Professional Documents

Culture Documents

16ME402 - Project Work Phase II: Design and Fabrication of Evaporative Cooling System For Food Storage

16ME402 - Project Work Phase II: Design and Fabrication of Evaporative Cooling System For Food Storage

Uploaded by

Bharath HariOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

16ME402 - Project Work Phase II: Design and Fabrication of Evaporative Cooling System For Food Storage

16ME402 - Project Work Phase II: Design and Fabrication of Evaporative Cooling System For Food Storage

Uploaded by

Bharath HariCopyright:

Available Formats

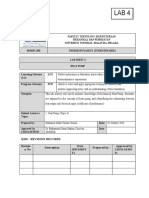

SNS College of Technology

Department of Mechanical Engineering

16ME402 –Project work Phase II

DESIGN AND FABRICATION OF EVAPORATIVE COOLING

SYSTEM FOR FOOD STORAGE

• Project Members:

1. A.AJITHKUMAR (16ME004)

2. M.ASHVANTH (16ME017)

3. S.DANIEL PHILIP STANLY (16ME023)

4. K.JOEL PRINCE (16ME053)

• Guide Name and Designation:

Ms.M.SINDHUKAVI/AP/Mech

Batch No: 04 Phase II Review: 1/15

SNS College of Technology

Department of Mechanical Engineering

16ME402 –Project work Phase II

Content of the Presentation

• Introduction

• Empathy

• Objectives

• Literature review

• Workplan

• Components used

• Working

• References

Batch No: 04 Phase II Review : 2/15

SNS College of Technology

Department of Mechanical Engineering

16ME402 –Project work Phase II

Introduction

• Evaporative cooling is a physical phenomenon in which evaporation of a liquid,

typically into surrounding air, cools an object or a liquid in contact with it.

Evaporative cooling occurs when air, that is not too humid, passes over a wet

surface, the faster the rate of evaporation the greater the cooling. It brings the

comfort by increasing the humidity in dry climates, improves the air quality, and

makes the air more breathable. The most familiar example of this is cooling

effect of evaporating perspiration on the human skin. In dry hot climates body

temperature is partially controlled by the rapid evaporation of perspiration from

the surface of the skin. The evaporation rate is raised as air movement is

increased. Both of these facts can be applied to natural cooling of structures.

This evaporation results in a reduced temperature and an increased vapor

content in the air. The bigger the area of contact between the air and water the

more evaporation occurs, resulting in more cooling and the addition of moisture.

Batch No: 04 Phase II Review : 3/15

SNS College of Technology

Department of Mechanical Engineering

16ME402 –Project work Phase II

Empathy part of the Project Work

The major cause of food waste are :

• Poor farmers harvest crops too early in response to a lack of food and

money.

• Food harvested too early cause loses in both economic and nutritional

value.

• Minimal farming technology such as plows, tractors, and pesticides.

• Inadequate market systems.

• Markets are often small, overcrowded, unsanitary, and lack proper cooling

equipment.

• Fresh produce, meat, and fish spoil in hot climates due to the lack of proper

transportation.

Batch No: 04 Phase II Review : 4/15

SNS College of Technology

Department of Mechanical Engineering

16ME402 –Project work Phase II

Objectives of Project Work

Appropriate cool storage technologies are required in India for

on farm storage of fresh horticultural produce in remote and

inaccessible areas, to reduce losses. Low-cost, low-energy,

environmentally friendly cool chambers made from locally

available materials, and which utilize the principles of

evaporative cooling, were therefore developed in response to

this problem. These cool chambers are able to maintain

temperatures at 10–15 °C below ambient, as well as at a

relative humidity of 90%, depending on the season.

Batch No: 04 Phase II Review : 5/15

SNS College of Technology

Department of Mechanical Engineering

16ME402 –Project work Phase II

Literature Review

S.No Journal Paper Title Author Name

1. A Review Paper on

Evaporative Cooling Methods

Suraj G.Vairagade, Piyush Shrivastava, Pratik

Wandhile,Shubham Kale

2. Performance and Analysis of

an Evaporative cooling

Rajesh Maurya, Dr. Nitin Shrivastav, Vipin

Shrivastava

System : A Review

3. A Review of Evaporative O. Amer, R. Boukhanouf, and H. G. Ibrahim

Cooling Technologies

4. Evaporative cooling

technologies for

Debajit Misra, Sudip Ghosh

greenhouses: a

comprehensive review

5. REVIEW PAPER ON kadam akash sunil, jadhav vishal

EVAPORATIVE COOLING

SYSTEM

Batch No: 04 Phase II Review : 6/15

SNS College of Technology

Department of Mechanical Engineering

16ME402 –Project work Phase II

Work plan of the Project Work

Equipments to be used: Condenser,Air Blower,Evaporator

Testing: Ground Based

Application of the Project:

Evaporative cooling system not only lowers the air temperature

surrounding the produce, it also increases the moisture content of the air. This

helps prevent the drying amount of the produce, therefore extends the shelf life

of horticultural produce. The system is well suited where; temperatures are high,

humidity is low, water can be spared for this use, and air movement is available.

Evaporative cooling has been found to be an efficient and economical means of

reducing temperatures and increasing humidity in an enclosure where the

humidity is comparatively low . Minimizing deteriorative reactions in fruit and

vegetables enhances their shelf lives, implying that the produce will be available

for longer periods; this would reduce fluctuation in market supply and prices

Batch No: 04 Phase II Review : 7/15

SNS College of Technology

Department of Mechanical Engineering

16ME402 –Project work Phase II

COMPONENTS

• Air Blower

• Condenser

• Evaporator

Batch No: 04 Phase II Review : 8/15

SNS College of Technology

Department of Mechanical Engineering

16ME402 –Project work Phase II

COMPONENTS

Air Blower

Batch No: 04 Phase II Review : 9/15

SNS College of Technology

Department of Mechanical Engineering

16ME402 –Project work Phase II

COMPONENTS

Condenser

Batch No: 04 Phase II Review : 10/15

SNS College of Technology

Department of Mechanical Engineering

16ME402 –Project work Phase II

COMPONENTS

Evaporator

Batch No: 04 Phase II Review : 11/15

SNS College of Technology

Department of Mechanical Engineering

16ME402 –Project work Phase II

WORKING

Batch No: 04 Phase II Review : 12/15

SNS College of Technology

Department of Mechanical Engineering

16ME402 –Project work Phase II

WORKING

Atmospheric air are Then the air is send to a

collected by Atmospheric condenser, where the air is

Air Blower condensed to liquid for

cooling.

Liquid is passed to evaporator

The cooled air Reaches the where the copper tube is used

food present inside the cold to evaporate the water and the

chamber temperature of the air is

dropped.

Batch No: 04 Phase II Review : 13/15

SNS College of Technology

Department of Mechanical Engineering

16ME402 –Project work Phase II

References

• Rajesh Maurya, Dr. Nitin Shrivastav, Vipin Shrivastava “Performance and Analysis of an

Evaporative cooling System : A Review”(2014) .

• O. Amer, R. Boukhanouf, and H. G. Ibrahim “A Review of Evaporative Cooling

Technologies”(2015).

• Debajit Misra, Sudip Ghosh “Evaporative cooling technologies for greenhouses: a

comprehensive review”(2018).

• kadam akash sunil, jadhav vishal “REVIEW PAPER ON EVAPORATIVE COOLING

SYSTEM”(2017).

• Suraj G.Vairagade, Piyush Shrivastava, Pratik Wandhile,Shubham Kale “A Review Paper on

Evaporative Cooling Methods”(2017).

Batch No: 04 Phase II Review : 14/15

SNS College of Technology

Department of Mechanical Engineering

16ME402 –Project work Phase II

Thank you

Batch No: 04 Phase II Review : 15/15

You might also like

- Lab 4 Termo Sem 2Document22 pagesLab 4 Termo Sem 2Fgj JhgNo ratings yet

- Construction of 1.5 HP Split Unit Air Conditioning SystemDocument43 pagesConstruction of 1.5 HP Split Unit Air Conditioning Systemikperha jomafuvweNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Lit AnalysisDocument4 pagesLit AnalysisHaylieClementNo ratings yet

- Refrigeration and Air Conditioning Digital NotesDocument112 pagesRefrigeration and Air Conditioning Digital NotesŤêk Mãñ JôśÿNo ratings yet

- Government Polytechnic Ambawadi, Ahmedabad-15: Design and Fabrication of Heat Powered RefrigeratorDocument41 pagesGovernment Polytechnic Ambawadi, Ahmedabad-15: Design and Fabrication of Heat Powered RefrigeratorNigNo ratings yet

- Air Conditioning TrainerDocument11 pagesAir Conditioning TrainerPratik PandeyNo ratings yet

- Yl (Me) 1Document16 pagesYl (Me) 1pranayNo ratings yet

- Project Report On Liquid NitrogenDocument23 pagesProject Report On Liquid Nitrogenneeltambe100% (2)

- MD Arif UddinDocument39 pagesMD Arif UddinMudavath BaburamNo ratings yet

- Irjet V4i4635 PDFDocument7 pagesIrjet V4i4635 PDFayyappaNo ratings yet

- Capstone Design Experience in A Thermal Fluid Applications Course and Development of An in House Refrigeration Recovery SystemDocument10 pagesCapstone Design Experience in A Thermal Fluid Applications Course and Development of An in House Refrigeration Recovery Systemuu4316No ratings yet

- Final Mini Project ReportDocument30 pagesFinal Mini Project ReportRatheesh SNo ratings yet

- Rizal Technological University College of Engineering and Industrial TechnologyDocument55 pagesRizal Technological University College of Engineering and Industrial Technologyアルビン ベネNo ratings yet

- RAC 2nd ModDocument45 pagesRAC 2nd ModSatheesh ChandranNo ratings yet

- Basic Refrigeration: Experiment No. 3Document14 pagesBasic Refrigeration: Experiment No. 3januel borelaNo ratings yet

- Submitted By: Mudavath BaburamDocument39 pagesSubmitted By: Mudavath BaburamEasy StudyNo ratings yet

- "Air Cooler" by Yojit Lokhande Swapnil Kumawat Gurudevkeware Mandar Pawar Swayam Ahire Parth Patil Guide Prof. S.D. MateDocument22 pages"Air Cooler" by Yojit Lokhande Swapnil Kumawat Gurudevkeware Mandar Pawar Swayam Ahire Parth Patil Guide Prof. S.D. MateswapnilNo ratings yet

- PBL FinalDocument21 pagesPBL FinalSarthak ShahNo ratings yet

- Jntuk M Tech r16 Te SyllabusDocument33 pagesJntuk M Tech r16 Te Syllabusvrmurtygandi0% (1)

- M.Tech.: Mechanical EngineeringDocument10 pagesM.Tech.: Mechanical EngineeringANMOLNo ratings yet

- Design Enginerering 2ADocument21 pagesDesign Enginerering 2AReilyNo ratings yet

- Engineering ThermodynamicsDocument1 pageEngineering ThermodynamicsAkshay PatoleNo ratings yet

- Vishnu Dange Rohit Jadhav RAC 22660 MicroprojectDocument19 pagesVishnu Dange Rohit Jadhav RAC 22660 Microprojectnarasihhinge4No ratings yet

- TE Lab Manual 1Document3 pagesTE Lab Manual 1KUNAL PATELNo ratings yet

- Test On Vapor Compression Refrigeration-Batch 18Document4 pagesTest On Vapor Compression Refrigeration-Batch 18Ovini De SilvaNo ratings yet

- Design and Fabrication of Three in One ADocument7 pagesDesign and Fabrication of Three in One ADanny DanNo ratings yet

- 20201019-Refrigeration Air ConditioningDocument111 pages20201019-Refrigeration Air ConditioningRavi KumarNo ratings yet

- G-12 Paau Term PaperDocument17 pagesG-12 Paau Term PaperARROW FFNo ratings yet

- Rac PDFDocument78 pagesRac PDFNarender SinghNo ratings yet

- Synopsis HardDocument24 pagesSynopsis HardcrisankuNo ratings yet

- Lesson Plan ThermalDocument4 pagesLesson Plan ThermalrohitnshenoyNo ratings yet

- Bino Seminar ReportDocument30 pagesBino Seminar ReportAkshayNo ratings yet

- Poster PresentaionDocument7 pagesPoster PresentaionAbdul Moeed AhmedNo ratings yet

- Performance Analysis of Atmospheric Water Extraction by Refrigerator Cum AircondtionerDocument56 pagesPerformance Analysis of Atmospheric Water Extraction by Refrigerator Cum AircondtionerMohamed SafinNo ratings yet

- A Report On Energy Efficient RefrigerationDocument42 pagesA Report On Energy Efficient RefrigerationNikhilesh KadukarNo ratings yet

- Final Report Design Engineering 2ADocument29 pagesFinal Report Design Engineering 2AReilyNo ratings yet

- Multi Evaporator Refrigeration System: Bachelor of TechnologyDocument34 pagesMulti Evaporator Refrigeration System: Bachelor of TechnologyMonday MonsterNo ratings yet

- Project Report For Major 1: A Study On The A Silicon Based Micro Jet Impingement Heat SinkDocument30 pagesProject Report For Major 1: A Study On The A Silicon Based Micro Jet Impingement Heat SinkPrakash SinghNo ratings yet

- Multiphase Simulation of Automotive Hvac Evaporator Using R134a and R1234yf RefrigerantsDocument8 pagesMultiphase Simulation of Automotive Hvac Evaporator Using R134a and R1234yf RefrigerantsIAEME PublicationNo ratings yet

- Distribution of Cooling To Avionics PDFDocument76 pagesDistribution of Cooling To Avionics PDFpuhumightNo ratings yet

- Gujarat Technological Univercity: Government Engineering College, PatanDocument16 pagesGujarat Technological Univercity: Government Engineering College, PatanAnkit SinghNo ratings yet

- M Tech R and Ac R15 SyllabusDocument37 pagesM Tech R and Ac R15 SyllabusEr. Ramji TripathiNo ratings yet

- Thermal Micro ProjectDocument15 pagesThermal Micro ProjectMonty 75750% (2)

- Project Report: ON Single Cavity Hot Tip Mould INDocument68 pagesProject Report: ON Single Cavity Hot Tip Mould INAtul GiteNo ratings yet

- HVAC Project Report 2.0Document33 pagesHVAC Project Report 2.0Màñëësh RèddyNo ratings yet

- EShop - Exp 4 - Study of Home Appliances II-Refrigeration & Air-Conditioning SystemsDocument8 pagesEShop - Exp 4 - Study of Home Appliances II-Refrigeration & Air-Conditioning SystemsKazi ShahadatNo ratings yet

- ETM Microproject-1Document16 pagesETM Microproject-1Akash MarkhaleNo ratings yet

- RAC Complete Notes PDFDocument76 pagesRAC Complete Notes PDFdipsankar chatterjeeNo ratings yet

- Solar RefrigerationDocument40 pagesSolar RefrigerationRajatNo ratings yet

- Chiller Faults Diagnosis A Case StudyDocument7 pagesChiller Faults Diagnosis A Case StudyBlack SmithNo ratings yet

- I JC A Performance Evaluation of Vapour Compression CycleDocument5 pagesI JC A Performance Evaluation of Vapour Compression CycleErnaNo ratings yet

- Performance Studyon AWindow Type Air Conditioner Condenser Using Alternative Refrigerant R407 CDocument10 pagesPerformance Studyon AWindow Type Air Conditioner Condenser Using Alternative Refrigerant R407 CAheron HizmoNo ratings yet

- RacDocument12 pagesRacRavindra_1202No ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19AkashNo ratings yet

- ResumeDocument9 pagesResumeAVES HUSAINYNo ratings yet

- Engineering & Technology Surat) : (C.K.Pithawala College ofDocument23 pagesEngineering & Technology Surat) : (C.K.Pithawala College of19006 Sahel GamitNo ratings yet

- Report New Saif ShabbriDocument5 pagesReport New Saif ShabbrirehmanNo ratings yet

- Review On Condenser Air Leak Test: International Journal of Pure and Applied Mathematics No. 16 2018, 3197-3205Document10 pagesReview On Condenser Air Leak Test: International Journal of Pure and Applied Mathematics No. 16 2018, 3197-3205Amir AbbaszadehNo ratings yet

- Faheem Riyaz Shaikh 3309 RAC MicroprojectDocument18 pagesFaheem Riyaz Shaikh 3309 RAC MicroprojectFaheem Shaikh100% (1)

- General Request Form: King Mongkut's University of Technology North BangkokDocument1 pageGeneral Request Form: King Mongkut's University of Technology North BangkokBharath HariNo ratings yet

- Tuition Fee For Master's Degree: Faculty of Industrial Education and TechnologyDocument5 pagesTuition Fee For Master's Degree: Faculty of Industrial Education and TechnologyBharath HariNo ratings yet

- Experimental Analysis of LPG Refrigeration SystemDocument4 pagesExperimental Analysis of LPG Refrigeration SystemBharath HariNo ratings yet

- Design of LPG Used Refrigeration System Using Nozzle ExpansionDocument8 pagesDesign of LPG Used Refrigeration System Using Nozzle ExpansionBharath HariNo ratings yet

- Dinesh Kumar.B Contact Information: Academic PerformanceDocument3 pagesDinesh Kumar.B Contact Information: Academic PerformanceBharath HariNo ratings yet

- Colegio de San Gabriel Arcangel, Inc.: READING REPORT in - BMEC1Document3 pagesColegio de San Gabriel Arcangel, Inc.: READING REPORT in - BMEC1Trisha Dela Cruz EstoniloNo ratings yet

- GB 2760-1996Document51 pagesGB 2760-1996Roger QuinterosNo ratings yet

- 5846-Article Text-43039-7-10-20220707Document15 pages5846-Article Text-43039-7-10-20220707jommphilipoNo ratings yet

- 761 Present Continuous Tense MCQ Grammar Quiz Test ExerciseDocument3 pages761 Present Continuous Tense MCQ Grammar Quiz Test ExerciseZoya AtanasovaNo ratings yet

- New C1 Final Test - AmandaDocument3 pagesNew C1 Final Test - AmandaThiarline Batista MoraisNo ratings yet

- Causative Have and GetDocument4 pagesCausative Have and GetCELERONNo ratings yet

- Tugas Tutorial Ke-1: A. Fill in The Blank!Document2 pagesTugas Tutorial Ke-1: A. Fill in The Blank!Ledy Tanaya FibriyantiNo ratings yet

- Soal Passive VoiceDocument8 pagesSoal Passive VoiceRazie zuNo ratings yet

- Principles, Classification, Ingredients and Guidelines in Preparing Stocks PRESENTATION 03-21-2022Document37 pagesPrinciples, Classification, Ingredients and Guidelines in Preparing Stocks PRESENTATION 03-21-2022Leslie Jane S. BlancaflorNo ratings yet

- COVID-19 Impact On Pharmaceuticals SectorDocument6 pagesCOVID-19 Impact On Pharmaceuticals SectorBhargav KumarNo ratings yet

- Bella, Cafetera ManualDocument20 pagesBella, Cafetera ManualLicuadora LaNo ratings yet

- Agricola - A Plain and Simple GuideDocument4 pagesAgricola - A Plain and Simple Guidedeltaxgaming101No ratings yet

- 4TH Periodical Test in Epp ViDocument6 pages4TH Periodical Test in Epp Vijane brent solasNo ratings yet

- Very Important Report Ethiopia Oilseeds Report Annual - Addis Ababa - Ethiopia - 03-04-2021Document21 pagesVery Important Report Ethiopia Oilseeds Report Annual - Addis Ababa - Ethiopia - 03-04-2021Tesfaye NokoNo ratings yet

- (Client) CDM Untukmu, Ku Akan 2024 Kol StorylineDocument19 pages(Client) CDM Untukmu, Ku Akan 2024 Kol StorylinesuchiNo ratings yet

- Our EnvironmentDocument9 pagesOur Environmentraimaali220077No ratings yet

- 500 Descriptive Words To Improve Your WritingDocument61 pages500 Descriptive Words To Improve Your WritingjamshedNo ratings yet

- Paleo Vegetarian DietDocument1 pagePaleo Vegetarian DietSubbaraman PadmanabhanNo ratings yet

- Physicochemical Changes During 4 Weeks Ripening of Camembert Cheeses Salted With Four Types of SaltsDocument12 pagesPhysicochemical Changes During 4 Weeks Ripening of Camembert Cheeses Salted With Four Types of SaltsGina FelyaNo ratings yet

- EF3e Intplus Filetest 10bDocument7 pagesEF3e Intplus Filetest 10bLin ShufenNo ratings yet

- 00 111國中英語1下平時測驗卷 學用 (111f602475)Document18 pages00 111國中英語1下平時測驗卷 學用 (111f602475)Kevin TzengNo ratings yet

- 3rd Quarter Exam in Values (Grade 1)Document3 pages3rd Quarter Exam in Values (Grade 1)Dyna Alonsagay LabindaoNo ratings yet

- Latihan 20 Soal PassiveDocument3 pagesLatihan 20 Soal PassiveDwi yunita sariNo ratings yet

- Aerogarden Harvest Elite 360 Tips CardDocument2 pagesAerogarden Harvest Elite 360 Tips CardT-BuzzardNo ratings yet

- Region 4 A CalabarzonDocument20 pagesRegion 4 A CalabarzonAloes BreciaNo ratings yet

- Reincarnated As A Sword Volume 2Document349 pagesReincarnated As A Sword Volume 2Phil100% (1)

- B-Your Experienced Partner in Petfood PlantsDocument11 pagesB-Your Experienced Partner in Petfood PlantsEMRENo ratings yet

- Four Ps - Example MC Donalds PRODUCTDocument9 pagesFour Ps - Example MC Donalds PRODUCTSnod SnodNo ratings yet

- Q1 G10 LP Cookery Tle 22 23Document13 pagesQ1 G10 LP Cookery Tle 22 23Jelyn Ezebb ArellanoNo ratings yet