Professional Documents

Culture Documents

TECH IT - Presentation Tata Power

TECH IT - Presentation Tata Power

Uploaded by

goudappa6Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TECH IT - Presentation Tata Power

TECH IT - Presentation Tata Power

Uploaded by

goudappa6Copyright:

Available Formats

4 th International Conference on Instrument

Transformers

LEARNINGS FROM FAILURE ANALYSIS AND FMEA OF INSTRUMENT

TRANSFORMERS LEADING TO IMPROVED SYSTEM RELIABILTY

Pramod Tupe. Prajjwala Patil.

The Tata Power Company Limited, Mumbai

13-14 December 2018, Hotel Crown Plaza, Gurgaon, NCR, India

INTRODUCTION

The population of 145 / 245 / 400kV Instrument Transformers in Tata Power system is

approx. 1500

Based on our experience, it is found that many CTs / CVTs have failed during service

without any major clues. Comparatively lesser failures of PTs are observed

Forced outages due to failure of Instrument Transformers lead to costly reconditioning /

repairs / replacement of the defective equipment

.

A need was felt to review existing maintenance / condition monitoring practices and

adopt new practices / standards / techniques for maintenance as well as condition

monitoring of Instrument Transformers as corrective / preventive measures because of

clueless failures of CT/CVTS

13-14 December 2018, Hotel Crown Plaza, Gurgaon, NCR, India

METHODOLOGY ADOPTED FOR ANALYSIS OF INSTRUMENT

TRANSFORMER FAILURES

•Data of failed (new and old) Instrument Transformers from year 2011 was compiled to

understand trends / patterns.

RCA of failed Instrument Transformers to identify root causes with focus on critical

condition monitoring parameters and maintenance history.

Failure Mode and Effect Analysis to determine pain areas and suggest probable

mitigation actions.

Relevant international / national technical standards and papers were also referred to

know the best practices in ‘Technical specification’ and ‘Condition Monitoring &

Maintenance’ followed by other utilities.

13-14 December 2018, Hotel Crown Plaza, Gurgaon, NCR, India

Based on inputs from RCAs and FMEA, Maintenance and Condition monitoring

guidelines of EHV oil filled Instrument Transformers were reviewed and finalized.

Key objectives of guidelines are -

•To follow a simplified approach for condition monitoring of Instrument Transformer thus

reduce maintenance and monitoring efforts

.

•Improve safety by eliminating the hazards associated with equipment failures.

•Adopt common practices and standards for equipment replacement based on

performance rather than age of assets.

•To reduce the risk of failure through proactive condition assessment thus ensuring

reliable operation with reduction of forced outages.

13-14 December 2018, Hotel Crown Plaza, Gurgaon, NCR, India

IMPROVEMENTS INTRODUCED THROUGH GUIDELINES

Introduction of DGA testing for CT oil as a standard practice and monitoring CT

parameters such as Capacitance & Tan-Delta with respect to reference values during

service life of CT.

•Introduction of on-line measurement of CVT secondary voltages as a standard practice

and monitoring PT / CVT parameters such as Capacitance & Tan-Delta with respect to

reference values during service life of PT / CVT.

•Inclusion of Thermo-vision and RF PD survey for oil filled Instrument Transformers.

•Replacement of Instrument Transformer rather than repairing / conditioning.

13-14 December 2018, Hotel Crown Plaza, Gurgaon, NCR, India

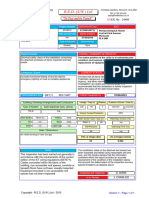

Recommended Maintenance schedule for the oil filled CT

.

S No. Checks / Activity FRQ Remarks

1 Checking of bellow expansion (level - high / low / normal) and freeness of bellow expansion QY High / low bellow level to be investigated.

Visual inspection of CT for oil leakages /seepages from:

Dead tank gasket joint

Oil sampling valve with plug

Primary conductor sealing gasket CT to be replaced at the first sighting of heavy oil leakage.

2 Gauge glass M In case minor oil leakage, necessary corrective action to be taken and CT need

Metal bellows to be put under close observation.

Insulator cemented joint

Secondary terminal box

Capacitance tap point

CT to be replaced if there is a major crack.

3 Visual inspection of CT for cracks on porcelain insulator M

If not healthy, replace gasket / apply sealant as necessary

4 Checking healthiness of gaskets and sealant in Secondary terminal box Y

5 Thermo vision scanning of CT body and primary connections 2M / QY Shall be within acceptable limits

6 Checking of correct primary connection strips and tightness, if provided externally Y Ensure correctness and firm connection

7 N2 pressure checking (if applicable) Y As per OEM’s recommendation

2Y or

8 Cleaning and Checking the tightness of PF terminal earthing connection. Ensure earthing

Unit S/D

2Y or

9 Measurement of Tan δ and capacitance (C1) Shall be within acceptable limits

Unit S/D

≤ 0.007 Tan δ for 220 KV and above 2Y or

a.

≤ 0.010 Tan δ for 110 KV Unit S/D

> 0.007 Tan δ for 220 KV and above

b. 1Y Close monitoring

> 0.010 Tan δ for 110 KV

Δ Tan δ (Tip up test at 2,4,6,8 & 10KV) 2Y or Shall be within acceptable limits

10

This test is applicable for HV Tan δ test Unit S/D

2Y or Shall be within acceptable limits

11 IR measurement

Unit S/D

12 DGA of oil sample SOS Shall be within acceptable limits

13 Oil tests (BDV, Moisture contents, Resistivity and Tan- delta) SOS Shall be within acceptable limits

14 Measurement of CT secondary resistance SOS

15 Magnetization characteristics SOS

As per equipment datasheet/ FAT reports

16 CT ratio test SOS

17 Checking of burden on the secondary winding SOS

18 On line acoustic PD measurement SOS RFI survey of the Switch yard

13-14 December 2018, Hotel Crown Plaza, Gurgaon, NCR, India

Recommended Maintenance schedule for the oil filled CVT & PT

.

S No. Checks / Activity FRQ Remarks

Checking of bellow expansion

1 Daily High / low bellow level to be investigated.

(level - high / low / normal)

Visual inspection of PT / CVT for oil leakages /seepages from:

Tank gasket joint

Oil sampling valve with plug

Primary conductor sealing gasket PT / CVT to be replaced at the first sighting of heavy oil leakage.

2 Gauge glass Daily In case minor oil leakage, necessary corrective action to be taken and PT / CVT need to be

Metal bellows put under close observation.

Insulator cemented joint

Capacitance tap point

Secondary Terminal box

3 Visual inspection of PT / CVT for cracks on porcelain insulator Daily PT / CVT to be replaced if there is a major crack.

4 On-line measurement of PT / CVT secondary voltages on SCADA and generate alarm for deviation. Capture voltage trend on SCADA Online Set alarm for any deviation beyond 5%

a Compare voltage of one phase w.r.t. other two phases (if PT / CVTs are provided on all phases)

In case of alarm, perform actual measurement with accurate meter. Analysis voltage

trends.

b Compare phase voltages between Bus & line side PT / CVTs

5 Thermo-vision scanning of PT / CVT body and primary connections QY Shall be within acceptable limits

2Y or

6 Inspection of PT / CVT installation

Unit S/D

a. Checking primary, secondary and earthing connections Ensure firm connection

b. N2 pressure checking(if applicable) N2 pressure as per OEM’s recommendation

c. Cleaning of insulators PT / CVT to be replaced if there is a major crack.

Checking of secondary terminal box

d. Check healthiness of gaskets Replace gasket if found damaged.

Check oil leakage in terminal box

e. Cleaning and Checking the tightness of PF terminal / HF terminal (in case it is not being used for PLCC) earthing connection. Ensure earthing

7 Measurement of Tan δ and capacitance (upto 2 kV due limitation of graded insulation / neutral bushing) for CVT / PT having “Neutral” point which can be isolated. Shall be within acceptable limits

Tan δ:

2Y or

a. ≤ 0.7% @ 20°C Tan δ for 220 kV and above

Unit S/D

≤ 1.0% @ 20°C Tan δ for 110 & 132 kV

Tan δ:

b. > 0.7% @ 20°C Tan δ for 220 KV and above 1Y Close monitoring

> 1.0% @ 20°C Tan δ for 110 & 132 kV

c. Rate of rise in Tan δ: 50% rise w.r.t earlier test value 1Y

13-14 December 2018, Hotel Crown Plaza, Gurgaon, NCR, India

IMPROVEMENT IN TECHNICAL SPECIFICATIONS

•Composite insulator housed CT in place of Porcelain insulator housed CT for 145-245kV

class.

•Composite insulator housed SF6 filled CT for 400kV class

•Procurement of Oil sampling kit for DGA along with CT

•Tan Delta acceptable limit during FAT - 0.4% for CT and 0.5% for PT

•Use of PT in place of CVT (except where PLCC facility required)

•Ingress Protection Secondary TBs /JBs IP 55 with additional rain protection

•Standardization of Instrument Transformer parameters

13-14 December 2018, Hotel Crown Plaza, Gurgaon, NCR, India

You might also like

- D6E Engine PDFDocument387 pagesD6E Engine PDFLinzaw Oo93% (15)

- Inverter/Charger: Service ManualDocument31 pagesInverter/Charger: Service ManualAbu HaithamNo ratings yet

- Failures of Instrument TransformersDocument11 pagesFailures of Instrument Transformersgoudappa6No ratings yet

- Failures of Instrument TransformersDocument11 pagesFailures of Instrument Transformersgoudappa6No ratings yet

- BRC Gap AnalysisDocument11 pagesBRC Gap AnalysisChiekoi PasaoaNo ratings yet

- 020-001 Manual Exc 2-500LDocument956 pages020-001 Manual Exc 2-500LPabloNo ratings yet

- Sample Transformer Life Assessment SheetDocument10 pagesSample Transformer Life Assessment SheetMuhammed Zubair NNo ratings yet

- Check Sheet For (Misc.)Document10 pagesCheck Sheet For (Misc.)Noor Ahmad WahgoNo ratings yet

- Check Sheet For (C&P Section)Document7 pagesCheck Sheet For (C&P Section)Noor Ahmad WahgoNo ratings yet

- Check Sheet For (M&G Section)Document7 pagesCheck Sheet For (M&G Section)Noor Ahmad WahgoNo ratings yet

- 80MVAR Reactor Test ReportDocument28 pages80MVAR Reactor Test ReportSARAVANAN ANo ratings yet

- Group21 4Document25 pagesGroup21 4Luis OliveroNo ratings yet

- BG-QA-CL-308-14 Check List.R3.Final - Modern.090214Document3 pagesBG-QA-CL-308-14 Check List.R3.Final - Modern.090214Yousaf RichuNo ratings yet

- L&T QapDocument2 pagesL&T Qapsriram.5230No ratings yet

- Instruction - Current and Voltage Instrument Transformers - Instruction For Installation, Use andDocument56 pagesInstruction - Current and Voltage Instrument Transformers - Instruction For Installation, Use anddaveadeNo ratings yet

- A/b/c/d/e/f - PassDocument6 pagesA/b/c/d/e/f - PassVikrant DeshmukhNo ratings yet

- CL-NG-6460-002-021 Checklist For Station Service Transformer Commissioning Rev02Document4 pagesCL-NG-6460-002-021 Checklist For Station Service Transformer Commissioning Rev02ahmed.fawzy.alalfy2050No ratings yet

- Failure Analysis & Diagnostics of Power Transformer Using Dielectric Dissipation FactorDocument5 pagesFailure Analysis & Diagnostics of Power Transformer Using Dielectric Dissipation Factorkong shiaw huiNo ratings yet

- Solar OperationsDocument2 pagesSolar OperationsChanchal PathakNo ratings yet

- Maintenance Transformer at Pahlawan PowerDocument6 pagesMaintenance Transformer at Pahlawan PowerSyer Khomainie Mohamad YakopNo ratings yet

- Current TransformerDocument12 pagesCurrent TransformerSyed AbbasNo ratings yet

- STEAG Energy Services (India) PVT LTD.: Name of The CustomerDocument2 pagesSTEAG Energy Services (India) PVT LTD.: Name of The CustomerJayam kondanNo ratings yet

- P9-MRPS-TK1007-01 - E Current Transformer ITP - AAR 2021-06-14Document11 pagesP9-MRPS-TK1007-01 - E Current Transformer ITP - AAR 2021-06-14owais khanNo ratings yet

- Automotive Electronics Council - StandardsDocument15 pagesAutomotive Electronics Council - StandardsAnonymous xaeuoo4No ratings yet

- Condition Monitoring of Instrument Transformers - POWERGRID ExperienceDocument36 pagesCondition Monitoring of Instrument Transformers - POWERGRID ExperiencebcqbaoNo ratings yet

- DCDB - Function TestDocument5 pagesDCDB - Function TestAmr ElkadyNo ratings yet

- Work - Instruction Transformer 33-11KV TRANSFORMERDocument5 pagesWork - Instruction Transformer 33-11KV TRANSFORMERTAHIR HUSAINNo ratings yet

- Training Copy Not For Execution: Sop No. Supersedes Effective Date Next Review DateDocument6 pagesTraining Copy Not For Execution: Sop No. Supersedes Effective Date Next Review Datemanohar kumarNo ratings yet

- Job Scope For Over Hauling of Power Transformers - FinalDocument7 pagesJob Scope For Over Hauling of Power Transformers - Finalrambihari100% (1)

- Importance of Sub-Station Equipment Maintenance: Presented by MD - Golam Mowla XEN (G&P)Document23 pagesImportance of Sub-Station Equipment Maintenance: Presented by MD - Golam Mowla XEN (G&P)rajshahieeeNo ratings yet

- EICR PennycomequickDocument6 pagesEICR PennycomequickTAJUDEEN AZEEZNo ratings yet

- Cro DC 01Document22 pagesCro DC 01فايز الحارثيNo ratings yet

- Page 1 of 13: Exc K oDocument13 pagesPage 1 of 13: Exc K oSARAVANAN ANo ratings yet

- HT Panel Test ReportDocument4 pagesHT Panel Test ReportItx Adi50% (2)

- MVTC All ItpDocument19 pagesMVTC All Itpcarlos vidalNo ratings yet

- RM 86Document14 pagesRM 86ingen88888No ratings yet

- Potential TransformerDocument8 pagesPotential TransformerSyed AbbasNo ratings yet

- Odhisha Power Generation Corporation LTD Page 1 of 2 BGR Energy Systems LTD - Power Project Division Date: 31.5.17Document2 pagesOdhisha Power Generation Corporation LTD Page 1 of 2 BGR Energy Systems LTD - Power Project Division Date: 31.5.17alagurajNo ratings yet

- Vol3-11 Miscellaneous ElectricalDocument20 pagesVol3-11 Miscellaneous Electricalmuhamad.badar9285No ratings yet

- Instruction - Current and Voltage Instrument Transformers - 1VLM000610 Rev.23, enDocument54 pagesInstruction - Current and Voltage Instrument Transformers - 1VLM000610 Rev.23, enVygantas BielskisNo ratings yet

- Uss 105Document12 pagesUss 105Soumya BhowmickNo ratings yet

- المحاضرة الخامسة :إختبارات محولات الجهدDocument26 pagesالمحاضرة الخامسة :إختبارات محولات الجهدوليد موسىNo ratings yet

- Ok Na Na Ok Ok Ok OkDocument2 pagesOk Na Na Ok Ok Ok OkGANESH KNo ratings yet

- Pre-Commissioning Format For Reactor: I. General DetailsDocument27 pagesPre-Commissioning Format For Reactor: I. General Detailsmayur dhandeNo ratings yet

- 19.station - Service TransformerDocument9 pages19.station - Service TransformerThameemul BuhariNo ratings yet

- Electromagnetic - Eddy Crrent Testing ProcedureDocument17 pagesElectromagnetic - Eddy Crrent Testing Procedurenathgsurendra100% (1)

- 7.2.5 CT'S, PT's & CVT'sDocument3 pages7.2.5 CT'S, PT's & CVT'sGAJANAN PNo ratings yet

- Transformer USS-01Document3 pagesTransformer USS-01Amr ElkadyNo ratings yet

- Ts 22Document44 pagesTs 22ashuNo ratings yet

- Acdb - Function TestDocument4 pagesAcdb - Function TestDinesh Pitchaivel0% (1)

- Test ReportDocument6 pagesTest ReportAmir ShahzadNo ratings yet

- Assessment Procedure for Generator (Ele) 发电机评估程序电气部分Document7 pagesAssessment Procedure for Generator (Ele) 发电机评估程序电气部分Kishore KumarNo ratings yet

- LK 4. - Charging System - OKDocument3 pagesLK 4. - Charging System - OKmurti sapto wahyudiNo ratings yet

- Site Test Report: Under Ground Cables Precommissioning Test SheetDocument1 pageSite Test Report: Under Ground Cables Precommissioning Test SheetNaser Mahamid100% (1)

- 130Document3 pages130hiddenhidden16No ratings yet

- Jf015e - Rebuild - Manualtcc p0740Document2 pagesJf015e - Rebuild - Manualtcc p0740hitecNo ratings yet

- Satr-P-3208 Rev 8 FinalDocument7 pagesSatr-P-3208 Rev 8 FinalMohamed HaleemNo ratings yet

- Mom 04-07-2019Document7 pagesMom 04-07-2019Jawad AmjadNo ratings yet

- Mainteance SOP - Rev 06Document25 pagesMainteance SOP - Rev 06Kushal SinghNo ratings yet

- RP 18 MPT 001 TCR AlupcoDocument3 pagesRP 18 MPT 001 TCR AlupcoRonel John Rodriguez CustodioNo ratings yet

- Nde ProceduresDocument66 pagesNde Proceduressoumaya yahyaouiNo ratings yet

- Power Transformer - For SwitchayrdDocument20 pagesPower Transformer - For SwitchayrdSindhuKumarNo ratings yet

- MV Switchgear Inspection and Test Procedure: October 2019Document21 pagesMV Switchgear Inspection and Test Procedure: October 2019sabamalarNo ratings yet

- Draft CEA (Technical Standards For Construc of Elec Plants and Electric Lines) Regulations 2010Document93 pagesDraft CEA (Technical Standards For Construc of Elec Plants and Electric Lines) Regulations 2010goudappa6No ratings yet

- Chapter 3.9 DG Set System PDFDocument14 pagesChapter 3.9 DG Set System PDFgoudappa6No ratings yet

- Instrument Transformer Dimensioning: Past and Future: November 2008Document9 pagesInstrument Transformer Dimensioning: Past and Future: November 2008goudappa6No ratings yet

- Operation and Maintenance ManualDocument9 pagesOperation and Maintenance ManualJAAZIM ALBERTO AGUILAR SALAS -IM BNo ratings yet

- Transmission Line Installation & Maintenance NC IIIDocument81 pagesTransmission Line Installation & Maintenance NC IIIAljon BalanagNo ratings yet

- AhlCleaner RB 300 HD - en EOMDocument24 pagesAhlCleaner RB 300 HD - en EOMcuongNo ratings yet

- Season Dependent Condition Based MaintenDocument12 pagesSeason Dependent Condition Based Maintenvitor gNo ratings yet

- "Thai Union Group Packaging Safety & Hygiene Requirements" (Version 2.0 - February 2018)Document21 pages"Thai Union Group Packaging Safety & Hygiene Requirements" (Version 2.0 - February 2018)Md Kamruzzaman MonirNo ratings yet

- Safety Management PlanDocument9 pagesSafety Management PlanMarjorie SedromeNo ratings yet

- VRIOGS 012.7.11 RevA - Public Transport VictoriaDocument23 pagesVRIOGS 012.7.11 RevA - Public Transport VictoriarajunagaNo ratings yet

- Elective 1 Module 1Document12 pagesElective 1 Module 1Geronimo LabadorNo ratings yet

- VS3 Service Guide Rel. A.03Document166 pagesVS3 Service Guide Rel. A.03Tim CrowleyNo ratings yet

- 10 Steps To Precision Maintenance Reliability SuccessDocument11 pages10 Steps To Precision Maintenance Reliability SuccessElvis DiazNo ratings yet

- Job Advert Central Zone - 2019Document8 pagesJob Advert Central Zone - 2019Rashid BumarwaNo ratings yet

- 08 - LM6000 Gas Turbine MaintenanceDocument24 pages08 - LM6000 Gas Turbine MaintenanceMohamed Bin Ierous100% (2)

- GMK4100L-1 CSM V3 11-25-2016Document356 pagesGMK4100L-1 CSM V3 11-25-2016Fabio Salas100% (1)

- USACE Quality Management GuideDocument57 pagesUSACE Quality Management GuideHamid AsadyNo ratings yet

- BLD Main Eric ChanDocument7 pagesBLD Main Eric Chansellitt ngNo ratings yet

- Capability List Document: Document QA-TCL FAA Approved Repair Station TAMY352IDocument12 pagesCapability List Document: Document QA-TCL FAA Approved Repair Station TAMY352IAlphard DarmawanNo ratings yet

- EPRI FMAC January 2000 UpdateDocument8 pagesEPRI FMAC January 2000 UpdateRoberto CastilloNo ratings yet

- Installation, Operation and Maintenance Manual For Vertical Rotalock™ ClosureDocument14 pagesInstallation, Operation and Maintenance Manual For Vertical Rotalock™ ClosureMuhammad GaneshaNo ratings yet

- Key Responsibilities & AuthoritiesDocument1 pageKey Responsibilities & Authoritiesfdfddf dfsdfNo ratings yet

- LCC and OEEDocument4 pagesLCC and OEESAURAV KUMARNo ratings yet

- Reliability Centered Maintenance: Johan O. Asmundvaag Peter Okoh Per Schjølberg For: Norsk Forening For Vedlikehold (NFV)Document32 pagesReliability Centered Maintenance: Johan O. Asmundvaag Peter Okoh Per Schjølberg For: Norsk Forening For Vedlikehold (NFV)Fransisco SimamoraNo ratings yet

- Q1 Module 1 TVL FOOD PROCESSING1Document220 pagesQ1 Module 1 TVL FOOD PROCESSING1Robie Priego50% (2)

- I General: Internal Audit ChecklistDocument32 pagesI General: Internal Audit ChecklistMehaboob BashaNo ratings yet

- Installation, Operation & Maintenance Manual For Cleveland Mixer Series AgitatorsDocument30 pagesInstallation, Operation & Maintenance Manual For Cleveland Mixer Series AgitatorsTIPAZONo ratings yet

- TVS XL100Document68 pagesTVS XL100Dar Sono SuNo ratings yet

- SM 64900Document48 pagesSM 64900HENKO7659No ratings yet

- Level 1 Bridge Inspection FrameworkDocument16 pagesLevel 1 Bridge Inspection FrameworkNaison StanleyNo ratings yet