Professional Documents

Culture Documents

CHAPTER 10 Managing Product and Services Operation

CHAPTER 10 Managing Product and Services Operation

Uploaded by

Reymark Abatayo0 ratings0% found this document useful (0 votes)

47 views39 pagesThe document discusses the key concepts of operations management. It defines planning, organizing, controlling, efficiency, effectiveness and different types of transformation processes. The transformation processes include manufacturing processes like job shop, batch flow, assembly lines and continuous flow. It also discusses service processes like service factory and professional services. The document concludes that the engineer manager needs knowledge of these concepts and production system parts to effectively manage operations.

Original Description:

Original Title

290835274-CHAPTER-10-Managing-Product-and-Services-Operation.pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses the key concepts of operations management. It defines planning, organizing, controlling, efficiency, effectiveness and different types of transformation processes. The transformation processes include manufacturing processes like job shop, batch flow, assembly lines and continuous flow. It also discusses service processes like service factory and professional services. The document concludes that the engineer manager needs knowledge of these concepts and production system parts to effectively manage operations.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

47 views39 pagesCHAPTER 10 Managing Product and Services Operation

CHAPTER 10 Managing Product and Services Operation

Uploaded by

Reymark AbatayoThe document discusses the key concepts of operations management. It defines planning, organizing, controlling, efficiency, effectiveness and different types of transformation processes. The transformation processes include manufacturing processes like job shop, batch flow, assembly lines and continuous flow. It also discusses service processes like service factory and professional services. The document concludes that the engineer manager needs knowledge of these concepts and production system parts to effectively manage operations.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 39

Planning is a method of doing something

that is worked out in advance

Planning is the management function that

involves anticipating future trends and

determining the best strategies and tactics

to achieve organizational objectives

Organizing is a method in which to apply or

impose efficient working methods in order

to work effectively or make somebody else

work effectively.

Organizing is a management function which

refers to the structuring of resources and

activities to accomplish objectives in an

efficient and effective manner.

Controlling means to exercise power or

authority over something such as a

business or nation.

Controlling refers to the process of

ascertaining whether organizational

objectives have been achieved and

determining what activities should then be

taken to achieve objectives better in the

future.

Efficiency refers to the degree to which

something is done well or without wasted

energy.

Efficiency is related to the cost of doing

something, or the resource utilization

involved.

Effectiveness is the means of causing a

result, especially the desired or intended

result.

Effectiveness refers to goal accomplishment.

Anengineer manager is expected to produce

some output at whatever management level

he is.

The engineer manager must have some

knowledge of the various types of

transformation process and there are two

types of transformation process and they are

the manufacturing process, and the service

process

Manufacturing refers to producing goods that

are necessary for modern life from raw

materials. The word manufacture comes

from the Latin manus (hand) and facere (to

make).

Manufacturing process are those that refer to

making of products by hand or with

machinery.

Job shop

Batch flow

Worker-paced line flow/ worker-paced

assembly line

Machine-paced line flow/ machine-paced

assembly line

Batch/continuous flow hybrid

Continuous flow

A job shop is one whose production is based

on sales orders for variety of small lots.

Job shops manufacture products in small lots

that are needed by, but cannot be produced

economically by many companies.

Job shops produce custom products, in

general. Products may be manufactured

within a short notice. And manufacturing in

job shops are usually in labor intensive and

machines are frequently idle or not in use.

Inthe batch flow process generally own

designed products are manufactured.

There is flexibility to produce either low or

high volumes.

Not all procedures are performed in all

products.

The type of equipment used are mostly for

general purpose.

The process layout is used where similar

machines are grouped together.

The operation of labor intensive, although

there is less machine idleness.

The size of operation is generally medium-

sized.

A worker-paced assembly line is an assembly

line that refers to a production layout that is

arranged in a sequence to accommodate

processing of large volumes of standardized

products or services.

In the worker-paced assembly line the

products manufactured are mostly

standardized.

There is a clear process pattern.

Specialized equipment is used.

The size of operation is variable.

The process is work-paced.

The type of layout used is the line flow.

Labor is still a big cost item.

This

type of production process production

process produces mostly standard products

with machines playing a significant role.

The process is of clear , rigid pattern.

Specialized type of equipment is used.

The line flow layout is used.

Capitalized equipment is a bigger cost item

than labor.

Operation is large.

The process is machine-paced.

Thecontinuous flow processing is

characterized by the rapid rate at which

items move through the system.

This process method is used in producing highly

standardized products like calculators,

typewriters, automobiles, televisions, cellular

phones and etc.

There is economy of scale in production,

resulting to low per unit cost of production.

The process is clear and very rigid.

Specialized equipment is used.

The line flow layout is used.

Operations are highly capital intensive.

The size of operations is very large.

Process is fast.

serviceprocess are those that refer to the

provision of services to persons by hand or

with machinery.

Service factory

Service shop

Mass service

Professional service

A service factory offers a limited mix of

service which results to some economies of

scale in operations.

Theprocess layout preferred by the service

factory is the rigid pattern of line flow.

A service shop provides a diverse mix of

services.

Thelayout used are those for job shops or

fixed position and are adaptable to various

requirements.

A mass service company provides services to

a large number of people simultaneuosly.

These are companies that provide specialized

services to other firms or individuals.

Product design.

Production planning and scheduling.

Purchasing and materials management.

Inventory control.

Quality control.

Productdesign refers to the process of

creating a set of product specifications

appropriate to the demands of the situation.

Production planning is defined as forecasting

the future sales of a given product,

translating this forecast into the demand it

generates for various production facilities,

and arranging for the procurement of these

facilities.

Refers to the approach that seeks efficiency

of operation through integration of material

acquisition, movement, and storage

activities in the firm.

Isthe process of establishing and maintaining

appropriate levels of reserve stocks of goods.

Isthe process of determining the physical

arrangement of the production system

Refersto the measurement of products or

services against standards set by the

company.

The management of operations is very crucial to the

survival of firms. Operations refer to the changing of

inputs into useful outputs. In the effort to manufacture

products, operations management must contribute its

share in the accomplishment of the company’s objectives.

The function of the operations manager is to plan,

organize, and control operations in order to achieve

objectives efficiently and effectively. The engineer

manager is often times assigned to perform the tasks of

the operations manager.

The transformation process may be classified generally as

the manufacturing or service process. These two are sub

classified into various types, each with built-in advantages

depending on certain conditions.

Production system consist of various parts that

complement one another in the production task. The

engineer manager needs to be familiar with these various

parts.

You might also like

- Managing Production and Service OperationsDocument3 pagesManaging Production and Service OperationsJijomar Mandapat Bautista100% (3)

- Managing Production and Service OperationsDocument10 pagesManaging Production and Service OperationsJuana Abetria100% (1)

- EOS Quartz Date Back E Instruction ManualDocument17 pagesEOS Quartz Date Back E Instruction ManualBrett RogersNo ratings yet

- Assignment-1: Energy Efficiency and ConservationDocument10 pagesAssignment-1: Energy Efficiency and ConservationSudha VermaNo ratings yet

- BoeingDocument42 pagesBoeingHarsh SaxenaNo ratings yet

- CHAPTER 10-Managing Product and Services OperationDocument39 pagesCHAPTER 10-Managing Product and Services Operationsimonatics0850% (4)

- Engineering Management Chapter 4Document39 pagesEngineering Management Chapter 4julito paquitNo ratings yet

- The Relationship Between Lay Out DecisionsDocument4 pagesThe Relationship Between Lay Out Decisionsadipoliachayan5235No ratings yet

- Managing Production and Service OperationsDocument22 pagesManaging Production and Service OperationsJam LarsonNo ratings yet

- Managing Production and Srvice OperationDocument5 pagesManaging Production and Srvice OperationJolo MaganaNo ratings yet

- Prod Chap 1Document10 pagesProd Chap 1Rutvik DicholkarNo ratings yet

- Chapter 10-Eneman20Document4 pagesChapter 10-Eneman20Reynald John PastranaNo ratings yet

- Managing Service OperationsDocument26 pagesManaging Service OperationsCharles Kent DolotinaNo ratings yet

- Figure 8.1: Production SystemDocument4 pagesFigure 8.1: Production SystemHaseeb KhalidNo ratings yet

- Production Operation ManagemenT (ALL 5 UNITS)Document134 pagesProduction Operation ManagemenT (ALL 5 UNITS)Archi VarshneyNo ratings yet

- Pom Notes - 064919Document9 pagesPom Notes - 064919suduh09No ratings yet

- Process Selection and Facility LayoutDocument4 pagesProcess Selection and Facility LayoutClyde TorresNo ratings yet

- POM Notes For Cycle TestDocument42 pagesPOM Notes For Cycle TestKiruthika BaskarNo ratings yet

- Production and Operation Management ProjectDocument51 pagesProduction and Operation Management ProjectsachitNo ratings yet

- Production and Operations ManagmentDocument26 pagesProduction and Operations ManagmentAakanshaNo ratings yet

- Ilovepdf MergedDocument35 pagesIlovepdf MergedMark Angelo NioscoNo ratings yet

- Unit 1:-Production ManagementDocument13 pagesUnit 1:-Production ManagementParag TravadiNo ratings yet

- Process Selection: Influence That Process Has On An OrganizationDocument8 pagesProcess Selection: Influence That Process Has On An OrganizationCarla Jamina IbeNo ratings yet

- BBA Module 1Document39 pagesBBA Module 1Saurabh PoteNo ratings yet

- Bustamante - Chapters 6-11Document21 pagesBustamante - Chapters 6-11Jona BustamanteNo ratings yet

- Bus 1010Document7 pagesBus 1010catherinegunneryNo ratings yet

- Product Design ProcessDocument7 pagesProduct Design ProcessMau BautistaNo ratings yet

- Question No:01: What Do You Understand by Process Strategy and Process Analysis?Document5 pagesQuestion No:01: What Do You Understand by Process Strategy and Process Analysis?richard gomesNo ratings yet

- Om0017 Solved AssignmentDocument13 pagesOm0017 Solved AssignmentAnant KumarNo ratings yet

- POM CLASS Notes PrintDocument17 pagesPOM CLASS Notes PrintvmktptNo ratings yet

- POM Unit IDocument18 pagesPOM Unit IShiVâ SãiNo ratings yet

- Module 1 OSCMDocument11 pagesModule 1 OSCMSasti NashaNo ratings yet

- Lesson 8 (Process Design/Advanced Operations Technologies)Document6 pagesLesson 8 (Process Design/Advanced Operations Technologies)Marica ShaneNo ratings yet

- Summer Training In: Under The Guidance Of-Mr - Pritam GhoshDocument37 pagesSummer Training In: Under The Guidance Of-Mr - Pritam GhoshParth Saxena 17IFT010No ratings yet

- OPREATIONS MANAGEMENT Module 1Document24 pagesOPREATIONS MANAGEMENT Module 1Badiger DiwakarNo ratings yet

- Managing Products and Services OperationsDocument11 pagesManaging Products and Services OperationsAnne PecadizoNo ratings yet

- MEP 407 Production Management ProductionDocument13 pagesMEP 407 Production Management ProductionMaryjane AdebayoNo ratings yet

- Chapter 3 Part II Process Selection and Facility LayoutDocument46 pagesChapter 3 Part II Process Selection and Facility LayoutHailemariamNo ratings yet

- Process Selection and Facility Layout NEWDocument15 pagesProcess Selection and Facility Layout NEWAlexis P. BatingNo ratings yet

- MMPC009Document4 pagesMMPC009210010502041.mgtNo ratings yet

- Operations Management AssignmentDocument8 pagesOperations Management AssignmentAkash ManekNo ratings yet

- Unit-3 Iem NotesDocument10 pagesUnit-3 Iem NotesAmar KoliNo ratings yet

- Smu Mb0044 Sem 2 Assignments 2012 Set 2Document10 pagesSmu Mb0044 Sem 2 Assignments 2012 Set 2krishsediNo ratings yet

- CH 10Document23 pagesCH 10monel_24671No ratings yet

- Om (6) ReviewerDocument9 pagesOm (6) ReviewerElle HeizelNo ratings yet

- Operation ManagementDocument8 pagesOperation ManagementZEESHAN ALINo ratings yet

- Introduction To Production ManagementDocument38 pagesIntroduction To Production ManagementsatexNo ratings yet

- Chapter 10Document2 pagesChapter 10Mark Anthony Mores FalogmeNo ratings yet

- Operations ManagementDocument43 pagesOperations ManagementViraja GuruNo ratings yet

- 2023 Business Management 1 Notes Second SemesterDocument53 pages2023 Business Management 1 Notes Second SemesterpreciousNo ratings yet

- Chapter 10Document2 pagesChapter 10Jeil Francisco100% (1)

- MB0044Document12 pagesMB0044sanket goreNo ratings yet

- Placement Preparation - Strategic Decision - OperationsDocument10 pagesPlacement Preparation - Strategic Decision - OperationsTopsy KreateNo ratings yet

- LOMDocument6 pagesLOMrajkumar0507No ratings yet

- Om Unit IDocument20 pagesOm Unit IMiyonNo ratings yet

- 2nd CONCEPT OF PRODUCTIONDocument6 pages2nd CONCEPT OF PRODUCTIONsetiawan jozzNo ratings yet

- Course Mba - 2 Semester Subject Assignment MB0044 - Set 1: Production and Operations ManagementDocument14 pagesCourse Mba - 2 Semester Subject Assignment MB0044 - Set 1: Production and Operations ManagementDantham ConpolwedsonNo ratings yet

- Introduction of Computer Aided Process PlanningDocument25 pagesIntroduction of Computer Aided Process PlanningParamtap MewadaNo ratings yet

- Unit IPPCDocument65 pagesUnit IPPCRajbir SinghNo ratings yet

- Operations Module-1 PDFDocument17 pagesOperations Module-1 PDFJeleetta MathewNo ratings yet

- Production and Operation ManagementDocument41 pagesProduction and Operation ManagementJessamine Romano AplodNo ratings yet

- How to Create Continuous Production Flow?: Toyota Production System ConceptsFrom EverandHow to Create Continuous Production Flow?: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- 1NH16MAE10 Provisional Grade CardDocument1 page1NH16MAE10 Provisional Grade CardawarialocksNo ratings yet

- Assignment 2 The N-FactorDocument2 pagesAssignment 2 The N-FactorAhmed Valentin KassemNo ratings yet

- Mobil ATF 3309: Automatic Transmission FluidDocument2 pagesMobil ATF 3309: Automatic Transmission FluidАндрей СилаевNo ratings yet

- Six Sigma Implementation Leverages Business ExcellenceDocument5 pagesSix Sigma Implementation Leverages Business Excellencemindi_thrNo ratings yet

- Aerion AS2 A 5 Billion Supersonic SagaDocument11 pagesAerion AS2 A 5 Billion Supersonic Sagaflateric74@yandex.ruNo ratings yet

- As ISO 1000-1998 The International System of Units (SI) and Its ApplicationDocument8 pagesAs ISO 1000-1998 The International System of Units (SI) and Its ApplicationSAI Global - APACNo ratings yet

- MidtermDocument12 pagesMidtermRaphaelaSimionNo ratings yet

- 09 Task Performance 1Document1 page09 Task Performance 1fransherl2004No ratings yet

- TWMC Price BookDocument171 pagesTWMC Price BookEdisonNo ratings yet

- Customer Satisfaction StudyDocument2 pagesCustomer Satisfaction StudyranasherdilNo ratings yet

- SI and MFTDocument354 pagesSI and MFTAbhishek DhawanNo ratings yet

- ASDASVRRSDASDDocument64 pagesASDASVRRSDASDbsrksg123No ratings yet

- COMPARISON OF STEEL GRADES - Part7Document1 pageCOMPARISON OF STEEL GRADES - Part7Ujwal KhandokarNo ratings yet

- Case Study-R12 12Document81 pagesCase Study-R12 12ranjitpandeyNo ratings yet

- WARCO BILTRITE Rubber Products Catalog PDFDocument39 pagesWARCO BILTRITE Rubber Products Catalog PDFsurjeetsandhuria4481No ratings yet

- Exhibitors CatalogueDocument128 pagesExhibitors CatalogueDeepakNo ratings yet

- Production-Technology-11 04 2020Document9 pagesProduction-Technology-11 04 2020Selvaraj SimiyonNo ratings yet

- Strategy Formulation of Biman Bangladesh Airlines Ltd. SIM: 501 (Fundamentals of Strategic Management)Document14 pagesStrategy Formulation of Biman Bangladesh Airlines Ltd. SIM: 501 (Fundamentals of Strategic Management)Shahidul Rassel100% (2)

- Operations Management Lecture - 1Document7 pagesOperations Management Lecture - 1tusharNo ratings yet

- PTC Creo GearDocument6 pagesPTC Creo Gearbrpnaidu2157No ratings yet

- 082.lusan Co., LTD Vietnam: Luciano Anthony FalascaDocument7 pages082.lusan Co., LTD Vietnam: Luciano Anthony FalascaFlinders TrusteesNo ratings yet

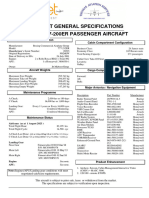

- B777 200ER General Specification SN 28525 080823Document1 pageB777 200ER General Specification SN 28525 080823Ruphin ElumbaNo ratings yet

- Ammo Manager Reference GuideDocument68 pagesAmmo Manager Reference GuideL2eman100% (1)

- Premium 323 Assembly Instructions (759kbDocument12 pagesPremium 323 Assembly Instructions (759kbLuis BoicetNo ratings yet

- Chapter 14mDocument24 pagesChapter 14mamirNo ratings yet

- Company ProfileDocument25 pagesCompany ProfileSyed Zuber Ahmed100% (1)

- 327101-A-Pln-0001 - 00 - Pep PDFDocument33 pages327101-A-Pln-0001 - 00 - Pep PDFGokulprabhuNo ratings yet