Professional Documents

Culture Documents

Supply Chain Planning and Control

Supply Chain Planning and Control

Uploaded by

Sumana Allagadda0 ratings0% found this document useful (0 votes)

138 views6 pagesbasic working of scm in manufacturing sector

Original Title

SCM use

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbasic working of scm in manufacturing sector

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

138 views6 pagesSupply Chain Planning and Control

Supply Chain Planning and Control

Uploaded by

Sumana Allagaddabasic working of scm in manufacturing sector

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 6

Supply Chain Planning and Control

Copyright © 2012 Mahindra & Mahindra Ltd. All rights reserved.

Overview of the presentation

• Evolution of Supply Chain Management

• Basic Definition of SCM

• Major Components in SCM

• Process of Procurement

•Activities of Buyer

• My Work

• Observations and scope of improvement areas

Copyright © 2012 Mahindra & Mahindra Ltd. All rights reserved.

Basic Definition of SCM:

•A set of approaches used to efficiently integrate

- Suppliers

-Manufacturers

-Warehouses

-Distribution centers

•So that the product is produced and distributed

- In the right quantities

- To the right locations

- And at the right time

Copyright © 2012 Mahindra & Mahindra Ltd. All rights reserved.

Major components of SCPC

PPC Buying Stores Logistics

• Coordinating • Ensuring • Receipt of • Inbound -

with CPPC for material materials. Transportation

production availability as • Put away , of material

planning at ZHB. per the plan storage and from suppliers

• Ensuring the released by PPC. Issuance of to plant.

production • Maintaining material as per • Outbound -

according to the inventory the production transportation

plan and norms. plan. of finished

material • Manage • Making tractors to the

availability. procurement of continual respective

• Liaison between material from improvement to Stockyards.

cross functional other Units accommodate

departments . (IUTN). new parts,

• Ensuring • Ensure material improve

adherence to availability for inventory

the model Model Migration accuracy.

migration plan .

Copyright © 2012 Mahindra & Mahindra Ltd. All rights reserved.

Types of Procurement:

1. Direct Procurement:

Acquiring raw material and goods for production.

Mostly acquired in large quantities, frequently necessary for key

business practices

2. Indirect Procurement:

Purchasing supplies or services required to keep the day to day

business alive.

Copyright © 2012 Mahindra & Mahindra Ltd. All rights reserved.

Activities of Buyer

• Daily planning meet with the planner

• Follow up and accelerate procurement to adhere with schedule

• Shortage list made for the critical components

• Raise premium freight request for critical parts

• Regular talks with hub-buyer about the schedules released for the parts

• By taking MLL help tracking the status of the parts in transit

• Track the go-down stocks on the regular basis and clear the pending ASN>25 days

• Aged part analysis and liquidation plan for the same

• Have to maintain inventory as per DBM norms and procurement is done accordingly

• Check the pending GR bills, vendor bills, Rejections and take required actions

• Status review of ER parts(old and New) accordingly plan given by ER coordinator

• Cross checking physical stocks with the SAP stock to avoid discrepancy

Copyright © 2012 Mahindra & Mahindra Ltd. All rights reserved.

You might also like

- Question 1. KANO MODEL ANALYSIS - Voice of Customer: ThemeDocument6 pagesQuestion 1. KANO MODEL ANALYSIS - Voice of Customer: Themesneha0895No ratings yet

- DGMP 14 IIML Placement Brochure (Final)Document24 pagesDGMP 14 IIML Placement Brochure (Final)Payasam AbhilashNo ratings yet

- 4922832271Document4 pages4922832271dsmita20No ratings yet

- CV - Vendor Development - 8 YrsDocument3 pagesCV - Vendor Development - 8 YrsGopi KrishnanNo ratings yet

- Manufacturing KRADocument1 pageManufacturing KRAchirag bhojakNo ratings yet

- Expt 2Document7 pagesExpt 2toshgangwarNo ratings yet

- Asset-V1 TUMx+QPLS1x+2T2018+type@asset+block@SixSigma Process-Improvement Methods ToolsDocument85 pagesAsset-V1 TUMx+QPLS1x+2T2018+type@asset+block@SixSigma Process-Improvement Methods ToolsAmar MohammedNo ratings yet

- Ims Operation Manual Purchase Department: Ivrcl Limited, HyderabadDocument14 pagesIms Operation Manual Purchase Department: Ivrcl Limited, HyderabadAkd DeshmukhNo ratings yet

- Questionnaire For Foundry Raw Material or Scrap MetalDocument8 pagesQuestionnaire For Foundry Raw Material or Scrap MetalMichelleNo ratings yet

- A 153Document1 pageA 153AnuranjanNo ratings yet

- Kraft Foods: Data Migration Backoffice AssociatesDocument3 pagesKraft Foods: Data Migration Backoffice AssociatesrsreevatsNo ratings yet

- Quality Circle Presentation From Cheese PlantDocument36 pagesQuality Circle Presentation From Cheese Plantshivam singhNo ratings yet

- Chapter3 SupplychaindriversametricsDocument24 pagesChapter3 SupplychaindriversametricsNoor Harlisa Irdina Mohd HasanNo ratings yet

- Booster Pump Quotation SPQ16-000169 PDFDocument4 pagesBooster Pump Quotation SPQ16-000169 PDFAdil Aziz0% (1)

- Structure of Utility Stores Corporation of Pakistan (PVT) LTD at A GlanceDocument9 pagesStructure of Utility Stores Corporation of Pakistan (PVT) LTD at A GlanceMuhammad UsmanNo ratings yet

- Va VeDocument5 pagesVa VePranayteja.G gottipamulaNo ratings yet

- Request For Quotation: (Supplier) (Puma Id) (Plant)Document7 pagesRequest For Quotation: (Supplier) (Puma Id) (Plant)Artur GerasimovNo ratings yet

- Balanced Scorecard AcumenDocument1 pageBalanced Scorecard Acumencommunityst100% (1)

- Sap Direct Procurement Process Flow (SAP Library - Plan-Driven Procurement)Document1 pageSap Direct Procurement Process Flow (SAP Library - Plan-Driven Procurement)Abeezar Tyebji0% (1)

- Vendor Registration FormDocument10 pagesVendor Registration FormPooja MasalNo ratings yet

- Chemcon Brochure 1Document2 pagesChemcon Brochure 1Elavarasan PandianNo ratings yet

- Sourcing and Supply Management: Author: B. Mahadevan Operations Management: Theory and Practice, 3eDocument24 pagesSourcing and Supply Management: Author: B. Mahadevan Operations Management: Theory and Practice, 3eakankshaNo ratings yet

- KRA Master ListDocument1 pageKRA Master ListashishNo ratings yet

- AFC2-Business Communication StudytextDocument222 pagesAFC2-Business Communication StudytextehsanNo ratings yet

- Dell QSA Audit Checklist - CNDocument52 pagesDell QSA Audit Checklist - CNMichael WuNo ratings yet

- Project Charter TemplateDocument3 pagesProject Charter TemplateSarvesh DaradeNo ratings yet

- Marketing ManagerDocument2 pagesMarketing ManagerANUBHAV SINGH TOMARNo ratings yet

- API DGM NewDocument2 pagesAPI DGM NewSyed Raunaq Hussain ZaidiNo ratings yet

- Quality Planning ProcessDocument36 pagesQuality Planning ProcessBhaswati PandaNo ratings yet

- SCLM 439-Group 4-Case Study Week 9Document6 pagesSCLM 439-Group 4-Case Study Week 9Hiếu PhamNo ratings yet

- Vendor Management Software and The Power of ADocument13 pagesVendor Management Software and The Power of AKhushi RawaniNo ratings yet

- QA Roles & ResponsibleDocument5 pagesQA Roles & ResponsibleMohd Ezan MohammadiahNo ratings yet

- Technical Data Sheet: Century Paper & Board Mills LimitedDocument1 pageTechnical Data Sheet: Century Paper & Board Mills LimitedSaad IqbalNo ratings yet

- G Sundar Pharmqa Compliance Services IndiaDocument26 pagesG Sundar Pharmqa Compliance Services IndiaTarikNo ratings yet

- MAGTECH-Presentation - Main 2020 - CompressedDocument68 pagesMAGTECH-Presentation - Main 2020 - CompressedMazaharul IslamNo ratings yet

- Quality & Industrial Performance: Supply Chain ManagementDocument50 pagesQuality & Industrial Performance: Supply Chain ManagementMojtaba MousaviNo ratings yet

- Job Description Procurement ExecutiveDocument1 pageJob Description Procurement ExecutiveZulqarnainNo ratings yet

- Cas and GacapDocument23 pagesCas and GacapMuraliprasad SaNo ratings yet

- Software Process Reviews/Audits Process OverviewDocument22 pagesSoftware Process Reviews/Audits Process OverviewVipendra SinghNo ratings yet

- Capricorn DHP Process Flow Chart NewDocument3 pagesCapricorn DHP Process Flow Chart NewmuralivijayNo ratings yet

- Advanced Accounting and Financial ReportingDocument6 pagesAdvanced Accounting and Financial ReportingAhmed Raza MirNo ratings yet

- Sipoc Diagram: Best-In-Class Template Analysis and RecommendationDocument12 pagesSipoc Diagram: Best-In-Class Template Analysis and RecommendationrinsuastiNo ratings yet

- WCSQ JourneyDocument28 pagesWCSQ JourneyAmit Kumar SinghNo ratings yet

- Disclosure To Promote The Right To InformationDocument15 pagesDisclosure To Promote The Right To InformationNitinNo ratings yet

- Plant LayoutDocument8 pagesPlant LayoutDaman KaurNo ratings yet

- 7 Logistics - WarehousingDocument20 pages7 Logistics - Warehousingashish.bms9100% (4)

- Quality Function DeploymentDocument8 pagesQuality Function DeploymentNivedh VijayakrishnanNo ratings yet

- Honda Motorcycle WarrantyDocument2 pagesHonda Motorcycle WarrantyDwaylon Rockcliffe100% (1)

- 1 - What Is ASES, 2 - Explanation of The QuestionnaireDocument50 pages1 - What Is ASES, 2 - Explanation of The QuestionnaireCarlos AguilarNo ratings yet

- Each Slide Contains Topics To Be Covered in Your PresentationDocument9 pagesEach Slide Contains Topics To Be Covered in Your Presentationhency2uNo ratings yet

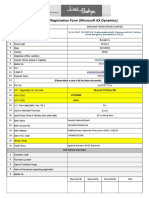

- ERP Vendor Registration Form (Microsoft AX Dynamics)Document1 pageERP Vendor Registration Form (Microsoft AX Dynamics)prashant dwivediNo ratings yet

- Vendor Registration FormatDocument6 pagesVendor Registration FormatMuthu Kumar RNo ratings yet

- Amul Supply Chain Management PracticesDocument4 pagesAmul Supply Chain Management PracticesAnchal BaggaNo ratings yet

- Class A Check ListDocument42 pagesClass A Check ListJose Daniel Garcia100% (1)

- SCM and E-BusinessDocument134 pagesSCM and E-BusinessketoqardiNo ratings yet

- Presentation On Organizational Visit On: Bend Joints Pvt. LTDDocument16 pagesPresentation On Organizational Visit On: Bend Joints Pvt. LTDPraveen MayarNo ratings yet

- SEML PresentationDocument47 pagesSEML PresentationalparathiNo ratings yet

- A163097733 - 22641 - 1 - 2019 - Unit 4Document106 pagesA163097733 - 22641 - 1 - 2019 - Unit 4avinasss1963_3707255No ratings yet

- Forecasting TechniquesDocument25 pagesForecasting TechniquesAshraf S. Youssef100% (3)

- CV - Ho Ngoc Tran (Resize)Document5 pagesCV - Ho Ngoc Tran (Resize)Phi ĐằngNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Industrial Training ReportDocument6 pagesIndustrial Training Reportmayank guptaNo ratings yet

- Chapter 5: Children'S Fiction: Lesson 1: Worlds and VoicesDocument5 pagesChapter 5: Children'S Fiction: Lesson 1: Worlds and VoicesRaquel LimboNo ratings yet

- Gosat Gs 7055 Hdi FirmwareDocument3 pagesGosat Gs 7055 Hdi FirmwareAntoinetteNo ratings yet

- En SATURNevo ZGS.10.20 User Manual 13Document1 pageEn SATURNevo ZGS.10.20 User Manual 13emadsafy20002239No ratings yet

- LOPC-mech Seal FailureDocument26 pagesLOPC-mech Seal FailureSanjeevi Kumar SpNo ratings yet

- John Deere - Parts Catalog - Frame 5 v-3103Document2 pagesJohn Deere - Parts Catalog - Frame 5 v-3103eliasNo ratings yet

- ATR72 Freighter VersionDocument6 pagesATR72 Freighter Versiontomay777No ratings yet

- Pontryagin's Maximum PrincipleDocument21 pagesPontryagin's Maximum PrincipleAhmed TalbiNo ratings yet

- Diffraction GratingsDocument5 pagesDiffraction GratingsJohn JohnsonNo ratings yet

- Lorentz Factor Formula - Google SearchDocument1 pageLorentz Factor Formula - Google Searchnppptry4kmNo ratings yet

- Syllabus For Applied ElectronicsDocument28 pagesSyllabus For Applied ElectronicsvinayakbondNo ratings yet

- PDS01.05.001 - Wouter Witzel - EVBLSDocument3 pagesPDS01.05.001 - Wouter Witzel - EVBLSVilius BukysNo ratings yet

- Comparative and Superlative AdjectivesDocument5 pagesComparative and Superlative AdjectivesYoussef BrsNo ratings yet

- The Ethnography of Communication: Mădălina MATEIDocument8 pagesThe Ethnography of Communication: Mădălina MATEIamir_marzbanNo ratings yet

- Blank 7E Lesson Plan TemplateDocument5 pagesBlank 7E Lesson Plan TemplateJoshuel AgpasaNo ratings yet

- Trends in Food Science & Technology: SciencedirectDocument13 pagesTrends in Food Science & Technology: SciencedirectIlija MileticNo ratings yet

- Case Study 148 169Document22 pagesCase Study 148 169Vonn GuintoNo ratings yet

- Computer Graphics - Chapter 3 (1) - 2Document35 pagesComputer Graphics - Chapter 3 (1) - 2Sương TrầnNo ratings yet

- Safety Rules and Laboratory Equipment: Experiment 1Document5 pagesSafety Rules and Laboratory Equipment: Experiment 1ricardojosecortinaNo ratings yet

- PreloadDocument21 pagesPreloadjainshani2No ratings yet

- Tunnel Engineering MCQ PDFDocument9 pagesTunnel Engineering MCQ PDFAkshayNo ratings yet

- The Advantages of Fiedler's Contingency ModelDocument10 pagesThe Advantages of Fiedler's Contingency ModelAnwar LaskarNo ratings yet

- Task Force ProposalDocument8 pagesTask Force ProposalForkLogNo ratings yet

- 1385 PDFDocument70 pages1385 PDFEdmund ZinNo ratings yet

- String/Arrays in JavaDocument7 pagesString/Arrays in JavaSaif HassanNo ratings yet

- Tata Motors's AchivementsDocument105 pagesTata Motors's AchivementsSunny SinghNo ratings yet

- 5S (Methodology) : 5S Is The Name of A Workplace Organization Methodology That Uses A List of FiveDocument3 pages5S (Methodology) : 5S Is The Name of A Workplace Organization Methodology That Uses A List of FiveRoberto DiyNo ratings yet

- Profile of Dr. APJ Abdul KalamDocument3 pagesProfile of Dr. APJ Abdul KalammukeshNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)