Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

51 viewsGroup 1 - Sun Microsystem - Group

Group 1 - Sun Microsystem - Group

Uploaded by

Aninda DuttaSun Microsystems manages supplier relationships through a VP of Supplier Management and commodity managers. They identify needs 3-5 years out, select suppliers, and communicate requirements. Suppliers are evaluated on lead times, prices, quality, technology, and support. Top scoring suppliers receive more business and lower total cost of ownership scores.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- The Sanlam Brand: Connecting Hearts and Minds MeaningfullyDocument26 pagesThe Sanlam Brand: Connecting Hearts and Minds MeaningfullyXolani Radebe RadebeNo ratings yet

- Arcadia - Syndicate 9Document6 pagesArcadia - Syndicate 9Uus FirdausNo ratings yet

- Business Valuation: Rajiv Bhutani IIM Sambalpur 2018Document21 pagesBusiness Valuation: Rajiv Bhutani IIM Sambalpur 2018Aninda DuttaNo ratings yet

- How To Formulate UVDocument16 pagesHow To Formulate UVtobass82100% (3)

- Iec 61400-22Document59 pagesIec 61400-22Barbu Alexandru Iulian50% (2)

- Group 1 - Sun MicrosystemDocument6 pagesGroup 1 - Sun MicrosystemAninda DuttaNo ratings yet

- 3.PDA Cigulung-MaribayaDocument14 pages3.PDA Cigulung-MaribayaigitNo ratings yet

- Current Raitings XLPEDocument1 pageCurrent Raitings XLPEshakeel212No ratings yet

- Lecture 4 - Simulation of A Queuing ProblemDocument13 pagesLecture 4 - Simulation of A Queuing ProblemMihlaliNo ratings yet

- Libro 1Document3 pagesLibro 1Kmby GabrielaNo ratings yet

- Automate+Worksheet+Population 27+feb+2024Document6 pagesAutomate+Worksheet+Population 27+feb+2024ponmanipm.054No ratings yet

- 6.PDA Cikapundung-MaribayaDocument14 pages6.PDA Cikapundung-MaribayaigitNo ratings yet

- Lab 03 Worksheet - Taylor Ingram DAR 3Document3 pagesLab 03 Worksheet - Taylor Ingram DAR 3tylringramNo ratings yet

- Service Factor Table - Tony Wild - 2002Document1 pageService Factor Table - Tony Wild - 2002jardineria de occidenteNo ratings yet

- Pulley On Shaft EfficiencyDocument2 pagesPulley On Shaft EfficiencyAndy YanNo ratings yet

- LMP-Lampiran - KPI USE April 2019 PT PERTAMINA F1.0-28-05-2019 - 170832943Document8 pagesLMP-Lampiran - KPI USE April 2019 PT PERTAMINA F1.0-28-05-2019 - 170832943Agung Ananta PutraNo ratings yet

- Attribute Statistical ReportDocument1 pageAttribute Statistical ReportQuality VenusNo ratings yet

- ClarksonDocument22 pagesClarksonfrankstandaert8714No ratings yet

- ALABAM A CaseDocument7 pagesALABAM A Casenesec62195No ratings yet

- BiostatDocument7 pagesBiostatyoan yulista hartivaNo ratings yet

- Table 21 25Document1 pageTable 21 25Ashwary Sheel Wali Research Scholar, Dept of Mech Engg., IIT (BHU)No ratings yet

- 7 QC ToolsDocument20 pages7 QC ToolsSotepNo ratings yet

- Revenue Leakage 07172019Document30 pagesRevenue Leakage 07172019AnkushNo ratings yet

- BBHS Level of Proficiency TLE HIGH SCHOOL 1st QuarterDocument11 pagesBBHS Level of Proficiency TLE HIGH SCHOOL 1st QuarterSmaw Iron RodNo ratings yet

- Employee TurnoverDocument20 pagesEmployee Turnoversneha fabeyNo ratings yet

- Lagtime AnalysisDocument7 pagesLagtime AnalysisRahul MayeeNo ratings yet

- Simula Encargos 1.2Document2 pagesSimula Encargos 1.2Fabio.soares RhNo ratings yet

- Project Report: Aman Mishra C-5 Sandeep Kumar C-61 Amanat Singh C-53 Abhishek Kumar 2020 - 22Document54 pagesProject Report: Aman Mishra C-5 Sandeep Kumar C-61 Amanat Singh C-53 Abhishek Kumar 2020 - 22AMAN MISHRANo ratings yet

- Gradation Fineness Modulus 9.43: Mass of Oven Dried Sample (G)Document3 pagesGradation Fineness Modulus 9.43: Mass of Oven Dried Sample (G)Joshua AbadNo ratings yet

- St. Louis Luxury Market Overview - August 9, 2010Document1 pageSt. Louis Luxury Market Overview - August 9, 2010rtnoltingNo ratings yet

- Diagrama de Massas - AlunosDocument5 pagesDiagrama de Massas - AlunosGuilherme NogueiraNo ratings yet

- Criterion - % Gravel 99.47 % 4 % Sand 0.41 % 1 CC 3 % Fine 0.14 % - % Total 100.00%Document3 pagesCriterion - % Gravel 99.47 % 4 % Sand 0.41 % 1 CC 3 % Fine 0.14 % - % Total 100.00%Joshua AbadNo ratings yet

- Sikap KorupsiDocument5 pagesSikap KorupsiRisyah Iriansyah100% (1)

- Moly-Cop Tools (Version 3.0) : Particle Size DistributionDocument3 pagesMoly-Cop Tools (Version 3.0) : Particle Size DistributionKelvin Gonzalez SanchezNo ratings yet

- Free CoolingDocument2,457 pagesFree CoolingBrad UpsonNo ratings yet

- EXAMPLE 20.1: Hotel Reservations: Inventory ManagementDocument2 pagesEXAMPLE 20.1: Hotel Reservations: Inventory Managementkael invokerNo ratings yet

- 1767-2NW4 1Document1 page1767-2NW4 1jcogollo88No ratings yet

- Grafik Total Padatan TerlarutDocument7 pagesGrafik Total Padatan TerlarutRiselena Alyssa AmaDheaNo ratings yet

- Annexure B Xlpe Derating FactorDocument2 pagesAnnexure B Xlpe Derating FactorKARAN PARIKHNo ratings yet

- V19 C12 148macdDocument8 pagesV19 C12 148macdRaditya Ananta NugrohoNo ratings yet

- Simulation and Forecasting Solutions: (From Table) (No. of Cars)Document18 pagesSimulation and Forecasting Solutions: (From Table) (No. of Cars)Debbie DebzNo ratings yet

- AgungDocument4 pagesAgungBela PrayogaNo ratings yet

- Vendor Rating - ExampleDocument5 pagesVendor Rating - Exampleaditya23986No ratings yet

- YTD Production StatusDocument29 pagesYTD Production StatusSeif CharafNo ratings yet

- Monte Carlo SimpleDocument24 pagesMonte Carlo SimpleDebasish DeyNo ratings yet

- % Weight (Sample) Graph: Screen Size (MM)Document5 pages% Weight (Sample) Graph: Screen Size (MM)Avian Tri KuncoroNo ratings yet

- Group AssignmentDocument3 pagesGroup Assignmentchegger accountNo ratings yet

- Pdfanddoc 834944 PDFDocument78 pagesPdfanddoc 834944 PDFAshish RanjangaonkarNo ratings yet

- Financial Statement Analysis: Grameenphone (2012-2016)Document24 pagesFinancial Statement Analysis: Grameenphone (2012-2016)Syed Mahmudul MuddassirNo ratings yet

- AbsDocument3 pagesAbsAmalime RuthNo ratings yet

- Customer Satisfaction Dashboard: Customer Effort Customer Retention Net PromoterDocument6 pagesCustomer Satisfaction Dashboard: Customer Effort Customer Retention Net Promoterenfa.patriziaNo ratings yet

- Lampiran: Hasil Uji Statistik Normalitas Data Case Processing SummaryDocument9 pagesLampiran: Hasil Uji Statistik Normalitas Data Case Processing SummaryWisanggeni RinandiNo ratings yet

- Agosto 23, 2020 20:04:52 3.3.14.0 - User - Company (Lavteam 31337)Document1 pageAgosto 23, 2020 20:04:52 3.3.14.0 - User - Company (Lavteam 31337)jcogollo88No ratings yet

- Escala Comisiones Prevendedores Escala de Comisiones SupervisoresDocument4 pagesEscala Comisiones Prevendedores Escala de Comisiones SupervisoresEnrique CosioNo ratings yet

- Component-A (MVC)Document16 pagesComponent-A (MVC)westewrNo ratings yet

- 6130 Test 2.2 PracticeDocument15 pages6130 Test 2.2 PracticeTash KentNo ratings yet

- Lesson 3.4Document7 pagesLesson 3.4MitzlNo ratings yet

- Traffic Rep0318Document20 pagesTraffic Rep0318Yaruqh KhanNo ratings yet

- Uts ImamDocument3 pagesUts ImamAde MaulanaNo ratings yet

- Kadar Air Pak Hasmar FixDocument11 pagesKadar Air Pak Hasmar FixMUHAMMAD IRWANNo ratings yet

- Ca BS 7671Document1 pageCa BS 7671Nawarathna Engineering Dept.No ratings yet

- Correlation and Model ErrorDocument7 pagesCorrelation and Model ErrorANIL PALNo ratings yet

- Final SimulationDocument71 pagesFinal SimulationNivedita JoshiNo ratings yet

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- BAV Examination Pre-ReadDocument10 pagesBAV Examination Pre-ReadAninda DuttaNo ratings yet

- Data To Use - Detail InformationDocument44 pagesData To Use - Detail InformationAninda DuttaNo ratings yet

- (All Non-Ratios in Millions)Document13 pages(All Non-Ratios in Millions)Aninda DuttaNo ratings yet

- Justdial Case Solution - 20191221001741Document8 pagesJustdial Case Solution - 20191221001741Aninda DuttaNo ratings yet

- Flipkart Solution-20191214161149Document2 pagesFlipkart Solution-20191214161149Aninda DuttaNo ratings yet

- Session 2 Getting Acquainted With The Platform R - A Brief: InstallationDocument3 pagesSession 2 Getting Acquainted With The Platform R - A Brief: InstallationAninda DuttaNo ratings yet

- Usiness Analytics Using R: Final Group PresentationDocument11 pagesUsiness Analytics Using R: Final Group PresentationAninda DuttaNo ratings yet

- Amazon's India Strategy: Focus On Every Geography To Become 'Everything For Everyone'Document2 pagesAmazon's India Strategy: Focus On Every Geography To Become 'Everything For Everyone'Aninda DuttaNo ratings yet

- Session 3 - Getting Familiar With R Interface A Brief SummaryDocument2 pagesSession 3 - Getting Familiar With R Interface A Brief SummaryAninda DuttaNo ratings yet

- BAR-Classification ModellingDocument2 pagesBAR-Classification ModellingAninda DuttaNo ratings yet

- Association Toy ExampleDocument1 pageAssociation Toy ExampleAninda DuttaNo ratings yet

- Classification Models-IntuitionDocument17 pagesClassification Models-IntuitionAninda DuttaNo ratings yet

- Manufact Model Sales Price Type Engine - S HorsepowDocument21 pagesManufact Model Sales Price Type Engine - S HorsepowAninda DuttaNo ratings yet

- Business Model Research ofDocument38 pagesBusiness Model Research ofAninda DuttaNo ratings yet

- Business Analytics Using R-Course OutlineDocument3 pagesBusiness Analytics Using R-Course OutlineAninda DuttaNo ratings yet

- Beacon/ Palo: Source: Company DocumentsDocument3 pagesBeacon/ Palo: Source: Company DocumentsAninda DuttaNo ratings yet

- Majority Stake in Flipkart $1.4 Billion Paytm Mall: I Analyze Trends and Current Events in Technology, Marketing and AIDocument5 pagesMajority Stake in Flipkart $1.4 Billion Paytm Mall: I Analyze Trends and Current Events in Technology, Marketing and AIAninda DuttaNo ratings yet

- Specialty Pharmacies Toe The Line Between Access, Cost and OutcomesDocument11 pagesSpecialty Pharmacies Toe The Line Between Access, Cost and OutcomesAninda DuttaNo ratings yet

- The Journey To Innovation Is A Long One ... : Why Leading Innovators Think Like ExplorersDocument1 pageThe Journey To Innovation Is A Long One ... : Why Leading Innovators Think Like ExplorersAninda DuttaNo ratings yet

- Business Valuaton: Rajiv Bhutani IIM Sambalpur 2018Document24 pagesBusiness Valuaton: Rajiv Bhutani IIM Sambalpur 2018Aninda DuttaNo ratings yet

- Am at Photogr 21 February 2015Document92 pagesAm at Photogr 21 February 2015TraficantdePufarineNo ratings yet

- SuperWale Data SheetDocument8 pagesSuperWale Data SheetMagnum CompositesNo ratings yet

- ADT Service ManualDocument152 pagesADT Service ManualZakhele MpofuNo ratings yet

- SR Designworks: Head OfficeDocument15 pagesSR Designworks: Head Officeihameed4100% (1)

- PDS01.05.001 - Wouter Witzel - EVBLSDocument3 pagesPDS01.05.001 - Wouter Witzel - EVBLSVilius BukysNo ratings yet

- Questão 20: Língua Inglesa 11 A 20Document3 pagesQuestão 20: Língua Inglesa 11 A 20Gabriel TeodoroNo ratings yet

- Moxon Sat AntDocument4 pagesMoxon Sat AntMaureen PegusNo ratings yet

- MC Practicals 2Document12 pagesMC Practicals 2Adi AdnanNo ratings yet

- Xenon Arc Exposure Test With Enhanced Light and Water Exposure For Transportation CoatingsDocument10 pagesXenon Arc Exposure Test With Enhanced Light and Water Exposure For Transportation Coatingso_l_0No ratings yet

- Plantain Breeding at CRBP: Strategies, Results and OutlookDocument5 pagesPlantain Breeding at CRBP: Strategies, Results and OutlookCédric KENDINE VEPOWONo ratings yet

- The Microsoft-Nokia Strategic Alliance PDFDocument25 pagesThe Microsoft-Nokia Strategic Alliance PDFmehedee129No ratings yet

- Harris Ts100 User ManualDocument24 pagesHarris Ts100 User ManualMiguel Alfonso Ruiz MendezNo ratings yet

- Chapter 1: Scientific Understanding of Behavior: Learning ObjectivesDocument13 pagesChapter 1: Scientific Understanding of Behavior: Learning Objectiveshallo BroNo ratings yet

- Procurement PlanDocument32 pagesProcurement Planario widjaksono100% (1)

- ASX Announcement 2021 23 - CRU Conference PresentationDocument26 pagesASX Announcement 2021 23 - CRU Conference PresentationÂngelo PereiraNo ratings yet

- December 2016Document192 pagesDecember 2016Ramesh MankaniNo ratings yet

- Author's Purpose Mini PassagesDocument5 pagesAuthor's Purpose Mini Passages18118No ratings yet

- Caserm/D: Publication Ordering InformationDocument326 pagesCaserm/D: Publication Ordering InformationjohnNo ratings yet

- File DisksDocument22 pagesFile DisksAlana PetersonNo ratings yet

- Rija PEEEL-TEEEL Paragraph Structure - Questions and Sentence StartersDocument1 pageRija PEEEL-TEEEL Paragraph Structure - Questions and Sentence Starterssaira sNo ratings yet

- Carbon Dioxide CO2 SensorDocument4 pagesCarbon Dioxide CO2 SensorgouttNo ratings yet

- DB Broadcast PM300 ManualDocument108 pagesDB Broadcast PM300 Manualfransferdinand2001100% (1)

- Translator 文华在线教育 - Collaboration Agreement Bilingual TemplateDocument5 pagesTranslator 文华在线教育 - Collaboration Agreement Bilingual TemplateАлтер КацизнеNo ratings yet

- Backtracking - Set 2 (Rat in A Maze) - GeeksforGeeksDocument7 pagesBacktracking - Set 2 (Rat in A Maze) - GeeksforGeeksAtul GargNo ratings yet

- Colah Github Io Posts 2015 08 Understanding LSTMsDocument16 pagesColah Github Io Posts 2015 08 Understanding LSTMsMithun PantNo ratings yet

- Classroom Management: Chapter 4 Richards/Renandya Methodology in Language Teaching. (Marilyn Lewis)Document4 pagesClassroom Management: Chapter 4 Richards/Renandya Methodology in Language Teaching. (Marilyn Lewis)Florencia CorenaNo ratings yet

- Industrial Training ReportDocument6 pagesIndustrial Training Reportmayank guptaNo ratings yet

Group 1 - Sun Microsystem - Group

Group 1 - Sun Microsystem - Group

Uploaded by

Aninda Dutta0 ratings0% found this document useful (0 votes)

51 views12 pagesSun Microsystems manages supplier relationships through a VP of Supplier Management and commodity managers. They identify needs 3-5 years out, select suppliers, and communicate requirements. Suppliers are evaluated on lead times, prices, quality, technology, and support. Top scoring suppliers receive more business and lower total cost of ownership scores.

Original Description:

Original Title

Group 1_Sun Microsystem_group_.pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSun Microsystems manages supplier relationships through a VP of Supplier Management and commodity managers. They identify needs 3-5 years out, select suppliers, and communicate requirements. Suppliers are evaluated on lead times, prices, quality, technology, and support. Top scoring suppliers receive more business and lower total cost of ownership scores.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

51 views12 pagesGroup 1 - Sun Microsystem - Group

Group 1 - Sun Microsystem - Group

Uploaded by

Aninda DuttaSun Microsystems manages supplier relationships through a VP of Supplier Management and commodity managers. They identify needs 3-5 years out, select suppliers, and communicate requirements. Suppliers are evaluated on lead times, prices, quality, technology, and support. Top scoring suppliers receive more business and lower total cost of ownership scores.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 12

Sun Microsystem: Managing

the Supplier Relationship

Group 1

Shubham Gupta

Rahul Sadhu

Kaushal Seth

Avneesh Bansal

Suraj Kandoi

Ameya Shire

Suman Sarkar

Company Background

• It is the leading supplier of enterprise computing products and

network workstations etc.

• It has 34% market share worldwide and some of its competitors

include HP,IBM, DEC, etc.

• They are highly cost focused company and is growing at a rapid pace

• There is significant pressure on SUN because of continuous

technological advances of personal computers

Business model

• They use a mix of standard industry components and 2 to 3 key

differentiators on which they are leading edge

• Standardization leads to lower cost due to economies of scale

• key product differentiators are: Scalability, Open System and

Proprietary Sun Technologies

• They use leverage model for manufacturing

1. Buy components/ Systems; assemble in house

2. Make and buy components/systems; assemble in house

3. Buy fully finished systems

Supplier Management

• Supplier management side comprises of VP of supplier management,

GCM, CM

• GCM heads multiple commodity managers and have 10-30 years of industrial

experience

• CM are responsible for managing relationship with suppliers, understand

there technological and manufacturing capacity

• CM’s are also responsible for maintaining score card of suppliers, act as point

of contact and internal advocate of the suppliers

Identification of Supplier Supplier Logistics

Negotiation Supplier Liaison

needs Identification communication Management

Identification of needs:

• Establish product requirements

• Understand technical direction

• Formulate 3-5 years strategy

Supplier Identification

• Determine make vs buy

• Pick sole-vs.-multiple suppliers

• Understand supplier capabilities; technical & manufacturing

Supplier communication

• Document product requirement

• Formulate an RFQ

Negotiation of Terms

• Develop contract agreement

Supplier Liaison

• Manage the scorecard

• Communicate with suppliers

Logistics Management

• Convey forecasts

• Control inventory costs

• Manage end-of-life cycle

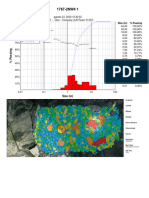

Lead-time rating Scheme

Demostration lead time Award points for lead time (max = 10)

At or below committed lead time 10

Less than 5% above committed lead time 6.6

5% to 9.9% above committed lead time 5

10% to 14.9% above committed lead time 3.3

15% to 24.9% above committed lead time 2

25% or more above committed lead time 0

Calculation of Lead-time award point and site roll-up score

Difference

Average Award point of Site roll up

Sun Part Number of compared to % above target

demonstrated lead time (Max score for lead

Number line items comittment of 30 of 30 days

in days = 10) time

days

17560 20 30 0 0% 10 0.95

17575 70 30 0 0% 10 3.33

17585 10 45 15 50% 0 0

17590 30 37 7 20% 2 0.29

17595 80 30 0 0% 10 3.81

Total 210 8.4

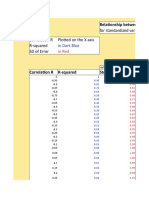

Price Index, as determined by ratio of Target Price to Actual Price

(Target Price)/(Actual Price) is (Target Price)/(Actual Price) is

Greater than or equal to less than Price Index

1.00 n/a 1.00

0.99 1.00 0.99

0.98 0.99 0.97

0.97 0.98 0.94

0.96 0.97 0.91

0.95 0.96 0.88

0.94 0.95 0.85

0.93 0.94 0.83

0.92 0.93 0.81

0.91 0.92 0.80

0.90 0.91 0.79

0.89 0.90 0.79

0.88 0.89 0.78

0.87 0.88 0.77

0.86 0.87 0.76

0.85 0.86 0.75

0.84 0.85 0.74

0.83 0.84 0.73

0.82 0.83 0.72

0.81 0.82 0.71

0.80 0.81 0.70

0.00 0.80* Target/Actual - 0.12

* Minimum price index is 0.50

Sample Calculation of the Scorecard

Score

Category Global Scores

Quality 27

Leadtime/ Delivery/ Flexibility 26

Technology 20

Support 15

Total for Performance Matrix 88

Price Index 0.98

Score Score 86.24

Total Cost of Ownership (TCOO) is calculated:

TCOO= [(100 – Score)/100]+1

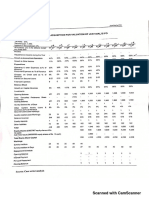

SMCC Scorecard- Electrical Components Quarter:

SUMMARY - SUPPLY UNIT or GLOBAL RESULTS FY:

Scorecard for: Commodity Rated: Done on:

Category Subcategory Data or Comment Max Points Actual Points Score

Receiving Inspection -8.00

Total Failure Rate (RPM/DPM) 20.00

Failure Vertification/ Retest 2.00

Quality

FA/ Corrective Action 8.00

Purge or Stop Ship -10.00

PPA, DOA, or Field Problem -10.00

Quality Subtotal: 30.00 pts

Lead/ Delivery/ Flexibity Leadtime 10.00

On-time delivery 15.00

Flexibility 5.00

L/D/F Subtotal: 30.00 pts

Product 9.00

Technology Manufacturing 16.00

Technology Subtot: 25.00 pts

Materials/ Purchasing 10.00

Support Sustaining Technical 5.00

Support Subtotal: 15.00 pts

Performance Matrix Total 100.00

Price Index 1.00

Score = performance matrix*price index 100.00

Total Cost of Ownership = [(100- Score)/100]+1 Goal: 1.00

Prior Performance Matrix Score:

Prior Price Performance:

Prior Total Cost of Ownership:

Thank You

You might also like

- The Sanlam Brand: Connecting Hearts and Minds MeaningfullyDocument26 pagesThe Sanlam Brand: Connecting Hearts and Minds MeaningfullyXolani Radebe RadebeNo ratings yet

- Arcadia - Syndicate 9Document6 pagesArcadia - Syndicate 9Uus FirdausNo ratings yet

- Business Valuation: Rajiv Bhutani IIM Sambalpur 2018Document21 pagesBusiness Valuation: Rajiv Bhutani IIM Sambalpur 2018Aninda DuttaNo ratings yet

- How To Formulate UVDocument16 pagesHow To Formulate UVtobass82100% (3)

- Iec 61400-22Document59 pagesIec 61400-22Barbu Alexandru Iulian50% (2)

- Group 1 - Sun MicrosystemDocument6 pagesGroup 1 - Sun MicrosystemAninda DuttaNo ratings yet

- 3.PDA Cigulung-MaribayaDocument14 pages3.PDA Cigulung-MaribayaigitNo ratings yet

- Current Raitings XLPEDocument1 pageCurrent Raitings XLPEshakeel212No ratings yet

- Lecture 4 - Simulation of A Queuing ProblemDocument13 pagesLecture 4 - Simulation of A Queuing ProblemMihlaliNo ratings yet

- Libro 1Document3 pagesLibro 1Kmby GabrielaNo ratings yet

- Automate+Worksheet+Population 27+feb+2024Document6 pagesAutomate+Worksheet+Population 27+feb+2024ponmanipm.054No ratings yet

- 6.PDA Cikapundung-MaribayaDocument14 pages6.PDA Cikapundung-MaribayaigitNo ratings yet

- Lab 03 Worksheet - Taylor Ingram DAR 3Document3 pagesLab 03 Worksheet - Taylor Ingram DAR 3tylringramNo ratings yet

- Service Factor Table - Tony Wild - 2002Document1 pageService Factor Table - Tony Wild - 2002jardineria de occidenteNo ratings yet

- Pulley On Shaft EfficiencyDocument2 pagesPulley On Shaft EfficiencyAndy YanNo ratings yet

- LMP-Lampiran - KPI USE April 2019 PT PERTAMINA F1.0-28-05-2019 - 170832943Document8 pagesLMP-Lampiran - KPI USE April 2019 PT PERTAMINA F1.0-28-05-2019 - 170832943Agung Ananta PutraNo ratings yet

- Attribute Statistical ReportDocument1 pageAttribute Statistical ReportQuality VenusNo ratings yet

- ClarksonDocument22 pagesClarksonfrankstandaert8714No ratings yet

- ALABAM A CaseDocument7 pagesALABAM A Casenesec62195No ratings yet

- BiostatDocument7 pagesBiostatyoan yulista hartivaNo ratings yet

- Table 21 25Document1 pageTable 21 25Ashwary Sheel Wali Research Scholar, Dept of Mech Engg., IIT (BHU)No ratings yet

- 7 QC ToolsDocument20 pages7 QC ToolsSotepNo ratings yet

- Revenue Leakage 07172019Document30 pagesRevenue Leakage 07172019AnkushNo ratings yet

- BBHS Level of Proficiency TLE HIGH SCHOOL 1st QuarterDocument11 pagesBBHS Level of Proficiency TLE HIGH SCHOOL 1st QuarterSmaw Iron RodNo ratings yet

- Employee TurnoverDocument20 pagesEmployee Turnoversneha fabeyNo ratings yet

- Lagtime AnalysisDocument7 pagesLagtime AnalysisRahul MayeeNo ratings yet

- Simula Encargos 1.2Document2 pagesSimula Encargos 1.2Fabio.soares RhNo ratings yet

- Project Report: Aman Mishra C-5 Sandeep Kumar C-61 Amanat Singh C-53 Abhishek Kumar 2020 - 22Document54 pagesProject Report: Aman Mishra C-5 Sandeep Kumar C-61 Amanat Singh C-53 Abhishek Kumar 2020 - 22AMAN MISHRANo ratings yet

- Gradation Fineness Modulus 9.43: Mass of Oven Dried Sample (G)Document3 pagesGradation Fineness Modulus 9.43: Mass of Oven Dried Sample (G)Joshua AbadNo ratings yet

- St. Louis Luxury Market Overview - August 9, 2010Document1 pageSt. Louis Luxury Market Overview - August 9, 2010rtnoltingNo ratings yet

- Diagrama de Massas - AlunosDocument5 pagesDiagrama de Massas - AlunosGuilherme NogueiraNo ratings yet

- Criterion - % Gravel 99.47 % 4 % Sand 0.41 % 1 CC 3 % Fine 0.14 % - % Total 100.00%Document3 pagesCriterion - % Gravel 99.47 % 4 % Sand 0.41 % 1 CC 3 % Fine 0.14 % - % Total 100.00%Joshua AbadNo ratings yet

- Sikap KorupsiDocument5 pagesSikap KorupsiRisyah Iriansyah100% (1)

- Moly-Cop Tools (Version 3.0) : Particle Size DistributionDocument3 pagesMoly-Cop Tools (Version 3.0) : Particle Size DistributionKelvin Gonzalez SanchezNo ratings yet

- Free CoolingDocument2,457 pagesFree CoolingBrad UpsonNo ratings yet

- EXAMPLE 20.1: Hotel Reservations: Inventory ManagementDocument2 pagesEXAMPLE 20.1: Hotel Reservations: Inventory Managementkael invokerNo ratings yet

- 1767-2NW4 1Document1 page1767-2NW4 1jcogollo88No ratings yet

- Grafik Total Padatan TerlarutDocument7 pagesGrafik Total Padatan TerlarutRiselena Alyssa AmaDheaNo ratings yet

- Annexure B Xlpe Derating FactorDocument2 pagesAnnexure B Xlpe Derating FactorKARAN PARIKHNo ratings yet

- V19 C12 148macdDocument8 pagesV19 C12 148macdRaditya Ananta NugrohoNo ratings yet

- Simulation and Forecasting Solutions: (From Table) (No. of Cars)Document18 pagesSimulation and Forecasting Solutions: (From Table) (No. of Cars)Debbie DebzNo ratings yet

- AgungDocument4 pagesAgungBela PrayogaNo ratings yet

- Vendor Rating - ExampleDocument5 pagesVendor Rating - Exampleaditya23986No ratings yet

- YTD Production StatusDocument29 pagesYTD Production StatusSeif CharafNo ratings yet

- Monte Carlo SimpleDocument24 pagesMonte Carlo SimpleDebasish DeyNo ratings yet

- % Weight (Sample) Graph: Screen Size (MM)Document5 pages% Weight (Sample) Graph: Screen Size (MM)Avian Tri KuncoroNo ratings yet

- Group AssignmentDocument3 pagesGroup Assignmentchegger accountNo ratings yet

- Pdfanddoc 834944 PDFDocument78 pagesPdfanddoc 834944 PDFAshish RanjangaonkarNo ratings yet

- Financial Statement Analysis: Grameenphone (2012-2016)Document24 pagesFinancial Statement Analysis: Grameenphone (2012-2016)Syed Mahmudul MuddassirNo ratings yet

- AbsDocument3 pagesAbsAmalime RuthNo ratings yet

- Customer Satisfaction Dashboard: Customer Effort Customer Retention Net PromoterDocument6 pagesCustomer Satisfaction Dashboard: Customer Effort Customer Retention Net Promoterenfa.patriziaNo ratings yet

- Lampiran: Hasil Uji Statistik Normalitas Data Case Processing SummaryDocument9 pagesLampiran: Hasil Uji Statistik Normalitas Data Case Processing SummaryWisanggeni RinandiNo ratings yet

- Agosto 23, 2020 20:04:52 3.3.14.0 - User - Company (Lavteam 31337)Document1 pageAgosto 23, 2020 20:04:52 3.3.14.0 - User - Company (Lavteam 31337)jcogollo88No ratings yet

- Escala Comisiones Prevendedores Escala de Comisiones SupervisoresDocument4 pagesEscala Comisiones Prevendedores Escala de Comisiones SupervisoresEnrique CosioNo ratings yet

- Component-A (MVC)Document16 pagesComponent-A (MVC)westewrNo ratings yet

- 6130 Test 2.2 PracticeDocument15 pages6130 Test 2.2 PracticeTash KentNo ratings yet

- Lesson 3.4Document7 pagesLesson 3.4MitzlNo ratings yet

- Traffic Rep0318Document20 pagesTraffic Rep0318Yaruqh KhanNo ratings yet

- Uts ImamDocument3 pagesUts ImamAde MaulanaNo ratings yet

- Kadar Air Pak Hasmar FixDocument11 pagesKadar Air Pak Hasmar FixMUHAMMAD IRWANNo ratings yet

- Ca BS 7671Document1 pageCa BS 7671Nawarathna Engineering Dept.No ratings yet

- Correlation and Model ErrorDocument7 pagesCorrelation and Model ErrorANIL PALNo ratings yet

- Final SimulationDocument71 pagesFinal SimulationNivedita JoshiNo ratings yet

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- BAV Examination Pre-ReadDocument10 pagesBAV Examination Pre-ReadAninda DuttaNo ratings yet

- Data To Use - Detail InformationDocument44 pagesData To Use - Detail InformationAninda DuttaNo ratings yet

- (All Non-Ratios in Millions)Document13 pages(All Non-Ratios in Millions)Aninda DuttaNo ratings yet

- Justdial Case Solution - 20191221001741Document8 pagesJustdial Case Solution - 20191221001741Aninda DuttaNo ratings yet

- Flipkart Solution-20191214161149Document2 pagesFlipkart Solution-20191214161149Aninda DuttaNo ratings yet

- Session 2 Getting Acquainted With The Platform R - A Brief: InstallationDocument3 pagesSession 2 Getting Acquainted With The Platform R - A Brief: InstallationAninda DuttaNo ratings yet

- Usiness Analytics Using R: Final Group PresentationDocument11 pagesUsiness Analytics Using R: Final Group PresentationAninda DuttaNo ratings yet

- Amazon's India Strategy: Focus On Every Geography To Become 'Everything For Everyone'Document2 pagesAmazon's India Strategy: Focus On Every Geography To Become 'Everything For Everyone'Aninda DuttaNo ratings yet

- Session 3 - Getting Familiar With R Interface A Brief SummaryDocument2 pagesSession 3 - Getting Familiar With R Interface A Brief SummaryAninda DuttaNo ratings yet

- BAR-Classification ModellingDocument2 pagesBAR-Classification ModellingAninda DuttaNo ratings yet

- Association Toy ExampleDocument1 pageAssociation Toy ExampleAninda DuttaNo ratings yet

- Classification Models-IntuitionDocument17 pagesClassification Models-IntuitionAninda DuttaNo ratings yet

- Manufact Model Sales Price Type Engine - S HorsepowDocument21 pagesManufact Model Sales Price Type Engine - S HorsepowAninda DuttaNo ratings yet

- Business Model Research ofDocument38 pagesBusiness Model Research ofAninda DuttaNo ratings yet

- Business Analytics Using R-Course OutlineDocument3 pagesBusiness Analytics Using R-Course OutlineAninda DuttaNo ratings yet

- Beacon/ Palo: Source: Company DocumentsDocument3 pagesBeacon/ Palo: Source: Company DocumentsAninda DuttaNo ratings yet

- Majority Stake in Flipkart $1.4 Billion Paytm Mall: I Analyze Trends and Current Events in Technology, Marketing and AIDocument5 pagesMajority Stake in Flipkart $1.4 Billion Paytm Mall: I Analyze Trends and Current Events in Technology, Marketing and AIAninda DuttaNo ratings yet

- Specialty Pharmacies Toe The Line Between Access, Cost and OutcomesDocument11 pagesSpecialty Pharmacies Toe The Line Between Access, Cost and OutcomesAninda DuttaNo ratings yet

- The Journey To Innovation Is A Long One ... : Why Leading Innovators Think Like ExplorersDocument1 pageThe Journey To Innovation Is A Long One ... : Why Leading Innovators Think Like ExplorersAninda DuttaNo ratings yet

- Business Valuaton: Rajiv Bhutani IIM Sambalpur 2018Document24 pagesBusiness Valuaton: Rajiv Bhutani IIM Sambalpur 2018Aninda DuttaNo ratings yet

- Am at Photogr 21 February 2015Document92 pagesAm at Photogr 21 February 2015TraficantdePufarineNo ratings yet

- SuperWale Data SheetDocument8 pagesSuperWale Data SheetMagnum CompositesNo ratings yet

- ADT Service ManualDocument152 pagesADT Service ManualZakhele MpofuNo ratings yet

- SR Designworks: Head OfficeDocument15 pagesSR Designworks: Head Officeihameed4100% (1)

- PDS01.05.001 - Wouter Witzel - EVBLSDocument3 pagesPDS01.05.001 - Wouter Witzel - EVBLSVilius BukysNo ratings yet

- Questão 20: Língua Inglesa 11 A 20Document3 pagesQuestão 20: Língua Inglesa 11 A 20Gabriel TeodoroNo ratings yet

- Moxon Sat AntDocument4 pagesMoxon Sat AntMaureen PegusNo ratings yet

- MC Practicals 2Document12 pagesMC Practicals 2Adi AdnanNo ratings yet

- Xenon Arc Exposure Test With Enhanced Light and Water Exposure For Transportation CoatingsDocument10 pagesXenon Arc Exposure Test With Enhanced Light and Water Exposure For Transportation Coatingso_l_0No ratings yet

- Plantain Breeding at CRBP: Strategies, Results and OutlookDocument5 pagesPlantain Breeding at CRBP: Strategies, Results and OutlookCédric KENDINE VEPOWONo ratings yet

- The Microsoft-Nokia Strategic Alliance PDFDocument25 pagesThe Microsoft-Nokia Strategic Alliance PDFmehedee129No ratings yet

- Harris Ts100 User ManualDocument24 pagesHarris Ts100 User ManualMiguel Alfonso Ruiz MendezNo ratings yet

- Chapter 1: Scientific Understanding of Behavior: Learning ObjectivesDocument13 pagesChapter 1: Scientific Understanding of Behavior: Learning Objectiveshallo BroNo ratings yet

- Procurement PlanDocument32 pagesProcurement Planario widjaksono100% (1)

- ASX Announcement 2021 23 - CRU Conference PresentationDocument26 pagesASX Announcement 2021 23 - CRU Conference PresentationÂngelo PereiraNo ratings yet

- December 2016Document192 pagesDecember 2016Ramesh MankaniNo ratings yet

- Author's Purpose Mini PassagesDocument5 pagesAuthor's Purpose Mini Passages18118No ratings yet

- Caserm/D: Publication Ordering InformationDocument326 pagesCaserm/D: Publication Ordering InformationjohnNo ratings yet

- File DisksDocument22 pagesFile DisksAlana PetersonNo ratings yet

- Rija PEEEL-TEEEL Paragraph Structure - Questions and Sentence StartersDocument1 pageRija PEEEL-TEEEL Paragraph Structure - Questions and Sentence Starterssaira sNo ratings yet

- Carbon Dioxide CO2 SensorDocument4 pagesCarbon Dioxide CO2 SensorgouttNo ratings yet

- DB Broadcast PM300 ManualDocument108 pagesDB Broadcast PM300 Manualfransferdinand2001100% (1)

- Translator 文华在线教育 - Collaboration Agreement Bilingual TemplateDocument5 pagesTranslator 文华在线教育 - Collaboration Agreement Bilingual TemplateАлтер КацизнеNo ratings yet

- Backtracking - Set 2 (Rat in A Maze) - GeeksforGeeksDocument7 pagesBacktracking - Set 2 (Rat in A Maze) - GeeksforGeeksAtul GargNo ratings yet

- Colah Github Io Posts 2015 08 Understanding LSTMsDocument16 pagesColah Github Io Posts 2015 08 Understanding LSTMsMithun PantNo ratings yet

- Classroom Management: Chapter 4 Richards/Renandya Methodology in Language Teaching. (Marilyn Lewis)Document4 pagesClassroom Management: Chapter 4 Richards/Renandya Methodology in Language Teaching. (Marilyn Lewis)Florencia CorenaNo ratings yet

- Industrial Training ReportDocument6 pagesIndustrial Training Reportmayank guptaNo ratings yet