Professional Documents

Culture Documents

Bored Pile Installation

Bored Pile Installation

Uploaded by

adnan0 ratings0% found this document useful (0 votes)

42 views134 pagesThis document provides information on bored pile construction including definitions, applicable inspection plans and checklists, references, coverage of pile machinery and methods, photos, and testing requirements. It aims to educate project personnel on bored piling processes and the importance of proper techniques and inspection. Key points covered include the use of bored piles for heavy foundations, drilling methods, inspection plans for materials and installation, references on standards and codes, photos of machinery and installation steps, and integrity testing requirements for foundations piles.

Original Description:

Bored Pile Installation ppt

Original Title

Bored Pile Installation ppt

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information on bored pile construction including definitions, applicable inspection plans and checklists, references, coverage of pile machinery and methods, photos, and testing requirements. It aims to educate project personnel on bored piling processes and the importance of proper techniques and inspection. Key points covered include the use of bored piles for heavy foundations, drilling methods, inspection plans for materials and installation, references on standards and codes, photos of machinery and installation steps, and integrity testing requirements for foundations piles.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

42 views134 pagesBored Pile Installation

Bored Pile Installation

Uploaded by

adnanThis document provides information on bored pile construction including definitions, applicable inspection plans and checklists, references, coverage of pile machinery and methods, photos, and testing requirements. It aims to educate project personnel on bored piling processes and the importance of proper techniques and inspection. Key points covered include the use of bored piles for heavy foundations, drilling methods, inspection plans for materials and installation, references on standards and codes, photos of machinery and installation steps, and integrity testing requirements for foundations piles.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 134

TABLE OF CONTENTS

I. INTRODUCTION & DEFINITION OF TERMS

II. APPLICABLE ITP & CHECKLIST

III.REFERENCES

IV.TOPIC

V.PHOTOS

VI.SUMMARY

VII.ATTENDANCE SHEET

VIII. COVERAGE

INTRODUCTION & DEFINITION OF TERMS

THE TERM “BORED PILE“

Bored pile is another type of reinforced concrete pile which is

used to support high building which has heavy vertical load.

Bored pile is a cast-in-place concrete pile where the bored

piles have to be cast on construction site.

Normally bored piling has be to carried on those tall buildings

or massive industrial complexes, which require foundations

which can bear the load of thousands of tons, most probably

in unstable or difficult soil conditions. Bored piling is cast by

using bored piling machine which has specially designed

drilling tools, buckets and grabs, it’s used to remove the soil

and rock. Normally it can be drilling into 50metres depth of

soil. The advantage of bored piling is its’ drilling method,

little vibration and lower noise level.

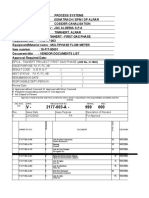

APPLICABLE ITP & CHECKLIST

JIGCC TYPICAL INSPECTION PLAN

Bored Cast-In-Place Concrete Piles

DOCUMENT REVIEW

1. Raw Materials Sampling Testing and Concrete Mix Design

Approval. Review and Approval of Procedures for Special

Construction Processes. SAIC-Q-1006

RECEIVING INSPECTION

1. Epoxy Coated Steel Bars and Embedded Items Receiving

Inspection. SAIC-Q-1007

2. Handling, Storage and Preservation of Epoxy Coated /

Uncoated Steel Bars. SAIC-Q-1008

INSTALLATION

1. Soil improvement and Pre- installation inspection. CHEC-IC-

BP-1001

2. FBE Coated Reinforcing Steel, Embedded Items and Form

Closure Inspection. SAIC- Q-1013

3. Drilling of Pile Bore Hole Inspection. CHEC-IC-BP-1002

4. Concrete Sampling, Testing and Placement Inspection and

Withdrawal of Casing Inspection. CHEC-IC-BP-1003

5. Concrete Finishing and Curing Inspection. SAIC-Q-1015

6. Verification and Testing of Drilled Cast In-Place Concrete

Piles Inspection. CHEC-IC-BP-1004

7. Concrete Compressive Strength Testing and Final Inspection.

CHEC-IC-BP-1005

REFERENCES

IFC Drawings & Method Statement.

ACI 117-06 Specifications for Tolerances for Concrete Construction

and Materials and Commentary.

AC1318M-11 Building Code Requirements for Structure Concrete and

Commentary.

ASCE 7-05 Minimum design loads for buildings and other structures.

ACI 350M-06 Code requirements for environmental engineering

concrete structures and commentary.

SABP-Q-009 Pile Foundation Specifications and Bearing Capacities.

ASTM D5882 (2007) Standard Test Methods for Low Strain Impact

Integrity Testing of Deep Foundations.

ASTM D3689 (2007) Standard Test Method for Individual Piles

under Static Axial.

Guides, Methods and Standard

Practices to Bored Pile

Installation

COVERAGE

1. Bore Pile Machinery

2. Bored Piling Method

PHOTO for Bore Pile Machinery

PHOTO for Bore Pile Methodology

ASTM D5882 REQUIREMENTS FOR PILE INTEGRITY TEST

Pile integrity test is to serve as a screening process to identify

acoustically anomalous piles. It is low strain dynamic test (a

light impact is applied to a pile it produces a low strain) based on

wave propagation theory. The impact produces a compression

wave that travels down the pile at a constant wave speed.

Changes in cross sectional area - such as a reduction in diameter

- or material - such as a void in concrete - produce wave

reflections.

This procedure is performed with a hand held hammer to

generate an impact, an accelerometer or geophone placed on top

of the pile to be tested to measure the response to the hammer

impact, and a data acquisition and interpretation electronic

instrument.

INTEGRITY TEST METHOD FOR FOUNDATION PILES

ACCELEROMETER WITH HAMMER HARD PLASTIC TIP

THE REQUIREMENTS OF THIS STANDARD ARE

Item Description Requirements

5.1.1. Impact force application Hammer with hard plastic tip

5.2.1. Accelerometer linearity Up to 50 g

5.2.1. Accelerometer time constant ≥0.5 sec

5.2.1. Resonant frequency ≥ 30 kHz

5.2.1 Calibration accuracy 5%

5.3. Signal transmission Low-noise shielded cable

5.4.1. Apparatus Permanent graphic display

5.4.1. Apparatus Permanent data storage capability

5.4.1. Apparatus Blow averaging capability

5.4.1. Apparatus Variable amplification

5.4.1. Apparatus Filtering capability

5.4.2. Recording apparatus 12 bit A/D resolution

5.4.2. Sample frequency 25 kHz

5.4.2. Clock jitter ≤0.01%

5.4.4. Signal duration scale 2 L/c plus 5 msec

SUMMARY

The intention of this short presentation is to

enlighten and educate people in our project on the

methods, guidance, execution, and inspection

regarding Bored Piling Activities. This

presentation is intended to all quality personnel,

site construction staff and even the management

on the significance and limitations of Bored piling

processes. It explains to every body how important

is our knowledge and techniques during Bored

Piling construction .

THE

END

You might also like

- HowTo BS8500 Feb23Document16 pagesHowTo BS8500 Feb23Amresh Kumar100% (1)

- Israel Standard SI 5435 - Fire Safety PDFDocument45 pagesIsrael Standard SI 5435 - Fire Safety PDFcocorruoNo ratings yet

- Guideline On RSA ManagementDocument103 pagesGuideline On RSA ManagementAmirul BassNo ratings yet

- JKR20710 0001 11 PDFDocument13 pagesJKR20710 0001 11 PDFGeneNo ratings yet

- Body Corporate Guidelines PDFDocument17 pagesBody Corporate Guidelines PDFmaNo ratings yet

- Ground Treatment at Landside ExpresswayDocument18 pagesGround Treatment at Landside Expresswaysanusi69No ratings yet

- Summary Average Price Sabah Ok T 09Document12 pagesSummary Average Price Sabah Ok T 09Jayson TeeNo ratings yet

- (2018) 1 LNS 1107 Legal Network SeriesDocument38 pages(2018) 1 LNS 1107 Legal Network SeriesSrikumar RameshNo ratings yet

- Audit Checklist - 04-12-2005Document25 pagesAudit Checklist - 04-12-2005adnanNo ratings yet

- 2.3 Introduction To Building CodesDocument17 pages2.3 Introduction To Building Codeszul100% (1)

- FIDIC Contract BooksDocument23 pagesFIDIC Contract BooksMadhusudan Tata92% (13)

- Ajiya Glass Product Presentation 2023Document51 pagesAjiya Glass Product Presentation 2023Cheng Gi NiNo ratings yet

- MS 1064 PT 8 2001 Confirmed Prepdf PDFDocument5 pagesMS 1064 PT 8 2001 Confirmed Prepdf PDFFauziah AzizNo ratings yet

- Price List - Fidic DocumentsDocument3 pagesPrice List - Fidic DocumentsShahnawaz AzizNo ratings yet

- Specification For Highway Works UK - SERIES 1900Document78 pagesSpecification For Highway Works UK - SERIES 1900Kévin JacobNo ratings yet

- Concrete Lab ManualDocument21 pagesConcrete Lab ManualMohammad Irshad AlamNo ratings yet

- Volume IV of IV Vol 1 of 2 - CLQ DrawingsDocument132 pagesVolume IV of IV Vol 1 of 2 - CLQ Drawingsjhtan84No ratings yet

- Post-Tensioned Box Girder Design Manual: June 2016Document389 pagesPost-Tensioned Box Girder Design Manual: June 2016aandueza_1No ratings yet

- Design Formula For EC2 Version 04 UTMDocument23 pagesDesign Formula For EC2 Version 04 UTMJackieSimNo ratings yet

- General Earthwork Procedures: PT Aurecon Indonesia ProcedureDocument16 pagesGeneral Earthwork Procedures: PT Aurecon Indonesia ProcedureMahmoud100% (1)

- Consulting Civil EngineerDocument2 pagesConsulting Civil EngineerRobbyTeresaNo ratings yet

- BS 5075-2-1982 - Concrete Admixtures - Specification For Air Entraining AdmixturesDocument19 pagesBS 5075-2-1982 - Concrete Admixtures - Specification For Air Entraining AdmixturesRaviranjan kumarNo ratings yet

- IWK Guide On FeeDocument1 pageIWK Guide On FeeJohnyReubenNo ratings yet

- Interlocking Sheet PileDocument17 pagesInterlocking Sheet PileAshman Daniel100% (1)

- ELS Sample Questions For 2010 HKPU T3 Top Up Course PDFDocument2 pagesELS Sample Questions For 2010 HKPU T3 Top Up Course PDFYu chung yinNo ratings yet

- Guide To Fill in Form G From BEM PDFDocument6 pagesGuide To Fill in Form G From BEM PDFJaya PrathabNo ratings yet

- SSB03 ActionsDocument64 pagesSSB03 Actionsanil97232No ratings yet

- FIDIC MDB 2010 & 2006 ComparisionDocument8 pagesFIDIC MDB 2010 & 2006 ComparisionSintayehu Ayele GoshuNo ratings yet

- Code of Practice For Structural Use of Concrete - HK - 1987Document68 pagesCode of Practice For Structural Use of Concrete - HK - 1987nebojsadj6411100% (1)

- BS 743 - 1970 - Materials For Damp-Proof CoursesDocument13 pagesBS 743 - 1970 - Materials For Damp-Proof CoursesPhyu Mar Thein Kyaw100% (1)

- Example Presentation APVODocument25 pagesExample Presentation APVOAbd Aziz MohamedNo ratings yet

- OKA G45 RC - Square PilesDocument4 pagesOKA G45 RC - Square PilesTee Bun PinNo ratings yet

- Signature of Owner: Borang PDC 2Document8 pagesSignature of Owner: Borang PDC 2Mageswary KunalanNo ratings yet

- BSR FinalDocument41 pagesBSR FinalGishan Sanjeewa100% (2)

- PilingDocument34 pagesPilingHariz HilmanNo ratings yet

- California: Engineering Services Division ofDocument1 pageCalifornia: Engineering Services Division ofsilvereyes18No ratings yet

- Natsteel - Reinforcement BarsDocument12 pagesNatsteel - Reinforcement BarsJianhua WuNo ratings yet

- IWK - Standardized Document For SCCDocument3 pagesIWK - Standardized Document For SCCazwarfahmi07100% (1)

- Esq 540 - Piling Operation-AssignmentDocument11 pagesEsq 540 - Piling Operation-AssignmentMoffat KangombeNo ratings yet

- Stripping Out Formwork DesignDocument9 pagesStripping Out Formwork DesignPrashant SunagarNo ratings yet

- MS-Concourse Roof - Rev. DDocument10 pagesMS-Concourse Roof - Rev. DJosephChongNo ratings yet

- BAUER (Piling & Earth Retaining Structure)Document16 pagesBAUER (Piling & Earth Retaining Structure)Khilbran MuhammadNo ratings yet

- JKR SIRIM PrePDFDocument4 pagesJKR SIRIM PrePDFkhairul AnwarNo ratings yet

- Concrete For Industrial FloorsDocument5 pagesConcrete For Industrial FloorsAlexTairaNo ratings yet

- Piling Work Spec Gue & PartnerDocument15 pagesPiling Work Spec Gue & PartnerMohamad Naiem100% (1)

- Soaked CBRDocument4 pagesSoaked CBRB S Praveen BspNo ratings yet

- MS 628-3 2014 - PrepdfDocument7 pagesMS 628-3 2014 - PrepdfMay OngNo ratings yet

- Method Comparison Between Ibs With Conventional MethodDocument2 pagesMethod Comparison Between Ibs With Conventional MethodWan Faiz100% (1)

- CLJ - 2010 - 1 - 309 - BC01034 (Extra Case) - Maxim of EquityDocument23 pagesCLJ - 2010 - 1 - 309 - BC01034 (Extra Case) - Maxim of EquityJIA WENNo ratings yet

- Choo Bee Catalogue PDFDocument185 pagesChoo Bee Catalogue PDFJohn MelvinNo ratings yet

- 1A Assignment 2 - IS 1200 Part 22Document11 pages1A Assignment 2 - IS 1200 Part 22Shantanu DuttaNo ratings yet

- Engineering SpecDocument304 pagesEngineering SpecSYifa ShuhaIliNo ratings yet

- IJM IBS Sales & Marketing Team Presentation 200330 - CompressedDocument41 pagesIJM IBS Sales & Marketing Team Presentation 200330 - CompressedCalvin NgNo ratings yet

- PreamblesDocument55 pagesPreamblesdophongxdNo ratings yet

- Method Statement Geotechnical Investigation Works: ProjectDocument20 pagesMethod Statement Geotechnical Investigation Works: ProjectShan NawazNo ratings yet

- Project PDFDocument36 pagesProject PDFMable MathewNo ratings yet

- Drawing Spun PileDocument5 pagesDrawing Spun Pile2C Nur Izzati Binti RamleeNo ratings yet

- Construction Joint PDFDocument4 pagesConstruction Joint PDFravinchandNo ratings yet

- The Assessment of Steel Highway and Bridges - BA56 - 96Document114 pagesThe Assessment of Steel Highway and Bridges - BA56 - 96pratip_bNo ratings yet

- LCP Multideck® 90Document6 pagesLCP Multideck® 90GarfieldNo ratings yet

- Mezzanine Floors Baseplate DesignDocument3 pagesMezzanine Floors Baseplate DesignLlonsson100% (1)

- Bored Pile InstallationDocument134 pagesBored Pile InstallationKMHoNo ratings yet

- Method Statement For Pile Integrity Test ProcedureDocument3 pagesMethod Statement For Pile Integrity Test ProcedureDharma Pratap Lamgade100% (1)

- Low Strain Pile Integrity TestingDocument6 pagesLow Strain Pile Integrity TestingWaqas SadiqNo ratings yet

- Exam SheetDocument1 pageExam SheetadnanNo ratings yet

- Wastewater Management System For Philip Morris Intl. PakistanDocument3 pagesWastewater Management System For Philip Morris Intl. PakistanadnanNo ratings yet

- Document 71Document1 pageDocument 71adnanNo ratings yet

- Outline Indsutrial Project Fall 2021Document7 pagesOutline Indsutrial Project Fall 2021adnanNo ratings yet

- LSPS Management Final Term Exam Date Sheet Winter 2021Document1 pageLSPS Management Final Term Exam Date Sheet Winter 2021adnanNo ratings yet

- Project Risk Management: Lecture#6Document58 pagesProject Risk Management: Lecture#6adnanNo ratings yet

- Logistics ActivitiesDocument4 pagesLogistics ActivitiesadnanNo ratings yet

- MRS Specification Volume I, Part-IDocument237 pagesMRS Specification Volume I, Part-IadnanNo ratings yet

- SWOT FinalDocument4 pagesSWOT FinaladnanNo ratings yet

- Plan Risk Management: Session#4Document31 pagesPlan Risk Management: Session#4adnanNo ratings yet

- Activity Duration Predecessor Resorce ES EF LSDocument4 pagesActivity Duration Predecessor Resorce ES EF LSadnanNo ratings yet

- Managing Facilitating Goods: Replenishment Order Replenishment Order Replenishment Order Customer OrderDocument28 pagesManaging Facilitating Goods: Replenishment Order Replenishment Order Replenishment Order Customer OrderadnanNo ratings yet

- Step 1 Draw A Room ScaleDocument18 pagesStep 1 Draw A Room ScaleadnanNo ratings yet

- Example 3. CPM: Activity Duration (Days) Events Preceding Activity (Predecessor)Document3 pagesExample 3. CPM: Activity Duration (Days) Events Preceding Activity (Predecessor)adnanNo ratings yet

- QC Inspectors Tool Box Meeting ScheduleDocument1 pageQC Inspectors Tool Box Meeting ScheduleadnanNo ratings yet

- File 1 PDFDocument165 pagesFile 1 PDFadnanNo ratings yet

- A61 Q FDN Va 046778 001 Pile Cap DetailsDocument1 pageA61 Q FDN Va 046778 001 Pile Cap DetailsadnanNo ratings yet

- Air Quality Index of LahoreDocument1 pageAir Quality Index of LahoreadnanNo ratings yet

- Root Cause AnalysisDocument16 pagesRoot Cause AnalysisadnanNo ratings yet

- Chec Jigcc6ook T 0861 Qms Audit ReportDocument34 pagesChec Jigcc6ook T 0861 Qms Audit ReportadnanNo ratings yet

- Technical ReportDocument6 pagesTechnical ReportAzrul AzimNo ratings yet

- (SOFTWARE) Requirements EngineeringDocument27 pages(SOFTWARE) Requirements EngineeringVũ Ngọc LinhNo ratings yet

- 1200 - 12.plastering & PointingDocument10 pages1200 - 12.plastering & PointingSivakumar Arul0% (2)

- #2 - BuildabilityDocument19 pages#2 - BuildabilityAyUb SAidi100% (1)

- Ahmed M. Atef Abdulghani: Regional Product Support Specialist WR-KSADocument2 pagesAhmed M. Atef Abdulghani: Regional Product Support Specialist WR-KSAAhmed AtefNo ratings yet

- Solution For Basic Engineering Circiut Analysis 8th Edition ChapterDocument126 pagesSolution For Basic Engineering Circiut Analysis 8th Edition ChapterMuzammil Ali KhanNo ratings yet

- AISI S201-07 Standard and Commentary (1st Printing) PDFDocument30 pagesAISI S201-07 Standard and Commentary (1st Printing) PDFthjozsefNo ratings yet

- Epc4 - Tinhert Project First Gas Phase: (JOB No.: 0-1802)Document6 pagesEpc4 - Tinhert Project First Gas Phase: (JOB No.: 0-1802)azzeddine guendouzNo ratings yet

- Review of Subcontracting Practice in Construction Industry: Lew Yoke-Lian, S. Hassim, R. Muniandy, and Law Teik-HuaDocument4 pagesReview of Subcontracting Practice in Construction Industry: Lew Yoke-Lian, S. Hassim, R. Muniandy, and Law Teik-HuaRaghavendraNo ratings yet

- Timetable For Ese SpitDocument10 pagesTimetable For Ese SpitPulkit ChaudhariNo ratings yet

- GRP Pipe For SeawaterDocument22 pagesGRP Pipe For Seawatersethu1091100% (2)

- Small Wind Certification PDFDocument17 pagesSmall Wind Certification PDFAhmet SahinozNo ratings yet

- Geo PipesDocument19 pagesGeo PipesJohn Francis PedrosoNo ratings yet

- Review: Manual of Multi-Storey Timber ConstructionDocument1 pageReview: Manual of Multi-Storey Timber ConstructionAlper KzNo ratings yet

- Types of Foundation and Their Uses in Building ConstructionDocument4 pagesTypes of Foundation and Their Uses in Building ConstructionCraig MNo ratings yet

- BS 368-1971, Precast Concrete Flags PDFDocument25 pagesBS 368-1971, Precast Concrete Flags PDFnickdash09100% (1)

- Geoguide 1 PDFDocument155 pagesGeoguide 1 PDFExile PeachNo ratings yet

- Advanced Piping Stress AnalysisDocument6 pagesAdvanced Piping Stress Analysisanurag7878100% (2)

- Software TestingDocument27 pagesSoftware TestingFrank Vijay100% (1)

- BS5628 Part 2, 2000, Reinforced and Prestressed MasonryDocument66 pagesBS5628 Part 2, 2000, Reinforced and Prestressed MasonryDawit Solomon100% (4)

- FCU & AHU Typical Piping ConnectionDocument2 pagesFCU & AHU Typical Piping ConnectionTee Chee Keong75% (4)

- Auxiliary Contactors Test FormatDocument1 pageAuxiliary Contactors Test FormatHumayun Ahsan100% (1)

- CE103 Thermal Control Process Datasheet 0518Document3 pagesCE103 Thermal Control Process Datasheet 0518Tamir ANo ratings yet

- CLOs PLOs MappingDocument4 pagesCLOs PLOs MappingIrfan AliNo ratings yet

- MT483 Chap3 Cost-Estimation TechniquesDocument78 pagesMT483 Chap3 Cost-Estimation Techniquesghufran ullahNo ratings yet

- Detailed Estimate (DLRB NOWDocument5 pagesDetailed Estimate (DLRB NOWDrrrrrNo ratings yet