Professional Documents

Culture Documents

Chapter 4. Gear Train: Engr. Jonathan S. Rodolfo

Chapter 4. Gear Train: Engr. Jonathan S. Rodolfo

Uploaded by

Brian Jasper0 ratings0% found this document useful (0 votes)

44 views16 pagesThe document discusses gear trains and planetary gear trains. It provides examples of how to calculate the velocity reduction and distance between shafts in a standard gear train. It then explains that planetary gear trains allow for movement of the gear centers and can achieve large speed reductions in a compact space. The document concludes by describing the steps to analyze a planetary gear train through superposition and providing sample problems to calculate the rotational velocity of members in given planetary gear train setups.

Original Description:

Gear tra

Career Objective is 5

Original Title

Geartrain.pdf

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses gear trains and planetary gear trains. It provides examples of how to calculate the velocity reduction and distance between shafts in a standard gear train. It then explains that planetary gear trains allow for movement of the gear centers and can achieve large speed reductions in a compact space. The document concludes by describing the steps to analyze a planetary gear train through superposition and providing sample problems to calculate the rotational velocity of members in given planetary gear train setups.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

44 views16 pagesChapter 4. Gear Train: Engr. Jonathan S. Rodolfo

Chapter 4. Gear Train: Engr. Jonathan S. Rodolfo

Uploaded by

Brian JasperThe document discusses gear trains and planetary gear trains. It provides examples of how to calculate the velocity reduction and distance between shafts in a standard gear train. It then explains that planetary gear trains allow for movement of the gear centers and can achieve large speed reductions in a compact space. The document concludes by describing the steps to analyze a planetary gear train through superposition and providing sample problems to calculate the rotational velocity of members in given planetary gear train setups.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 16

Chapter 4.

Gear Train

Engr. Jonathan S. Rodolfo

Introduction

A gear train is a series of mating gear sets. Gear trains

are commonly used to achieve large speed reductions.

Many mechanical power sources, such as engines,

turbines, and electric motors, operate efficiently at high

speeds (1800–10,000 rpm). Many uses for this power,

such as garage door openers, automotive drive wheels,

and ceiling fans, require low speeds (10–100 rpm) for

operation. Therefore, a desire to achieve large-velocity

reductions is common, and the use of gear trains is

very common.

Introduction

Forexample, it may be desired to reduce the speed of a

shaft from 1800 rpm to 10 rpm. Thus, a velocity reduction

of 180:1 is required. If this reduction were attempted with

one gear set, it would reveal that the driven gear would be

180 times larger than the drive gear.

Introduction

Example

A gear train is shown above. The gears have the following

properties:

Determine the rotational velocity of gear 7 as gear 2 drives

at 1800 rpm counterclockwise. Also determine the distance

between the shafts that carry gears 2 and 7.

IDLER GEARS

PLANETARY GEAR TRAINS

The gear trains presented in preceding sections all

had gear centers attached to fixed bodies. With

planetary gear trains, this restriction is removed. In

these trains, a link that holds the center of the gears

is allowed to move. A planetary gear train is also

called an epicyclic train.

Planetary trains can be used to achieve large speed

reductions in a more compact space than a conventional

gear train. However, a greater benefit is the ability to

readily alter the train value. Because all links are capable

of moving, one can alter the train value by holding

different gears or carriers. For this reason, planetary gear

trains are very common in automotive transmissions.

Planetary gear analysis by superposition

Step 1: The first step is to relax the constraint on the fixed

link and temporarily assume that the carrier is locked.

Turn one gear one revolution and calculate the effect on

the entire train

Step 2: The second step is to free all constraints and

record the movement of rotating each link one revolution

in the opposite direction of the rotation in step one.

Step 3: The motion of all links is determined by

combining the rotations from the first two steps.

Finally, velocities are proportional to the rotational

movements.

Sample

A planetary gear train is illustrated in Figure 10.24. The

carrier (link 2) serves as the input to the train. The sun

(gear 1) is the fixed gear and has 30 teeth. The planet gear

(gear 3) has 35 teeth. The ring gear serves as the output

from the train and has 100 teeth. Determine the rotational

velocity of all members of this gear train when the input

shaft rotates at 1200 rpm clockwise.

A planetary gear train is illustrated in Figure 10.25.

The carrier (link 2) serves as the input to the train.

The ring gear (gear 1) is the fixed gear and has 120

teeth. The planet gear (gear 4) has 40 teeth. The sun

gear (gear 3) serves as the output from the train and

has 30 teeth. Determine the rotational velocity of al

members of this gear train when the input shaft

rotates at 1200 rpm clockwise.

End

You might also like

- dsg6 DQ 250Document4 pagesdsg6 DQ 250EsquisofNo ratings yet

- Study of a reluctance magnetic gearbox for energy storage system applicationFrom EverandStudy of a reluctance magnetic gearbox for energy storage system applicationRating: 1 out of 5 stars1/5 (1)

- Valliammai Engineering College Department of Mechanical Engineering Question Bank Subject: Me 6505-Dynamics of Machines UNIT-I PART-A (2 Marks)Document15 pagesValliammai Engineering College Department of Mechanical Engineering Question Bank Subject: Me 6505-Dynamics of Machines UNIT-I PART-A (2 Marks)Johnson JohnsonNo ratings yet

- Epicyclical Gear Train System Lab ReportDocument15 pagesEpicyclical Gear Train System Lab ReportIbrahim Hussain50% (2)

- 6F50 TipsDocument10 pages6F50 TipsNoah Istre100% (2)

- Auman Kunlun Dump Truck Service Manual (Iii) PDFDocument804 pagesAuman Kunlun Dump Truck Service Manual (Iii) PDFMiguel Martinez0% (1)

- Friction Belt Drive ProblemsDocument4 pagesFriction Belt Drive ProblemsKenta Hirohata100% (1)

- Chapter 4. Gear Train: Engr. Jonathan S. RodolfoDocument15 pagesChapter 4. Gear Train: Engr. Jonathan S. Rodolfojoshua alhambraNo ratings yet

- Case Study of Planetary GearsDocument5 pagesCase Study of Planetary GearsSANGE MOHAMMEDNo ratings yet

- 2.1 Tractor TransparencyDocument9 pages2.1 Tractor Transparencystephene larimNo ratings yet

- 2.1 Tractor TransparencyDocument9 pages2.1 Tractor TransparencyLorenzo Niño BlasquezNo ratings yet

- ME 323 Lab 4-Omar AlfahadDocument9 pagesME 323 Lab 4-Omar Alfahadengineer.mohammedtahhanNo ratings yet

- Aries Polytechnic College: 5052-Automobile TransmissionDocument15 pagesAries Polytechnic College: 5052-Automobile TransmissionZiyad KprNo ratings yet

- Automatic TransmissionDocument20 pagesAutomatic TransmissionDwy Bagus NNo ratings yet

- Tractor TransparencyDocument10 pagesTractor TransparencyMark Kevin AlletoNo ratings yet

- Power Generation System Through Foot Steps1Document24 pagesPower Generation System Through Foot Steps1Dasari Anuroop ReddyNo ratings yet

- Lab 1Document8 pagesLab 1Mansoob BukhariNo ratings yet

- Automatic TransmissionDocument20 pagesAutomatic TransmissionAravindSaju100% (3)

- Epicyclic Gear Train and Worm Wheel Reducer (1) ..Document12 pagesEpicyclic Gear Train and Worm Wheel Reducer (1) ..22r237No ratings yet

- 1 Epicyclic Gear Train ExperimentDocument6 pages1 Epicyclic Gear Train Experimentshuyun88100% (6)

- IES ALJANADIC .POSADAS (CORDOBA) Maria Dolores García Fernández Http://Www.petervaldivia.com/Technology/Mechanisms/Index.php Http://Www.bbc.Co.uk/Schools/Gcsebitesize/Design/Systemscontrol/Mechanismsrev1.ShtmlDocument14 pagesIES ALJANADIC .POSADAS (CORDOBA) Maria Dolores García Fernández Http://Www.petervaldivia.com/Technology/Mechanisms/Index.php Http://Www.bbc.Co.uk/Schools/Gcsebitesize/Design/Systemscontrol/Mechanismsrev1.Shtmltechnologyaljanadic0910No ratings yet

- Planetary Servo TransmissionDocument21 pagesPlanetary Servo TransmissionScribdTranslationsNo ratings yet

- OCW Analisis of Gear TrainsDocument11 pagesOCW Analisis of Gear TrainsVictor SibandaNo ratings yet

- Epicyclic Gear TrainDocument6 pagesEpicyclic Gear TrainLow Kian JinNo ratings yet

- 26 181 GigerDocument6 pages26 181 GigerYouMineNo ratings yet

- 081 - ME8594, ME6505 Dynamics of Machines - Important QuestionsDocument20 pages081 - ME8594, ME6505 Dynamics of Machines - Important QuestionsKannathal3008 88No ratings yet

- 9A03502 Dynamics of MachineryDocument4 pages9A03502 Dynamics of MachinerysivabharathamurthyNo ratings yet

- Republic of YemenDocument10 pagesRepublic of YemenNagwan QassemNo ratings yet

- DOM Model PaperDocument2 pagesDOM Model PaperRambabuDaraNo ratings yet

- ME 323 Lab 4 Mohammed Ahmed Tahhan 392027113Document10 pagesME 323 Lab 4 Mohammed Ahmed Tahhan 392027113engineer.mohammedtahhanNo ratings yet

- Chap-8 Gear TrainDocument18 pagesChap-8 Gear TrainAlysNo ratings yet

- ME 2213 (Gear Train)Document36 pagesME 2213 (Gear Train)tanvir2013004No ratings yet

- Kassahun Tadess GeerboxDocument16 pagesKassahun Tadess Geerboxabubekery61No ratings yet

- WIRE ROPE HAULAGE WordDocument16 pagesWIRE ROPE HAULAGE WordAnshul yadavNo ratings yet

- Epicyclic Gear TrainDocument5 pagesEpicyclic Gear TrainRachan PancheNo ratings yet

- Mechanical Actuation SystemsDocument14 pagesMechanical Actuation SystemsnkchandruNo ratings yet

- Structural Analysis of Three Stage Coupled Planetary Gear Train and Determination of EfficiencyDocument3 pagesStructural Analysis of Three Stage Coupled Planetary Gear Train and Determination of EfficiencyInnovative Research PublicationsNo ratings yet

- Tutorial 3 19BME069Document14 pagesTutorial 3 19BME06920BME005 INAM SABRINo ratings yet

- Lesson 3: Power Train Drive SystemsDocument12 pagesLesson 3: Power Train Drive SystemsMaimun maimunNo ratings yet

- Sun and Planet GearDocument9 pagesSun and Planet GeararifulseuNo ratings yet

- DOM TutorialsDocument11 pagesDOM TutorialsNishankzattNo ratings yet

- 07a60304 - Dynamics of MachineryDocument8 pages07a60304 - Dynamics of MachineryRajaganapathy GanaNo ratings yet

- OTM 364 Elektrikli Ve Hibrit TaşıtlarDocument116 pagesOTM 364 Elektrikli Ve Hibrit TaşıtlarEspri FuuNo ratings yet

- Dynamics of Machinary - Question BANKDocument17 pagesDynamics of Machinary - Question BANKS A ABDUL SUKKURNo ratings yet

- Automatic Door Open @close Report FinalDocument36 pagesAutomatic Door Open @close Report FinalFelixJosephNo ratings yet

- Unit 1 PPT Introduction To Electric VehicleDocument97 pagesUnit 1 PPT Introduction To Electric VehicleAnonymous xaeuoo450% (2)

- Design of Machinery Jntua Previous PapersDocument20 pagesDesign of Machinery Jntua Previous PapersHimadhar SaduNo ratings yet

- Solved Questions MTM PDFDocument12 pagesSolved Questions MTM PDFRajendrakumarNo ratings yet

- Structural Analysis of A Wind Turbine and Its Drive Train Using The Flexible Multibody Simulation TechniqueDocument16 pagesStructural Analysis of A Wind Turbine and Its Drive Train Using The Flexible Multibody Simulation TechniquerachitmatNo ratings yet

- Mechanical Actuation SystemDocument34 pagesMechanical Actuation Systemdildar123100% (2)

- Automatic Transmission5 ReportDocument17 pagesAutomatic Transmission5 ReportManhar MidhaNo ratings yet

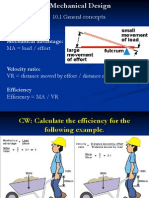

- 10 Mechanical Design HL ExtensionDocument38 pages10 Mechanical Design HL ExtensionSyeda Fariya Nisar AliNo ratings yet

- Exp 3Document21 pagesExp 3Ramanbhaman BhamanNo ratings yet

- Jntu Question PaperDocument3 pagesJntu Question Paperrohitchanakya76No ratings yet

- Introduction To Mechanisms and Simple MachinesDocument4 pagesIntroduction To Mechanisms and Simple MachinesAkash SoniNo ratings yet

- DOM Assignment 2022-23Document11 pagesDOM Assignment 2022-23Pratham DakoriaNo ratings yet

- Trends Regarding Needle Roller Bearings For Automatic Transmission Planetary GearsDocument0 pagesTrends Regarding Needle Roller Bearings For Automatic Transmission Planetary GearsankitsarvaiyaNo ratings yet

- GS01 System Modeling PDFDocument3 pagesGS01 System Modeling PDFJerald Morelos HabilNo ratings yet

- CH 13Document27 pagesCH 13Sanjay KumarNo ratings yet

- Special Machines: Theory, Modeling, Control and ApplicationsDocument31 pagesSpecial Machines: Theory, Modeling, Control and ApplicationsRAJA MNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- A New System of Alternating Current Motors and Transformers and Other EssaysFrom EverandA New System of Alternating Current Motors and Transformers and Other EssaysRating: 5 out of 5 stars5/5 (1)

- 1.1 Ojt Requirement List PDFDocument1 page1.1 Ojt Requirement List PDFBrian JasperNo ratings yet

- THESIS Team No Choice UpdatedDocument47 pagesTHESIS Team No Choice UpdatedBrian JasperNo ratings yet

- Wave Energy Converters PDFDocument4 pagesWave Energy Converters PDFBrian JasperNo ratings yet

- Automotive Control Systems: Leader: Belingon, Mark Anthony Member: Garzota, Herminio Jr. Estacio, Mary AnnDocument32 pagesAutomotive Control Systems: Leader: Belingon, Mark Anthony Member: Garzota, Herminio Jr. Estacio, Mary AnnBrian JasperNo ratings yet

- Chapter 1. Introduction PDFDocument3 pagesChapter 1. Introduction PDFBrian JasperNo ratings yet

- Circuit With A Switch: Parts and MaterialsDocument2 pagesCircuit With A Switch: Parts and MaterialsBrian JasperNo ratings yet

- Derivatives of Trigonometric Function: Example 1Document2 pagesDerivatives of Trigonometric Function: Example 1Brian JasperNo ratings yet

- 2011 Transtar Automatic Transmission CatalogDocument76 pages2011 Transtar Automatic Transmission Catalogshanestarbuck68100% (2)

- Complete CatalogDocument651 pagesComplete CatalogFernando EscriváNo ratings yet

- Diagrama OKI B930Document19 pagesDiagrama OKI B930jrodriguezb0% (1)

- ZF16S220Document11 pagesZF16S220John Mendoza Pacheco100% (4)

- Chapter 5 GearDocument9 pagesChapter 5 GearNEF RIDERSNo ratings yet

- Manual Caja Citroen Al4Document59 pagesManual Caja Citroen Al4JcMarquez100% (1)

- AGMA2003 CommentsDocument18 pagesAGMA2003 CommentsalfavectorNo ratings yet

- DTS QBDocument19 pagesDTS QBHem KumarNo ratings yet

- Curved Tooth Flexible Gear Couplings 2Document3 pagesCurved Tooth Flexible Gear Couplings 2Traveller RawatNo ratings yet

- MPTA-B4c-2008R 2013: Mechanical Power Transmission Association 5672 Strand Court, Suite 2, Naples, FL 34110Document3 pagesMPTA-B4c-2008R 2013: Mechanical Power Transmission Association 5672 Strand Court, Suite 2, Naples, FL 34110l_aguilar_mNo ratings yet

- WC7132Document95 pagesWC7132Андрей КотеневNo ratings yet

- DrivetrainDocument3 pagesDrivetrainhardcore cylinderNo ratings yet

- Chapter Three: Troubleshooting: Chery A15 Maintenance ManualDocument1 pageChapter Three: Troubleshooting: Chery A15 Maintenance ManualCarlos TecnicNo ratings yet

- Eaton Fuller FSO 6406A Transmission Parts ManualDocument22 pagesEaton Fuller FSO 6406A Transmission Parts ManualDaniel marques100% (1)

- Belt TransmissionDocument15 pagesBelt TransmissionSurf tubeNo ratings yet

- Power Shuttle, Input Shaft and Forward ClutchDocument3 pagesPower Shuttle, Input Shaft and Forward ClutchNeftali FuentesNo ratings yet

- Tripper Belt Conveyor CalculationDocument5 pagesTripper Belt Conveyor Calculationbashok20No ratings yet

- ChaindriveDocument34 pagesChaindriveCssNo ratings yet

- Axles MF5710Document43 pagesAxles MF5710SudarsonoNo ratings yet

- NEW DAILY Hi-Matic LeafletDocument2 pagesNEW DAILY Hi-Matic LeafletГеорги ЖелязковNo ratings yet

- Power Take-Off: Paragraph 130 Deutz-AllisDocument5 pagesPower Take-Off: Paragraph 130 Deutz-AllisEdin HadzicNo ratings yet

- ZF List Book4 For TrucksDocument15 pagesZF List Book4 For TrucksHeptagon Automotive100% (2)

- Tutorial MOM GearDocument15 pagesTutorial MOM GearEQ-solutionsNo ratings yet

- A Look at The : FeaturesDocument10 pagesA Look at The : FeaturesDavid Lacunes100% (3)

- Manual Transmission / Transaxle (R151F, R151) : ComponentsDocument6 pagesManual Transmission / Transaxle (R151F, R151) : Componentsvõ đăng tiến100% (1)

- Europe, Samurai - SJ, SJ413 E-III (Santana), Transmission, 24 - TRANSMISSION - Catcar - InfoDocument4 pagesEurope, Samurai - SJ, SJ413 E-III (Santana), Transmission, 24 - TRANSMISSION - Catcar - InfoiestagcrNo ratings yet