Professional Documents

Culture Documents

Investigational Medicinal Products:: Regulatory and Practical Considerations For Clinical Trials

Investigational Medicinal Products:: Regulatory and Practical Considerations For Clinical Trials

Uploaded by

MODEPHARMAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Investigational Medicinal Products:: Regulatory and Practical Considerations For Clinical Trials

Investigational Medicinal Products:: Regulatory and Practical Considerations For Clinical Trials

Uploaded by

MODEPHARMACopyright:

Available Formats

INVESTIGATIONAL MEDICINAL PRODUCTS:

Regulatory and Practical Considerations for Clinical Trials

November 2010

Introduction 2

Investigational Medicinal Products

Introduction

EU and UK regulations relating to investigational medicinal products

Implications for undertaking clinical trials with IMPs

Common challenges across the clinical trial lifecycle

Patient population factors and dosage forms

Imports from Non-EU countries

Labels

Expiry dates and stability

Technical agreements

Other common GMP related challenges

CTA

VAT

GMP: Behind the Scenes

Overview of a clinical supply project

© 2010 MODEPHARMA www.modepharma.com

Introduction 3

About MODEPHARMA

MANUFACTURING

Placebos to match

Tablets and capsules

Investigational Medicinal Products for clinical trials Semi-solids

Injectables

Powders

Inhalers

Advise, plan and coordinate on all aspects around the IMP Liquids

PACKAGING

Bulk supplies

Comprehensive sourcing and management of trial medication Re-labelling

Patient kits

Ampoules

Sachets

MODEPHARMA is the only UK company to Blisters

Bottles

specialise in clinical supplies for non-commercial Tubes

clinical Vials

trials

RELATED SERVICES

Full support around the IMP solution QP release

Imports

Randomisation

Regulatory support

Site monitoring

Pharmacy SOPs

IMP training

© 2010 MODEPHARMA www.modepharma.com

Regulatory Aspects of IMPs 4

EU and UK Regulations Relating to Investigational Medicinal Products

EU Directives:

Clinical Trials Directive 2001/20/EC

» The principles of good manufacturing practice should be

applied to investigational medicinal products.

GMP Directive 2003/94/EC

» Replaces original GMP Directive 91/356/EEC

GCP Directive 2005/28/EC

» Additional principles and detailed guidelines with regards

to IMPs are specified to verify compliance of clinical trials

with the Clinical Trials Directive 2001/20/EC.

Transposed into Member State Laws:

UK: Statutory Instrument 2004/1031: The Medicines for Human Use (Clinical Trials) Regulations 2004 and its

amendments.

Despite harmonisation, differences remain between Member States in clinical trial requirements

Practical guidance:

GCP: ICH Guidelines for GCP

GMP: Eudralex Vol 4 (EU GMP Guide aka “Orange Guide”)

» Annex 13: GMP for investigational products

» Annex 16: QP responsibilities

See the MODEPHARMA Knowledge Centre: www.modepharma.com

© 2010 MODEPHARMA www.modepharma.com

Regulatory Aspects of IMPs 5

Implications for Undertaking Clinical Trials with IMPs

All IMPs must be manufactured according to GMP:

Requirement for appropriate IMP manufacturing/import

authorisation

Facility must be licensed for the dosage form & activities required

Qualified Person (QP):

Ensure compliance with EU GMP (for own sites and contractors),

the PSF, and the request for CTA

Responsible for the certification and release of batches of clinical

trial material before they can be used in a clinical trial.

Exception: Regulation 37 in SI 2004/1031

» Assembly (repacking, randomising and labelling) in a

hospital/health centre under supervision of a

doctor/pharmacist for use within that institution

» No need for QP release but QC recommended

» There are restrictions!

All facilities used for the manufacture or import of IMPs are

subject to an inspection by the competent authority

If IMP manufactured outside EU, appropriate checks/retests

for “Import” and before EU release

© 2010 MODEPHARMA www.modepharma.com

IMP Considerations 6

Common IMP Challenges Across the Clinical Trial Life-Cycle

Protocol Development Trial Setup Trial Implementation

Insufficient

Insufficient consideration

consideration of

of patient

patient Little or no experience with contract

Poor blinding

blinding of

of IMPs

IMPs

population factors manufacturers

Sub-optimal choice of active/placebo Hidden costs in quotes making them

Inadequate labelling of IMPs

dosage forms difficult to interpret and compare

Lack of awareness on regulatory

One-sided Technical Agreements Poor quality IMP and packaging

requirements

requirements for

for IMP

IMP manufacturing

manufacturing

IMP adversely

adversely affected

affected during

during storage

storage

Inaccurate budgeting of IMP costs Inadequate project planning

and transport

Risks: Risks: Risks:

•Non-compliance or high withdrawal rate • Poor IMP quality and design •Credibility of results

•Poor trial design / wastage of drug • Paying more than expected •Patient safety risk/regulatory non-compliance

•Regulatory approval delayed/failed • Sponsor’s responsibilities not adequately covered •Patient loss of confidence and drop-outs

•Insufficient funding for the trial to continue • Manufacturing delays • Early trial stop by Sponsor or MHRA

© 2010 MODEPHARMA www.modepharma.com

IMP Considerations 7

Patient Population Factors and IMP Dosage Forms

Consider patient population factors and IMP hand-in-hand

Blinding mechanisms:

New dosage forms (e.g. Over-encapsulation for solid dosage

forms)

New packaging :

» Formulation and development of placebo-to-match (e.g.

tablets, liquids)

» Repack into new packaging (e.g. sachets)

Other innovative solutions

Common issues:

Chosen dosage form not the most optimal for the trial’s

patient population

Not economically feasible to develop a placebo

Formulation work is not a precise science

Poor quality placebos (e.g. taste, texture, colour, film-coating,

hardness, primary packaging)

© 2010 MODEPHARMA www.modepharma.com

IMP Considerations 8

‘Imports’ from Non-EU Countries

IMP manufactured outside EU:

QP to verify that the IMP was manufactured to GMP

standards equivalent to EU GMP

QP may have to performs site audits

Additional analytical testing of IMPs may be

required on import to Europe

QP declaration on GMP equivalence to EU GMP

using the template available on the MHRA website

Signed by a QP named on the manufacturer’s

authorisation of the importer

Should be trial and product specific

Applies to placebos as well

Common issues:

Lack of substance behind QP declaration

» How does the QP know the actual site of

manufacture?

» How does the QP assure EU GMP?

Transportation conditions not known

The QP certified an imported IMP as free of

Transmissible Spongiform Encephalopathy (TSE) but

no evidence was available to support this decision.

© 2010 MODEPHARMA www.modepharma.com

IMP Considerations 9

Technical Agreements Set Out the Roles and Responsibilities of Each Party

Responsibility Contract Contract

Common issues:

Acceptor (CA) Giver (CG) Non-existent

Material safety of active substance and other

starting materials

R Essentially commercial in nature

Specifications R Agreement not in place before manufacturing

Purchasing R commences

Qualification of the supplier R Lack of detail concerning GMP responsibilities:

Identification and analysis R » Sourcing of materials

Release for processing R » QP duties

Storage R » Recall responsibilities

Reference Samples R » Approval and supply of relevant documents

Stability study R » Taking of samples/testing/retention

Enforcement of recalls R

» No requirement for signed QP certification

… … …

Refer to Appendices that do not exist

© 2010 MODEPHARMA www.modepharma.com

IMP Considerations 10

Labels

GMP Directive 2003/94/EC:

AMAZING_TRIAL

Preamble 9: In order to protect the human beings involved in FOR CLINICAL TRIAL USE ONLY

clinical trials and to ensure that investigational medicinal EudraCT No: 2007-00534-99

28 x Lisinopril 5mg Tablets or Placebo-to-Match

products can be traced, specific provisions on the labelling of Patient Trial No: J789 Visit: _____ Dispensing Date: ________

those products are necessary. Dose Instructions: Take ONE tablet orally once a day.

Batch No: 09B897 Expiry Date: 12/DEC/2010

Article 15 Labelling: In the case of an investigational medicinal Storage Instructions: Store below 25ºC.

product, labelling shall be such as to ensure protection of the KEEP OUT OF THE REACH OF CHILDREN

subject and traceability, to enable identification of the product Professor XXXXX, SPONSOR NAME, Address, City,

and trial, and to facilitate proper use of the investigational Post Code, UK, Tel: 07979797979

medicinal product.

Detailed guidance in Annex 13, paragraphs 26 to 33:

Paragraph 26 and Table 1 sets out 11 items of information which

should be included on labels

» unless absence can be justified, e.g. use of a centralised

electronic randomisation system

Paragraph 33 covers labelling to change use-by-dates

Common issues:

Missing labels with CTA applications

Labels missing key information

Different batch numbers/expiry dates for active and placebo

© 2010 MODEPHARMA www.modepharma.com

IMP Considerations 11

Expiry Dates and Stability

IMP expiry date and stability information is the Sponsor’s responsibility!

GCP Guideline 5.14.5 (a):

» Sponsor should take steps to ensure that the investigational product(s) are

stable over the period of use

Annex 13 (§20):

» The expiry date stated for the comparator product in its original packaging

might not be applicable to the product where it has been repackaged in a

different container that may not offer equivalent protection, or be compatible

with the product.

» A suitable use-by date, taking into account the nature of the product, the

characteristics of the container and the storage conditions to which the article

may be subjected, should be determined by or on behalf of the sponsor.

» Such a date should be justified and must not be later than the expiry date of

the original package.

» There should be compatibility of expiry dating and clinical trial duration.

Common issues:

Not considering shelf-life of IMPs

Having to commission additional [unplanned] manufacturing

Cost of analytical method development, validation and stability studies

© 2010 MODEPHARMA www.modepharma.com

IMP Considerations 12

Other Common GMP Issues

Creation and maintenance of the Product Specification File:

Not available or incomplete

Lack of structure to the file

No system for updating the file following changes in

instructions, packaging etc.

Recall SOP

Insufficient detail with reference to recalls instigated by

manufacturers of comparator products

No consideration that the IMP may identify defects with

comparator products during handling/use

Failure to notify the MHRA in the event of a potential recall

situation being identified.

Transport and storage conditions

Lack of controlled storage

Temperature deviations

© 2010 MODEPHARMA www.modepharma.com

IMP Considerations 13

CTAs

Common issues:

“Invalid” applications

» Failure to supply an XML file

» Missing sponsor authorisation letter

» Non-machine readable PDFs

» Password protected disks

Quality of applications

» Section on IMPs (active and placebo)

left blank

» Confusion on final EU site releasing

the IMP

» Missing supporting documents:

– Sample labels

– IMPD / IB / SmPCs

– Manufacturing authorisations

– TSE certificates

© 2010 MODEPHARMA www.modepharma.com

IMP Considerations 14

VAT

VAT

» Clinical supplies for non-commercial trials are not

automatically VAT exempt

» VAT exemptions only for trials funded by charitable sources

See www.modepharma.com/vat for further guidance

© 2010 MODEPHARMA www.modepharma.com

Clinical Supply Manufacturing and Packaging Activities 15

Overview of a Clinical Supply Project

Client Enquiry and Confidential Disclosure Proposal Acceptance Project Manager and

Requirement Definition Agreement and Payment of Deposit Project Plan

Label Design Procurement of Documents for CTA including Product

Technical Agreement

and Approval Raw Materials Specification Files

Approval of Batch Manufacturing Clinical Manufacturing, Packaging and

Randomisation Code QP Release

Record QC Testing

Project Close Shipment on Demand Storage Invoicing

© 2010 MODEPHARMA www.modepharma.com

Further Reading 16

Annex 13 Manufacture of IMPs

Sections on:

Principle

Glossary

Quality Management

Personnel

Premises and Equipment

Documentation

Production

» Packaging materials

» Manufacturing operations

» Principles applicable to comparator products

» Blinding operations

» Randomisation code

» Packaging

» Labelling

Quality Control

Release of Batches

Shipping

Complaints

Recalls and Returns

Destruction

© 2010 MODEPHARMA www.modepharma.com

Contact 17

http://www.modepharma.com

MODEPHARMA

Registered Office: Suite 16, Beaufort Court, London E14 9XL, UK

Company No: 6332969 in England and Wales

VAT Registration: GB 909535016

Phone: +44 (0) 2070 432 442

Email: info@modepharma.com

© 2010 MODEPHARMA www.modepharma.com

You might also like

- ECA Sampling StrategiesDocument6 pagesECA Sampling StrategiesThiago Pessoa0% (1)

- MHRA Guidelines - Pharmaceutical GuidelinesDocument1 pageMHRA Guidelines - Pharmaceutical Guidelinessandro Cardoso0% (2)

- GMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsFrom EverandGMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsRating: 5 out of 5 stars5/5 (2)

- ECA QC Raw Mat 2015Document4 pagesECA QC Raw Mat 2015endorengasNo ratings yet

- cGMPPi Topic 1 Principles of CGMPDocument37 pagescGMPPi Topic 1 Principles of CGMPJia YingNo ratings yet

- Presentation Module 9 Good Practice Inspections enDocument67 pagesPresentation Module 9 Good Practice Inspections enMahmoud AshourNo ratings yet

- M1-Introduction - Rev 2024Document12 pagesM1-Introduction - Rev 2024EnggerianiNo ratings yet

- Differences Between The PICS EU GMP Guidelines and WHO Guidelines - FinalDocument20 pagesDifferences Between The PICS EU GMP Guidelines and WHO Guidelines - FinalSrinivasaRaoNo ratings yet

- Quality Assurance: Carlos M. Cammayo, RPHDocument48 pagesQuality Assurance: Carlos M. Cammayo, RPHJackielou MaquisoNo ratings yet

- Regulatory Control of Generic Medicine in MalaysiaDocument45 pagesRegulatory Control of Generic Medicine in MalaysiaLong ChongNo ratings yet

- Guide GMP Checklist 2.0Document57 pagesGuide GMP Checklist 2.0Jem VasquezNo ratings yet

- London, 22 February 2006 EMEA/CHMP/BMWP/31329/2005: Evaluation of Medicines For Human UseDocument6 pagesLondon, 22 February 2006 EMEA/CHMP/BMWP/31329/2005: Evaluation of Medicines For Human Usealex.pharmathNo ratings yet

- Modul-1 Industrial Pharmacy 2021 Rev1Document13 pagesModul-1 Industrial Pharmacy 2021 Rev1Fadhilah PalensiaNo ratings yet

- New Features of IP 20107592310671Document7 pagesNew Features of IP 20107592310671Banu PetiwalaNo ratings yet

- Pharmacy 10 00101Document12 pagesPharmacy 10 00101bertNo ratings yet

- Regulation of Radiopharmaceuticals - What Is Required For A Good Clinical ApplicationDocument19 pagesRegulation of Radiopharmaceuticals - What Is Required For A Good Clinical ApplicationEmilija JanevikNo ratings yet

- Stability Testing For Applications For Variations To A Marketing AuthorisationDocument6 pagesStability Testing For Applications For Variations To A Marketing AuthorisationJelena StankovićNo ratings yet

- Cefotaxime 1g Powder For Solution For Injection or Infusion PL 14894 0397 Cefotaxime 2g Powder For Solution For Injection or Infusion PL 14894 0398Document48 pagesCefotaxime 1g Powder For Solution For Injection or Infusion PL 14894 0397 Cefotaxime 2g Powder For Solution For Injection or Infusion PL 14894 0398CongluanNo ratings yet

- Stability Studies: Gabriel K. Kaddu Head, Drug Assessment and Registration National Drug Authority UgandaDocument38 pagesStability Studies: Gabriel K. Kaddu Head, Drug Assessment and Registration National Drug Authority UgandadeaNo ratings yet

- GMP Annex 13 - 03 Feb 2010 (Track Changes)Document19 pagesGMP Annex 13 - 03 Feb 2010 (Track Changes)chris2272No ratings yet

- Finished Pharmaceutical Product Specifications: Rutendo KuwanaDocument17 pagesFinished Pharmaceutical Product Specifications: Rutendo KuwanaStuNo ratings yet

- Excipient Risk AssessmentDocument6 pagesExcipient Risk Assessmentmailtorubal2573No ratings yet

- Formulation of Small Molecules: Prof Abdul BasitDocument32 pagesFormulation of Small Molecules: Prof Abdul Basitchegu BusinessNo ratings yet

- Unnati Garg (ICH Guidelines)Document66 pagesUnnati Garg (ICH Guidelines)Unnati GargNo ratings yet

- Usp 1078 Good Manufacturing Practices For Bulk Pharmaceutical Excipients PDFDocument13 pagesUsp 1078 Good Manufacturing Practices For Bulk Pharmaceutical Excipients PDFMayson BaliNo ratings yet

- Good Manufacturing Practices (GMPS) : Developments and UpdatesDocument29 pagesGood Manufacturing Practices (GMPS) : Developments and UpdatesPatel PrakashkumarNo ratings yet

- GMP For Facility Design References April06Document17 pagesGMP For Facility Design References April06madhubiochemNo ratings yet

- ECA Combination Products 2024 Live Online TrainingDocument4 pagesECA Combination Products 2024 Live Online Trainingmichael.lichfieldNo ratings yet

- 2p FPSDocument46 pages2p FPSamitNo ratings yet

- July 1996 CPMP/ICH/138/95Document9 pagesJuly 1996 CPMP/ICH/138/95MAHESHNo ratings yet

- Manufacture of RadiopharmaceuticalsDocument9 pagesManufacture of RadiopharmaceuticalsRainMan75No ratings yet

- 1205WHO Vs GMP Slide 16 OnwardsDocument31 pages1205WHO Vs GMP Slide 16 OnwardsTumma RamaraoNo ratings yet

- CHMP Assessment Report: Review Under Article 5 (3) of Regulation (EC) No 726/2004 Octagam and Associated NamesDocument7 pagesCHMP Assessment Report: Review Under Article 5 (3) of Regulation (EC) No 726/2004 Octagam and Associated NamesselmaNo ratings yet

- Questions - Answers - Positions On Specific Questionsaddressed Pharmacokinetics Working Party - enDocument48 pagesQuestions - Answers - Positions On Specific Questionsaddressed Pharmacokinetics Working Party - enlhthang1990No ratings yet

- ECA InhalationDrugProductDocument4 pagesECA InhalationDrugProductReinaldo MeléndrezNo ratings yet

- Industrial Pharmacy: Processes and Requirements in The Pharmaceutical IndustryDocument4 pagesIndustrial Pharmacy: Processes and Requirements in The Pharmaceutical IndustryMukesh TiwariNo ratings yet

- Risk Assessment Single-Use White Paper en MRK March 2017 LowDocument4 pagesRisk Assessment Single-Use White Paper en MRK March 2017 LowRui PiresNo ratings yet

- Indian PharmacopoeiaDocument24 pagesIndian Pharmacopoeiaaparna tiwariNo ratings yet

- Course NotesDocument125 pagesCourse Notesfuji_reihNo ratings yet

- GMP and Preparation in Hospital Pharmacies: Yvonne Bouwman, Lilli Møller AndersenDocument6 pagesGMP and Preparation in Hospital Pharmacies: Yvonne Bouwman, Lilli Møller AndersenTayyab SiddiquiNo ratings yet

- Pharmacy Profession in Bangladesh Future PDFDocument5 pagesPharmacy Profession in Bangladesh Future PDFFerdous MostofaNo ratings yet

- Pharmaceutical Manufacturing:: New Technology Opportunities.Document45 pagesPharmaceutical Manufacturing:: New Technology Opportunities.Vincent JohnsonNo ratings yet

- 5991 1876enDocument32 pages5991 1876enBeatriz ReyesNo ratings yet

- Indian PharmacopoeiaDocument24 pagesIndian Pharmacopoeiakamalsami150% (8)

- The IPEC Excipient GuideDocument4 pagesThe IPEC Excipient GuiderajnayakpawarNo ratings yet

- Establishing A Pharmacy-BasedDocument9 pagesEstablishing A Pharmacy-BasedleandrofigNo ratings yet

- Stability Studies: Gabriel K. Kaddu Head, Drug Assessment and Registration National Drug Authority UgandaDocument38 pagesStability Studies: Gabriel K. Kaddu Head, Drug Assessment and Registration National Drug Authority Ugandanajiha0% (1)

- Stability StudiesDocument60 pagesStability StudiesJaya SukmanaNo ratings yet

- Jurnal Internasional Aso PDFDocument8 pagesJurnal Internasional Aso PDFAffrilinaNo ratings yet

- GMP and Preparation in Hospital Pharmacies - Bouwman and Andersen 19 (5) - 469 - European Journal of Hospital Pharmacy - Science and PracticeDocument4 pagesGMP and Preparation in Hospital Pharmacies - Bouwman and Andersen 19 (5) - 469 - European Journal of Hospital Pharmacy - Science and Practicecarbou0% (1)

- Pharmaceutical Development: Lynda PaleshnuikDocument57 pagesPharmaceutical Development: Lynda PaleshnuikhuynhvinhquangNo ratings yet

- International Conference Harmonisation Technical Requirements Registration Pharmaceuticals Human Use - en 25Document16 pagesInternational Conference Harmonisation Technical Requirements Registration Pharmaceuticals Human Use - en 25Karla GarcíaNo ratings yet

- ECA Appropriate GMP For Pharmaceutical ExcipientsDocument4 pagesECA Appropriate GMP For Pharmaceutical Excipientsmailtorubal2573No ratings yet

- Slide 1: Industrial PharmacyDocument5 pagesSlide 1: Industrial PharmacyI KADEK SUNGKAR NUGRAHANo ratings yet

- 2016 WCBP ChartonEmmanuelleDocument26 pages2016 WCBP ChartonEmmanuelleyolsuzzNo ratings yet

- Emea Validation Non STD ProcessDocument3 pagesEmea Validation Non STD ProcessMorcos LokaNo ratings yet

- Regulasi BE TGA - Guidance-15-Biopharmaceutic-StudiesDocument18 pagesRegulasi BE TGA - Guidance-15-Biopharmaceutic-StudiesFaradina Astari MunandarNo ratings yet

- Giz2012 0398en Eu Who GuidelinesDocument51 pagesGiz2012 0398en Eu Who Guidelinesmailtorubal2573No ratings yet

- Imds Newsletter 53Document4 pagesImds Newsletter 53taleshNo ratings yet

- Mac 5000Document228 pagesMac 5000anwar1971No ratings yet

- 07-Oct. ..... (Nilam...Document3 pages07-Oct. ..... (Nilam...krishna vermaNo ratings yet

- A Guide To The Methods To Data AnalysisDocument8 pagesA Guide To The Methods To Data AnalysisRui AbílioNo ratings yet

- Manual de Intretinere Si Reparatii Auto in Limba Romana GratisDocument3 pagesManual de Intretinere Si Reparatii Auto in Limba Romana Gratisviper33_4u25% (4)

- 3 2 Kisor ApprovedDocument40 pages3 2 Kisor Approvedsujiv_sujiv1278No ratings yet

- Teachers Who Write Conference: Jay PariniDocument3 pagesTeachers Who Write Conference: Jay PariniJenny AlbrightNo ratings yet

- CG Group AssDocument14 pagesCG Group AssSiew TengNo ratings yet

- PMIS 2. Construction CostDocument63 pagesPMIS 2. Construction Costangelica suazoNo ratings yet

- Our Know-How Your Higher Performance: Danieli Lynxs ShreddersDocument7 pagesOur Know-How Your Higher Performance: Danieli Lynxs ShreddersrezaNo ratings yet

- ListDocument36 pagesListsldjadNo ratings yet

- Liban, MIchelle Ann Rose - BSIT - AC4Document1 pageLiban, MIchelle Ann Rose - BSIT - AC4Michelle Ann Rose LibanNo ratings yet

- Linux Programming and Data Mining Lab ManualDocument97 pagesLinux Programming and Data Mining Lab ManualKomali RavindraNo ratings yet

- McLaren 570S COUPE Order SummaryDocument4 pagesMcLaren 570S COUPE Order SummarysolejNo ratings yet

- Equity Markets in India1Document86 pagesEquity Markets in India1anand_jobsNo ratings yet

- Cmos ReportDocument25 pagesCmos ReportNaveen KumarNo ratings yet

- Executive Summary Ent300Document1 pageExecutive Summary Ent300Bukhari Suhaidin100% (1)

- Toxin ReportDocument240 pagesToxin ReportTRUMPET OF GODNo ratings yet

- SIE 321 Probabilistic Models in OR Homework 4: Problem 1Document3 pagesSIE 321 Probabilistic Models in OR Homework 4: Problem 1sherryy619No ratings yet

- Arch Appointment LTRDocument3 pagesArch Appointment LTRshaikhaziz8450% (2)

- 1z0 447 DemoDocument5 pages1z0 447 Demojosegitijose24No ratings yet

- INV01604226 3962674 08272023+-+tokboxDocument2 pagesINV01604226 3962674 08272023+-+tokboxAnkit VermaNo ratings yet

- BSCID (1) Punjab Technical University Jalandhar Syllabus Scheme (1 ST To 6 TH Semester) For BSC in Interior DesigningDocument24 pagesBSCID (1) Punjab Technical University Jalandhar Syllabus Scheme (1 ST To 6 TH Semester) For BSC in Interior DesigningTollamu SanaNo ratings yet

- Aadipandey Teri MbaDocument101 pagesAadipandey Teri MbaADITYA PANDEY100% (1)

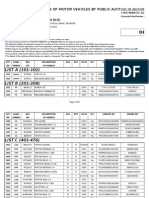

- Draft List: Proclamation of Sales of Motor Vehicles by Public AuctDocument20 pagesDraft List: Proclamation of Sales of Motor Vehicles by Public AuctHd YusNo ratings yet

- FPSC Annual Report 2016 Final - 0Document160 pagesFPSC Annual Report 2016 Final - 0haniya khanNo ratings yet

- Resume: Name: XXXXXX XXXXXX XXXXXXXXXDocument2 pagesResume: Name: XXXXXX XXXXXX XXXXXXXXXAditya Sangita Kisan SonawaneNo ratings yet

- Week 12 DigestDocument16 pagesWeek 12 DigestEdz Votefornoymar Del RosarioNo ratings yet

- Combination StrategyDocument5 pagesCombination StrategyNadya ShaminiNo ratings yet

- Youtubedownloader CodeDocument3 pagesYoutubedownloader CodeYusa 85No ratings yet