Professional Documents

Culture Documents

P6 of CE 104 Eng Mat Metal Alloys

P6 of CE 104 Eng Mat Metal Alloys

Uploaded by

mubashir ahmedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P6 of CE 104 Eng Mat Metal Alloys

P6 of CE 104 Eng Mat Metal Alloys

Uploaded by

mubashir ahmedCopyright:

Available Formats

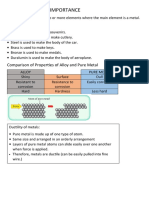

Medium Carbon

Low Carbon (Mild) Steel High Carbon Steel

Steel

Carbon content is Carbon content is Carbon content is

approximately from 0.1 to from 0.3 to 0.8% approximately from 0.8 to

0.3% 1.5%

Properties

Structure is fibrous Structure is granular

More tough and elastic Balanced ductility More tough and elastic

than cast/ wrought irons and strength than mild steel

Ductile and malleable; More difficult to forge and

easy to forge and weld weld

Difficult to harden and Easier to harden and

temper temper

Equally strong in tension, Stronger in compression

compression and shear than tension

Can withstand shocks and Better shock and impact

impacts resistance than mild steel

Low Carbon (Mild) Steel High Carbon Steel

Used in rolled steel sections Used in making tools, e.g.

drills, etc

Making tools and equipment Making machinery parts that

and as reinforcement in needs a hard, tough, durable

reinforced concretes (RCs) materials to withstand

shocks and impacts

Railway tracks and

transmission towers

Plain and corrugated sheets

as roof sheets

Property Cast Iron Wrought Iron Steel

Composition Crude form of Purest form of Midway b/w cast

iron containing iron containing and wrought irons

2.0 to 4.5% 0.1 to 0.25% containing 0.25 to

carbon carbon 1.5% carbon

Structure Crystalline Fibrous with a Granular

silky luster

Specific gravity 7.0 to 7.5 7.7 7.85

Melting point 1200oC 1500oC 1300 to 1400oC

Hardness Quite hard; more Can’t be Can be hardened

hardened by hardened or or tempered

heating and tempered

sudden cooling

Ultimate tensile 110 MPa 310-380 MPa 450-900 MPa

strength

Resistance to Poor Fair Very good

shocks/ impacts

First Group Second Group Third Group

Carbon < 0.4% Carbon < 0.4% Carbon : little

Chromium < 16% Chromium ≥ 16% Chromium: sufficient

Can be used up to Don’t respond good to Don’t respond readily to

800oC; also can be heat treatment heat treatment; best for

welded use under very high

temperature

Satisfactory resistance Better resistance Machining is very

against corrosion against corrosion difficult ; can be forged

Not exclusively brittle Brittle or rolled

Ingredients

Burning in Molten iron

1. Iron ore

Blast (can be cast into pig

2. Limestone

furnace iron)

3. Coke

Molten Steel

1. Remove

Steel mill converts them into the

impurities following semi-finished product of

(e.g. sulphur, varying widths, lengths & thicknesses

phosphorus & (i) Blooms: generally square lengths

excessive carbon of steel (> 36in2 or 232cm2)

Molten

iron (ii) Billets: generally square or round

2. Add alloying in section (< 36in2 or 232cm2)

elements

(e.g. manganese,

(iii) Slabs: generally flat and wide

chromium & (iv) Ingots: usually resembles a

vanadium) rectangle or square with generous

fillets

You might also like

- EASA Module 6 - Detailed NotesDocument37 pagesEASA Module 6 - Detailed NotesSteven J. SelcukNo ratings yet

- AWWA M11 Steel Pipe - A Guide For Desing and Installation 5ed 2017Document291 pagesAWWA M11 Steel Pipe - A Guide For Desing and Installation 5ed 2017vasotermiNo ratings yet

- Astm A514Document3 pagesAstm A514aahil ahmadNo ratings yet

- A Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesFrom EverandA Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesRating: 4 out of 5 stars4/5 (1)

- Astm A 668Document9 pagesAstm A 668Ryan Lasaca100% (1)

- A941Document7 pagesA941rohit kumarNo ratings yet

- Types of SteelDocument6 pagesTypes of SteelKhadeeja AslamNo ratings yet

- Ferrous MetallurgyDocument30 pagesFerrous MetallurgyGaurav KumarNo ratings yet

- Ferrous Metallurgy: The Chemistry and Structure of Iron and SteelDocument30 pagesFerrous Metallurgy: The Chemistry and Structure of Iron and SteelArjed Ali ShaikhNo ratings yet

- Ferrous Metallurgy: The Chemistry and Structure of Iron and SteelDocument30 pagesFerrous Metallurgy: The Chemistry and Structure of Iron and SteelKeith Tanaka MagakaNo ratings yet

- Metal AlignmentDocument16 pagesMetal AlignmentAli AbidNo ratings yet

- Ferrous Metallurgy: The Chemistry and Structure of Iron and SteelDocument30 pagesFerrous Metallurgy: The Chemistry and Structure of Iron and SteeltayyabNo ratings yet

- DESIGN 1 NotesDocument7 pagesDESIGN 1 NoteslordyNo ratings yet

- Metal May 2018 PDFDocument82 pagesMetal May 2018 PDFTZShengNo ratings yet

- Steel: Arch. Allen R. Buenaventura, MSCMDocument69 pagesSteel: Arch. Allen R. Buenaventura, MSCMDenzel NgNo ratings yet

- Metal and AlloysDocument45 pagesMetal and AlloysNarender KumarNo ratings yet

- 7 Steel and Steel AlloysDocument3 pages7 Steel and Steel AlloysKent Clark VillaNo ratings yet

- Civil Engineering Materials Lecture 15 & 16 Steel, Alloy Steel Composition and ClassificationDocument21 pagesCivil Engineering Materials Lecture 15 & 16 Steel, Alloy Steel Composition and Classificationsameer khanNo ratings yet

- Structure and Application of Non Ferrous MetalsDocument79 pagesStructure and Application of Non Ferrous MetalsRachmat HermawanNo ratings yet

- Metallurgy of Grey Cast IronDocument15 pagesMetallurgy of Grey Cast IronAmit PathakNo ratings yet

- Ch13 Materials ApplicationsDocument69 pagesCh13 Materials ApplicationsRhanganath ArivudainambiNo ratings yet

- Week 1 - High Alloy SteelDocument47 pagesWeek 1 - High Alloy SteelRifqi AwaluddinNo ratings yet

- Structural Steel 8768Document44 pagesStructural Steel 8768michelle geejoNo ratings yet

- Metals and Alloys & Heat Treatment of Steels 2,4Document82 pagesMetals and Alloys & Heat Treatment of Steels 2,4Vimukthi KumaraNo ratings yet

- Lecture 3 - Metals 2Document49 pagesLecture 3 - Metals 2abdullaharoon458No ratings yet

- Construction Materials Ii: 1.1 Ferrous MetalDocument6 pagesConstruction Materials Ii: 1.1 Ferrous MetalQila HusinNo ratings yet

- Metallurgy of Grey Cast IronDocument15 pagesMetallurgy of Grey Cast IronshahaNo ratings yet

- 10020dep-Notice 11042020Document32 pages10020dep-Notice 11042020Shivam VermaNo ratings yet

- Aircraft Materials and Processes (Summary)Document12 pagesAircraft Materials and Processes (Summary)Tetra HedronNo ratings yet

- Ch13 Materials ApplicationsDocument63 pagesCh13 Materials ApplicationsThefairman UnkownNo ratings yet

- Week 12 Engineering MaterialsDocument32 pagesWeek 12 Engineering MaterialsMohaiminul Islam TalhaNo ratings yet

- Engineering Materials - FNLDocument26 pagesEngineering Materials - FNLrhythmgoyal1410No ratings yet

- L-1 Steel StructureDocument22 pagesL-1 Steel StructureRukhsar JoueNo ratings yet

- Maintenance and Repair Welding Training ModuleDocument59 pagesMaintenance and Repair Welding Training ModuleAtefNo ratings yet

- Non Ferrous Metals and Alloys and Their Heat TreatmentDocument39 pagesNon Ferrous Metals and Alloys and Their Heat TreatmentMuhammed Adil IqbalNo ratings yet

- An Overview: MetalsDocument61 pagesAn Overview: MetalsjswldeepNo ratings yet

- Structural Steel 8768Document43 pagesStructural Steel 8768ravi 127No ratings yet

- MaTek #9 Metal-AlloyDocument32 pagesMaTek #9 Metal-AlloyJefri SinuratNo ratings yet

- Steel KnowledgeDocument13 pagesSteel Knowledgebyebyedd06No ratings yet

- AlloysDocument91 pagesAlloysNiccoloNo ratings yet

- 1.0 Introduction To Materials Sains BahanDocument17 pages1.0 Introduction To Materials Sains BahandianaNo ratings yet

- 211 2aDocument33 pages211 2aMada ChohNo ratings yet

- Ferrous MetalsDocument37 pagesFerrous MetalsGidNo ratings yet

- 5 Ferrous and Non FerrousDocument63 pages5 Ferrous and Non FerrousKiran ThunuguntlaNo ratings yet

- 8.1 Alloy and Its ImportanceDocument12 pages8.1 Alloy and Its ImportanceOw hui ziNo ratings yet

- 2023MSE-II Handout3Document12 pages2023MSE-II Handout3王竣右No ratings yet

- Materials and HardwareDocument364 pagesMaterials and HardwareHasrul Hadi0% (1)

- Aluminum and SteelDocument22 pagesAluminum and SteelDany ChNo ratings yet

- Stainless Steel and Elgiloy: G.Shekar Subramanian First Year PGDocument67 pagesStainless Steel and Elgiloy: G.Shekar Subramanian First Year PGShekar SubramanianNo ratings yet

- Modern SteelDocument16 pagesModern SteelAli AbidNo ratings yet

- 1.1 Classification of Materials (Tutorial)Document55 pages1.1 Classification of Materials (Tutorial)AIZAT ZUL HAIRIE BIN WAHI MoeNo ratings yet

- Metal Alloys Application and ProcessingDocument57 pagesMetal Alloys Application and ProcessingtbmariNo ratings yet

- Prepared By: Pallav Radia Asst Prof. Aits, RajkotDocument33 pagesPrepared By: Pallav Radia Asst Prof. Aits, Rajkotnaseema shaikNo ratings yet

- Lecture # 7 Steel and Cast IronDocument29 pagesLecture # 7 Steel and Cast IronTalha SheikhNo ratings yet

- Cast IronDocument21 pagesCast Irondellibabu509No ratings yet

- Lec 02Document19 pagesLec 02أمير حامد100% (1)

- Cast IronDocument27 pagesCast IronSanthoshsharma Devaraju100% (1)

- Chapter 7 SteelDocument44 pagesChapter 7 SteelDdeqz Elina Bueno INo ratings yet

- Alloys and CeramicsDocument19 pagesAlloys and CeramicsSHYAM PATELNo ratings yet

- Anirudha Samant REG NO.-16BME1044 Slot - C1 Alloy SteelsDocument12 pagesAnirudha Samant REG NO.-16BME1044 Slot - C1 Alloy SteelsAnirudhaNo ratings yet

- Unit - Iii: Ferrous and Non Ferrous MetalsDocument101 pagesUnit - Iii: Ferrous and Non Ferrous Metalssenthilkumar tsNo ratings yet

- Structural Steel 8768Document43 pagesStructural Steel 8768Nidhi MehtaNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Tempered Martensite: H. K. D. H. BhadeshiaDocument20 pagesTempered Martensite: H. K. D. H. BhadeshiaBahaa Eldin Sayed BahaaNo ratings yet

- En 24Document1 pageEn 24nikhil nagannavarNo ratings yet

- Astm B 221M - 02 Aluminum Alloy Extruded Bars Rods Wire Profile and TubesDocument14 pagesAstm B 221M - 02 Aluminum Alloy Extruded Bars Rods Wire Profile and TubesLazarasBenny Isprithiyone100% (2)

- The 4 Types of Heat Treatment Steel Undergoes - Kloeckner MetalsDocument5 pagesThe 4 Types of Heat Treatment Steel Undergoes - Kloeckner MetalsSrivishnu vemulaNo ratings yet

- PFI ES-11-1975 (R1990) Permanent Marking On Piping MaterialsDocument3 pagesPFI ES-11-1975 (R1990) Permanent Marking On Piping MaterialsThao NguyenNo ratings yet

- Revision NotesDocument21 pagesRevision NotesSam StideNo ratings yet

- Astm A668mDocument7 pagesAstm A668mcacalinoNo ratings yet

- Failure Analysis of Coal Pulverizer Mill PDFDocument12 pagesFailure Analysis of Coal Pulverizer Mill PDFHendraNo ratings yet

- En10272-01 (2008)Document42 pagesEn10272-01 (2008)kpurnimaNo ratings yet

- Genesis of Spalling in Tandem Mill Work-RollsDocument9 pagesGenesis of Spalling in Tandem Mill Work-Rolls54321qazNo ratings yet

- Esfuerzos Maximo Permisibles Tablas Ucs Ii Asme Viii Div 1 PDFDocument643 pagesEsfuerzos Maximo Permisibles Tablas Ucs Ii Asme Viii Div 1 PDFChuy Ramos0% (1)

- Criogenic MaterialDocument554 pagesCriogenic MaterialmariovalentiNo ratings yet

- Specification For Pressure Vessel Plates, Alloy Steel, NickelDocument4 pagesSpecification For Pressure Vessel Plates, Alloy Steel, NickelMauricio FernándezNo ratings yet

- Brake Disc Rotor Manufacturing ProcessesDocument3 pagesBrake Disc Rotor Manufacturing Processessumukha nadigNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 282, - , - : Carbon Steel For Large ForgingsDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 282, - , - : Carbon Steel For Large Forgingsbaskaran ayyapparajNo ratings yet

- A Report On Placement Training at Peekay Steels PVT LTD CalicutDocument63 pagesA Report On Placement Training at Peekay Steels PVT LTD CalicutDilrupa JmNo ratings yet

- ISO 898 Grade 10.9Document2 pagesISO 898 Grade 10.9Mihaela NastaseNo ratings yet

- FEB09SSIDocument24 pagesFEB09SSILouHew100% (2)

- Piping Fittings of Wrought Carbon Steel and Alloy Steel For Low-Temperature ServiceDocument6 pagesPiping Fittings of Wrought Carbon Steel and Alloy Steel For Low-Temperature ServiceWily Marin LopezNo ratings yet

- Case Hardening Steel 16MnCr5 AUSADocument3 pagesCase Hardening Steel 16MnCr5 AUSAShubhangi ShindeNo ratings yet

- Material Datasheet C45: 1. SteelmakingDocument1 pageMaterial Datasheet C45: 1. SteelmakingSETHUBALAN B 15BAU033No ratings yet

- 1 5736Document2 pages1 5736solidwormNo ratings yet

- Materials Standards For Metal Injection Molded PartsDocument39 pagesMaterials Standards For Metal Injection Molded PartsJoão TarelhoNo ratings yet

- Astm A194Document1 pageAstm A194theoNo ratings yet

- Tolerances For Cold-Finished BarsDocument9 pagesTolerances For Cold-Finished BarsugurNo ratings yet

- High Manganese Carbon Steels (1500 Series) / 231Document4 pagesHigh Manganese Carbon Steels (1500 Series) / 231Gil CabreraNo ratings yet