Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

138 viewsTypes of Fermenters

Types of Fermenters

Uploaded by

Stephen MooreThe document describes four main types of fermenters: stirred tank bioreactors, airlift fermenters, bubble column fermenters, and fluidized bed bioreactors. Stirred tank bioreactors are widely used and have advantages like continuous operation, good temperature control, and easy cleaning. Airlift fermenters use gas sparging to create an upward liquid flow in the riser zone and downward flow in the downcomer zone. Bubble column fermenters sparge gas into a cylindrical chamber to transfer oxygen and mix the fluid. Fluidized bed bioreactors are similar to bubble columns but have an expanded top to reduce fluid velocity and retain solids.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- 12a. Introduction To Steam BoilersDocument17 pages12a. Introduction To Steam BoilersDr. BIBIN CHIDAMBARANATHANNo ratings yet

- ANSI Color CodesDocument2 pagesANSI Color CodesFrederik0No ratings yet

- Heat ExchangerDocument4 pagesHeat ExchangerIzwanaRahimiNo ratings yet

- II Law of GeneticsDocument10 pagesII Law of GeneticsStephen MooreNo ratings yet

- Coatings Word August 2012Document52 pagesCoatings Word August 2012sami_sakrNo ratings yet

- Flexural Strengthing of Beam With FRP LamintaesDocument6 pagesFlexural Strengthing of Beam With FRP LamintaesEngDbtNo ratings yet

- Construction of FermenterDocument23 pagesConstruction of FermenterSajjad Hossain ShuvoNo ratings yet

- Classification of BioreactorsDocument4 pagesClassification of Bioreactorssaahiba16No ratings yet

- TOPIC 5 - Types of BioreactorDocument35 pagesTOPIC 5 - Types of BioreactorfadhilahmadNo ratings yet

- PU01-301-33-012-023-D30-002 - Z15211-414-00 - Suction Box For Existing Silo - A01Document1 pagePU01-301-33-012-023-D30-002 - Z15211-414-00 - Suction Box For Existing Silo - A01Kriengsak RuangdechNo ratings yet

- 1b. Introduction - Classification of InstrumentDocument30 pages1b. Introduction - Classification of Instrumenttkjing33% (6)

- Installation and Operating Manual: GREENFILTER ABC - Compressed Air FilterDocument8 pagesInstallation and Operating Manual: GREENFILTER ABC - Compressed Air FilterSandeep50% (2)

- Valves PresentationDocument45 pagesValves PresentationChiheb Kaaniche100% (1)

- Thermodynamics of Microbial Growth and MetabolismDocument17 pagesThermodynamics of Microbial Growth and MetabolismJeimy MaciasNo ratings yet

- Pressure VesselDocument9 pagesPressure VesselbekkuNo ratings yet

- Fluid Flow in T-Junction of Pipes PDFDocument75 pagesFluid Flow in T-Junction of Pipes PDFpokengchemaNo ratings yet

- Tank Level Control ExperimentDocument3 pagesTank Level Control ExperimentLi Xue0% (1)

- w8 ManualDocument4 pagesw8 ManualPong VongNo ratings yet

- Gas - Liquid ChromatographyDocument14 pagesGas - Liquid ChromatographySELVI ANo ratings yet

- Mixing TankDocument3 pagesMixing Tankleslie_adolfoNo ratings yet

- Supply Air Diffuser Selection - Telecom Room at Upstream BuildingDocument17 pagesSupply Air Diffuser Selection - Telecom Room at Upstream BuildingKeerthi KrishnanNo ratings yet

- Tube Removal Catalog Web ELLIOTDocument24 pagesTube Removal Catalog Web ELLIOTJose Luis RattiaNo ratings yet

- Principal Types of Atmospheric Storage TanksDocument9 pagesPrincipal Types of Atmospheric Storage Tanksmohsen ranjbarNo ratings yet

- TGA - CalibrationDocument5 pagesTGA - CalibrationDiego FrancoNo ratings yet

- Shell and Tube Heat ExchangersDocument11 pagesShell and Tube Heat ExchangersSuresh SjNo ratings yet

- HDPE Pipe PresentationDocument17 pagesHDPE Pipe PresentationSiddiqui Muhammad AshfaqueNo ratings yet

- Melaku Tesfaye (Parafin Oil)Document55 pagesMelaku Tesfaye (Parafin Oil)aberNo ratings yet

- PETRO Cube BrochureDocument13 pagesPETRO Cube Brochurepaulm3565No ratings yet

- IMI Bopp+Reuther SIRADocument4 pagesIMI Bopp+Reuther SIRAangelo100% (1)

- Thermodynamics An Engineering Approach 8Document1 pageThermodynamics An Engineering Approach 8Aracely PenaNo ratings yet

- Habte Atle (Parafin Oil)Document87 pagesHabte Atle (Parafin Oil)aberNo ratings yet

- KT & Ky Parafin OilDocument45 pagesKT & Ky Parafin OilaberNo ratings yet

- 5 Sedimentary Hydrocarbons Biomarkers For Early LifeDocument53 pages5 Sedimentary Hydrocarbons Biomarkers For Early LifeLambok ManurungNo ratings yet

- Accra Workshop Jul07 - Topic 1Document32 pagesAccra Workshop Jul07 - Topic 1Lit Phen TuNo ratings yet

- BIOREACTOR DESIGN MixingDocument26 pagesBIOREACTOR DESIGN MixingFelix SunjayaNo ratings yet

- Determination of Chemical Oxygen DemandDocument9 pagesDetermination of Chemical Oxygen DemandAnand SolomonNo ratings yet

- Nutsche Filter DesignDocument6 pagesNutsche Filter Designmaurya888No ratings yet

- Proces Equipment Design Guide For FermenDocument23 pagesProces Equipment Design Guide For FermenTheodoros AtheridisNo ratings yet

- What Is Design Interpretation?Document17 pagesWhat Is Design Interpretation?Qaisir MehmoodNo ratings yet

- 02-Ideal Reactors 2008Document24 pages02-Ideal Reactors 2008maha20No ratings yet

- Flexible Intermediate Bulk Containers Specifications PDFDocument13 pagesFlexible Intermediate Bulk Containers Specifications PDFZahir Khira100% (1)

- Flying Wind Mill: by Shantanu Mandal Roll - 16ME62R015 Department of Mechanical Engineering IIT KharagpurDocument14 pagesFlying Wind Mill: by Shantanu Mandal Roll - 16ME62R015 Department of Mechanical Engineering IIT Kharagpuranon_688074713No ratings yet

- Ideas To Achieve Optimal Combination of Axial & Cross FlowDocument28 pagesIdeas To Achieve Optimal Combination of Axial & Cross FlowAmirah SufianNo ratings yet

- How Does It Work?: High Temperature ReservoirDocument28 pagesHow Does It Work?: High Temperature Reservoirsiddharthupes100% (1)

- ChE 404-Chapter 08Document38 pagesChE 404-Chapter 08aliNo ratings yet

- 8 Infrared Drying: November 2006Document17 pages8 Infrared Drying: November 2006satish kumarNo ratings yet

- Manometers: Types of ManometerDocument4 pagesManometers: Types of ManometerArun LogeshNo ratings yet

- Mogas Msds 2014-2Document39 pagesMogas Msds 2014-2KalkiHereNo ratings yet

- Butterfly ValveDocument25 pagesButterfly ValveRahul JadhavNo ratings yet

- Compressible Flow Bench: Yeditepe University Department of Mechanical EngineeringDocument5 pagesCompressible Flow Bench: Yeditepe University Department of Mechanical EngineeringAhmad AbukhashabehNo ratings yet

- PSG 02 Issue 01 Dated 20 03 00Document29 pagesPSG 02 Issue 01 Dated 20 03 00uriiiNo ratings yet

- 3 Element ControlDocument5 pages3 Element Controlugun87No ratings yet

- A Study On The PH of Commonly Used Soaps/cleansers Available in The Indian MarketDocument3 pagesA Study On The PH of Commonly Used Soaps/cleansers Available in The Indian MarketpalliNo ratings yet

- Presented By: Merry Ann M. Cabral BSME-421Document36 pagesPresented By: Merry Ann M. Cabral BSME-421Marlon Evangelista100% (1)

- LPG Pump IOM LGL2 LGL3 PDFDocument12 pagesLPG Pump IOM LGL2 LGL3 PDFAfani Roma A100% (1)

- E7200 10 02 08 - D Type FilterDocument8 pagesE7200 10 02 08 - D Type FiltermecambNo ratings yet

- Solutions For Long-Term Storage of Electronic Components and CompositionsDocument3 pagesSolutions For Long-Term Storage of Electronic Components and CompositionsJoão Pedro AlmeidaNo ratings yet

- Richards Bay Minerals: General RBM ProcedureDocument7 pagesRichards Bay Minerals: General RBM ProcedureHuzaifa KtkNo ratings yet

- Specification For GasketsDocument8 pagesSpecification For GasketsMehdi NouriNo ratings yet

- Chapter 8 Steam CondenserDocument53 pagesChapter 8 Steam CondenserPHƯƠNG ĐẶNG YẾN100% (1)

- Bioreactor Types For Products of Microbial, Plant and Animal OriginDocument45 pagesBioreactor Types For Products of Microbial, Plant and Animal Origint.a.m.cooldarkboyNo ratings yet

- Fermentation: Presented By: Sagar Dutt 1 Year M.Pharm Sdpgips Pt. B.D. Sharma UhsrDocument25 pagesFermentation: Presented By: Sagar Dutt 1 Year M.Pharm Sdpgips Pt. B.D. Sharma UhsrAparna RohillaNo ratings yet

- Reactors Ppt4Document55 pagesReactors Ppt4DanishNo ratings yet

- Microbial Analysis of WaterDocument9 pagesMicrobial Analysis of WaterStephen Moore0% (1)

- ExtremophilesDocument7 pagesExtremophilesStephen MooreNo ratings yet

- Extremely Thermophilic S - MetabolizersDocument2 pagesExtremely Thermophilic S - MetabolizersStephen MooreNo ratings yet

- Microbiology Environmental Factors Affecting GrowthDocument10 pagesMicrobiology Environmental Factors Affecting GrowthStephen MooreNo ratings yet

- Microbiology Methods of Monitoring PopulationsDocument17 pagesMicrobiology Methods of Monitoring PopulationsStephen MooreNo ratings yet

- List of PhDs in ShodhgangaDocument2 pagesList of PhDs in ShodhgangaStephen MooreNo ratings yet

- Microbiology Basic and Applied: Dr. Bipinraj N KDocument165 pagesMicrobiology Basic and Applied: Dr. Bipinraj N KStephen MooreNo ratings yet

- BBT Genetics 1Document7 pagesBBT Genetics 1Stephen MooreNo ratings yet

- NAAC SSR For Affiliated CollegesDocument195 pagesNAAC SSR For Affiliated CollegesStephen MooreNo ratings yet

- Genetics PracticalsDocument5 pagesGenetics PracticalsStephen MooreNo ratings yet

- TransposonsDocument7 pagesTransposonsStephen MooreNo ratings yet

- ProtocolDocument2 pagesProtocolStephen MooreNo ratings yet

- Landguard A900: An Enzyme-Based Remediant For The Detoxification of Organophosphate Insecticides in Animal DipsDocument31 pagesLandguard A900: An Enzyme-Based Remediant For The Detoxification of Organophosphate Insecticides in Animal DipsStephen MooreNo ratings yet

- ProtocolDocument2 pagesProtocolStephen MooreNo ratings yet

- B.Sc. Biotechnology Semester IV BBT 401: Practicals in Molecular Biology Total 15 PDocument1 pageB.Sc. Biotechnology Semester IV BBT 401: Practicals in Molecular Biology Total 15 PStephen MooreNo ratings yet

- Potential Impact of Alternaria Macrospora On Cotton Production in West TexasDocument14 pagesPotential Impact of Alternaria Macrospora On Cotton Production in West TexasStephen MooreNo ratings yet

- Bvu-Rgitbt B.Sc. Biotechnology Sem V Test No.2 Subject Genetics. Topic ChromosomeDocument1 pageBvu-Rgitbt B.Sc. Biotechnology Sem V Test No.2 Subject Genetics. Topic ChromosomeStephen MooreNo ratings yet

- Bvu-Rgitbt B.Sc. Biotechnology Sem V Test No.1 Subject Genetics Topic Concepts of GeneticsDocument1 pageBvu-Rgitbt B.Sc. Biotechnology Sem V Test No.1 Subject Genetics Topic Concepts of GeneticsStephen MooreNo ratings yet

- Course Med BTDocument2 pagesCourse Med BTStephen MooreNo ratings yet

- Rajiv Gandhi Institute of IT and BiotechnologyDocument2 pagesRajiv Gandhi Institute of IT and BiotechnologyStephen MooreNo ratings yet

- Case Study-Failure in SolebarDocument24 pagesCase Study-Failure in SolebardonendrajNo ratings yet

- Enciclopedia de SoldaduraDocument768 pagesEnciclopedia de SoldaduraJORGEHERRNo ratings yet

- Overview of Materials For Polypropylene With 20% Glass Fiber FillerDocument4 pagesOverview of Materials For Polypropylene With 20% Glass Fiber FillerbiroutiNo ratings yet

- Packaging PDFDocument48 pagesPackaging PDFDebasis Kumar SahaNo ratings yet

- Seattle City LightDocument6 pagesSeattle City Lightfasih_baqai4252No ratings yet

- Types of Peripheral Devices:: Printer IsDocument1 pageTypes of Peripheral Devices:: Printer Issky29No ratings yet

- Aashto T 88Document20 pagesAashto T 88nedkovbgNo ratings yet

- History of Drill Consumable ControlDocument8 pagesHistory of Drill Consumable ControlanfiboleNo ratings yet

- Bettis Valve Actuator GuideDocument12 pagesBettis Valve Actuator Guideprufino2No ratings yet

- Brosur Tokico Dan Data Sheet-D7a93-3206 339Document6 pagesBrosur Tokico Dan Data Sheet-D7a93-3206 339galih santosoNo ratings yet

- GPCB SOP For De-Contamination FacilityDocument9 pagesGPCB SOP For De-Contamination FacilityEHS HalolNo ratings yet

- Designing Piping For Gravity Flow PDFDocument4 pagesDesigning Piping For Gravity Flow PDFicingrock100% (2)

- SBS5311 1718 07-RefrigerationDocument66 pagesSBS5311 1718 07-RefrigerationSam C M Hui100% (1)

- SSP 255Document40 pagesSSP 255get_prasadns3358100% (1)

- 555 Datasheet Revb1Document8 pages555 Datasheet Revb1Flavio GaluppoNo ratings yet

- Pilot Valve SizingDocument4 pagesPilot Valve SizingJason ThomasNo ratings yet

- Pre Requisite Programs Main PresentationDocument19 pagesPre Requisite Programs Main PresentationASIF EJAZNo ratings yet

- Alwasail Electrofusion CatalogueDocument24 pagesAlwasail Electrofusion Cataloguenour eldinNo ratings yet

- Is 1626 Part 3Document14 pagesIs 1626 Part 3Sheetal JindalNo ratings yet

- CTM HardnessTests SoWDocument6 pagesCTM HardnessTests SoWkratos_upcNo ratings yet

- Drs 2170Document4 pagesDrs 2170Ronaldo JuniorNo ratings yet

- BSR Inspection Case Study - CycloneDocument12 pagesBSR Inspection Case Study - Cyclonelinhcdt3100% (1)

- Pattern Disk FilterDocument3 pagesPattern Disk FilterIqbalNo ratings yet

- Lubricants in Refrigerant Systems: Related Commercial ResourcesDocument29 pagesLubricants in Refrigerant Systems: Related Commercial ResourcesAndrés Felipe NaranjoNo ratings yet

- US4143639 Friction Heat Space Heater, Eugene FrenetteDocument6 pagesUS4143639 Friction Heat Space Heater, Eugene FrenetteBastien Gall de SilléNo ratings yet

- Aldesme - Flash25 Stair PressurisationDocument8 pagesAldesme - Flash25 Stair PressurisationjaicektmNo ratings yet

- Stanley Stella LookbookDocument126 pagesStanley Stella LookbookOCC ApparelNo ratings yet

Types of Fermenters

Types of Fermenters

Uploaded by

Stephen Moore0 ratings0% found this document useful (0 votes)

138 views9 pagesThe document describes four main types of fermenters: stirred tank bioreactors, airlift fermenters, bubble column fermenters, and fluidized bed bioreactors. Stirred tank bioreactors are widely used and have advantages like continuous operation, good temperature control, and easy cleaning. Airlift fermenters use gas sparging to create an upward liquid flow in the riser zone and downward flow in the downcomer zone. Bubble column fermenters sparge gas into a cylindrical chamber to transfer oxygen and mix the fluid. Fluidized bed bioreactors are similar to bubble columns but have an expanded top to reduce fluid velocity and retain solids.

Original Description:

Types of fermenters

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes four main types of fermenters: stirred tank bioreactors, airlift fermenters, bubble column fermenters, and fluidized bed bioreactors. Stirred tank bioreactors are widely used and have advantages like continuous operation, good temperature control, and easy cleaning. Airlift fermenters use gas sparging to create an upward liquid flow in the riser zone and downward flow in the downcomer zone. Bubble column fermenters sparge gas into a cylindrical chamber to transfer oxygen and mix the fluid. Fluidized bed bioreactors are similar to bubble columns but have an expanded top to reduce fluid velocity and retain solids.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

138 views9 pagesTypes of Fermenters

Types of Fermenters

Uploaded by

Stephen MooreThe document describes four main types of fermenters: stirred tank bioreactors, airlift fermenters, bubble column fermenters, and fluidized bed bioreactors. Stirred tank bioreactors are widely used and have advantages like continuous operation, good temperature control, and easy cleaning. Airlift fermenters use gas sparging to create an upward liquid flow in the riser zone and downward flow in the downcomer zone. Bubble column fermenters sparge gas into a cylindrical chamber to transfer oxygen and mix the fluid. Fluidized bed bioreactors are similar to bubble columns but have an expanded top to reduce fluid velocity and retain solids.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 9

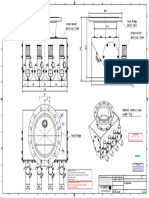

Fermenter: Types

• (Continuous) Stirred Tank Bioreactors

• Airlift Fermenter

• Bubble Column Fermenter

• Fluidized Bed Bioreactors

(Continuous) Stirred Tank Bioreactors

• Functions: homogenization, suspension of solids,

dispersion of gas-liquid mixtures, aeration of liquid

and heat exchange.

• The Stirred tank reactor is provided with a baffle

and a rotating stirrer is attached either at the top

or at the bottom of the bioreactor.

• The typical decision variables are: type, size,

location and the number of impellers; sparger size

and location.

• These determine the hydrodynamic pattern in the

reactor, which in turn influence mixing times, mass

and heat transfer coefficients, shear rates etc.

• In Continuous Stirred Tank Bioreactor, the contents of the vessel will not vary, the steady state is

maintained by continuous supply of nutrition or microorganism and by continuous removal of the

product or waste.

• Widely used in fermentation industry, waste water treatment etc.

• Important point in this reactor is to maintain the autocatalytic nature of microbiological reactions.

• This is because the presence of one of the products, additional micro-organisms, enhances the

overall rate of reaction.

• In the absence of micro-organisms no reaction can take place.

• Therefore, it is essential to retain at least a portion within the fermentor. It follows that if the flow

rate is raised to a high value, then all the micro-organisms will be swept from the fermentor, and

the conversion will cease. This phenomenon is commonly known as 'Wash-out'. if micro-organisms

are fed to the fermentor simultaneously with the substrate feed, the problems associated with

wash-out are abated, and the reaction proceeds normally.

• Advantages of Stirred Tank Bioreactor

• Continuous operation

• Good temperature control

• Easily adapts to two phase runs

• Good control

• Simplicity of construction

• Low operating (labor) cost

• Easy to clean

Airlift Fermenter

• In airlift fermenter the liquid culture volume of the vessel is divided into two interconnected zones by means of a baffle or

draft tube.

• Air or other gas are sparged through one zone, and this sparged zone is known as the riser.

• The other zone that receives no gas is called down-comer.

• The bulk density of the gas-liquid dispersion in the gas-sparged riser tends to be lower than the bulk density in the down-

comer.

• Consequently the dispersion flows up in the riser zone and down-flow occurs in the down-comer.

• Advantages:

• Energy efficient

• Suitable for animal cell cultures

• More effective in suspending solids

Bubble column Fermenter

• Bubble column fermenter a simple cylindrical glass

chamber with an aspect (height to diameter) ratio of 4-6.

• Gas is sparged at the base of the column through

perforated pipes, perforated plates, or sintered glass or

metal micro-porous spargers.

• O2 transfer, mixing and other performance factors are

influenced mainly by the gas flow rate and the properties

of the fluid.

• Internal devices such as horizontal perforated

plates,vertical baffles and corrugated sheet packing,s

may be placed in the vessel to improve mass transfer and

modify the basic design

Fluidized bed bioreactor

• Fluidized bed bioreactor is comparable to bubble

column bioreactor except the top position is

expanded to reduce the velocity of the fluid.

• The design of the fluidized bioreactors (expanded

top and narrow reaction column) is such that the

solids are retained in the reactor while the liquid

flows out.

• These bioreactors are suitable for use to carry

out reactions involving fluid suspended

biocatalysts such as immobilized enzymes,

immobilized cells, and microbial flocs

You might also like

- 12a. Introduction To Steam BoilersDocument17 pages12a. Introduction To Steam BoilersDr. BIBIN CHIDAMBARANATHANNo ratings yet

- ANSI Color CodesDocument2 pagesANSI Color CodesFrederik0No ratings yet

- Heat ExchangerDocument4 pagesHeat ExchangerIzwanaRahimiNo ratings yet

- II Law of GeneticsDocument10 pagesII Law of GeneticsStephen MooreNo ratings yet

- Coatings Word August 2012Document52 pagesCoatings Word August 2012sami_sakrNo ratings yet

- Flexural Strengthing of Beam With FRP LamintaesDocument6 pagesFlexural Strengthing of Beam With FRP LamintaesEngDbtNo ratings yet

- Construction of FermenterDocument23 pagesConstruction of FermenterSajjad Hossain ShuvoNo ratings yet

- Classification of BioreactorsDocument4 pagesClassification of Bioreactorssaahiba16No ratings yet

- TOPIC 5 - Types of BioreactorDocument35 pagesTOPIC 5 - Types of BioreactorfadhilahmadNo ratings yet

- PU01-301-33-012-023-D30-002 - Z15211-414-00 - Suction Box For Existing Silo - A01Document1 pagePU01-301-33-012-023-D30-002 - Z15211-414-00 - Suction Box For Existing Silo - A01Kriengsak RuangdechNo ratings yet

- 1b. Introduction - Classification of InstrumentDocument30 pages1b. Introduction - Classification of Instrumenttkjing33% (6)

- Installation and Operating Manual: GREENFILTER ABC - Compressed Air FilterDocument8 pagesInstallation and Operating Manual: GREENFILTER ABC - Compressed Air FilterSandeep50% (2)

- Valves PresentationDocument45 pagesValves PresentationChiheb Kaaniche100% (1)

- Thermodynamics of Microbial Growth and MetabolismDocument17 pagesThermodynamics of Microbial Growth and MetabolismJeimy MaciasNo ratings yet

- Pressure VesselDocument9 pagesPressure VesselbekkuNo ratings yet

- Fluid Flow in T-Junction of Pipes PDFDocument75 pagesFluid Flow in T-Junction of Pipes PDFpokengchemaNo ratings yet

- Tank Level Control ExperimentDocument3 pagesTank Level Control ExperimentLi Xue0% (1)

- w8 ManualDocument4 pagesw8 ManualPong VongNo ratings yet

- Gas - Liquid ChromatographyDocument14 pagesGas - Liquid ChromatographySELVI ANo ratings yet

- Mixing TankDocument3 pagesMixing Tankleslie_adolfoNo ratings yet

- Supply Air Diffuser Selection - Telecom Room at Upstream BuildingDocument17 pagesSupply Air Diffuser Selection - Telecom Room at Upstream BuildingKeerthi KrishnanNo ratings yet

- Tube Removal Catalog Web ELLIOTDocument24 pagesTube Removal Catalog Web ELLIOTJose Luis RattiaNo ratings yet

- Principal Types of Atmospheric Storage TanksDocument9 pagesPrincipal Types of Atmospheric Storage Tanksmohsen ranjbarNo ratings yet

- TGA - CalibrationDocument5 pagesTGA - CalibrationDiego FrancoNo ratings yet

- Shell and Tube Heat ExchangersDocument11 pagesShell and Tube Heat ExchangersSuresh SjNo ratings yet

- HDPE Pipe PresentationDocument17 pagesHDPE Pipe PresentationSiddiqui Muhammad AshfaqueNo ratings yet

- Melaku Tesfaye (Parafin Oil)Document55 pagesMelaku Tesfaye (Parafin Oil)aberNo ratings yet

- PETRO Cube BrochureDocument13 pagesPETRO Cube Brochurepaulm3565No ratings yet

- IMI Bopp+Reuther SIRADocument4 pagesIMI Bopp+Reuther SIRAangelo100% (1)

- Thermodynamics An Engineering Approach 8Document1 pageThermodynamics An Engineering Approach 8Aracely PenaNo ratings yet

- Habte Atle (Parafin Oil)Document87 pagesHabte Atle (Parafin Oil)aberNo ratings yet

- KT & Ky Parafin OilDocument45 pagesKT & Ky Parafin OilaberNo ratings yet

- 5 Sedimentary Hydrocarbons Biomarkers For Early LifeDocument53 pages5 Sedimentary Hydrocarbons Biomarkers For Early LifeLambok ManurungNo ratings yet

- Accra Workshop Jul07 - Topic 1Document32 pagesAccra Workshop Jul07 - Topic 1Lit Phen TuNo ratings yet

- BIOREACTOR DESIGN MixingDocument26 pagesBIOREACTOR DESIGN MixingFelix SunjayaNo ratings yet

- Determination of Chemical Oxygen DemandDocument9 pagesDetermination of Chemical Oxygen DemandAnand SolomonNo ratings yet

- Nutsche Filter DesignDocument6 pagesNutsche Filter Designmaurya888No ratings yet

- Proces Equipment Design Guide For FermenDocument23 pagesProces Equipment Design Guide For FermenTheodoros AtheridisNo ratings yet

- What Is Design Interpretation?Document17 pagesWhat Is Design Interpretation?Qaisir MehmoodNo ratings yet

- 02-Ideal Reactors 2008Document24 pages02-Ideal Reactors 2008maha20No ratings yet

- Flexible Intermediate Bulk Containers Specifications PDFDocument13 pagesFlexible Intermediate Bulk Containers Specifications PDFZahir Khira100% (1)

- Flying Wind Mill: by Shantanu Mandal Roll - 16ME62R015 Department of Mechanical Engineering IIT KharagpurDocument14 pagesFlying Wind Mill: by Shantanu Mandal Roll - 16ME62R015 Department of Mechanical Engineering IIT Kharagpuranon_688074713No ratings yet

- Ideas To Achieve Optimal Combination of Axial & Cross FlowDocument28 pagesIdeas To Achieve Optimal Combination of Axial & Cross FlowAmirah SufianNo ratings yet

- How Does It Work?: High Temperature ReservoirDocument28 pagesHow Does It Work?: High Temperature Reservoirsiddharthupes100% (1)

- ChE 404-Chapter 08Document38 pagesChE 404-Chapter 08aliNo ratings yet

- 8 Infrared Drying: November 2006Document17 pages8 Infrared Drying: November 2006satish kumarNo ratings yet

- Manometers: Types of ManometerDocument4 pagesManometers: Types of ManometerArun LogeshNo ratings yet

- Mogas Msds 2014-2Document39 pagesMogas Msds 2014-2KalkiHereNo ratings yet

- Butterfly ValveDocument25 pagesButterfly ValveRahul JadhavNo ratings yet

- Compressible Flow Bench: Yeditepe University Department of Mechanical EngineeringDocument5 pagesCompressible Flow Bench: Yeditepe University Department of Mechanical EngineeringAhmad AbukhashabehNo ratings yet

- PSG 02 Issue 01 Dated 20 03 00Document29 pagesPSG 02 Issue 01 Dated 20 03 00uriiiNo ratings yet

- 3 Element ControlDocument5 pages3 Element Controlugun87No ratings yet

- A Study On The PH of Commonly Used Soaps/cleansers Available in The Indian MarketDocument3 pagesA Study On The PH of Commonly Used Soaps/cleansers Available in The Indian MarketpalliNo ratings yet

- Presented By: Merry Ann M. Cabral BSME-421Document36 pagesPresented By: Merry Ann M. Cabral BSME-421Marlon Evangelista100% (1)

- LPG Pump IOM LGL2 LGL3 PDFDocument12 pagesLPG Pump IOM LGL2 LGL3 PDFAfani Roma A100% (1)

- E7200 10 02 08 - D Type FilterDocument8 pagesE7200 10 02 08 - D Type FiltermecambNo ratings yet

- Solutions For Long-Term Storage of Electronic Components and CompositionsDocument3 pagesSolutions For Long-Term Storage of Electronic Components and CompositionsJoão Pedro AlmeidaNo ratings yet

- Richards Bay Minerals: General RBM ProcedureDocument7 pagesRichards Bay Minerals: General RBM ProcedureHuzaifa KtkNo ratings yet

- Specification For GasketsDocument8 pagesSpecification For GasketsMehdi NouriNo ratings yet

- Chapter 8 Steam CondenserDocument53 pagesChapter 8 Steam CondenserPHƯƠNG ĐẶNG YẾN100% (1)

- Bioreactor Types For Products of Microbial, Plant and Animal OriginDocument45 pagesBioreactor Types For Products of Microbial, Plant and Animal Origint.a.m.cooldarkboyNo ratings yet

- Fermentation: Presented By: Sagar Dutt 1 Year M.Pharm Sdpgips Pt. B.D. Sharma UhsrDocument25 pagesFermentation: Presented By: Sagar Dutt 1 Year M.Pharm Sdpgips Pt. B.D. Sharma UhsrAparna RohillaNo ratings yet

- Reactors Ppt4Document55 pagesReactors Ppt4DanishNo ratings yet

- Microbial Analysis of WaterDocument9 pagesMicrobial Analysis of WaterStephen Moore0% (1)

- ExtremophilesDocument7 pagesExtremophilesStephen MooreNo ratings yet

- Extremely Thermophilic S - MetabolizersDocument2 pagesExtremely Thermophilic S - MetabolizersStephen MooreNo ratings yet

- Microbiology Environmental Factors Affecting GrowthDocument10 pagesMicrobiology Environmental Factors Affecting GrowthStephen MooreNo ratings yet

- Microbiology Methods of Monitoring PopulationsDocument17 pagesMicrobiology Methods of Monitoring PopulationsStephen MooreNo ratings yet

- List of PhDs in ShodhgangaDocument2 pagesList of PhDs in ShodhgangaStephen MooreNo ratings yet

- Microbiology Basic and Applied: Dr. Bipinraj N KDocument165 pagesMicrobiology Basic and Applied: Dr. Bipinraj N KStephen MooreNo ratings yet

- BBT Genetics 1Document7 pagesBBT Genetics 1Stephen MooreNo ratings yet

- NAAC SSR For Affiliated CollegesDocument195 pagesNAAC SSR For Affiliated CollegesStephen MooreNo ratings yet

- Genetics PracticalsDocument5 pagesGenetics PracticalsStephen MooreNo ratings yet

- TransposonsDocument7 pagesTransposonsStephen MooreNo ratings yet

- ProtocolDocument2 pagesProtocolStephen MooreNo ratings yet

- Landguard A900: An Enzyme-Based Remediant For The Detoxification of Organophosphate Insecticides in Animal DipsDocument31 pagesLandguard A900: An Enzyme-Based Remediant For The Detoxification of Organophosphate Insecticides in Animal DipsStephen MooreNo ratings yet

- ProtocolDocument2 pagesProtocolStephen MooreNo ratings yet

- B.Sc. Biotechnology Semester IV BBT 401: Practicals in Molecular Biology Total 15 PDocument1 pageB.Sc. Biotechnology Semester IV BBT 401: Practicals in Molecular Biology Total 15 PStephen MooreNo ratings yet

- Potential Impact of Alternaria Macrospora On Cotton Production in West TexasDocument14 pagesPotential Impact of Alternaria Macrospora On Cotton Production in West TexasStephen MooreNo ratings yet

- Bvu-Rgitbt B.Sc. Biotechnology Sem V Test No.2 Subject Genetics. Topic ChromosomeDocument1 pageBvu-Rgitbt B.Sc. Biotechnology Sem V Test No.2 Subject Genetics. Topic ChromosomeStephen MooreNo ratings yet

- Bvu-Rgitbt B.Sc. Biotechnology Sem V Test No.1 Subject Genetics Topic Concepts of GeneticsDocument1 pageBvu-Rgitbt B.Sc. Biotechnology Sem V Test No.1 Subject Genetics Topic Concepts of GeneticsStephen MooreNo ratings yet

- Course Med BTDocument2 pagesCourse Med BTStephen MooreNo ratings yet

- Rajiv Gandhi Institute of IT and BiotechnologyDocument2 pagesRajiv Gandhi Institute of IT and BiotechnologyStephen MooreNo ratings yet

- Case Study-Failure in SolebarDocument24 pagesCase Study-Failure in SolebardonendrajNo ratings yet

- Enciclopedia de SoldaduraDocument768 pagesEnciclopedia de SoldaduraJORGEHERRNo ratings yet

- Overview of Materials For Polypropylene With 20% Glass Fiber FillerDocument4 pagesOverview of Materials For Polypropylene With 20% Glass Fiber FillerbiroutiNo ratings yet

- Packaging PDFDocument48 pagesPackaging PDFDebasis Kumar SahaNo ratings yet

- Seattle City LightDocument6 pagesSeattle City Lightfasih_baqai4252No ratings yet

- Types of Peripheral Devices:: Printer IsDocument1 pageTypes of Peripheral Devices:: Printer Issky29No ratings yet

- Aashto T 88Document20 pagesAashto T 88nedkovbgNo ratings yet

- History of Drill Consumable ControlDocument8 pagesHistory of Drill Consumable ControlanfiboleNo ratings yet

- Bettis Valve Actuator GuideDocument12 pagesBettis Valve Actuator Guideprufino2No ratings yet

- Brosur Tokico Dan Data Sheet-D7a93-3206 339Document6 pagesBrosur Tokico Dan Data Sheet-D7a93-3206 339galih santosoNo ratings yet

- GPCB SOP For De-Contamination FacilityDocument9 pagesGPCB SOP For De-Contamination FacilityEHS HalolNo ratings yet

- Designing Piping For Gravity Flow PDFDocument4 pagesDesigning Piping For Gravity Flow PDFicingrock100% (2)

- SBS5311 1718 07-RefrigerationDocument66 pagesSBS5311 1718 07-RefrigerationSam C M Hui100% (1)

- SSP 255Document40 pagesSSP 255get_prasadns3358100% (1)

- 555 Datasheet Revb1Document8 pages555 Datasheet Revb1Flavio GaluppoNo ratings yet

- Pilot Valve SizingDocument4 pagesPilot Valve SizingJason ThomasNo ratings yet

- Pre Requisite Programs Main PresentationDocument19 pagesPre Requisite Programs Main PresentationASIF EJAZNo ratings yet

- Alwasail Electrofusion CatalogueDocument24 pagesAlwasail Electrofusion Cataloguenour eldinNo ratings yet

- Is 1626 Part 3Document14 pagesIs 1626 Part 3Sheetal JindalNo ratings yet

- CTM HardnessTests SoWDocument6 pagesCTM HardnessTests SoWkratos_upcNo ratings yet

- Drs 2170Document4 pagesDrs 2170Ronaldo JuniorNo ratings yet

- BSR Inspection Case Study - CycloneDocument12 pagesBSR Inspection Case Study - Cyclonelinhcdt3100% (1)

- Pattern Disk FilterDocument3 pagesPattern Disk FilterIqbalNo ratings yet

- Lubricants in Refrigerant Systems: Related Commercial ResourcesDocument29 pagesLubricants in Refrigerant Systems: Related Commercial ResourcesAndrés Felipe NaranjoNo ratings yet

- US4143639 Friction Heat Space Heater, Eugene FrenetteDocument6 pagesUS4143639 Friction Heat Space Heater, Eugene FrenetteBastien Gall de SilléNo ratings yet

- Aldesme - Flash25 Stair PressurisationDocument8 pagesAldesme - Flash25 Stair PressurisationjaicektmNo ratings yet

- Stanley Stella LookbookDocument126 pagesStanley Stella LookbookOCC ApparelNo ratings yet