Professional Documents

Culture Documents

Pharmaceutical Stability Programmes

Pharmaceutical Stability Programmes

Uploaded by

Pasyc Business0 ratings0% found this document useful (0 votes)

50 views7 pagesStability studies help estimate how transportation and storage conditions impact drug efficacy by stressing materials under exaggerated environmental conditions. Appropriate temperature, humidity, and light levels ensure drugs are delivered without losing therapeutic properties. Sales of active pharmaceutical ingredients are rising due to increased manufacturing of high-potency and peptide drugs. Stability testing guidelines from the ICH and FDA require controlling, monitoring, and documenting environmental parameters like temperature and humidity in test chambers to maintain drug integrity during testing.

Original Description:

Original Title

PHARMACEUTICAL STABILITY PROGRAMMES.pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStability studies help estimate how transportation and storage conditions impact drug efficacy by stressing materials under exaggerated environmental conditions. Appropriate temperature, humidity, and light levels ensure drugs are delivered without losing therapeutic properties. Sales of active pharmaceutical ingredients are rising due to increased manufacturing of high-potency and peptide drugs. Stability testing guidelines from the ICH and FDA require controlling, monitoring, and documenting environmental parameters like temperature and humidity in test chambers to maintain drug integrity during testing.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

50 views7 pagesPharmaceutical Stability Programmes

Pharmaceutical Stability Programmes

Uploaded by

Pasyc BusinessStability studies help estimate how transportation and storage conditions impact drug efficacy by stressing materials under exaggerated environmental conditions. Appropriate temperature, humidity, and light levels ensure drugs are delivered without losing therapeutic properties. Sales of active pharmaceutical ingredients are rising due to increased manufacturing of high-potency and peptide drugs. Stability testing guidelines from the ICH and FDA require controlling, monitoring, and documenting environmental parameters like temperature and humidity in test chambers to maintain drug integrity during testing.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 7

The conditions under which drug substance and drug

products are manufactured, transported

and stored can influence their efficacy. Stability

studies in the pharmaceutical industry help to

estimate the impact of transportation and storage on

drug and medical device performance by

stressing materials under exaggerated environmental

conditions. Appropriate temperature,

humidity, and light conditions guarantee that drugs

are delivered to patients without loss of

therapeutic properties.

An active pharmaceutical ingredient is used in a finished

pharmaceutical product (FPP), intended to carry certain

pharmacological actions or otherwise have a direct effect

in the diagnosis, cure, treatment, mitigation or prevention

of various diseases, or in some cases in restoring,

correcting or modifying human physiological functions.

Sales of pharmaceutical ingredient are on the rise due to a

substantial increase in high-potency API (HPAPI) and

peptide API manufacturing. A new study conducted by

Persistence Market Research reveals that the US$ 151.9 Bn

global active pharmaceutical ingredient market will grow

to US$ 158.3 Bn by 2017 end, reflecting a Y-o-Y growth

rate of 4.2%. This market is estimated to further increase

to US$ 225.2 Bn, expanding at a CAGR of 4.5% over the

forecast period (2016 –2025)

The design of the stability studies for the FPP should be based on

knowledge of the behaviour

and properties of the API, information from stability studies on the

API and on experience gained from preformulation studies and

investigational FPPs. Data from stability studies should be

provided on at least three primary batches of the FPP. The

primary batches should be of the same formulation and

packaged in the same container closure systemas proposed

formarketing. The manufacturing process used for primary

batches should simulate that to be applied to production batches

and should provide product of the same quality and meeting the

same specification as that intended for marketing. Stability

studies should be performed on each individual strength, dosage

form and container type and size of the FPP unless bracketing or

matrixing is applied.

Stability testing of pharmaceutical products is addressed by the ICH (International Conference

on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human

Use) and the final guidance on stability testing has been adopted across Europe, Japan and the

United States.

Furthermore, the FDA states in 21 CFR part 203 section that manufacturers, authorized

distributors of drugs and their representatives shall store and handle all drug samples under

“conditions that will maintain their stability, integrity and effectiveness,” ensuring that the

drug samples are free of contamination, deterioration and adulteration.

Within stability test chambers, parameters such as temperature, humidity, differential

pressure, lighting, gas levels and other environmental conditions must be controlled,

monitored and documented. To reduce the risk of failed studies, a monitoring system designed

for both functionality and compliance is required. Functions should include data logging,

automated date file backup, monitoring and reporting via Internet access, connectivity options

including wireless, email, phone or text alarm notifications, multiple levels of data security,

which can include digital signatures, complete event and interaction history and audit trail.

You might also like

- Global Pharmaceutical Industry-Overview and Success FactorsDocument13 pagesGlobal Pharmaceutical Industry-Overview and Success FactorsKumar Reddy67% (3)

- Regulatory AffairsDocument14 pagesRegulatory AffairsSiddarth Reddy100% (2)

- Regulatory Affairs PDFDocument27 pagesRegulatory Affairs PDFDipak BhingardeveNo ratings yet

- PPM Cannamimetics White PaperDocument33 pagesPPM Cannamimetics White PaperChadBerginNo ratings yet

- Dietary Supplements in Dermatology: A Review of The Evidence For Zinc, Biotin, Vitamin D, Nicotinamide, and PolypodiumDocument9 pagesDietary Supplements in Dermatology: A Review of The Evidence For Zinc, Biotin, Vitamin D, Nicotinamide, and PolypodiumNazihan Safitri AlkatiriNo ratings yet

- Bioequivalence Requirements in Various Global Jurisdictions-Springer International Publishing (2017)Document348 pagesBioequivalence Requirements in Various Global Jurisdictions-Springer International Publishing (2017)Solomon100% (1)

- Rules and Regulations in Preformulation StudiesDocument2 pagesRules and Regulations in Preformulation StudiesAzhar DkNo ratings yet

- AJPTR Article Kamaljit Singh - 5537Document30 pagesAJPTR Article Kamaljit Singh - 5537sherepunjabNo ratings yet

- WHO Good Trade and Distribution PDFDocument19 pagesWHO Good Trade and Distribution PDFsadiq455No ratings yet

- Bioequivalence: Faculty of Pharmacy, Nursing and Health Professions Master in Industrial Pharmaceutical TechnologyDocument16 pagesBioequivalence: Faculty of Pharmacy, Nursing and Health Professions Master in Industrial Pharmaceutical TechnologyMayson BaliNo ratings yet

- Bioequivalence: Faculty of Pharmacy, Nursing and Health Professions Master in Industrial Pharmaceutical TechnologyDocument15 pagesBioequivalence: Faculty of Pharmacy, Nursing and Health Professions Master in Industrial Pharmaceutical TechnologyMayson Bali100% (1)

- Commentary Global Harmonization of Comparator Products For Bioequivalence StudiesDocument4 pagesCommentary Global Harmonization of Comparator Products For Bioequivalence StudiesBilal AbbasNo ratings yet

- Cristo Fo Letti 2018Document12 pagesCristo Fo Letti 2018Ibrahim Al SharabiNo ratings yet

- Lecture 5 - 6 & 7 - 2022-1Document20 pagesLecture 5 - 6 & 7 - 2022-1Koki KingNo ratings yet

- Encouraging The Use of Generic Medicines Implications For Transition Economies PDFDocument8 pagesEncouraging The Use of Generic Medicines Implications For Transition Economies PDFRodrigo LeiteNo ratings yet

- Who & IchDocument19 pagesWho & IchMacbethNo ratings yet

- 1.preface The International Pharmacopoeia, Tenth EditionDocument3 pages1.preface The International Pharmacopoeia, Tenth Editionزيد هشام السيدNo ratings yet

- Impurity Profiling Theory and PracticeDocument6 pagesImpurity Profiling Theory and PracticesrichainuluNo ratings yet

- DI332 194 225 EngDocument32 pagesDI332 194 225 EngChandraNo ratings yet

- Maria Mushtaque Assignment DrapDocument3 pagesMaria Mushtaque Assignment DrapMaria MushtaqueNo ratings yet

- BP702T Ip IiiDocument27 pagesBP702T Ip IiiGURU PRASAD TIWARINo ratings yet

- Environmental Friendly Pharmaceutical Excipients Towards Green ManufacturingDocument12 pagesEnvironmental Friendly Pharmaceutical Excipients Towards Green Manufacturingnikhilsachan100% (1)

- FDA PhotostabilityDocument8 pagesFDA PhotostabilityLina SakellariouNo ratings yet

- Combination Product (FDC)Document5 pagesCombination Product (FDC)shah777No ratings yet

- ArticleDocument8 pagesArticleprachi singhNo ratings yet

- Ds Stability ProfilesDocument12 pagesDs Stability ProfilesjustanothergunnutNo ratings yet

- Castillo (2018) - Compatibility Study Preformulation of Immediate Release Rupatadine Fumarate 10 MG Tablets. DDIPDocument13 pagesCastillo (2018) - Compatibility Study Preformulation of Immediate Release Rupatadine Fumarate 10 MG Tablets. DDIPAlejandro RestrepoNo ratings yet

- Clinical Pharmacokinetic Studies of PharmaceuticalsDocument23 pagesClinical Pharmacokinetic Studies of PharmaceuticalsPankaj SharmaNo ratings yet

- JETIR2106052Document18 pagesJETIR2106052ahmunde2002No ratings yet

- Good Manufacturing PracticeDocument5 pagesGood Manufacturing PracticeBipul BiplavNo ratings yet

- How The Pharmaceutical Industry Runs On The Foundation of PharmacopoeiaDocument8 pagesHow The Pharmaceutical Industry Runs On The Foundation of Pharmacopoeiarushikeshraut.013No ratings yet

- Pharmacopolitics, Implications and Implementation in Clinical StudiesDocument3 pagesPharmacopolitics, Implications and Implementation in Clinical StudiesNantarat KengkeatchaiNo ratings yet

- Tirupati MedicareDocument40 pagesTirupati MedicareAmit KumarNo ratings yet

- Innovative in Vitro Methodologies For Establishing Therapeutic EquivalenceDocument6 pagesInnovative in Vitro Methodologies For Establishing Therapeutic EquivalenceAnonymous 6OPLC9UNo ratings yet

- 1049 Quality of Biotechnological Products: Stability Testing of Biotechnological/ Biological ProductsDocument4 pages1049 Quality of Biotechnological Products: Stability Testing of Biotechnological/ Biological ProductsMeisy LantikaNo ratings yet

- Food Inspired Innovations To Improve The Stabilit - 2022 - International JournalDocument19 pagesFood Inspired Innovations To Improve The Stabilit - 2022 - International JournalDana MateiNo ratings yet

- Who Trs 917 Annex2Document19 pagesWho Trs 917 Annex2Selva Bavani SelwaduraiNo ratings yet

- Investigational New Drug (IND) Submission Checklist: WWW - Fda.gov/cder/forms/1571-1572-Help - HTMLDocument5 pagesInvestigational New Drug (IND) Submission Checklist: WWW - Fda.gov/cder/forms/1571-1572-Help - HTMLDivyaNo ratings yet

- Guideline On Bioavailability and BioequivalanceDocument26 pagesGuideline On Bioavailability and BioequivalanceGima Amezia SariNo ratings yet

- PharmacoDocument20 pagesPharmacoBrian OkariNo ratings yet

- Comparative Study of Generic Drug Approval Process in Eu, Usa and China - A ReviewDocument16 pagesComparative Study of Generic Drug Approval Process in Eu, Usa and China - A ReviewTuyến Đặng ThịNo ratings yet

- Report 2Document13 pagesReport 2api-3711225No ratings yet

- Biosimilars Latin AmericaDocument17 pagesBiosimilars Latin AmericamaryNo ratings yet

- Microbiological Analysis of Pharmaceutical Products.Document40 pagesMicrobiological Analysis of Pharmaceutical Products.Ayush KesriNo ratings yet

- (첨부 1) Guideline for Registration of Medicines (FMHACA)Document8 pages(첨부 1) Guideline for Registration of Medicines (FMHACA)Talha MuhammadNo ratings yet

- Scientific Insights: ICH S6 (R1) - Preclinical Safety of BiopharmaceuticalsDocument4 pagesScientific Insights: ICH S6 (R1) - Preclinical Safety of BiopharmaceuticalsHuntingdon Life Sciences100% (1)

- Comparing Generic and Innovator Drugs A Review ofDocument16 pagesComparing Generic and Innovator Drugs A Review ofPrachi PandeyNo ratings yet

- Craneetal 2019Document16 pagesCraneetal 2019บอส เลิศเกียรติรัชตะNo ratings yet

- Stability Profiles of Drug Products Extended Beyond Labeled Expiration DatesDocument12 pagesStability Profiles of Drug Products Extended Beyond Labeled Expiration Datesrodrigo4590No ratings yet

- Practical Approaches To Protein Formulation DevelopmentDocument25 pagesPractical Approaches To Protein Formulation DevelopmentEvelyn TapiaNo ratings yet

- Research & Development (R&D) - FormulationDocument2 pagesResearch & Development (R&D) - FormulationAliah ZuhairahNo ratings yet

- IntroductionDocument6 pagesIntroductionعبدالعزيز بدرNo ratings yet

- OTC Drug Marketing - Global Trends and Indian ExperiencesDocument8 pagesOTC Drug Marketing - Global Trends and Indian Experienceskush_vashNo ratings yet

- Development of Biopharmaceutical Drug-Device Products (Feroz Jameel, John W. Skoug, Robert R. Nesbitt Etc.) (Z-Library)Document888 pagesDevelopment of Biopharmaceutical Drug-Device Products (Feroz Jameel, John W. Skoug, Robert R. Nesbitt Etc.) (Z-Library)flam.inggeezNo ratings yet

- Pharmgkb Tutorial For Pharmacogenomics of Drugs Potentially Used in The Context of Covid-19Document7 pagesPharmgkb Tutorial For Pharmacogenomics of Drugs Potentially Used in The Context of Covid-19Dyahsekarayupudak wangiNo ratings yet

- Global Regulatory Strategy For Veterinary MedicinesDocument11 pagesGlobal Regulatory Strategy For Veterinary MedicinesCsar Sanchez Gracia50% (2)

- 8416-Article Text-11800-1-10-20200127Document16 pages8416-Article Text-11800-1-10-20200127raginiNo ratings yet

- Unnati Garg IB and IMPDDocument8 pagesUnnati Garg IB and IMPDUnnati GargNo ratings yet

- Paper Control 3Document7 pagesPaper Control 3Chrystal araya mugaNo ratings yet

- Bioequivalence Studies - A Regulatory PerspectiveDocument12 pagesBioequivalence Studies - A Regulatory Perspectivebhanu99100% (2)

- GMP DocumentDocument49 pagesGMP DocumentDinesh SenathipathiNo ratings yet

- Global Pharmacopoeia Standards: Why Harmonization Is NeededDocument6 pagesGlobal Pharmacopoeia Standards: Why Harmonization Is NeededLinh NguyenNo ratings yet

- The FDA and Worldwide Current Good Manufacturing Practices and Quality System Requirements Guidebook for Finished PharmaceuticalsFrom EverandThe FDA and Worldwide Current Good Manufacturing Practices and Quality System Requirements Guidebook for Finished PharmaceuticalsNo ratings yet

- GingerDocument28 pagesGingerMary Joy M. HinautanNo ratings yet

- Temar Diagnostics (Head Office) : Clinical PathologyDocument1 pageTemar Diagnostics (Head Office) : Clinical PathologyJaadi 786No ratings yet

- Suki Medical ReportDocument2 pagesSuki Medical ReportResdy BenyaminNo ratings yet

- Diabetes Causes and SympthomsDocument24 pagesDiabetes Causes and SympthomsTinke WinkeNo ratings yet

- Lap Kasus Listiana - Rev1Document6 pagesLap Kasus Listiana - Rev1Gunawan pnsNo ratings yet

- Quotation Request Form: Customer DetailsDocument1 pageQuotation Request Form: Customer DetailsAmanda RezendeNo ratings yet

- ALKALOIDS EmirekuDocument61 pagesALKALOIDS EmirekuAmoako KingsleyNo ratings yet

- Nama Antibiotik Regimen Dosis Dosis Per-Hari Rute No Kode PasienDocument10 pagesNama Antibiotik Regimen Dosis Dosis Per-Hari Rute No Kode PasienAri AnggaraNo ratings yet

- Human Sexuality and Sexual DisordersDocument42 pagesHuman Sexuality and Sexual DisordersAbdul Gafoor FahmyNo ratings yet

- Reusable Injection Pen Patient Usage Guide: Injecting Rekovelle Using Your PenDocument2 pagesReusable Injection Pen Patient Usage Guide: Injecting Rekovelle Using Your PenlynneNo ratings yet

- Medical Science Books 11 10 2021Document25 pagesMedical Science Books 11 10 2021Anil DasNo ratings yet

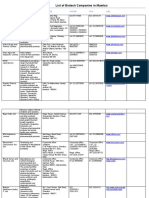

- List of Biotech Companies in Mumbai: Off Andheri-Kurla RD, Marol Naka, Andheri (East), MumbaiDocument10 pagesList of Biotech Companies in Mumbai: Off Andheri-Kurla RD, Marol Naka, Andheri (East), MumbaiPooja Bhamrrah0% (1)

- Myers 7th Edition Psychology: Chapter 17 OutlineDocument6 pagesMyers 7th Edition Psychology: Chapter 17 OutlineHockeyboy41100% (3)

- Poster Ipaci RmsDocument3 pagesPoster Ipaci RmsRizalMarubobSilalahiNo ratings yet

- Annexure For Hospital Annexure 1 Furniture and Fixtures S.N ItemsDocument10 pagesAnnexure For Hospital Annexure 1 Furniture and Fixtures S.N ItemsSiva KasaraneniNo ratings yet

- Drug StudyDocument2 pagesDrug StudyCheska YsabelleNo ratings yet

- W2 Emergency ECG (DR Refli)Document47 pagesW2 Emergency ECG (DR Refli)indahflsaragihNo ratings yet

- Berberine Ebook by Anthony Musso June 2011Document26 pagesBerberine Ebook by Anthony Musso June 2011anthony musso100% (4)

- Handbook of Cancer Chemotherapy - Skeel, Roland TDocument813 pagesHandbook of Cancer Chemotherapy - Skeel, Roland TJesús BlancoNo ratings yet

- LNWH Alcohol GUIDELINE SUMMARY 2018Document1 pageLNWH Alcohol GUIDELINE SUMMARY 2018Ai Hwa LimNo ratings yet

- Principles of HemodynamicDocument48 pagesPrinciples of HemodynamicdevdsantoshNo ratings yet

- Uia 19 MANAGEMENT OF ORGANOPHOSPHORUS POISONINGDocument5 pagesUia 19 MANAGEMENT OF ORGANOPHOSPHORUS POISONINGAmanuel GirmayeNo ratings yet

- Pharmacology Antibiotics: Fluoroquinolone - Chloramphenicol - TetracycllineDocument40 pagesPharmacology Antibiotics: Fluoroquinolone - Chloramphenicol - TetracycllinemluthfidunandNo ratings yet

- Role of Pharmacists in The IndustryDocument10 pagesRole of Pharmacists in The IndustryGerald Limo Arap ChebiiNo ratings yet

- Guideline 133FM PDFDocument13 pagesGuideline 133FM PDFPangestu DhikaNo ratings yet

- Narrative Review of Guggulu Formulations of AyurveDocument7 pagesNarrative Review of Guggulu Formulations of Ayurvesuhas MNo ratings yet

- Po 2021 FebruariDocument28 pagesPo 2021 FebruariNila Permata SariNo ratings yet