InchDocument6 pagesVARGUS - Gear Milling New - InchGilberto ManhattanNo ratings yet

- Bill of Materials: RDMP Ru V Balikpapan RDMP Balikpapan JoDocument1 pageBill of Materials: RDMP Ru V Balikpapan RDMP Balikpapan JoDavid LekaNo ratings yet

- Cutting ToolsDocument17 pagesCutting Toolszaldy p. beloyNo ratings yet

- Maintenance Group AssignmentDocument21 pagesMaintenance Group Assignmentdawit gashuNo ratings yet

- NOVEMBER 2020 Surplus Record Machinery & Equipment DirectoryDocument715 pagesNOVEMBER 2020 Surplus Record Machinery & Equipment DirectorySurplus RecordNo ratings yet

- Handouts-EIM. - SS1-Week-3Document5 pagesHandouts-EIM. - SS1-Week-3myco sauraNo ratings yet

- Mxz-2a20na & Mxz-3a30na Ob444aDocument77 pagesMxz-2a20na & Mxz-3a30na Ob444aSLAMET PAMBUDINo ratings yet

- Hydraulic Calculation For Fire PumpDocument9 pagesHydraulic Calculation For Fire PumpShaifful NizamNo ratings yet

- Great Plains Parts Manual FCN8308MDocument54 pagesGreat Plains Parts Manual FCN8308Ma04205No ratings yet

- Coil - Tine - Harrow - With - Basket - Spike - Basket - QX2 - and - XL2 - 2007 - UpDocument7 pagesCoil - Tine - Harrow - With - Basket - Spike - Basket - QX2 - and - XL2 - 2007 - UpArmorNo ratings yet

- Catalogue-Clamping ElementsDocument22 pagesCatalogue-Clamping Elementsanujkumartyagi9275No ratings yet

- Table Saw Sled - Taper Jig Accessory: Cut One or Many Tapers With Ease!Document8 pagesTable Saw Sled - Taper Jig Accessory: Cut One or Many Tapers With Ease!LinNo ratings yet