Professional Documents

Culture Documents

100%(1)100% found this document useful (1 vote)

330 viewsHigh Voltage On Ships

High Voltage On Ships

Uploaded by

Deni Kurnia One Here are the answers to the questions:

1. Higher power demand for heavy consumers on ships is the first reason to choose high voltage on ships.

2. Danger of arcing, chances of arc flash and arc blast.

3. High voltage systems are more extensive with complex networks and connections.

4. 1001 Volts AC or 1500 Volts DC.

5. As current carrying capacity reduces with high voltage, size of conductor can be reduced much. This considerable reduction in conductor material results in reduced size of machinery and save space for installation.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- High Voltage Safety Course Handout CD 1Document337 pagesHigh Voltage Safety Course Handout CD 1Venkatesh Mec100% (6)

- Automation Monitoring and Alarms of Steering SystemDocument7 pagesAutomation Monitoring and Alarms of Steering SystemAlden Camasosa100% (1)

- Marine Electrical TechnologyDocument8 pagesMarine Electrical TechnologyAnis BagwanNo ratings yet

- Shipboard High Voltage Application and Safeties - Hanif Dewan's BlogDocument26 pagesShipboard High Voltage Application and Safeties - Hanif Dewan's BlogWisnu KertaningnagoroNo ratings yet

- HV Manual MCADocument262 pagesHV Manual MCAsocrates19582405100% (1)

- Antwerp Maritime Academy - High Voltage Safety PDFDocument159 pagesAntwerp Maritime Academy - High Voltage Safety PDFjmmendes100% (2)

- Battery Maintenance and Care PDFDocument1 pageBattery Maintenance and Care PDFEleAltındağNo ratings yet

- K Pos Compact DP or Joystick ControllerDocument2 pagesK Pos Compact DP or Joystick ControllereajNo ratings yet

- Characterization of Materials: METE 310Document33 pagesCharacterization of Materials: METE 310Cezmi BacaksızNo ratings yet

- Manual Generador ENGGADocument20 pagesManual Generador ENGGAmanuel100% (2)

- Shipboard High VoltageDocument64 pagesShipboard High VoltageHarendra GuptaNo ratings yet

- HV Marine Ele Sys - 2012-F Class - 1Document510 pagesHV Marine Ele Sys - 2012-F Class - 1Lyn LynNo ratings yet

- Shipboard High VoltageDocument62 pagesShipboard High VoltageArun SNo ratings yet

- High Voltage On ShipsDocument10 pagesHigh Voltage On ShipsBogdan Ancuta100% (2)

- Main Switch Board (MSB) Safeties, Protection and MaintenanceDocument9 pagesMain Switch Board (MSB) Safeties, Protection and MaintenanceRajeev Valunjkar100% (2)

- Standard Safety High Voltage 12Document4 pagesStandard Safety High Voltage 12clinthenNo ratings yet

- High Voltage Course Guidelines PDFDocument20 pagesHigh Voltage Course Guidelines PDFvishnu100% (1)

- MEO Orals On Marine Electro Technology Function 5Document19 pagesMEO Orals On Marine Electro Technology Function 5Rajeev ValunjkarNo ratings yet

- High Voltage GroundingDocument23 pagesHigh Voltage GroundingOladokun Sulaiman OlanrewajuNo ratings yet

- Generation and Distribution of ElectricityDocument38 pagesGeneration and Distribution of ElectricityAlp ŞENER100% (2)

- Meo Met OralsDocument18 pagesMeo Met OralsAnjali ChandravanshiNo ratings yet

- Ship's Emergency PowerDocument3 pagesShip's Emergency Powerrajjsmit1989No ratings yet

- Marine Electrical Equipment and PracticeDocument16 pagesMarine Electrical Equipment and PracticeShaip SankarNo ratings yet

- Marine High Voltage SystemsDocument27 pagesMarine High Voltage SystemsRajeev Valunjkar100% (4)

- ETO Part ADocument16 pagesETO Part AManny VasquezNo ratings yet

- EWK RatingsDocument131 pagesEWK RatingsPeter Maxwell DG100% (3)

- AC DC FormulasDocument9 pagesAC DC FormulasJay Mark BalaneNo ratings yet

- Eto Coc Written Examination Questions & Answers Part-1: by Minbox - February 11, 2020Document15 pagesEto Coc Written Examination Questions & Answers Part-1: by Minbox - February 11, 2020Gokul RajNo ratings yet

- Marine Electrical Power System: by Dr. Oladokun Sulaiman Olanrewaju, Ceng, CmarengDocument17 pagesMarine Electrical Power System: by Dr. Oladokun Sulaiman Olanrewaju, Ceng, CmarengMd Rodi BidinNo ratings yet

- High Voltage On Ships, Safety, Equipment Testing: (Adapted from:D.T. Hall:Practical Marine Electrical Knowledge)Document18 pagesHigh Voltage On Ships, Safety, Equipment Testing: (Adapted from:D.T. Hall:Practical Marine Electrical Knowledge)World GamesNo ratings yet

- Stcw-Chapter 3 CompetencyDocument11 pagesStcw-Chapter 3 CompetencySamir BelkarNo ratings yet

- Marine Engineering QuestionsDocument9 pagesMarine Engineering QuestionsGupta RohitNo ratings yet

- Marine Electrical Power DistributionDocument4 pagesMarine Electrical Power DistributionVyas SrinivasanNo ratings yet

- PST Presetation Revised For CVMTRCDocument195 pagesPST Presetation Revised For CVMTRCJancel Melanis100% (3)

- Ship Electrical PDFDocument111 pagesShip Electrical PDFAgung HidayatullahNo ratings yet

- Polarization Index TestDocument3 pagesPolarization Index TestShahriar AhmedNo ratings yet

- Battery Charging On Board Ship.Document10 pagesBattery Charging On Board Ship.stamatisNo ratings yet

- Met Class 4 Electrical WrittenDocument83 pagesMet Class 4 Electrical WrittenAjeet Jha86% (7)

- Deck MachineryDocument18 pagesDeck MachineryJohn SnowNo ratings yet

- Parallel Operation of Three-Phase AlternatorsDocument12 pagesParallel Operation of Three-Phase AlternatorsNayan Manna100% (2)

- Electric Propulsion SystemDocument2 pagesElectric Propulsion SystemABIR MUKHERJEENo ratings yet

- Trips and Safety PDFDocument6 pagesTrips and Safety PDFManage Don Gnanathilaka100% (1)

- Marine Electro-Technology Test Part1Document6 pagesMarine Electro-Technology Test Part1Grid Lock100% (1)

- HV Sytem in ShipsDocument40 pagesHV Sytem in ShipsvenugopalNo ratings yet

- Bow ThrusterDocument19 pagesBow ThrusterAnakin Skywalker100% (1)

- Shipboard Electrical EquipmentDocument16 pagesShipboard Electrical EquipmentastefanovichNo ratings yet

- Steering Gear SystemsDocument23 pagesSteering Gear SystemsEzy WaqaNo ratings yet

- High Voltage Testing of TransformerDocument18 pagesHigh Voltage Testing of TransformerDinesh mor100% (2)

- IInd ED CONTROL - Steering SystemDocument49 pagesIInd ED CONTROL - Steering SystemRamprabu ChandrasekarNo ratings yet

- ElectricalDocument36 pagesElectricalAlvinNo ratings yet

- SOLAS Emergency Power Requirements CH 2 Sec 2Document8 pagesSOLAS Emergency Power Requirements CH 2 Sec 2lalinda100% (1)

- Function 5 Questions BankDocument18 pagesFunction 5 Questions BankOm Prakash RajNo ratings yet

- Understanding The Importance of Marine Navigation LightingDocument4 pagesUnderstanding The Importance of Marine Navigation Lightingนัทเดช เรืองสวนNo ratings yet

- Class 4 Safety Oral Ship Construction & Naval FileDocument72 pagesClass 4 Safety Oral Ship Construction & Naval Fileclinton100% (4)

- Marine Electrical Check ListDocument62 pagesMarine Electrical Check ListthanhtanNo ratings yet

- Electro 3 Research May 16, 2022Document6 pagesElectro 3 Research May 16, 2022Juan Miguel TorresNo ratings yet

- High Voltage System On ShipsDocument3 pagesHigh Voltage System On ShipsRachit100% (1)

- Powerpoint Presentation (ML)Document25 pagesPowerpoint Presentation (ML)Shirajul IslamNo ratings yet

- Technical Subjective QuestionsDocument52 pagesTechnical Subjective QuestionsEngr AHmed Ali Dall100% (1)

- Electrical Q&A Part-4Document15 pagesElectrical Q&A Part-4supermannonNo ratings yet

- A Brief Study On: Electrical Power TransmissionDocument30 pagesA Brief Study On: Electrical Power TransmissionAritra SinhaNo ratings yet

- An Electric Fence EnergiserDocument8 pagesAn Electric Fence EnergiserissaekendhaNo ratings yet

- DVD S663 - DV S6165Document37 pagesDVD S663 - DV S6165Johny FrancisNo ratings yet

- Bender VMD461 Anleitung EN PDFDocument10 pagesBender VMD461 Anleitung EN PDFAlexandru IonNo ratings yet

- lpv345f 2Document6 pageslpv345f 2lucianoNo ratings yet

- Manual de Hardware Lenovo Yoga c740Document63 pagesManual de Hardware Lenovo Yoga c740jhonNo ratings yet

- Integral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Document16 pagesIntegral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Kishor JadhavNo ratings yet

- The Story of Electricity - A.K.chakraborty, S.C.bhattacharyaDocument90 pagesThe Story of Electricity - A.K.chakraborty, S.C.bhattacharyaGEMMA PUIG100% (1)

- Study The Vocabulary: TransformersDocument5 pagesStudy The Vocabulary: TransformersАндрей РоманенкоNo ratings yet

- SFERE Energy Meter3706581013667435464Document2 pagesSFERE Energy Meter3706581013667435464Cho Cho MyintNo ratings yet

- Megger Multifunction Tester MFT1500/2 MFT1552 and MFT1553 SeriesDocument32 pagesMegger Multifunction Tester MFT1500/2 MFT1552 and MFT1553 SeriesJustin HartleyNo ratings yet

- Beacons of The World: Frequency Callsign Town QTH Loc Erpw AntennaDocument62 pagesBeacons of The World: Frequency Callsign Town QTH Loc Erpw AntennabaymanNo ratings yet

- CT Question PapersDocument6 pagesCT Question PapersdevNo ratings yet

- Motoniveladora 24M Plano Electrico 2015 SISDocument43 pagesMotoniveladora 24M Plano Electrico 2015 SISFabrizio Jesus Morales SalirrosasNo ratings yet

- Operation & Maintenance of Electrical EquipmentDocument114 pagesOperation & Maintenance of Electrical EquipmentPrudhvi Raj Samrat100% (2)

- Chapter 8Document11 pagesChapter 8SalvadoRaulJr.No ratings yet

- Generator Protection REG670: Application ManualDocument608 pagesGenerator Protection REG670: Application ManualLeandro FerrariNo ratings yet

- Elect 09 Method Statement For MCC Modification and RecommissioningDocument7 pagesElect 09 Method Statement For MCC Modification and RecommissioningQwe7 Al-AlNo ratings yet

- CS3000 Service v6 E5 09 1 EDocument83 pagesCS3000 Service v6 E5 09 1 EHarman SandhuNo ratings yet

- Question Bank Class X Magnetic Effects of Electric CurrentDocument7 pagesQuestion Bank Class X Magnetic Effects of Electric CurrentSuryank sharmaNo ratings yet

- SysCat - I191E EN 01A+IO Link+DatasheetDocument10 pagesSysCat - I191E EN 01A+IO Link+DatasheetLucas Vinícius CostaNo ratings yet

- Mosfet Using Tanner ToolDocument20 pagesMosfet Using Tanner ToolParmeet SinghNo ratings yet

- DXX-790-960/1710-2180-65/65-17i/18.5 - M/M: Model: ADU451807v01Document3 pagesDXX-790-960/1710-2180-65/65-17i/18.5 - M/M: Model: ADU451807v01jhon mirandaNo ratings yet

- DC Voltage Converter Circuits: Ray MarstonDocument6 pagesDC Voltage Converter Circuits: Ray MarstonManuel BarriosNo ratings yet

- Service Manual: CPD-G500Document62 pagesService Manual: CPD-G500PedroNo ratings yet

- Design of LV Compensation CubiclesDocument43 pagesDesign of LV Compensation CubiclesKhaled Salahul DenNo ratings yet

- 63A Series Transfer Switch User ManualDocument1 page63A Series Transfer Switch User ManualOgie SeptiawanNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2011/0156494 A1Document16 pagesPatent Application Publication (10) Pub. No.: US 2011/0156494 A1Tony GaryNo ratings yet

- 10 Sme-RrDocument2 pages10 Sme-RrprakashebhangaleNo ratings yet

- Xantrex SW Plus 2524 Users Manual 473755Document344 pagesXantrex SW Plus 2524 Users Manual 473755Daniel CabreraNo ratings yet

High Voltage On Ships

High Voltage On Ships

Uploaded by

Deni Kurnia One100%(1)100% found this document useful (1 vote)

330 views12 pages Here are the answers to the questions:

1. Higher power demand for heavy consumers on ships is the first reason to choose high voltage on ships.

2. Danger of arcing, chances of arc flash and arc blast.

3. High voltage systems are more extensive with complex networks and connections.

4. 1001 Volts AC or 1500 Volts DC.

5. As current carrying capacity reduces with high voltage, size of conductor can be reduced much. This considerable reduction in conductor material results in reduced size of machinery and save space for installation.

Original Description:

Original Title

HIGH VOLTAGE ON SHIPS.pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document Here are the answers to the questions:

1. Higher power demand for heavy consumers on ships is the first reason to choose high voltage on ships.

2. Danger of arcing, chances of arc flash and arc blast.

3. High voltage systems are more extensive with complex networks and connections.

4. 1001 Volts AC or 1500 Volts DC.

5. As current carrying capacity reduces with high voltage, size of conductor can be reduced much. This considerable reduction in conductor material results in reduced size of machinery and save space for installation.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

100%(1)100% found this document useful (1 vote)

330 views12 pagesHigh Voltage On Ships

High Voltage On Ships

Uploaded by

Deni Kurnia One Here are the answers to the questions:

1. Higher power demand for heavy consumers on ships is the first reason to choose high voltage on ships.

2. Danger of arcing, chances of arc flash and arc blast.

3. High voltage systems are more extensive with complex networks and connections.

4. 1001 Volts AC or 1500 Volts DC.

5. As current carrying capacity reduces with high voltage, size of conductor can be reduced much. This considerable reduction in conductor material results in reduced size of machinery and save space for installation.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 12

HIGH VOLTAGE SYSTEMS ON SHIPS

Deni Kurnia One – ETO Penyetaraan 2019/2020

Introduction

As we all know usually the ship operates with a 3

phase. 60Hz. 440 Volts supply which is being generated

and distributed on board. Every day the owners and

designers aim for bigger ships for more profitability. As

the ship size increases, there is a need to install more

powerful engines and other machinery. This increase in

size or machinery and other equipment demands more

electrical power and thus it is required to use higher

voltages on board a ship.

What is High Voltage ?

In Marine Practice majority of merchant ships have a 3-

phase 3 wire, 440 V insulated neutral earth power

systems. This power system falls in the category Of Low

Voltage and meets the power demands of medium

capacity motors up to 200 kW.

Voltages up to & Including 1000V is known as Low

voltage system and Voltages 1001 and above is called

as High Voltage system in maritime practice for ships.

However voltages up to 11kV are called as medium

voltage in land based practices.

Definition

The numerical definition of high voltage depends on

context. Two factors considered in classifying a voltage

as "high voltage" are the possibility of causing a spark

in air, and the danger of electric shock by contact or

proximity. The definitions may refer to the voltage

between two conductors of a system, or between any

conductor and ground.

IEC voltage range AC (Vrms) DC (V) Defining Risk

High Voltage >1000 >1500 Electrical Arcing

Low Voltage 50-1000 120-1500 Electrical Shock

Extra-Low Voltage <50 <120 Low Risk

Differences Between HV & LV

Supply

1. High voltage systems are more extensive with complex

networks and connections,

2. Isolated equipment MUST BE earthed down

3. Access to high voltage areas should be strictly limited

and controlled

4. Isolation procedures are more involved

5. Switching strategies should be formulated and recorded

6. Specific high voltage test probes and instruments must

be used

7. Diagnostic insulation resistance testing is necessary

8. High voltage systems are usually earthed neutral and

use current limiting

9. Special high voltage circuit breakers have to be installed

Why High Voltage in Ships?

(Advantages)

1. Higher power demand for heavy consumers on ships is

the first reason to choose high voltage on ships. High

power bow thruster electric motors, reefer containers

in container ships, cargo cooling machineries in gas

carriers, etc. are examples of such heavy power

consumers.

2. High voltage machineries have much reduced size and

weight compared to same power low voltage

counterpart.

3. Reduced weight and space for machinery means

increased space for cargo and more profit.

4. Using electric propulsion further reduces

engine room size, again more cargo space

and profit.

5. Ease of installation and reduced installation

cost.

6. Conductor size is reduced due to low

current flow in high voltage system, means

reduced copper requirement and low cost.

7. In high voltage system, copper loss or I²R

losses are much reduced when compared

to low voltage system, as the current flow is

less.

8. Overall estimated 1/3 reduction in cost

compared to low voltage system.

Disadvantages of High Voltage

System on Ships

1. Handling high voltage means high class insulation to

be used on conductors. (Generally ‘F’ class and

above)

2. Higher voltages means greater risk and hence

require stringent safety procedures.

3. Skilled labour required for handling high voltage

system.

4. Danger of arcing, chances of arc flash and arc blast.

5. Special switch gears are required to preventing

arcing.

High Voltage System Reduce

Weight and Size

Consider an electric motor consuming power of 500 kW

We have the power, P = √3 V I Cos ∅

In low voltage system, power, P = Similarly, In high voltage system,

500 x 1000 Watts, power factor, power, P = 500 x 1000 Watts, power

Cos ∅ = 0.8, Voltage, V = 440 factor, Cos ∅ = 0.8, Voltage, V = 3.3

P = √3 V I Cos ∅ kV

Current, I = P / (√3 V Cos ∅) P = √3 V I Cos ∅

I = 500000 / (√3 x 440 x 0.8 ) Current, I = P / (√3 V Cos ∅)

I = 820 Ampere I = 500000 / (√3 x 3.3 x 1000 x 0.8 )

I = 109 Ampere

So for an electric motor, working in high voltage system draw very low

current compared to that of low voltage system. As current carrying

capacity of conductor reduces, size of the conductor can also be reduced

much. This considerable reduction in conductor material result in reduced

size of machinery and save space for installation.

High Voltage System Reduce

Cost

From the above comparison on current flow between a

high voltage system and low voltage system, it is clear

that current draw with high voltage is much lesser.

Hence copper loss or I²R losses and iron loss are

considerably lesser.

THANK YOU

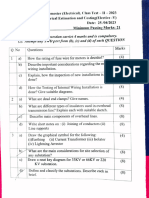

Questions

1. What is the advantage of using high voltage systems

on ships? (mention 1)

2. What is the disadvantage of using high voltage

systems on ships? (mention 1)

3. What is the differences between high voltage and

low voltage? (mention 1)

4. What is the minimum value for the voltage to be

called as a high voltage?

5. Why machinery working in high voltage system has

reduced weight, size and cost ?

You might also like

- High Voltage Safety Course Handout CD 1Document337 pagesHigh Voltage Safety Course Handout CD 1Venkatesh Mec100% (6)

- Automation Monitoring and Alarms of Steering SystemDocument7 pagesAutomation Monitoring and Alarms of Steering SystemAlden Camasosa100% (1)

- Marine Electrical TechnologyDocument8 pagesMarine Electrical TechnologyAnis BagwanNo ratings yet

- Shipboard High Voltage Application and Safeties - Hanif Dewan's BlogDocument26 pagesShipboard High Voltage Application and Safeties - Hanif Dewan's BlogWisnu KertaningnagoroNo ratings yet

- HV Manual MCADocument262 pagesHV Manual MCAsocrates19582405100% (1)

- Antwerp Maritime Academy - High Voltage Safety PDFDocument159 pagesAntwerp Maritime Academy - High Voltage Safety PDFjmmendes100% (2)

- Battery Maintenance and Care PDFDocument1 pageBattery Maintenance and Care PDFEleAltındağNo ratings yet

- K Pos Compact DP or Joystick ControllerDocument2 pagesK Pos Compact DP or Joystick ControllereajNo ratings yet

- Characterization of Materials: METE 310Document33 pagesCharacterization of Materials: METE 310Cezmi BacaksızNo ratings yet

- Manual Generador ENGGADocument20 pagesManual Generador ENGGAmanuel100% (2)

- Shipboard High VoltageDocument64 pagesShipboard High VoltageHarendra GuptaNo ratings yet

- HV Marine Ele Sys - 2012-F Class - 1Document510 pagesHV Marine Ele Sys - 2012-F Class - 1Lyn LynNo ratings yet

- Shipboard High VoltageDocument62 pagesShipboard High VoltageArun SNo ratings yet

- High Voltage On ShipsDocument10 pagesHigh Voltage On ShipsBogdan Ancuta100% (2)

- Main Switch Board (MSB) Safeties, Protection and MaintenanceDocument9 pagesMain Switch Board (MSB) Safeties, Protection and MaintenanceRajeev Valunjkar100% (2)

- Standard Safety High Voltage 12Document4 pagesStandard Safety High Voltage 12clinthenNo ratings yet

- High Voltage Course Guidelines PDFDocument20 pagesHigh Voltage Course Guidelines PDFvishnu100% (1)

- MEO Orals On Marine Electro Technology Function 5Document19 pagesMEO Orals On Marine Electro Technology Function 5Rajeev ValunjkarNo ratings yet

- High Voltage GroundingDocument23 pagesHigh Voltage GroundingOladokun Sulaiman OlanrewajuNo ratings yet

- Generation and Distribution of ElectricityDocument38 pagesGeneration and Distribution of ElectricityAlp ŞENER100% (2)

- Meo Met OralsDocument18 pagesMeo Met OralsAnjali ChandravanshiNo ratings yet

- Ship's Emergency PowerDocument3 pagesShip's Emergency Powerrajjsmit1989No ratings yet

- Marine Electrical Equipment and PracticeDocument16 pagesMarine Electrical Equipment and PracticeShaip SankarNo ratings yet

- Marine High Voltage SystemsDocument27 pagesMarine High Voltage SystemsRajeev Valunjkar100% (4)

- ETO Part ADocument16 pagesETO Part AManny VasquezNo ratings yet

- EWK RatingsDocument131 pagesEWK RatingsPeter Maxwell DG100% (3)

- AC DC FormulasDocument9 pagesAC DC FormulasJay Mark BalaneNo ratings yet

- Eto Coc Written Examination Questions & Answers Part-1: by Minbox - February 11, 2020Document15 pagesEto Coc Written Examination Questions & Answers Part-1: by Minbox - February 11, 2020Gokul RajNo ratings yet

- Marine Electrical Power System: by Dr. Oladokun Sulaiman Olanrewaju, Ceng, CmarengDocument17 pagesMarine Electrical Power System: by Dr. Oladokun Sulaiman Olanrewaju, Ceng, CmarengMd Rodi BidinNo ratings yet

- High Voltage On Ships, Safety, Equipment Testing: (Adapted from:D.T. Hall:Practical Marine Electrical Knowledge)Document18 pagesHigh Voltage On Ships, Safety, Equipment Testing: (Adapted from:D.T. Hall:Practical Marine Electrical Knowledge)World GamesNo ratings yet

- Stcw-Chapter 3 CompetencyDocument11 pagesStcw-Chapter 3 CompetencySamir BelkarNo ratings yet

- Marine Engineering QuestionsDocument9 pagesMarine Engineering QuestionsGupta RohitNo ratings yet

- Marine Electrical Power DistributionDocument4 pagesMarine Electrical Power DistributionVyas SrinivasanNo ratings yet

- PST Presetation Revised For CVMTRCDocument195 pagesPST Presetation Revised For CVMTRCJancel Melanis100% (3)

- Ship Electrical PDFDocument111 pagesShip Electrical PDFAgung HidayatullahNo ratings yet

- Polarization Index TestDocument3 pagesPolarization Index TestShahriar AhmedNo ratings yet

- Battery Charging On Board Ship.Document10 pagesBattery Charging On Board Ship.stamatisNo ratings yet

- Met Class 4 Electrical WrittenDocument83 pagesMet Class 4 Electrical WrittenAjeet Jha86% (7)

- Deck MachineryDocument18 pagesDeck MachineryJohn SnowNo ratings yet

- Parallel Operation of Three-Phase AlternatorsDocument12 pagesParallel Operation of Three-Phase AlternatorsNayan Manna100% (2)

- Electric Propulsion SystemDocument2 pagesElectric Propulsion SystemABIR MUKHERJEENo ratings yet

- Trips and Safety PDFDocument6 pagesTrips and Safety PDFManage Don Gnanathilaka100% (1)

- Marine Electro-Technology Test Part1Document6 pagesMarine Electro-Technology Test Part1Grid Lock100% (1)

- HV Sytem in ShipsDocument40 pagesHV Sytem in ShipsvenugopalNo ratings yet

- Bow ThrusterDocument19 pagesBow ThrusterAnakin Skywalker100% (1)

- Shipboard Electrical EquipmentDocument16 pagesShipboard Electrical EquipmentastefanovichNo ratings yet

- Steering Gear SystemsDocument23 pagesSteering Gear SystemsEzy WaqaNo ratings yet

- High Voltage Testing of TransformerDocument18 pagesHigh Voltage Testing of TransformerDinesh mor100% (2)

- IInd ED CONTROL - Steering SystemDocument49 pagesIInd ED CONTROL - Steering SystemRamprabu ChandrasekarNo ratings yet

- ElectricalDocument36 pagesElectricalAlvinNo ratings yet

- SOLAS Emergency Power Requirements CH 2 Sec 2Document8 pagesSOLAS Emergency Power Requirements CH 2 Sec 2lalinda100% (1)

- Function 5 Questions BankDocument18 pagesFunction 5 Questions BankOm Prakash RajNo ratings yet

- Understanding The Importance of Marine Navigation LightingDocument4 pagesUnderstanding The Importance of Marine Navigation Lightingนัทเดช เรืองสวนNo ratings yet

- Class 4 Safety Oral Ship Construction & Naval FileDocument72 pagesClass 4 Safety Oral Ship Construction & Naval Fileclinton100% (4)

- Marine Electrical Check ListDocument62 pagesMarine Electrical Check ListthanhtanNo ratings yet

- Electro 3 Research May 16, 2022Document6 pagesElectro 3 Research May 16, 2022Juan Miguel TorresNo ratings yet

- High Voltage System On ShipsDocument3 pagesHigh Voltage System On ShipsRachit100% (1)

- Powerpoint Presentation (ML)Document25 pagesPowerpoint Presentation (ML)Shirajul IslamNo ratings yet

- Technical Subjective QuestionsDocument52 pagesTechnical Subjective QuestionsEngr AHmed Ali Dall100% (1)

- Electrical Q&A Part-4Document15 pagesElectrical Q&A Part-4supermannonNo ratings yet

- A Brief Study On: Electrical Power TransmissionDocument30 pagesA Brief Study On: Electrical Power TransmissionAritra SinhaNo ratings yet

- An Electric Fence EnergiserDocument8 pagesAn Electric Fence EnergiserissaekendhaNo ratings yet

- DVD S663 - DV S6165Document37 pagesDVD S663 - DV S6165Johny FrancisNo ratings yet

- Bender VMD461 Anleitung EN PDFDocument10 pagesBender VMD461 Anleitung EN PDFAlexandru IonNo ratings yet

- lpv345f 2Document6 pageslpv345f 2lucianoNo ratings yet

- Manual de Hardware Lenovo Yoga c740Document63 pagesManual de Hardware Lenovo Yoga c740jhonNo ratings yet

- Integral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Document16 pagesIntegral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Kishor JadhavNo ratings yet

- The Story of Electricity - A.K.chakraborty, S.C.bhattacharyaDocument90 pagesThe Story of Electricity - A.K.chakraborty, S.C.bhattacharyaGEMMA PUIG100% (1)

- Study The Vocabulary: TransformersDocument5 pagesStudy The Vocabulary: TransformersАндрей РоманенкоNo ratings yet

- SFERE Energy Meter3706581013667435464Document2 pagesSFERE Energy Meter3706581013667435464Cho Cho MyintNo ratings yet

- Megger Multifunction Tester MFT1500/2 MFT1552 and MFT1553 SeriesDocument32 pagesMegger Multifunction Tester MFT1500/2 MFT1552 and MFT1553 SeriesJustin HartleyNo ratings yet

- Beacons of The World: Frequency Callsign Town QTH Loc Erpw AntennaDocument62 pagesBeacons of The World: Frequency Callsign Town QTH Loc Erpw AntennabaymanNo ratings yet

- CT Question PapersDocument6 pagesCT Question PapersdevNo ratings yet

- Motoniveladora 24M Plano Electrico 2015 SISDocument43 pagesMotoniveladora 24M Plano Electrico 2015 SISFabrizio Jesus Morales SalirrosasNo ratings yet

- Operation & Maintenance of Electrical EquipmentDocument114 pagesOperation & Maintenance of Electrical EquipmentPrudhvi Raj Samrat100% (2)

- Chapter 8Document11 pagesChapter 8SalvadoRaulJr.No ratings yet

- Generator Protection REG670: Application ManualDocument608 pagesGenerator Protection REG670: Application ManualLeandro FerrariNo ratings yet

- Elect 09 Method Statement For MCC Modification and RecommissioningDocument7 pagesElect 09 Method Statement For MCC Modification and RecommissioningQwe7 Al-AlNo ratings yet

- CS3000 Service v6 E5 09 1 EDocument83 pagesCS3000 Service v6 E5 09 1 EHarman SandhuNo ratings yet

- Question Bank Class X Magnetic Effects of Electric CurrentDocument7 pagesQuestion Bank Class X Magnetic Effects of Electric CurrentSuryank sharmaNo ratings yet

- SysCat - I191E EN 01A+IO Link+DatasheetDocument10 pagesSysCat - I191E EN 01A+IO Link+DatasheetLucas Vinícius CostaNo ratings yet

- Mosfet Using Tanner ToolDocument20 pagesMosfet Using Tanner ToolParmeet SinghNo ratings yet

- DXX-790-960/1710-2180-65/65-17i/18.5 - M/M: Model: ADU451807v01Document3 pagesDXX-790-960/1710-2180-65/65-17i/18.5 - M/M: Model: ADU451807v01jhon mirandaNo ratings yet

- DC Voltage Converter Circuits: Ray MarstonDocument6 pagesDC Voltage Converter Circuits: Ray MarstonManuel BarriosNo ratings yet

- Service Manual: CPD-G500Document62 pagesService Manual: CPD-G500PedroNo ratings yet

- Design of LV Compensation CubiclesDocument43 pagesDesign of LV Compensation CubiclesKhaled Salahul DenNo ratings yet

- 63A Series Transfer Switch User ManualDocument1 page63A Series Transfer Switch User ManualOgie SeptiawanNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2011/0156494 A1Document16 pagesPatent Application Publication (10) Pub. No.: US 2011/0156494 A1Tony GaryNo ratings yet

- 10 Sme-RrDocument2 pages10 Sme-RrprakashebhangaleNo ratings yet

- Xantrex SW Plus 2524 Users Manual 473755Document344 pagesXantrex SW Plus 2524 Users Manual 473755Daniel CabreraNo ratings yet