Professional Documents

Culture Documents

Severity Evaluation Criteria

Severity Evaluation Criteria

Uploaded by

khmortezaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Severity Evaluation Criteria

Severity Evaluation Criteria

Uploaded by

khmortezaCopyright:

Available Formats

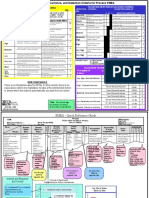

Severity, Occurrence, and Detection Criteria for Design FMEA

SEVERITY EVALUATION CRITERIA SUGGESTED DETECTION EVALUATION CRITERIA

EFFECT CRITERIA: Severity of Effect RNK. DETECTION CRITERIA RNK.

Design Control will not and/or cannot detect a potential cause/

Hazardous- Very high severity ranking when a potential failure mode affects safe Absolute

without vehicle operation and/or involves noncompliance with government 10 mechanism and subsequent failure mode; or there is no 10

Uncertainty Design Control.

warning regulation without warning

Very Remote chance the Design Control will detect a potential

Hazardous- Very high severity ranking when a potential failure mode affects safe Very Remote cause/mechanism and subsequent failure mode. 9

with vehicle operation and/or involves noncompliance with government 9

warning regulation with warning Remote chance the Design Control will detect a potential cause/

Remote mechanism and subsequent failure mode. 8

Very High Vehicle/item inoperable (loss of primary function). 8

Very Low chance the Design Control will detect a potential

Vehicle/item operable but at a reduced level of performance.

Very Low cause/mechanism and subsequent failure mode. 7

High

Customer very dissatisfied. 7

Low chance the Design Control will detect a potential

Low cause/mechanism and subsequent failure mode. 6

Vehicle/item operable but Comfort/Convenience item(s) inoperable.

Moderate

Customer dissatisfied. 6

Moderate chance the Design Control will detect a potential cause/

Vehicle/item operable but Comfort/Convenience item(s) operable at a Moderate mechanism and subsequent failure mode. 5

Low

reduced level of performance. Customer somewhat dissatisfied. 5

Moderately Moderately High chance the Design Control will detect a potential

Very Low

Fit & Finish/Squeak & Rattle item does not conform. Defect noticed

4 cause/mechanism and subsequent failure mode. 4

by most customers (greater than 75%). High

High chance the Design Control will detect a potential cause/

Fit & Finish/Squeak & Rattle item does not conform. Defect noticed High 3

Minor

by 50% of customers. 3 mechanism and subsequent failure mode.

Very High chance the Design Control will detect a potential cause/

Fit & Finish/Squeak & Rattle item does not conform. Defect noticed Very High mechanism and subsequent failure mode. 2

Very Minor

by discriminating customers (less than 25%).

2

Almost Design Controls will almost certainly detect a potential cause/

None No discernable effect. 1 mechanism and subsequent failure mode. 1

Certain

SUGGESTED OCCURRENCE EVALUATION CRITERIA RPN THRESHOLD

Probability of Possible Failure Rates Ppk Rank There is no threshold value for RPNs. In other words, there is

Failure no value above which it is mandatory to take a

100 per thousand vehicles/items <0.55 10 Recommended Action or below which the team is automatically

Very High: Persistent failures

50 per thousand vehicles/items ≥0.55 9 excused from an action.

20 per thousand vehicles/items ≥0.78 8

High: Frequent failures

10 per thousand vehicles/items ≥0.86 7

5 per thousand vehicles/items ≥0.94 6

Moderate: Occasional failures 2 per thousand vehicles/items ≥1.00 5

1 per thousand vehicles/items ≥1.10 4

0.5 per thousand vehicles/items ≥1.20 3

Low: Relatively few failures

0.1 per thousand vehicles/items ≥1.30 2

Remote: Failure is unlikely 0.01 per thousand vehicles/items ≥1.67 1

(248) 280 - 4800

*Note: Zero (0) rankings for Severity, Occurrence or Detection are not allowed www.quality-one.com

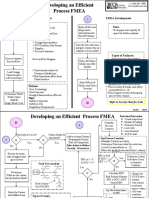

FMEA - Quick Reference Guide

System Potential

Sub System FMEA Number:

X Component: Generic Decision

Failure Mode and Effects Analysis Page 1 of 1

Model Year/Vehicle (s): 98.5 Design Responsibility: QAI, Inc. (Design FMEA) Prepared by: Lee Dawson

Core Team: M. Moore, M. Weber, D. Wojcik, L. Dawson Key Date: Engineering Rel. 2/3/98 FMEA Date (orig.):

Potential O Current

Item Potential Potential S Cl c

D R.

e

Responsibility Action Results

e a Cause(s)/ Design Recommended Actions S O D R.

Failure Effect(s) of c t P. & Target

v s Mechanism(s) u Controls e N. Action(s) Taken e c e P.

Function Mode Failure s r c Completion Date v t N.

Failure Prevent Detect c

Must provide an FMEA FMEA not • Product liability 10 YC Inadequate FMEA 5 •Design 2 100 Call an FMEA Design team leader FMEA performed 10 2 2 40

•Mistake verification,

which determines design adequately • Customer development Proofing facilitator to or project manager; under the supervision

• Cross functional planning

risk and addresses performed; high dissatisfaction reduce time required ASAP and leadership of

and testing

potential significant and risk remains • Reduced performance team not assembled •Training and improve quality an expert/certified

critical characteristic of system or • Facilitation not of the FMEA process FMEA facilitator

selection: component used

Measurable: • Potential risk of • FMEA expertise is

• Reduced RPN injury limited

• Number of significant Actions should: Brief action

and critical characteristics. • eliminate failure • Name of team

Detect result Recalculate RPN, after

• Number of design mode SEV=9/10 member to

Planned tests • eliminate causes description action has been

actions. • Transfer to carry issue.

Customer on YS • Name of Date action taken

or from DV Plan • reduce occurrence taken • occurrence

focus/experience • evaluations champion

• end user • improve tests • detection

Brainstorm causes • builds “detection • Date action

• assembler • man • bucks Note: severity will

• Verb-noun reduction last desired

• maker • material Note: Must have option” likely stay the same

• measurable completion

Anti function • regulatory • method written instructions. unless failure mode is

is desirable • machine Prevent eliminated

for functional body •Reduces Occurrence

• objective • environment

approach Determine Root

• subjective

• full cause if YC

• partial See Occurrence

• intermittent

See Severity See Detection

Chart on Chart on Chart on

• excess function

opposite side opposite side opposite side

Actions are Required: Critical & Significant

(by Priority) Characteristics Action Guidelines

1.) When this exists (initiate 10

Top 20% of Failure

Process FMEA to verify) 1.) Potential Critical Characteristic

9 Modes by RPN

8

S 2.) Potential Significant

2.) When this exists (initiate 7

Characteristic; Action

Process FMEA to verify) e R

v 6 Required P

e 5

N

r

4 ANNOYANCE

3.) For the top 20% Failure i

t ZONE

Modes / Causes (Pareto by 3

3.) RPN-Top

y

RPN) 2 20% by pareto Failure Modes

1

1 2 3 4 5 6 7 8 9 10

Occurrence

You might also like

- Formal Verification: An Essential Toolkit for Modern VLSI DesignFrom EverandFormal Verification: An Essential Toolkit for Modern VLSI DesignRating: 4 out of 5 stars4/5 (4)

- National Safety Council - Accident Prevention Manual For Business & Industry - Engineering & Technology - National Safety Council (2001)Document881 pagesNational Safety Council - Accident Prevention Manual For Business & Industry - Engineering & Technology - National Safety Council (2001)aaa100% (2)

- Instructions For Using and Servicing: The Articulated Multi-FunctionDocument72 pagesInstructions For Using and Servicing: The Articulated Multi-FunctionMaris PriedeNo ratings yet

- Robot Programming: A Practical Guide to Behavior-Based RoboticsFrom EverandRobot Programming: A Practical Guide to Behavior-Based RoboticsRating: 4.5 out of 5 stars4.5/5 (1)

- Failure Modes and Effect Analysis of Electro-Pneumatics SystemDocument9 pagesFailure Modes and Effect Analysis of Electro-Pneumatics SystemmutluNo ratings yet

- VDA 8D Fehlerursachenkategorien V2.1 en EnglishDocument37 pagesVDA 8D Fehlerursachenkategorien V2.1 en EnglishkhmortezaNo ratings yet

- Severity, Occurrence, and Detection Criteria For Design FMEADocument2 pagesSeverity, Occurrence, and Detection Criteria For Design FMEAaddinulichsanNo ratings yet

- Ranking Automotive Matrix Rev 1Document2 pagesRanking Automotive Matrix Rev 1Venkataramana BhagavatiNo ratings yet

- All+Rating+Guidelines ServiceDocument4 pagesAll+Rating+Guidelines ServiceSegu PratheekNo ratings yet

- Effect Criteria Rank: Typical Rankings of Severity Indices (Ford Motor Company, 2001)Document4 pagesEffect Criteria Rank: Typical Rankings of Severity Indices (Ford Motor Company, 2001)ain liyanaNo ratings yet

- Fmea RatingDocument6 pagesFmea RatingjanaprathapNo ratings yet

- FMEA ScoreDocument2 pagesFMEA ScorebbaskaranNo ratings yet

- PFMEA Reference Card PDFDocument2 pagesPFMEA Reference Card PDFRajesh Yadav100% (6)

- SeverityDocument10 pagesSeverityVijayamalar AmruthalingamNo ratings yet

- Fmea Notes-1Document6 pagesFmea Notes-1sagarvadhel78No ratings yet

- FMEA TemplateDocument6 pagesFMEA TemplateHiếu Trần100% (1)

- Failure Mode Effect Analysis: Dr. Ir. Muhammad SabriDocument42 pagesFailure Mode Effect Analysis: Dr. Ir. Muhammad Sabricalvin100% (1)

- FMEA Scoring GuidelinesDocument3 pagesFMEA Scoring Guidelineskalpesh prajapatiNo ratings yet

- Severity Evaluation CriteriaDocument2 pagesSeverity Evaluation CriteriakhmortezaNo ratings yet

- Severity, Occurrence, and Detection Criteria For Design FMEADocument2 pagesSeverity, Occurrence, and Detection Criteria For Design FMEAtejashraj93No ratings yet

- Dfmea TemplateDocument5 pagesDfmea TemplateHerbert WeigeltNo ratings yet

- SOD Machinery FMEADocument3 pagesSOD Machinery FMEAUmashankar Gautam100% (1)

- RPN RankingsDocument5 pagesRPN RankingsThế PhongNo ratings yet

- Xfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsDocument6 pagesXfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsRoland JoldisNo ratings yet

- Detection: Evaluation Criteria: Ref:As Per AIAG PFMEA Standards Ril/Pfmea/Annex-C Likelihood of DetectionDocument1 pageDetection: Evaluation Criteria: Ref:As Per AIAG PFMEA Standards Ril/Pfmea/Annex-C Likelihood of DetectionaslamNo ratings yet

- FMEA HandbookDocument1 pageFMEA Handbookavinashchauhan2695No ratings yet

- Failure Mode and Effect AnalysisDocument25 pagesFailure Mode and Effect AnalysislokelooksNo ratings yet

- "Fmea & Case Study": Kelompok: Rohmat Setiawan Titin NuryawatiDocument41 pages"Fmea & Case Study": Kelompok: Rohmat Setiawan Titin Nuryawatirohmat_setiawan77No ratings yet

- FMEA StandardDocument4 pagesFMEA Standardjawahar ramNo ratings yet

- PFMEA Ranking Table Rating Criteria Action GuidelineDocument10 pagesPFMEA Ranking Table Rating Criteria Action GuidelineEnrico Miguel AquinoNo ratings yet

- DFMEArefcard PDFDocument2 pagesDFMEArefcard PDFIgor PNo ratings yet

- DFMEA Rating Table v01Document4 pagesDFMEA Rating Table v01Balakumaran MurugesanNo ratings yet

- Anirudh Acharya FA Exp 1Document5 pagesAnirudh Acharya FA Exp 1Anirudh AcharyaNo ratings yet

- Failure Mode and Effect Analysis Severity RatingDocument5 pagesFailure Mode and Effect Analysis Severity RatingRemus CicuNo ratings yet

- Delphi Supplier Quality Fmea Severity RankingsDocument3 pagesDelphi Supplier Quality Fmea Severity Rankingsmani317No ratings yet

- Updates Dec09 AIAG FMEA-Ranking-TablesDocument3 pagesUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- All+Rating+Guidelines ManufacturingDocument4 pagesAll+Rating+Guidelines ManufacturingSegu PratheekNo ratings yet

- DfmeaDocument13 pagesDfmeaAshisNo ratings yet

- PFMEA RankingDocument1 pagePFMEA RankingSachin KumbharNo ratings yet

- Fmea - Failure Mode Effect AnalysisDocument23 pagesFmea - Failure Mode Effect AnalysisAsawari JoshiNo ratings yet

- Print # Rev. FMEA Number: Item: Process Responsibility: Prepared By: Model Year(s) /vehicle(s) Key Date Date (Orig.) Team: Date (Rev.)Document2 pagesPrint # Rev. FMEA Number: Item: Process Responsibility: Prepared By: Model Year(s) /vehicle(s) Key Date Date (Orig.) Team: Date (Rev.)Anonymous 8lxxbNcA0sNo ratings yet

- FMEA Failure Mode Effect AnalysisDocument61 pagesFMEA Failure Mode Effect AnalysisAbhijeet RandhirNo ratings yet

- FMEA - 4th EditionsDocument3 pagesFMEA - 4th Editionsmezal rdNo ratings yet

- PFMEA EncodeDocument4 pagesPFMEA EncodeBooniz-bonice EliasNo ratings yet

- MeasureDocument51 pagesMeasureAshwani KumarNo ratings yet

- 203 LSS Gbo - FmeaDocument47 pages203 LSS Gbo - FmeaRocker byNo ratings yet

- FEMEA Ranking TablesDocument3 pagesFEMEA Ranking TablesAhmed KsibiNo ratings yet

- FMEADocument24 pagesFMEARaajha MunibathiranNo ratings yet

- Design and Process Failure Mode and Effect Analysis (Dfmea & Pfmea)Document19 pagesDesign and Process Failure Mode and Effect Analysis (Dfmea & Pfmea)Mohammed KassemNo ratings yet

- FMEADocument3 pagesFMEAyadiNo ratings yet

- Six Sigma Analyze PhaseDocument12 pagesSix Sigma Analyze PhaseerinelNo ratings yet

- Fmea Failure Mode and Effects Analysis: Adapted From Presentation by Dr. StamperDocument23 pagesFmea Failure Mode and Effects Analysis: Adapted From Presentation by Dr. Stamperhasan_taşkınNo ratings yet

- Failure Mode and Effects Analysis of Hotwell System Motor Operated Butterfly ValveDocument19 pagesFailure Mode and Effects Analysis of Hotwell System Motor Operated Butterfly ValveBalan SelvanNo ratings yet

- Barringer FMEA 11 17 09Document9 pagesBarringer FMEA 11 17 09peach5100% (1)

- Process Fmea: Table 6 Suggested Pfmea Severity Evaluation CriteriaDocument4 pagesProcess Fmea: Table 6 Suggested Pfmea Severity Evaluation CriteriaSelvakumaran Dhandapani100% (1)

- D2 L5, Module-7 ABC of Product ReliabilityDocument46 pagesD2 L5, Module-7 ABC of Product ReliabilityRAVI SHANKARNo ratings yet

- Xfmea Report Sample - Design FMEA: in Addition To This Summary, This Report Includes The Following FormsDocument6 pagesXfmea Report Sample - Design FMEA: in Addition To This Summary, This Report Includes The Following FormsVilas m ChinkeNo ratings yet

- Fmea TableDocument4 pagesFmea TableAfzal RNo ratings yet

- Boleh Merevisi Kriteria Severity, Kecuali 9 Dan 10Document3 pagesBoleh Merevisi Kriteria Severity, Kecuali 9 Dan 10Reza WijayaNo ratings yet

- GM PFMEA RankingsDocument1 pageGM PFMEA RankingssathyabalaramanNo ratings yet

- 7 Knowledge Management and Organizational Performance An Exploratory Zack 2009Document23 pages7 Knowledge Management and Organizational Performance An Exploratory Zack 2009khmortezaNo ratings yet

- Explaining The Relationships of Knowledge Management Processes With Organizational Performance Through The Mediator Organizational LearningDocument8 pagesExplaining The Relationships of Knowledge Management Processes With Organizational Performance Through The Mediator Organizational LearningkhmortezaNo ratings yet

- 14 Dimensions and Measures of Manufacturing PerformanceDocument6 pages14 Dimensions and Measures of Manufacturing PerformancekhmortezaNo ratings yet

- Gauge Development Plan: Part Name Part NoDocument1 pageGauge Development Plan: Part Name Part NokhmortezaNo ratings yet

- 8 Knowledge Management and Organizational Performance - A Decomposed View Mills 2011Document18 pages8 Knowledge Management and Organizational Performance - A Decomposed View Mills 2011khmortezaNo ratings yet

- 10 Knowledge Management An Organizational Capabilities Perspective Gold & Malhotra 2001Document30 pages10 Knowledge Management An Organizational Capabilities Perspective Gold & Malhotra 2001khmortezaNo ratings yet

- List of GaugesDocument1 pageList of GaugeskhmortezaNo ratings yet

- 3 7-4 BSCDocument22 pages3 7-4 BSCkhmortezaNo ratings yet

- Manufacturing Operations Checklist (Readiness Review For Ppap/Run@Rate)Document5 pagesManufacturing Operations Checklist (Readiness Review For Ppap/Run@Rate)khmorteza100% (1)

- A-Systems-Approach-to-Failure-Modes-v1 Paper Good For Functions and Failure MechanismDocument19 pagesA-Systems-Approach-to-Failure-Modes-v1 Paper Good For Functions and Failure Mechanismkhmorteza100% (1)

- Initial Feasibility Study For Quotation: Company NameDocument2 pagesInitial Feasibility Study For Quotation: Company NamekhmortezaNo ratings yet

- QSYS Professional - APQP: Advanced Product Quality PlanningDocument2 pagesQSYS Professional - APQP: Advanced Product Quality PlanningkhmortezaNo ratings yet

- Type 1: Technology Council Management ReviewDocument1 pageType 1: Technology Council Management ReviewkhmortezaNo ratings yet

- APQP Procedure From Elsmar - 2020-05Document6 pagesAPQP Procedure From Elsmar - 2020-05khmortezaNo ratings yet

- Severity Evaluation CriteriaDocument2 pagesSeverity Evaluation CriteriakhmortezaNo ratings yet

- Planning For FMEA Gather: FMEA Development: Page 1 ©2000Document2 pagesPlanning For FMEA Gather: FMEA Development: Page 1 ©2000khmorteza100% (1)

- Planning For FMEA Gather: FMEA Development: MediumDocument2 pagesPlanning For FMEA Gather: FMEA Development: MediumkhmortezaNo ratings yet

- VDA Volume 8D V1.0 EN English PDFDocument18 pagesVDA Volume 8D V1.0 EN English PDFSaravanan SNo ratings yet

- Risk Assessment Dan HAccpDocument27 pagesRisk Assessment Dan HAccpNurjana Sigiro100% (1)

- LG HSN09ISS User ManualDocument40 pagesLG HSN09ISS User ManualMark Jhomel OlimonNo ratings yet

- 6.0 Emergency Evacuation - RevisedDocument6 pages6.0 Emergency Evacuation - RevisedJacob JohnNo ratings yet

- The Effectiveness of Contract Management PDFDocument58 pagesThe Effectiveness of Contract Management PDFNASH GODFREYNo ratings yet

- HIRA No. 02-Use of Access Scaffolding SBDDocument2 pagesHIRA No. 02-Use of Access Scaffolding SBDVenkadesh Periathambi25% (4)

- AlarpDocument1 pageAlarpSalmanNo ratings yet

- Complete Guide CSP - 0718 PDFDocument36 pagesComplete Guide CSP - 0718 PDFWaleed MorsyNo ratings yet

- Triacontanol Msds Stoma EcDocument6 pagesTriacontanol Msds Stoma EcpoeypresentsNo ratings yet

- LOTODocument13 pagesLOTOElmerjr NavarezNo ratings yet

- Jsa Instrument InstallationDocument7 pagesJsa Instrument InstallationMuhammad YusufNo ratings yet

- BP RP50-1 PDFDocument17 pagesBP RP50-1 PDFMohd Khairul0% (1)

- Msds Silicona Roja 65010 VersachemDocument8 pagesMsds Silicona Roja 65010 VersachemErik Evans Saravia0% (1)

- 14.daily HSE Inspection Check ListDocument6 pages14.daily HSE Inspection Check ListSABITH KHNo ratings yet

- Chemical Spill Plan NewDocument1 pageChemical Spill Plan NewSameer ParambathNo ratings yet

- JSA Transformer InstallationDocument1 pageJSA Transformer Installationpushpanath reddyNo ratings yet

- AAnalyst 200 Users GuideDocument257 pagesAAnalyst 200 Users GuiderayatdnNo ratings yet

- Contractor Safety Management: Getting StartedDocument3 pagesContractor Safety Management: Getting StartedAntonius Dwi Putranto NNo ratings yet

- Mu 14055Document413 pagesMu 14055oleg-spb100% (2)

- Operating Instructions Flexi Soft Gateways Hardware en IM0033218Document88 pagesOperating Instructions Flexi Soft Gateways Hardware en IM0033218jamNo ratings yet

- Manual Haulotte PDFDocument82 pagesManual Haulotte PDFWalid AouiniNo ratings yet

- Food Handlers Daily Handwashing Tracking Log SheetDocument1 pageFood Handlers Daily Handwashing Tracking Log SheetWeston Musonda Jr.No ratings yet

- Material Safety Data Sheet (MSDS) : John Carlo B. Coniendo, RCHT Engr. Dolores A. Tumbos InstructorDocument21 pagesMaterial Safety Data Sheet (MSDS) : John Carlo B. Coniendo, RCHT Engr. Dolores A. Tumbos InstructorGio GinolosNo ratings yet

- Managing Medical Devices MHRADocument34 pagesManaging Medical Devices MHRALeyla BaşgülNo ratings yet

- 2 Safety Handbook 2011 enDocument404 pages2 Safety Handbook 2011 enErickx Palatema GalaelNo ratings yet

- Case Study: Occupational Health and Safety: Course: Human Resource Management Professor: Nicole BonenfantDocument9 pagesCase Study: Occupational Health and Safety: Course: Human Resource Management Professor: Nicole Bonenfantaakhil mattaNo ratings yet

- COSHH Assessment FormDocument2 pagesCOSHH Assessment Formsupriyo sarkar100% (1)

- Iom Vertical Turbine PumpDocument33 pagesIom Vertical Turbine PumpSanto ENo ratings yet

- Hazard Identification Classification PDFDocument29 pagesHazard Identification Classification PDFManuel Retagi100% (1)