Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

40 views4-Gas Welding

4-Gas Welding

Uploaded by

Ramu AmaraThis document provides an overview of gas welding, specifically oxy-acetylene welding. It discusses how gas welding works by using a flame to heat and melt metal pieces to be joined. Different gas mixtures can be used, but oxy-acetylene welding is popular due to the high temperatures it can achieve. The document describes the equipment used, including cylinders for oxygen and acetylene, regulators, blowpipes, and consumables. It also covers the different types of flames that can be produced and their characteristics and uses.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- Gas WeldingDocument5 pagesGas WeldingAbdullah ArshadNo ratings yet

- Gas WeldingDocument30 pagesGas WeldingNagendrababu BabuNo ratings yet

- Unit-Ii Manufacturing ProcessesDocument16 pagesUnit-Ii Manufacturing ProcessesArya PrakashNo ratings yet

- Types of FlameDocument4 pagesTypes of FlameRoween SernalNo ratings yet

- Gas WeldingDocument15 pagesGas WeldingAbhimanyuPradhanNo ratings yet

- Documents - Pub - Advanced Welding TechnologyDocument60 pagesDocuments - Pub - Advanced Welding TechnologybalamuruganNo ratings yet

- Gas WeldingDocument17 pagesGas WeldingMuhammad AbubakarNo ratings yet

- D06-002 - Fundamentals of Gas Cutting and Welding - USDocument73 pagesD06-002 - Fundamentals of Gas Cutting and Welding - USAjesh TGNo ratings yet

- S S ElectrodeDocument1 pageS S ElectrodeRajeev KhantwalNo ratings yet

- MODULE 3 RAC Servicing and MaintenanceDocument23 pagesMODULE 3 RAC Servicing and MaintenanceBembem DelfinNo ratings yet

- Bohler Welding in Tool MakingDocument24 pagesBohler Welding in Tool MakingcfcshakerNo ratings yet

- Refrigeration 1Document13 pagesRefrigeration 1Vishwanathan RishanthNo ratings yet

- Piping SolderingDocument33 pagesPiping SolderingKristian UretaNo ratings yet

- Air Condition Refilling Automobile Ac SystamDocument11 pagesAir Condition Refilling Automobile Ac SystamMechanical DepartmentNo ratings yet

- Refrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearDocument9 pagesRefrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearKhaled HakimNo ratings yet

- Refrigeration System Components: - Vishakh GaneshDocument34 pagesRefrigeration System Components: - Vishakh GaneshS R Akhil KrishnanNo ratings yet

- MODULE 1 Introduction To Refrigeration SystemDocument9 pagesMODULE 1 Introduction To Refrigeration SystemBembem DelfinNo ratings yet

- The Four Types of Refrigeration Systems You Need To KnowDocument2 pagesThe Four Types of Refrigeration Systems You Need To KnowtakayNo ratings yet

- Refrigerator: Prasad Murumkar Simran Jagtap Prasanna GramopadhyeDocument13 pagesRefrigerator: Prasad Murumkar Simran Jagtap Prasanna GramopadhyeSHREYAS JOSHINo ratings yet

- Complete Guide To Room and Central Air Conditioners: Last Updated: July 2015Document26 pagesComplete Guide To Room and Central Air Conditioners: Last Updated: July 2015QOBITNo ratings yet

- CH 1Document53 pagesCH 1huien ababuNo ratings yet

- Basic Guide of Arc Welding ElectrodesDocument25 pagesBasic Guide of Arc Welding ElectrodesrajuNo ratings yet

- Household Refrigerators and FreezersDocument12 pagesHousehold Refrigerators and FreezersLuis Carlos PardoNo ratings yet

- Rac PPT1.Document22 pagesRac PPT1.andu gashuNo ratings yet

- Basics of Refrig PDFDocument17 pagesBasics of Refrig PDFHoàngViệtAnhNo ratings yet

- Joining Stainless Steel by Soldering, Brazing and Resistance WeldingDocument4 pagesJoining Stainless Steel by Soldering, Brazing and Resistance WeldingA K SinghNo ratings yet

- Weldability TestDocument11 pagesWeldability TestRajan BhadoriyaNo ratings yet

- How A Refrigerator WorksDocument9 pagesHow A Refrigerator WorksNetsanet ShikurNo ratings yet

- Repairing A Crack in CastingDocument2 pagesRepairing A Crack in CastingpriaNo ratings yet

- Introduction To Arc WeldingDocument36 pagesIntroduction To Arc WeldingcfcshakerNo ratings yet

- Kertas Penerangan 3Document23 pagesKertas Penerangan 3neddylalolaNo ratings yet

- CompressorDocument20 pagesCompressorS R Akhil KrishnanNo ratings yet

- RefrigeratorDocument12 pagesRefrigeratorVikram PorjeNo ratings yet

- Nozzle Flow: Submitted ToDocument6 pagesNozzle Flow: Submitted Toদুর্জয় দুর্বারNo ratings yet

- Refrigeration and Air Conditioning 2Document33 pagesRefrigeration and Air Conditioning 2Christina OhNo ratings yet

- Quat 170503144904Document21 pagesQuat 170503144904Alfie LariosaNo ratings yet

- Assignment Style GuideDocument7 pagesAssignment Style GuideAhmed Farazv SoomroNo ratings yet

- 3 Ways To Determine The Fitness of Your Refrigeration Compressor - Stellar Food For ThoughtDocument2 pages3 Ways To Determine The Fitness of Your Refrigeration Compressor - Stellar Food For ThoughtAshfaq Ali KhanNo ratings yet

- ME 362: Instrumentation and Measurement Sessional: Lecture 1: The Process of MeasurementDocument14 pagesME 362: Instrumentation and Measurement Sessional: Lecture 1: The Process of Measurementদুর্জয় দুর্বারNo ratings yet

- Automatic Protection FinalDocument50 pagesAutomatic Protection FinalAhmed SalemNo ratings yet

- Refrigerator Common ProblemsDocument3 pagesRefrigerator Common ProblemsMateo, Dale Vincent A.No ratings yet

- Ultrasonic FlowmeterDocument6 pagesUltrasonic Flowmeterদুর্জয় দুর্বারNo ratings yet

- 10.troubleshooting Method: 10-1. The Refrigerator Does Not OperateDocument4 pages10.troubleshooting Method: 10-1. The Refrigerator Does Not OperateMario FabrisNo ratings yet

- WeldingDocument19 pagesWeldingAlexander Muñoz SánchezNo ratings yet

- 4.expansion DevicesDocument18 pages4.expansion DevicesAbdullahNo ratings yet

- Basic Information About BrazingDocument10 pagesBasic Information About BrazingKristian UretaNo ratings yet

- Lesson 6 & 7: Results and DiscussionDocument29 pagesLesson 6 & 7: Results and DiscussionJ i n100% (1)

- Recovering, Recycling and Retrofitting PACU Amd CREDocument72 pagesRecovering, Recycling and Retrofitting PACU Amd CREBeth AusteNo ratings yet

- 409 - 5 Refrigeration & Air ConditioningDocument104 pages409 - 5 Refrigeration & Air Conditioningisrat jahanNo ratings yet

- Protection SystemsDocument15 pagesProtection SystemsVishwanathan RishanthNo ratings yet

- Welding An Its TypesDocument54 pagesWelding An Its TypesChaithu ChandrasekaranNo ratings yet

- My Freezer Isn't Freezing - HomeServe USADocument9 pagesMy Freezer Isn't Freezing - HomeServe USAAla SamuelNo ratings yet

- Schematic Diagram of Cold Air Flow: EvaporatorDocument1 pageSchematic Diagram of Cold Air Flow: EvaporatorMario FabrisNo ratings yet

- Ref BasicsDocument15 pagesRef BasicsManasvini KarthihaNo ratings yet

- Fridge/Freezer Repair AdviceDocument32 pagesFridge/Freezer Repair AdviceTemporiusNo ratings yet

- Compressor, Main Parts, Types and Working Principle: PV NRT P TDocument6 pagesCompressor, Main Parts, Types and Working Principle: PV NRT P TMuhammad Arslan AfzalNo ratings yet

- Lesson 2 Commercial Refrigeration and Airconditioning TypesDocument41 pagesLesson 2 Commercial Refrigeration and Airconditioning TypesEddie AbugNo ratings yet

- ASME P Material Numbers ExplainedDocument4 pagesASME P Material Numbers ExplainedFaisal MbmNo ratings yet

- Gas Welding: Dr. Vishvesh J. Badheka, Associate Professor, School of Technology, Pandit Deendayal Petroleum UniversityDocument33 pagesGas Welding: Dr. Vishvesh J. Badheka, Associate Professor, School of Technology, Pandit Deendayal Petroleum UniversityAnuragShrivastavNo ratings yet

- Gas Welding: Dr. Vishvesh J. Badheka, Associate Professor, School of Technology, Pandit Deendayal Petroleum UniversityDocument33 pagesGas Welding: Dr. Vishvesh J. Badheka, Associate Professor, School of Technology, Pandit Deendayal Petroleum UniversitySaurabh TripathiNo ratings yet

- 1.4 Stress-Strain Diagram For Mild SteelDocument20 pages1.4 Stress-Strain Diagram For Mild SteelRamu Amara100% (1)

- Stress-Strain Relations: Class-Ii-Ii Sem Branch-Mechanical Subject: Echanics F AterialsDocument23 pagesStress-Strain Relations: Class-Ii-Ii Sem Branch-Mechanical Subject: Echanics F AterialsRamu AmaraNo ratings yet

- Stresses and Strains: Class-Ii-Ii Sem Branch-Mechanical Subject: Echanics F AterialsDocument23 pagesStresses and Strains: Class-Ii-Ii Sem Branch-Mechanical Subject: Echanics F AterialsRamu AmaraNo ratings yet

- Mechanics of Materials: Class-Ii-Ii Sem Branch-MechanicalDocument13 pagesMechanics of Materials: Class-Ii-Ii Sem Branch-MechanicalRamu AmaraNo ratings yet

- 1.4-Core, Types of Cores, Core Box, Core PrintsDocument39 pages1.4-Core, Types of Cores, Core Box, Core PrintsRamu AmaraNo ratings yet

- Manufacturing Processes: Prepared BY A.RamanajaneyuluDocument25 pagesManufacturing Processes: Prepared BY A.RamanajaneyuluRamu AmaraNo ratings yet

- 1.5 - GATING SYSTEM, RequirementsDocument38 pages1.5 - GATING SYSTEM, RequirementsRamu AmaraNo ratings yet

- 12-Plasma Arc CuttingDocument9 pages12-Plasma Arc CuttingRamu AmaraNo ratings yet

- 1.2-Introduction To CastingDocument11 pages1.2-Introduction To CastingRamu AmaraNo ratings yet

- Water Jet Cutting: Unit-Iii (B)Document12 pagesWater Jet Cutting: Unit-Iii (B)Ramu AmaraNo ratings yet

- Oxy-Acetylene Cutting: Unit-Iii (B)Document18 pagesOxy-Acetylene Cutting: Unit-Iii (B)Ramu AmaraNo ratings yet

- 8-Thermit WeldingDocument21 pages8-Thermit WeldingRamu AmaraNo ratings yet

- 5-Explosion WeldingDocument13 pages5-Explosion WeldingRamu AmaraNo ratings yet

- Plasma Arc Welding: Unit-IiiDocument32 pagesPlasma Arc Welding: Unit-IiiRamu AmaraNo ratings yet

- 6,7-Forge Welding, Resistance WeldingDocument13 pages6,7-Forge Welding, Resistance WeldingRamu AmaraNo ratings yet

- 4 - Induction Welding MFTDocument10 pages4 - Induction Welding MFTRamu AmaraNo ratings yet

- 8-Adhesive BondingDocument13 pages8-Adhesive BondingRamu Amara100% (1)

- Soldering & Brazing: Unit-IvDocument15 pagesSoldering & Brazing: Unit-IvRamu AmaraNo ratings yet

- 3-Design of Welded JointsDocument9 pages3-Design of Welded JointsRamu AmaraNo ratings yet

- 3-Friction Welding MFTDocument14 pages3-Friction Welding MFTRamu AmaraNo ratings yet

- 2-Mig Welding MFTDocument28 pages2-Mig Welding MFTRamu AmaraNo ratings yet

- 10 - Destructive and Non-Destructive Tests Os WeldsDocument20 pages10 - Destructive and Non-Destructive Tests Os WeldsRamu Amara0% (1)

- 9-Haz, Welding Defecs, Causes and RemdiesDocument24 pages9-Haz, Welding Defecs, Causes and RemdiesRamu Amara100% (1)

- 6-Laser Beam Welding MFTDocument11 pages6-Laser Beam Welding MFTRamu AmaraNo ratings yet

- Objectives:: On The Completion of This Period, You Would Be Able To KnowDocument17 pagesObjectives:: On The Completion of This Period, You Would Be Able To KnowRamu AmaraNo ratings yet

- AssignmentDocument1 pageAssignmentRamu AmaraNo ratings yet

- Objectives: On Completion of This Period, You Would Be Able To KnowDocument26 pagesObjectives: On Completion of This Period, You Would Be Able To KnowRamu AmaraNo ratings yet

- Objective: On The Completion of This Period, You Would Able To KnowDocument23 pagesObjective: On The Completion of This Period, You Would Able To KnowRamu AmaraNo ratings yet

- Nel Pro Fuser GuideDocument64 pagesNel Pro Fuser GuideChan PhingNo ratings yet

- Turbine Vs OrificeDocument107 pagesTurbine Vs OrificePurwanto NugrohoNo ratings yet

- 5 Viscosity PDFDocument8 pages5 Viscosity PDFDENY MOL BENNYNo ratings yet

- S03 AccumulatorDocument12 pagesS03 AccumulatorRaphael Ruiz RamosNo ratings yet

- Air Compressor Plant PDFDocument162 pagesAir Compressor Plant PDFissam elmoharir100% (2)

- LPG Cargo Measurement and Calculation ProcedureDocument5 pagesLPG Cargo Measurement and Calculation ProcedureJaspal Singh Sahota100% (2)

- Head Calculation LatestDocument18 pagesHead Calculation LatestChinnathambi DhanagopalNo ratings yet

- Aircon QuotesDocument2 pagesAircon QuotesSteven TanNo ratings yet

- Calculated Primary AirDocument1 pageCalculated Primary AirIrfan AhmedNo ratings yet

- Fluid Mechancis and Machinery Question Bank For 2013 RegulationDocument90 pagesFluid Mechancis and Machinery Question Bank For 2013 RegulationAshok Kumar Rajendran100% (9)

- Fluid and Oxidizer Feed SystemsDocument34 pagesFluid and Oxidizer Feed Systems'Izzad AfifNo ratings yet

- LNGPumps Technologies R0Document14 pagesLNGPumps Technologies R0yavor karaivanovNo ratings yet

- Gujarat BOE 2013 Paper 1 SolutionDocument9 pagesGujarat BOE 2013 Paper 1 Solutionpadmashree sonawaneNo ratings yet

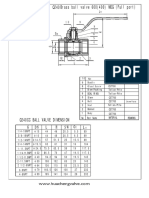

- Ball Valve Data Sheet Q240Document1 pageBall Valve Data Sheet Q240faruk hossain100% (2)

- JB Principles of Vacuum Presention PDFDocument40 pagesJB Principles of Vacuum Presention PDFAmr Kamel100% (1)

- Field Testing of Brownian Diffusion Fiberbed Mist Eliminators For Sulphuric Acid Plant ServiceDocument14 pagesField Testing of Brownian Diffusion Fiberbed Mist Eliminators For Sulphuric Acid Plant ServiceAlex Tarrillo VelasquezNo ratings yet

- Production of Hydrogen From Refinery Off-GasDocument79 pagesProduction of Hydrogen From Refinery Off-GasJai PrakashNo ratings yet

- Leser SizingDocument6 pagesLeser SizingCarlos FiorilloNo ratings yet

- Bfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingDocument25 pagesBfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingtutuionutNo ratings yet

- Rotary DryerDocument9 pagesRotary DryerKadir EraslanNo ratings yet

- Feasibility of A Thrust Control Mechanism by Regulating The Flow at The EngineDocument9 pagesFeasibility of A Thrust Control Mechanism by Regulating The Flow at The EngineIJRASETPublicationsNo ratings yet

- Fluids Laboratory Experiment (Friction Loss Along A Pipe)Document17 pagesFluids Laboratory Experiment (Friction Loss Along A Pipe)Chrionny AlumediNo ratings yet

- Inert Gas SystemDocument45 pagesInert Gas Systempiliyandalaleos100% (5)

- 8,9-Equipment For Vapor-Liquid SeparationsDocument39 pages8,9-Equipment For Vapor-Liquid SeparationsFawadNo ratings yet

- D2162-06 Calibrations ViscosimeterDocument7 pagesD2162-06 Calibrations Viscosimeterhesigu73No ratings yet

- Pipe - 2Document3 pagesPipe - 2Victor John PingkianNo ratings yet

- K20V MNL-0413Document155 pagesK20V MNL-0413RubenSolisNo ratings yet

- Vortex Induced Vibrations: Flow Separation and Pressure DragDocument7 pagesVortex Induced Vibrations: Flow Separation and Pressure DragDanial KhanNo ratings yet

- Module-III (4) Boilers in Food IndustryDocument5 pagesModule-III (4) Boilers in Food IndustryArpit MaknwalNo ratings yet

- Paper Presentation: Alternative Fuels (Hho Gas)Document13 pagesPaper Presentation: Alternative Fuels (Hho Gas)Yemmina MadhusudhanNo ratings yet

4-Gas Welding

4-Gas Welding

Uploaded by

Ramu Amara0 ratings0% found this document useful (0 votes)

40 views23 pagesThis document provides an overview of gas welding, specifically oxy-acetylene welding. It discusses how gas welding works by using a flame to heat and melt metal pieces to be joined. Different gas mixtures can be used, but oxy-acetylene welding is popular due to the high temperatures it can achieve. The document describes the equipment used, including cylinders for oxygen and acetylene, regulators, blowpipes, and consumables. It also covers the different types of flames that can be produced and their characteristics and uses.

Original Description:

Original Title

4-Gas welding

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an overview of gas welding, specifically oxy-acetylene welding. It discusses how gas welding works by using a flame to heat and melt metal pieces to be joined. Different gas mixtures can be used, but oxy-acetylene welding is popular due to the high temperatures it can achieve. The document describes the equipment used, including cylinders for oxygen and acetylene, regulators, blowpipes, and consumables. It also covers the different types of flames that can be produced and their characteristics and uses.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

40 views23 pages4-Gas Welding

4-Gas Welding

Uploaded by

Ramu AmaraThis document provides an overview of gas welding, specifically oxy-acetylene welding. It discusses how gas welding works by using a flame to heat and melt metal pieces to be joined. Different gas mixtures can be used, but oxy-acetylene welding is popular due to the high temperatures it can achieve. The document describes the equipment used, including cylinders for oxygen and acetylene, regulators, blowpipes, and consumables. It also covers the different types of flames that can be produced and their characteristics and uses.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 23

Gas Welding

Introduction to Gas Welding

• It is a fusion welding in which strong gas flame is used to generate heat

and raise temperature of metal pieces localized at the place where joint

is to be made.

• In this welding metal pieces to be joined are heated. The metal thus

melted starts flowing along the edges where joint is to be made.

• A filler metal may also be added to the flowing molten metal to fill up

the cavity at the edges.

• The cavity filled with molten metal is allowed to solidify to get the strong

joint.

• Different combinations of gases can be used to obtain a heating flame.

• The popular gas combinations are oxy-hydrogen mixture, oxygen-

acetylene, etc. different mixing proportion of two gases in a mixture can

generate different types of flames with different characteristics.

Oxy-Acetylene Welding

• Oxy-acetylene welding can used for welding of wide

range of metals and alloys.

• Acetylene mixed with oxygen when burnt under a

controlled environment produces large amount of

heat giving higher temperature rise.

• This burning also produces carbon dioxide which

helps in preventing oxidation of metals being welded.

• Highest temperature that can be produced by this

welding is 3300oC.

Oxy-Acetylene Welding

Oxy-Acetylene Welding

• The chemical reaction involved in burning of

acetylene is

• on the basis of supply pressure of gases oxy-

acetylene welding is categorized as

high pressure welding

Low pressure welding

High pressure welding

• In this system both gases oxygen and

acetylene supplied to welding zone are high

pressure from their respective high pressure

cylinders.

Low pressure welding

• The other one is low pressure welding in

which oxygen is supplied from high pressure

cylinder but acetylene is generated by the

action of water on calcium carbide and

supplied at low pressure.

• In this case high pressure supply of oxygen

pulls acetylene at the welding zone.

comparison

• A comparison can be drawn between low

pressure and high pressure welding. High

pressure welding equipment is handy, supplies

pure acetylene at constant pressure, with

better control and low expenses as compared

to low pressure welding.

FLAME FORMATION AND ITS DIFFERENT

TYPES

• Flame is established by burning (controlled) of the two

gases mixture at the outlet of blow pipe or torch.

• The proportion of gasses in the mixture is controlled by

controlling the flow rate of each of the two gasses.

• Here, it should be clear that burning of acetylene

generates heat and oxygen only supports acetylene in

burning.

• Insufficient supply of oxygen leaves acetylene unburnt

in atmosphere creating pollution and adding cost of

waste acetylene.

FLAME FORMATION AND ITS DIFFERENT

TYPES

• A general nomenclature of the flame established in oxy-acetylene

welding is given in Figure 5.1.

• The flame can be divided into three zones. Zone ‘1’ is very near to the

outlet of torch, where oxygen reacts with acetylene and burning of

two gases takes place.

FLAME FORMATION AND ITS DIFFERENT

TYPES

• Zone ‘2’ produces carbon monoxide and

hydrogen in ratio 2 : 1 by volume. This zone gives

the highest temperature of the flame.

• This zone is suppose to consume the oxygen

available here and contribute reducing properly

to the flame.

• Zone ‘3’ is the outermost zone of the flame.

Temperature of this zone is comparatively low.

• This zone converts CO to CO2 and H2O vapors.

Types of flames

• On the basis of supply proportion of acetylene

and oxygen, flames can be divided into three

categories, neutral flame, carburizing flame

and oxidizing flame. These are described here.

Neutral Flame

• A neutral flame is obtained when equal amount of

O2 and C2H2 are mixed and burnt at the outlet of

welding torch.

• The flame consists of two sharply defined zones

inner white flame cone outer envelope of blue colour

as shown in Figure 5.2.

• In this flame none of two gasses is supplied in excess.

• This flame is of white cone and has the maximum

use for successful welding of many metals.

Carburizing Flame

• This flame is obtained when excess of acetylene is supplied than which is theoretically

required.

• This flame is identified by three zones the inner cone which is not sharply defined, an

outer envelope as same in case of neutral flamed and middle zone surrounds inner

one extended to outer envelope.

• It is white in colour due to excess acetylene. Larger the excess of acetylene larger will

be its length.

• To get a neutral flame a systematic procedure is to make carburizing flame first and

then increase oxygen supply gradually till the excess acetylene zone disappears.

• The resulting flame will a carburizing flame.

• Its temperature generation range is 3100oC to 3300oC.

• It is used for the welding of metals where risk of oxidation at elevated temperature is

more like aluminium, its alloys and lead and its alloys.

• The metals which have tendency to absorb carbon should not be welded by

carburizing flame as they become brittle localized.

Oxidizing Flame

• This flame as an excess of oxygen over that required for a

neutral flame.

• The ratio O2 : C2H2 = 1.15 to 1.50.

• To have this flame set carburizing flame first convert it to

neutral flame and than reduce the supply of acetylene to get

oxidizing flame.

• Its inner cone is relatively shorter and excess oxygen turns the

flame to light blue colour.

• It burns with a harsh sound.

• It is used for metals which are not oxidized readily like

brasses and bronzes.

GAS WELDING TOOLS AND EQUIPMENTS

• Equipment for gas welding as well as for gas

cutting are almost similar.

• It consists of two large steel cylinders one

containing oxygen at high pressure and other

dissolved acetylene also at high pressure.

• In addition to tools and equipments some

consumables are also used in gas welding.

• Major tools and equipment and consumables are

listed below followed by their brief description.

Tools and Equipment

(a) Gas cylinders (two)

(b) Hose pipes and valves

(c) Cylinder pressure gauge

(d) Outlet pressure gauge

(e) Pressure regulators

(f) Blow pipe or torch and spark lights

(g) Welding screens

(h) Goggles, screens, gloves and apron

(i) Wire brush, trolley, chipping hammer.

Consumables

(a) Oxygen gas

(b) Acetylene gas

(c) Filler metal (rod or wire)

(d) Fluxes.

Blow Pipe and Spark Lighter

• Blow pipes are used in welding or cutting. These are

made in different design and size to suit the work.

• Both the gases are mixed in a chamber of blow pipe and

then driven out through the orifice of the blow pipe

nozzle and burnt by spark lighter.

• Blow pipes are classified as high pressure torch used in

gas cutting and low pressure torch used in gas welding.

In case of high pressure blow pipe acetylene is supplied

at high pressure as compared to low pressure blow pipe.

• Construction of a blow pipe is given below in Figure 5.3.

Gas Welding torch

You might also like

- Gas WeldingDocument5 pagesGas WeldingAbdullah ArshadNo ratings yet

- Gas WeldingDocument30 pagesGas WeldingNagendrababu BabuNo ratings yet

- Unit-Ii Manufacturing ProcessesDocument16 pagesUnit-Ii Manufacturing ProcessesArya PrakashNo ratings yet

- Types of FlameDocument4 pagesTypes of FlameRoween SernalNo ratings yet

- Gas WeldingDocument15 pagesGas WeldingAbhimanyuPradhanNo ratings yet

- Documents - Pub - Advanced Welding TechnologyDocument60 pagesDocuments - Pub - Advanced Welding TechnologybalamuruganNo ratings yet

- Gas WeldingDocument17 pagesGas WeldingMuhammad AbubakarNo ratings yet

- D06-002 - Fundamentals of Gas Cutting and Welding - USDocument73 pagesD06-002 - Fundamentals of Gas Cutting and Welding - USAjesh TGNo ratings yet

- S S ElectrodeDocument1 pageS S ElectrodeRajeev KhantwalNo ratings yet

- MODULE 3 RAC Servicing and MaintenanceDocument23 pagesMODULE 3 RAC Servicing and MaintenanceBembem DelfinNo ratings yet

- Bohler Welding in Tool MakingDocument24 pagesBohler Welding in Tool MakingcfcshakerNo ratings yet

- Refrigeration 1Document13 pagesRefrigeration 1Vishwanathan RishanthNo ratings yet

- Piping SolderingDocument33 pagesPiping SolderingKristian UretaNo ratings yet

- Air Condition Refilling Automobile Ac SystamDocument11 pagesAir Condition Refilling Automobile Ac SystamMechanical DepartmentNo ratings yet

- Refrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearDocument9 pagesRefrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearKhaled HakimNo ratings yet

- Refrigeration System Components: - Vishakh GaneshDocument34 pagesRefrigeration System Components: - Vishakh GaneshS R Akhil KrishnanNo ratings yet

- MODULE 1 Introduction To Refrigeration SystemDocument9 pagesMODULE 1 Introduction To Refrigeration SystemBembem DelfinNo ratings yet

- The Four Types of Refrigeration Systems You Need To KnowDocument2 pagesThe Four Types of Refrigeration Systems You Need To KnowtakayNo ratings yet

- Refrigerator: Prasad Murumkar Simran Jagtap Prasanna GramopadhyeDocument13 pagesRefrigerator: Prasad Murumkar Simran Jagtap Prasanna GramopadhyeSHREYAS JOSHINo ratings yet

- Complete Guide To Room and Central Air Conditioners: Last Updated: July 2015Document26 pagesComplete Guide To Room and Central Air Conditioners: Last Updated: July 2015QOBITNo ratings yet

- CH 1Document53 pagesCH 1huien ababuNo ratings yet

- Basic Guide of Arc Welding ElectrodesDocument25 pagesBasic Guide of Arc Welding ElectrodesrajuNo ratings yet

- Household Refrigerators and FreezersDocument12 pagesHousehold Refrigerators and FreezersLuis Carlos PardoNo ratings yet

- Rac PPT1.Document22 pagesRac PPT1.andu gashuNo ratings yet

- Basics of Refrig PDFDocument17 pagesBasics of Refrig PDFHoàngViệtAnhNo ratings yet

- Joining Stainless Steel by Soldering, Brazing and Resistance WeldingDocument4 pagesJoining Stainless Steel by Soldering, Brazing and Resistance WeldingA K SinghNo ratings yet

- Weldability TestDocument11 pagesWeldability TestRajan BhadoriyaNo ratings yet

- How A Refrigerator WorksDocument9 pagesHow A Refrigerator WorksNetsanet ShikurNo ratings yet

- Repairing A Crack in CastingDocument2 pagesRepairing A Crack in CastingpriaNo ratings yet

- Introduction To Arc WeldingDocument36 pagesIntroduction To Arc WeldingcfcshakerNo ratings yet

- Kertas Penerangan 3Document23 pagesKertas Penerangan 3neddylalolaNo ratings yet

- CompressorDocument20 pagesCompressorS R Akhil KrishnanNo ratings yet

- RefrigeratorDocument12 pagesRefrigeratorVikram PorjeNo ratings yet

- Nozzle Flow: Submitted ToDocument6 pagesNozzle Flow: Submitted Toদুর্জয় দুর্বারNo ratings yet

- Refrigeration and Air Conditioning 2Document33 pagesRefrigeration and Air Conditioning 2Christina OhNo ratings yet

- Quat 170503144904Document21 pagesQuat 170503144904Alfie LariosaNo ratings yet

- Assignment Style GuideDocument7 pagesAssignment Style GuideAhmed Farazv SoomroNo ratings yet

- 3 Ways To Determine The Fitness of Your Refrigeration Compressor - Stellar Food For ThoughtDocument2 pages3 Ways To Determine The Fitness of Your Refrigeration Compressor - Stellar Food For ThoughtAshfaq Ali KhanNo ratings yet

- ME 362: Instrumentation and Measurement Sessional: Lecture 1: The Process of MeasurementDocument14 pagesME 362: Instrumentation and Measurement Sessional: Lecture 1: The Process of Measurementদুর্জয় দুর্বারNo ratings yet

- Automatic Protection FinalDocument50 pagesAutomatic Protection FinalAhmed SalemNo ratings yet

- Refrigerator Common ProblemsDocument3 pagesRefrigerator Common ProblemsMateo, Dale Vincent A.No ratings yet

- Ultrasonic FlowmeterDocument6 pagesUltrasonic Flowmeterদুর্জয় দুর্বারNo ratings yet

- 10.troubleshooting Method: 10-1. The Refrigerator Does Not OperateDocument4 pages10.troubleshooting Method: 10-1. The Refrigerator Does Not OperateMario FabrisNo ratings yet

- WeldingDocument19 pagesWeldingAlexander Muñoz SánchezNo ratings yet

- 4.expansion DevicesDocument18 pages4.expansion DevicesAbdullahNo ratings yet

- Basic Information About BrazingDocument10 pagesBasic Information About BrazingKristian UretaNo ratings yet

- Lesson 6 & 7: Results and DiscussionDocument29 pagesLesson 6 & 7: Results and DiscussionJ i n100% (1)

- Recovering, Recycling and Retrofitting PACU Amd CREDocument72 pagesRecovering, Recycling and Retrofitting PACU Amd CREBeth AusteNo ratings yet

- 409 - 5 Refrigeration & Air ConditioningDocument104 pages409 - 5 Refrigeration & Air Conditioningisrat jahanNo ratings yet

- Protection SystemsDocument15 pagesProtection SystemsVishwanathan RishanthNo ratings yet

- Welding An Its TypesDocument54 pagesWelding An Its TypesChaithu ChandrasekaranNo ratings yet

- My Freezer Isn't Freezing - HomeServe USADocument9 pagesMy Freezer Isn't Freezing - HomeServe USAAla SamuelNo ratings yet

- Schematic Diagram of Cold Air Flow: EvaporatorDocument1 pageSchematic Diagram of Cold Air Flow: EvaporatorMario FabrisNo ratings yet

- Ref BasicsDocument15 pagesRef BasicsManasvini KarthihaNo ratings yet

- Fridge/Freezer Repair AdviceDocument32 pagesFridge/Freezer Repair AdviceTemporiusNo ratings yet

- Compressor, Main Parts, Types and Working Principle: PV NRT P TDocument6 pagesCompressor, Main Parts, Types and Working Principle: PV NRT P TMuhammad Arslan AfzalNo ratings yet

- Lesson 2 Commercial Refrigeration and Airconditioning TypesDocument41 pagesLesson 2 Commercial Refrigeration and Airconditioning TypesEddie AbugNo ratings yet

- ASME P Material Numbers ExplainedDocument4 pagesASME P Material Numbers ExplainedFaisal MbmNo ratings yet

- Gas Welding: Dr. Vishvesh J. Badheka, Associate Professor, School of Technology, Pandit Deendayal Petroleum UniversityDocument33 pagesGas Welding: Dr. Vishvesh J. Badheka, Associate Professor, School of Technology, Pandit Deendayal Petroleum UniversityAnuragShrivastavNo ratings yet

- Gas Welding: Dr. Vishvesh J. Badheka, Associate Professor, School of Technology, Pandit Deendayal Petroleum UniversityDocument33 pagesGas Welding: Dr. Vishvesh J. Badheka, Associate Professor, School of Technology, Pandit Deendayal Petroleum UniversitySaurabh TripathiNo ratings yet

- 1.4 Stress-Strain Diagram For Mild SteelDocument20 pages1.4 Stress-Strain Diagram For Mild SteelRamu Amara100% (1)

- Stress-Strain Relations: Class-Ii-Ii Sem Branch-Mechanical Subject: Echanics F AterialsDocument23 pagesStress-Strain Relations: Class-Ii-Ii Sem Branch-Mechanical Subject: Echanics F AterialsRamu AmaraNo ratings yet

- Stresses and Strains: Class-Ii-Ii Sem Branch-Mechanical Subject: Echanics F AterialsDocument23 pagesStresses and Strains: Class-Ii-Ii Sem Branch-Mechanical Subject: Echanics F AterialsRamu AmaraNo ratings yet

- Mechanics of Materials: Class-Ii-Ii Sem Branch-MechanicalDocument13 pagesMechanics of Materials: Class-Ii-Ii Sem Branch-MechanicalRamu AmaraNo ratings yet

- 1.4-Core, Types of Cores, Core Box, Core PrintsDocument39 pages1.4-Core, Types of Cores, Core Box, Core PrintsRamu AmaraNo ratings yet

- Manufacturing Processes: Prepared BY A.RamanajaneyuluDocument25 pagesManufacturing Processes: Prepared BY A.RamanajaneyuluRamu AmaraNo ratings yet

- 1.5 - GATING SYSTEM, RequirementsDocument38 pages1.5 - GATING SYSTEM, RequirementsRamu AmaraNo ratings yet

- 12-Plasma Arc CuttingDocument9 pages12-Plasma Arc CuttingRamu AmaraNo ratings yet

- 1.2-Introduction To CastingDocument11 pages1.2-Introduction To CastingRamu AmaraNo ratings yet

- Water Jet Cutting: Unit-Iii (B)Document12 pagesWater Jet Cutting: Unit-Iii (B)Ramu AmaraNo ratings yet

- Oxy-Acetylene Cutting: Unit-Iii (B)Document18 pagesOxy-Acetylene Cutting: Unit-Iii (B)Ramu AmaraNo ratings yet

- 8-Thermit WeldingDocument21 pages8-Thermit WeldingRamu AmaraNo ratings yet

- 5-Explosion WeldingDocument13 pages5-Explosion WeldingRamu AmaraNo ratings yet

- Plasma Arc Welding: Unit-IiiDocument32 pagesPlasma Arc Welding: Unit-IiiRamu AmaraNo ratings yet

- 6,7-Forge Welding, Resistance WeldingDocument13 pages6,7-Forge Welding, Resistance WeldingRamu AmaraNo ratings yet

- 4 - Induction Welding MFTDocument10 pages4 - Induction Welding MFTRamu AmaraNo ratings yet

- 8-Adhesive BondingDocument13 pages8-Adhesive BondingRamu Amara100% (1)

- Soldering & Brazing: Unit-IvDocument15 pagesSoldering & Brazing: Unit-IvRamu AmaraNo ratings yet

- 3-Design of Welded JointsDocument9 pages3-Design of Welded JointsRamu AmaraNo ratings yet

- 3-Friction Welding MFTDocument14 pages3-Friction Welding MFTRamu AmaraNo ratings yet

- 2-Mig Welding MFTDocument28 pages2-Mig Welding MFTRamu AmaraNo ratings yet

- 10 - Destructive and Non-Destructive Tests Os WeldsDocument20 pages10 - Destructive and Non-Destructive Tests Os WeldsRamu Amara0% (1)

- 9-Haz, Welding Defecs, Causes and RemdiesDocument24 pages9-Haz, Welding Defecs, Causes and RemdiesRamu Amara100% (1)

- 6-Laser Beam Welding MFTDocument11 pages6-Laser Beam Welding MFTRamu AmaraNo ratings yet

- Objectives:: On The Completion of This Period, You Would Be Able To KnowDocument17 pagesObjectives:: On The Completion of This Period, You Would Be Able To KnowRamu AmaraNo ratings yet

- AssignmentDocument1 pageAssignmentRamu AmaraNo ratings yet

- Objectives: On Completion of This Period, You Would Be Able To KnowDocument26 pagesObjectives: On Completion of This Period, You Would Be Able To KnowRamu AmaraNo ratings yet

- Objective: On The Completion of This Period, You Would Able To KnowDocument23 pagesObjective: On The Completion of This Period, You Would Able To KnowRamu AmaraNo ratings yet

- Nel Pro Fuser GuideDocument64 pagesNel Pro Fuser GuideChan PhingNo ratings yet

- Turbine Vs OrificeDocument107 pagesTurbine Vs OrificePurwanto NugrohoNo ratings yet

- 5 Viscosity PDFDocument8 pages5 Viscosity PDFDENY MOL BENNYNo ratings yet

- S03 AccumulatorDocument12 pagesS03 AccumulatorRaphael Ruiz RamosNo ratings yet

- Air Compressor Plant PDFDocument162 pagesAir Compressor Plant PDFissam elmoharir100% (2)

- LPG Cargo Measurement and Calculation ProcedureDocument5 pagesLPG Cargo Measurement and Calculation ProcedureJaspal Singh Sahota100% (2)

- Head Calculation LatestDocument18 pagesHead Calculation LatestChinnathambi DhanagopalNo ratings yet

- Aircon QuotesDocument2 pagesAircon QuotesSteven TanNo ratings yet

- Calculated Primary AirDocument1 pageCalculated Primary AirIrfan AhmedNo ratings yet

- Fluid Mechancis and Machinery Question Bank For 2013 RegulationDocument90 pagesFluid Mechancis and Machinery Question Bank For 2013 RegulationAshok Kumar Rajendran100% (9)

- Fluid and Oxidizer Feed SystemsDocument34 pagesFluid and Oxidizer Feed Systems'Izzad AfifNo ratings yet

- LNGPumps Technologies R0Document14 pagesLNGPumps Technologies R0yavor karaivanovNo ratings yet

- Gujarat BOE 2013 Paper 1 SolutionDocument9 pagesGujarat BOE 2013 Paper 1 Solutionpadmashree sonawaneNo ratings yet

- Ball Valve Data Sheet Q240Document1 pageBall Valve Data Sheet Q240faruk hossain100% (2)

- JB Principles of Vacuum Presention PDFDocument40 pagesJB Principles of Vacuum Presention PDFAmr Kamel100% (1)

- Field Testing of Brownian Diffusion Fiberbed Mist Eliminators For Sulphuric Acid Plant ServiceDocument14 pagesField Testing of Brownian Diffusion Fiberbed Mist Eliminators For Sulphuric Acid Plant ServiceAlex Tarrillo VelasquezNo ratings yet

- Production of Hydrogen From Refinery Off-GasDocument79 pagesProduction of Hydrogen From Refinery Off-GasJai PrakashNo ratings yet

- Leser SizingDocument6 pagesLeser SizingCarlos FiorilloNo ratings yet

- Bfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingDocument25 pagesBfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingtutuionutNo ratings yet

- Rotary DryerDocument9 pagesRotary DryerKadir EraslanNo ratings yet

- Feasibility of A Thrust Control Mechanism by Regulating The Flow at The EngineDocument9 pagesFeasibility of A Thrust Control Mechanism by Regulating The Flow at The EngineIJRASETPublicationsNo ratings yet

- Fluids Laboratory Experiment (Friction Loss Along A Pipe)Document17 pagesFluids Laboratory Experiment (Friction Loss Along A Pipe)Chrionny AlumediNo ratings yet

- Inert Gas SystemDocument45 pagesInert Gas Systempiliyandalaleos100% (5)

- 8,9-Equipment For Vapor-Liquid SeparationsDocument39 pages8,9-Equipment For Vapor-Liquid SeparationsFawadNo ratings yet

- D2162-06 Calibrations ViscosimeterDocument7 pagesD2162-06 Calibrations Viscosimeterhesigu73No ratings yet

- Pipe - 2Document3 pagesPipe - 2Victor John PingkianNo ratings yet

- K20V MNL-0413Document155 pagesK20V MNL-0413RubenSolisNo ratings yet

- Vortex Induced Vibrations: Flow Separation and Pressure DragDocument7 pagesVortex Induced Vibrations: Flow Separation and Pressure DragDanial KhanNo ratings yet

- Module-III (4) Boilers in Food IndustryDocument5 pagesModule-III (4) Boilers in Food IndustryArpit MaknwalNo ratings yet

- Paper Presentation: Alternative Fuels (Hho Gas)Document13 pagesPaper Presentation: Alternative Fuels (Hho Gas)Yemmina MadhusudhanNo ratings yet