Professional Documents

Culture Documents

Zara

Zara

Uploaded by

Vidushi Khare0 ratings0% found this document useful (0 votes)

23 views2 pages1. Zara follows a just-in-time inventory system with deliveries every 2 weeks influenced by customer demand rather than designer push.

2. It aims to reduce lead times through a dynamic response system, tight control of the design process, and local manufacturing, decrease quantities to reduce risk of overstock, and increase variety to maximize sales.

3. The distribution process uses store shipment requests, forecasts, inventory levels, and assortment data in an optimization model to determine store shipments.

Original Description:

Original Title

zara

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. Zara follows a just-in-time inventory system with deliveries every 2 weeks influenced by customer demand rather than designer push.

2. It aims to reduce lead times through a dynamic response system, tight control of the design process, and local manufacturing, decrease quantities to reduce risk of overstock, and increase variety to maximize sales.

3. The distribution process uses store shipment requests, forecasts, inventory levels, and assortment data in an optimization model to determine store shipments.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

23 views2 pagesZara

Zara

Uploaded by

Vidushi Khare1. Zara follows a just-in-time inventory system with deliveries every 2 weeks influenced by customer demand rather than designer push.

2. It aims to reduce lead times through a dynamic response system, tight control of the design process, and local manufacturing, decrease quantities to reduce risk of overstock, and increase variety to maximize sales.

3. The distribution process uses store shipment requests, forecasts, inventory levels, and assortment data in an optimization model to determine store shipments.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 2

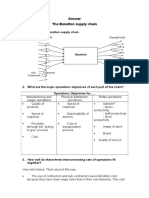

Inventory Management 1.

Zara follows a very agile true JIT inventory

system and deliveries happen every 2weeks.

Assortment

Decisions 2. Its inventory system is influenced by the pull of

Store

Post Sale the customer instead of a push from the designer.

Manager

I/P

Data

3. Three Strategic objectives

Forecasting a) Reduce lead times by creating a dynamic

Model response system .They have tight control over the

design and manufacturing process .Strategic

agreements with local manufacturers for cutting,

Demand

Forecasts

dyeing and sewing and also acquire fabric in 4

Inventory Warehouse colors.

Inventory

in Stores b) Decrease the quantities produced to decrease

the risk of outdating.

Optimizing

Process c) Increase the available variety to maximize the

spread-Design changes are decided after the

season has started as a response to actual sales

information which eases the matching of supply

and demand. The company takes nearly 4-5

weeks to design a new product and get it to the

Distribution of Inventory

1) The Distribution Process consists of using the shipment requests from

store managers(based on a subset of data available in the warehouse)

along with past historical sales to build demand forecasts. It then uses

these forecasts, the inventory of each article and size remaining both in

the warehouse and each store, and the assortment decisions as inputs

to an optimization model having shipment quantities as its main

decision variables to ship the shipment at various stores.

2) Distribution process could be further improved in the future by

introducing explicit incentives for the stores to contribute accurate.

You might also like

- Raymond Case StudyDocument4 pagesRaymond Case StudyANANTA VISHAIN-IB 21IB307No ratings yet

- Solution Manual For Principles of Cost Accounting 16th Edition by VanderbeckDocument36 pagesSolution Manual For Principles of Cost Accounting 16th Edition by Vanderbecka75590393775% (4)

- Case Analysis On Hill's Automotive, IncDocument7 pagesCase Analysis On Hill's Automotive, IncNnickyle LaboresNo ratings yet

- Decision Phases in Supply ChainDocument16 pagesDecision Phases in Supply ChainShowkat HossainNo ratings yet

- Decision Phases in A Supply ChainDocument4 pagesDecision Phases in A Supply ChainADARSH RAGESHNo ratings yet

- Vdocuments - MX - Ascp Training Day1Document170 pagesVdocuments - MX - Ascp Training Day1Karthick ManiNo ratings yet

- Supply Chain DriversDocument5 pagesSupply Chain Driversshivashankar hrNo ratings yet

- Gross National Product (GNP) :: Design Purchase Manufacture Assemble Ship Engineer To OrderDocument5 pagesGross National Product (GNP) :: Design Purchase Manufacture Assemble Ship Engineer To OrdervdfbdfhNo ratings yet

- Purchasing and Supply Management 15th Edition Johnson Solutions ManualDocument19 pagesPurchasing and Supply Management 15th Edition Johnson Solutions Manualdavidphillipsmcyaqbeogf100% (30)

- QuizletDocument6 pagesQuizletNam LêNo ratings yet

- Lec 6 Aggregate Planning Managing Supply and DemandDocument45 pagesLec 6 Aggregate Planning Managing Supply and DemandZEESHAN MEHMOODNo ratings yet

- Cherpumple Aditya Periwal, Gargi Pitale, Samir Tandon SBM, NmimsDocument6 pagesCherpumple Aditya Periwal, Gargi Pitale, Samir Tandon SBM, NmimsAniket ChavanNo ratings yet

- Makalah Management OperationsDocument7 pagesMakalah Management OperationsAry SandiNo ratings yet

- Supply Chain Management NoteDocument53 pagesSupply Chain Management Notelemur761No ratings yet

- Prod. Planning and Inventory BriefDocument25 pagesProd. Planning and Inventory BriefFrank KyandoNo ratings yet

- Ssupply Chain 1Document53 pagesSsupply Chain 1Tedros AbrehamNo ratings yet

- Management Advisory Services Adb/Jju/Bdt MAS.2814 - Activity-Based Costing System MAY 2020Document2 pagesManagement Advisory Services Adb/Jju/Bdt MAS.2814 - Activity-Based Costing System MAY 2020Donny TrumpNo ratings yet

- Seminar 1 Presentation - Just-In-Time (Group 4)Document22 pagesSeminar 1 Presentation - Just-In-Time (Group 4)NUR SHAHIRA ISANo ratings yet

- Operations Management Chapter 5Document36 pagesOperations Management Chapter 5sandulliNo ratings yet

- Chapter 7 The Conversion Cycle: Batch Processing SystemDocument6 pagesChapter 7 The Conversion Cycle: Batch Processing SystemAnne Rose EncinaNo ratings yet

- MS 3413 Activity-Based Costing SystemDocument5 pagesMS 3413 Activity-Based Costing SystemMonica GarciaNo ratings yet

- Intelligent Warehouse Allocator For Optimal Regional UtilizationDocument7 pagesIntelligent Warehouse Allocator For Optimal Regional UtilizationHitesh DemlaNo ratings yet

- 10 Q OM FinalsDocument3 pages10 Q OM FinalsCielo Marie G. AndajaoNo ratings yet

- duplex flashcards mod2Document20 pagesduplex flashcards mod2fullyfaltoo1No ratings yet

- 8 SCM Aggregate-Rccp - Adl - 2020 - DistDocument69 pages8 SCM Aggregate-Rccp - Adl - 2020 - DistJoe RobsonNo ratings yet

- The Production ParadigmDocument15 pagesThe Production ParadigmmltgNo ratings yet

- The Production ParadigmDocument15 pagesThe Production ParadigmRoland KouameNo ratings yet

- Cbmec FinalsDocument7 pagesCbmec FinalsApple DacaldacalNo ratings yet

- Cheat SheetDocument3 pagesCheat Sheetonlysj134No ratings yet

- SCM NOTES Copy RepairedDocument12 pagesSCM NOTES Copy RepairedRistie LimbagNo ratings yet

- Handout Group 5Document4 pagesHandout Group 5Sev BlancoNo ratings yet

- PAG POV Fashion Vs Basic Assortment PlanningDocument7 pagesPAG POV Fashion Vs Basic Assortment PlanningThoa NguyenNo ratings yet

- GRP 1 Multiple ChoiceDocument38 pagesGRP 1 Multiple ChoiceFind DeviceNo ratings yet

- Supply Chain StrategyDocument13 pagesSupply Chain StrategyGeline Suzane Combalicer TobiasNo ratings yet

- CrocsDocument14 pagesCrocsOjasvita123100% (2)

- Inventory Control System PDFDocument2 pagesInventory Control System PDFAalif IbràhimNo ratings yet

- OML6 - Supply Chain ManagementDocument34 pagesOML6 - Supply Chain ManagementBENZINNo ratings yet

- Purchasing and Supply Management 14th Edition Johnson Test BankDocument19 pagesPurchasing and Supply Management 14th Edition Johnson Test Bankvolitiveacrosporedur100% (27)

- OPMAN ReviewerDocument8 pagesOPMAN ReviewerAaron Jan FelicildaNo ratings yet

- Index: CPIM Exam - Basics of Supply Chain Management Practice Study SheetDocument31 pagesIndex: CPIM Exam - Basics of Supply Chain Management Practice Study SheetSH ZHOUNo ratings yet

- Supply Chain Analysis of NikeDocument13 pagesSupply Chain Analysis of NikeRasbin SharmaNo ratings yet

- Group 9 PPT - Material Requirements Planning (MRP) - CompressedDocument62 pagesGroup 9 PPT - Material Requirements Planning (MRP) - Compressed32MJI Made Angga Dwipaguna MudithaNo ratings yet

- (Copy) OPERATION RADHIKA KHANDELWAL 2019-1805-0001-0016 B2B5 MR1Document2 pages(Copy) OPERATION RADHIKA KHANDELWAL 2019-1805-0001-0016 B2B5 MR1radhikaNo ratings yet

- TOAACC217 - Tan Ding Han - Y1810538Document6 pagesTOAACC217 - Tan Ding Han - Y1810538Chan Yi LinNo ratings yet

- ABM 359 Assignment Inventory ManagementDocument3 pagesABM 359 Assignment Inventory Managementcoco 007No ratings yet

- Ch13 Case1 ADocument2 pagesCh13 Case1 AVandana Aggarwal100% (1)

- Week 02 - Fundamentals of Supply Chain ManagementDocument36 pagesWeek 02 - Fundamentals of Supply Chain ManagementMUHAMMAD FAYZAN TAYYABNo ratings yet

- BBA-SCM: 3201 - : Material Requirement Planning (MRP)Document22 pagesBBA-SCM: 3201 - : Material Requirement Planning (MRP)Tony TangNo ratings yet

- FOM Chapter 10 and 11Document26 pagesFOM Chapter 10 and 11maylinalorraine23estoyaNo ratings yet

- OM - Bayer Crop ScienceDocument3 pagesOM - Bayer Crop ScienceVidita SharmaNo ratings yet

- Chapter 14: The Production CycleDocument9 pagesChapter 14: The Production CycleLet it beNo ratings yet

- BM602 Assignment#1Document2 pagesBM602 Assignment#1Irish Nicole RouraNo ratings yet

- What Is Assemble To OrderDocument3 pagesWhat Is Assemble To OrderRashmi KanungoNo ratings yet

- Om Introduction, Material Requirement and Aggregate PlanningDocument15 pagesOm Introduction, Material Requirement and Aggregate PlanningSaloni SawantNo ratings yet

- تجميع تشابترات اداره تجزئهDocument20 pagesتجميع تشابترات اداره تجزئهiishiiw67No ratings yet

- Introduction To OM Semester - I: ITM - PGDM - 2022 - 24Document56 pagesIntroduction To OM Semester - I: ITM - PGDM - 2022 - 24SANDIP NAYEKNo ratings yet

- Supply Chain IntegrationDocument8 pagesSupply Chain IntegrationMan Singh0% (1)

- Supply Chain Management (SCM)Document25 pagesSupply Chain Management (SCM)Anu DNo ratings yet

- Marketing Strategy Text and Cases 6th Edition Ferrell Solutions Manual DownloadDocument9 pagesMarketing Strategy Text and Cases 6th Edition Ferrell Solutions Manual DownloadDinorah Strack100% (23)