Professional Documents

Culture Documents

Construction of Roadbed

Construction of Roadbed

Uploaded by

John Mark Tabor0 ratings0% found this document useful (0 votes)

263 views34 pagesThe document discusses the construction of roadbeds and their major structural parts. It describes the following:

1) The sub-grade or sub-base is the layer of soil or earth beneath the road that is properly graded, compacted, and stabilized.

2) The base course consists of crushed stone or gravel laid on top of the sub-grade to form a stable foundation.

3) The pavement is the top layer of asphalt concrete or Portland cement concrete laid over the base course.

The document provides details on road construction methods and equipment used to grade, compact, and stabilize the different layers according to engineering specifications.

Original Description:

Power point

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses the construction of roadbeds and their major structural parts. It describes the following:

1) The sub-grade or sub-base is the layer of soil or earth beneath the road that is properly graded, compacted, and stabilized.

2) The base course consists of crushed stone or gravel laid on top of the sub-grade to form a stable foundation.

3) The pavement is the top layer of asphalt concrete or Portland cement concrete laid over the base course.

The document provides details on road construction methods and equipment used to grade, compact, and stabilize the different layers according to engineering specifications.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

263 views34 pagesConstruction of Roadbed

Construction of Roadbed

Uploaded by

John Mark TaborThe document discusses the construction of roadbeds and their major structural parts. It describes the following:

1) The sub-grade or sub-base is the layer of soil or earth beneath the road that is properly graded, compacted, and stabilized.

2) The base course consists of crushed stone or gravel laid on top of the sub-grade to form a stable foundation.

3) The pavement is the top layer of asphalt concrete or Portland cement concrete laid over the base course.

The document provides details on road construction methods and equipment used to grade, compact, and stabilize the different layers according to engineering specifications.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 34

Construction of Roadbed

Soil as a Structure

with the long study of the unending road

failures, road agencies have established a

more detailed procedure regarding the

kind of materials to be used on a

particular condition, type and behavior of

the soil where the road is to be

constructed.

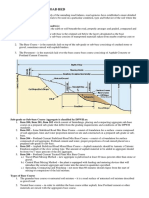

Three Major Structural Parts of

Roadway

1. The Sub-grade or sub-base is the earth

or soil beneath the road, properly arranges and

graded, compacted and stabilized.

a.) Cut Section of Road – the sub-base

is the original soil below the layers designated

as the base

b.) Fill Section of Road – the sub-base

consists of transported materials taken from

nearby roadway cuts or from borrow pit.

2. The Base Coarse – is the

materials laid on top of the sub-grade

or sub-base consisting of crushed

stone or gravel, sometimes mixed with

asphalt binders.

3. The Pavement – is the materials

laid over the base coarse base course

consisting of Asphalt Concrete or

Portland Cement Concrete.

Sub-grade or Sub-base Coarse

Aggregate is classified by

DPWH

1. Item 200, Item 201, Item 202 which consist

of furnishings, placing and compacting aggregate

sub-base coarse on a prepared sub-grade that

differ from the grading requirements and

conditions of the DPWH standards.

2. Item 203 – Lime Stabilized Road Mix Base

Coarse - consist of foundation for a surface

coarse composed of soil aggregate, lime and

water proportion mixed on site and constructed

on a prepared sub-grade or sub-base.

Item 204 – Portland Cement Stabilized Road

Mix Base Coarse – consist of a foundation for

surface composed of soil aggregate, Portland

cement and water, proper proportions of road-

mixed placed on a prepared sub-grade or sub-

base.

Item 205 – Asphalt Stabilized Road Mixed Base

Coarse – Asphalt materials should be Anionic or

Cationic Emulsion asphalt of the slow setting type.

The amount of asphalt material to be added to

aggregate should be from 4 to 7 mass percent of

the dry aggregate.

Item 206 – Portland Cement Treated Plant Mix

Base Coarse

a.) Travel Plant Mixing Method – new

aggregate is pulverized at least 80 mass percent

other than stone or gravel.

b.) Central Plant Mixing Method – the plant is

equipped with feeding and metering devices that

will introduce the cement aggregate and water into

the mixer in quantities specified.

c.) Spreading, Compacting and Finishing – not

more than 60 minutes should elapse from the start

of mixing to compaction of the laid mixture.

Types of Base Coarse

1. The granular base coarse or untreated

soil mixture – it is a road surface of untreated

soil mixture described as gravel road

2. Treated base coarse – in order to stabilize

the base coarse either asphalt, lime Portland

cement or other materials are mixed with the

aggregates base coarse.

a.) Sand and Asphalt Base Coarse –

composed of either loose beach sand, dune pit or

river sand cemented with asphalt materials.

b.) Fine Grain Asphalt Base – is an asphalt

stabilized base and sub-grade constructed with

fine grained has a controlled Plastic Index of 6 to

10.

c.) Soil and Base Coarse Stabilized with

Cement – cement stabilization y mixing natural

materials and Portland cement compacted at

optimum moisture content and cured to hydrate

the cement is considerably strong and stable

base.

Clearing and Grubbing is

categorized by DPWH

standard specifications

1. Item 100 – which consist of clearing,

grubbing, removing and disposing of all

vegetable matter and debris except those

objects that are designated to remain in

place or are to be removed in consonance

with other provisions of the specifications.

2. Method of Measurement

a.) Area Basis – by hectare and fractions thereof

acceptably cleared and grubbed.

b.) Lump Sum Basis – no measurement will be

made

c.) Individual Unit Basis – selective clearing.

Diameter of trees will be measured 1.4 meters

above the ground.

d.) Pay item designation according to

schedule of sizes:

- Over 15 cm to 90 cm - Small

- Over 90 cm - Large

Excavation

The process of loosening and

removing earth or rock from its

original position in a cut and

transporting it to a fill or to waste

deposit.

Classification of Road

Excavation:

1. Unclassified excavation – excavation

and disposal of all materials regardless of its

nature, or not classified and included in the

Bill of Quantities under other pay item

2. Rock excavation – consist of rocks that

cannot be excavated without blasting or use

of rippers and all boulders or other

detached stones each having a volume of 1

cubic meter.

3. Common excavation – not included in the

Bill of Quantities under rock excavation or

other pay items.

4. Muck excavation – removal and disposal of

saturated or unsaturated mixtures of soils and

organic matter not suitable for foundation

materials regardless of moisture contents.

5. Borrow excavation – excavation and

utilization of approved materials for the

construction of embankment

Free Haul and Overhaul

Free Haul – is the specified distance

wherein an excavated material will

be hauled without additional cost,

usually 600 meters unless specified in

the contract.

Overhaul – is an authorized hauling

in excess of free haul distance

Construction of Fill and

Embankment

Fill - refers to a volume of earthen

material that is placed and

compacted for the purpose of filling

in a hole or depression.

Embankments or Fills - are

constructed of materials that usually

consist of soil, but may also include

aggregate, rock, or crushed paving

material.

Construction -stable embankment

is attained by spreading the materials

into thin layers then compacted at

moisture content closer to optimum.

Embankment Control

1. Specify the expected value and to

ascertain from the fill density test that the

specified amount is obtained

2. Specify the manner and methods of

constructing the embankment particularly

the layer thickness, moisture control and

the number of passes by a roller of specified

type and weight.

3. Use of proper spreading and compaction

equipment

Construction Requirements &

Equipment

1. Density test requirements

2. Moisture control

3. Compaction equipment

DPWH Specifications on

Embankment is Item 104

1. Embankment shall be constructed of suitable materials

2. Must follow the construction method as specified

a.) Sods and vegetable matters must be removed

for embankment below 120 cm below the sub-grade

b.) Loose volume of soil must be compacted not

exceeding 20 cm before the next layer is placed

c.) Remove rocks greater than the thickness of the

layers prescribed

d.) Hauling and leveling equipment should be

routed and distributed over each layer of the fill to make

use of compaction efforts affording and to minimize

rutting and uneven compaction.

Compaction and Stabilization

Materials placed in the sub-base should

acquire the following properties:

1. The soil must have adequate strength

2. The soil must be relatively incompressible to

avoid insignificant future settlement

3. The soil must be stable against volume change

as water content or other factors vary

4. The soil must be durable and save against

deterioration

5. The soil must possess proper permeability

3. Must conduct full-scale compaction trials on

areas not less than 10 meters wide and 50 meters

long, before any work with the corresponding

material is allowed to start.

4. Protection of Roadbed during construction it

shall be maintained and drained at all times.

5. Rounding and Warping Slope - the top and

bottom of all slopes including the slope drainage,

ditches, are rounded as planned. Warping slope in

order to avoid injury to trees.

Sub-grade Preparation

Sub-grade preparation is categorized under

Item 105 of the DPWH standard

specifications.

Material requirements :

1. Depth of sub-grade materials should

be 15 cm or more

2. Prior to start of the sub-grade

preparation, all culverts, cross drains, conduits

and the like including the backfill, ditches,

drains and drainage outlets are thoroughly

compacted.

Compaction Equipment

Tamping Roller

Grid Roller

Pneumatic Tire Roller

Vibratory Compactor

Hauling Equipment

Bulldozer

Dump Trucks

Thank you!

You might also like

- Steel Delhi NCRDocument27 pagesSteel Delhi NCRabhay bhardwajNo ratings yet

- 2 Constructing The Roadbed WTH Assignments PDFDocument4 pages2 Constructing The Roadbed WTH Assignments PDFAngelo John R. Javinez50% (2)

- Parties Involved in ConstructionDocument11 pagesParties Involved in ConstructionSuhaimi BohariNo ratings yet

- Ce161p A88 q1 MakeupDocument1 pageCe161p A88 q1 MakeupRam RamirezNo ratings yet

- Road Construction NotesDocument19 pagesRoad Construction NotesVanessa Apolinario100% (8)

- MQCHD Test QuestionDocument94 pagesMQCHD Test Questionanon_728940158No ratings yet

- Structural Design Analysis: Reinforced Concrete BuildingsDocument30 pagesStructural Design Analysis: Reinforced Concrete BuildingsGani Anosa100% (1)

- Hitech Horticulture PDFDocument7 pagesHitech Horticulture PDFSofi MehrajNo ratings yet

- Checklist For Toilet WaterproofingDocument2 pagesChecklist For Toilet Waterproofingyash shah100% (1)

- Constructing The RoadbedDocument156 pagesConstructing The RoadbedLyka Isabel TanNo ratings yet

- Road Bed ConstructionDocument34 pagesRoad Bed ConstructionJek Yuson Junio100% (2)

- 7-4 Grading and Maintenance of Untreated SurfaceDocument10 pages7-4 Grading and Maintenance of Untreated SurfaceJobay Guden0% (1)

- Angel Rose Miranda Grace Ann Cabanban Rey Rowil Almojuela: Prepared byDocument42 pagesAngel Rose Miranda Grace Ann Cabanban Rey Rowil Almojuela: Prepared byGrace Ann CabanbanNo ratings yet

- By Ivy Joy E. PanganibanDocument28 pagesBy Ivy Joy E. Panganibanilocam313100% (3)

- 60 PDFDocument7 pages60 PDFYogiIndraPrayogaNo ratings yet

- Types of PavementDocument4 pagesTypes of Pavementibrahim0007100% (1)

- Highway MaintenanceDocument13 pagesHighway MaintenancePia CajayonNo ratings yet

- Rigid Pavement DesignDocument11 pagesRigid Pavement DesignAjit P. SinghNo ratings yet

- South East Asian Institute of Technology, Inc. National Highway, Crossing Rubber, Tupi, South CotabatoDocument17 pagesSouth East Asian Institute of Technology, Inc. National Highway, Crossing Rubber, Tupi, South CotabatoJaymark S. GicaleNo ratings yet

- Lec 8 Pavement DesignDocument87 pagesLec 8 Pavement DesignMay de Vera100% (1)

- Chapter 5 - Flexible and Composite Pavements Final (Individual Narrative Reports)Document30 pagesChapter 5 - Flexible and Composite Pavements Final (Individual Narrative Reports)Frederick AgliamNo ratings yet

- Asphalt Overlay Method Statement-FinalDocument10 pagesAsphalt Overlay Method Statement-FinalYEHIANo ratings yet

- Bridge EngineeringDocument42 pagesBridge EngineeringkiranNo ratings yet

- French and British RoadsDocument8 pagesFrench and British RoadsAditya DhuriaNo ratings yet

- Gabion Chapter 2 and 3Document10 pagesGabion Chapter 2 and 3Patrick Ray TanNo ratings yet

- Importance of Ground Water in Civili EngineeringDocument3 pagesImportance of Ground Water in Civili EngineeringLyn OzitlamNo ratings yet

- Design Pavement: Thickness of Pavement Using Mcleod MethodDocument12 pagesDesign Pavement: Thickness of Pavement Using Mcleod MethodAbigail Joy AbingNo ratings yet

- Flexible PavementsDocument13 pagesFlexible PavementsAhmad NajiNo ratings yet

- Collapsible SoilsDocument19 pagesCollapsible SoilsJose280678% (9)

- Soil Test For Road ConstructionDocument3 pagesSoil Test For Road ConstructionKhalid Rehman100% (5)

- Component Parts of Flexible and Rigid Road Pavements Structure and Their FunctionDocument4 pagesComponent Parts of Flexible and Rigid Road Pavements Structure and Their FunctionRajesh KhadkaNo ratings yet

- SPLM - Construction Pre-Planning PDFDocument11 pagesSPLM - Construction Pre-Planning PDFJommarVocalTagalogNo ratings yet

- Unit 3 RIGID AND FLEXIBLE PAVEMENTSDocument33 pagesUnit 3 RIGID AND FLEXIBLE PAVEMENTSAnonymous SEDun6PWNo ratings yet

- Highway and Pavement ConstructionDocument35 pagesHighway and Pavement ConstructionCherylNo ratings yet

- Open Channel Design Channels PDFDocument27 pagesOpen Channel Design Channels PDFSS100% (1)

- Highway and Railroad EngineeringDocument30 pagesHighway and Railroad EngineeringNarte, Angelo C.No ratings yet

- Part IV Earthwork QuantitiesDocument72 pagesPart IV Earthwork QuantitiesAlemayehu Miteku100% (1)

- Flexible Pavement ConstructionDocument18 pagesFlexible Pavement ConstructionThopuri Maruthi Chowdary100% (1)

- Concrete Proportion and Concrete Mixture RatioDocument1 pageConcrete Proportion and Concrete Mixture RatioJett SorianoNo ratings yet

- Factors Causing Failures in Cement Concrete PavementsDocument3 pagesFactors Causing Failures in Cement Concrete PavementsAnonymous kB6xcEvLg100% (1)

- Chapter-One ROAD CONSTRUCTIONDocument71 pagesChapter-One ROAD CONSTRUCTIONamareNo ratings yet

- Road Construction StagesDocument2 pagesRoad Construction StagesZohaibShoukatBalochNo ratings yet

- TRAININGDocument24 pagesTRAININGDheeraj dhiman100% (1)

- 25 Slope ProtectionDocument8 pages25 Slope ProtectionNasir ZakiNo ratings yet

- Designing The HighwayDocument44 pagesDesigning The HighwayAl-Fahme Sajiran100% (1)

- Flexible Pavement Design in India - Past, Present and FutureDocument17 pagesFlexible Pavement Design in India - Past, Present and FutureSanjay GargNo ratings yet

- Chapter 2 Pavement DesignDocument9 pagesChapter 2 Pavement DesignSemNo ratings yet

- Highway Maintenance and RehabilitationDocument41 pagesHighway Maintenance and Rehabilitationkhessiejulle67% (9)

- Foundation or Footing Is The Most Important and Basic Part of ADocument12 pagesFoundation or Footing Is The Most Important and Basic Part of Ahabtamu abateNo ratings yet

- Full Report On Isolated FootingDocument22 pagesFull Report On Isolated Footingabidur77100% (2)

- Practical 2 Soil CompactionDocument5 pagesPractical 2 Soil CompactionBanujan KuhaneswaranNo ratings yet

- Paver Block SpecificationDocument8 pagesPaver Block SpecificationsintuNo ratings yet

- Road Construction Inplant TrainingDocument31 pagesRoad Construction Inplant TrainingAditya ChopraNo ratings yet

- MortarDocument17 pagesMortarFiazNo ratings yet

- Shrinkage Limit PresentationDocument10 pagesShrinkage Limit PresentationMuhammad Ilyas LanjarNo ratings yet

- Field Density TestDocument15 pagesField Density TestSohail Khan100% (1)

- 1 - Soil Mechanics Laboratory Manual by Engr. Yasser M.S.Document104 pages1 - Soil Mechanics Laboratory Manual by Engr. Yasser M.S.admirodebritoNo ratings yet

- Surface TreatmentDocument11 pagesSurface Treatmentchaichu15No ratings yet

- What Is Floor Screed - Its Types, Materials, Construction and UsesDocument5 pagesWhat Is Floor Screed - Its Types, Materials, Construction and UsesJustin MusopoleNo ratings yet

- Constructing The RoadbedDocument15 pagesConstructing The RoadbedMoira Santos100% (1)

- Constructing The Roadbed (BSCE3-EC1)Document6 pagesConstructing The Roadbed (BSCE3-EC1)Jayson J. PagalNo ratings yet

- Constructing The Roadbed (BSCE3-EC1)Document6 pagesConstructing The Roadbed (BSCE3-EC1)Jayson J. PagalNo ratings yet

- 5.Ms-Internal Plaster WorkDocument8 pages5.Ms-Internal Plaster WorkShenbagaraja PandianNo ratings yet

- Native Plant Landscaping in Southwest MontanaDocument38 pagesNative Plant Landscaping in Southwest MontanaSamanthaWilsonNo ratings yet

- BuildingDocument14 pagesBuildingshaman chauhanNo ratings yet

- Chapter 14 Water Management (Drainage)Document202 pagesChapter 14 Water Management (Drainage)ecossich123100% (1)

- Engineer'S Observations & Recommendations: ST NDDocument3 pagesEngineer'S Observations & Recommendations: ST NDSamitha SoysaNo ratings yet

- Soil Moisture Regime (SMR) & Soil Temperature Regime (STR)Document14 pagesSoil Moisture Regime (SMR) & Soil Temperature Regime (STR)Ajaya Poudel0% (1)

- Wytree Owners ManualDocument40 pagesWytree Owners ManualsccdofwyoNo ratings yet

- Double Fertilization in PlantsDocument24 pagesDouble Fertilization in PlantsAshmit Srinjoy DuttaNo ratings yet

- Coconut PlantationDocument6 pagesCoconut PlantationSoosai RajanNo ratings yet

- Groasis Waterbox Used by Master Gardeners of Hill Country, Texas, To Save WaterDocument10 pagesGroasis Waterbox Used by Master Gardeners of Hill Country, Texas, To Save WaterU8x58No ratings yet

- Sugar BeatDocument13 pagesSugar Beatijazqamar7704No ratings yet

- Hydroponics DRAFTDocument38 pagesHydroponics DRAFTShree LakshmiNo ratings yet

- Greenhouse Tomato Production PracticesDocument7 pagesGreenhouse Tomato Production PracticesWyoming Native Plant SocietyNo ratings yet

- Propagation PDFDocument6 pagesPropagation PDFmNo ratings yet

- Completed Revised Variation 06-01-2020Document48 pagesCompleted Revised Variation 06-01-2020Narendra BokreNo ratings yet

- Soil and Major Data Types in KenyaDocument8 pagesSoil and Major Data Types in Kenyatony frankNo ratings yet

- Benefits Derived From Planting Trees and Fruit - Bearing - PPTX Grade 6 EppDocument15 pagesBenefits Derived From Planting Trees and Fruit - Bearing - PPTX Grade 6 EppRacquel SupsupNo ratings yet

- How To Calculate Cement Sand and Aggregate Quantity in ConcreteDocument5 pagesHow To Calculate Cement Sand and Aggregate Quantity in ConcreteAl Patrick Dela Calzada100% (1)

- Tissue Culture ProjectDocument6 pagesTissue Culture ProjectANONNo ratings yet

- Concrete Mix Design M-40 (RCC) GradeDocument6 pagesConcrete Mix Design M-40 (RCC) GradeAshok amlapure100% (1)

- Bill of Quantity (Boq) : DMHDPDocument17 pagesBill of Quantity (Boq) : DMHDPmihiretu TeferaNo ratings yet

- Pervious Pavement City PortlandDocument2 pagesPervious Pavement City PortlandAjmalPkNo ratings yet

- Geotechnical Eng1 Lab - Moisture ContentDocument5 pagesGeotechnical Eng1 Lab - Moisture ContentChelsea LimNo ratings yet

- Bamboo and SalinityDocument1 pageBamboo and SalinityNishant MandhotraNo ratings yet

- Price List April 2012 - March 2013Document15 pagesPrice List April 2012 - March 2013Sajjad Amin AminNo ratings yet

- Technik Plus Conservation Agriculture in AfricaDocument9 pagesTechnik Plus Conservation Agriculture in AfricavodounnouNo ratings yet

- Insect Pests of Cucurbit VegetablesDocument5 pagesInsect Pests of Cucurbit VegetablesshivakumarhdNo ratings yet