Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

37 viewsMBM Engineering College Jodhpur: Belt Conveyor System

MBM Engineering College Jodhpur: Belt Conveyor System

Uploaded by

narendra lambaThe document discusses belt conveyor systems used for material transportation in surface and underground mines. It describes the main components of belt conveyors including the belt itself, idlers, supporting structures, and drive systems. The belt is an endless woven fabric covered in rubber or plastic. Idlers are long pulleys that provide shape and support. The document also covers advantages like adaptability and noiseless operation, as well as disadvantages like need for monitoring and difficulty cleaning sticky materials. Formulas are provided for calculating capacity and number of belt plies based on factors like speed, material properties, and tensile strength.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Fabric Properties and Their Relevance in End UsesDocument77 pagesFabric Properties and Their Relevance in End UsesBhupendra Singh ButolaNo ratings yet

- Splintered City - SeattleDocument82 pagesSplintered City - SeattleSelurinhe100% (8)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Unit 13 - Queuing Analysis (Part 1)Document4 pagesUnit 13 - Queuing Analysis (Part 1)Joshua John JulioNo ratings yet

- Belt ConveyorDocument11 pagesBelt Conveyornarendra lambaNo ratings yet

- Belt Conveyor Lecture Notes Up To 08.02.2024Document22 pagesBelt Conveyor Lecture Notes Up To 08.02.2024Abhinav GanveerNo ratings yet

- BMHE Lecture Notes 3 0Document18 pagesBMHE Lecture Notes 3 022je0398No ratings yet

- Beltconveyor PDFDocument24 pagesBeltconveyor PDFrao159951No ratings yet

- Beltconveyor 170407133414Document24 pagesBeltconveyor 170407133414Ganesh Sakhalkar GSNo ratings yet

- Lecture 4 - Conveyor BeltsDocument55 pagesLecture 4 - Conveyor BeltsGRAHAM KUNDAI DENGEZANo ratings yet

- IPE 309 Lecture 7 and 8Document40 pagesIPE 309 Lecture 7 and 8Mamunur Rashid MashukNo ratings yet

- Presentación Equipo 2Document62 pagesPresentación Equipo 2Ruben Lopez RicoNo ratings yet

- MHE (Sirawdink Getachew)Document8 pagesMHE (Sirawdink Getachew)sirawdinkgetachew15No ratings yet

- Belt Conveyor by Alok VardhanDocument30 pagesBelt Conveyor by Alok VardhanLOKENDRA9150% (2)

- CeRyEx Conveyor Belt PDSDocument1 pageCeRyEx Conveyor Belt PDSMejía Mendoza Jaime EfraínNo ratings yet

- Mining System Lec 3Document26 pagesMining System Lec 3shoaib ahmedNo ratings yet

- Hmpe Manual Rev 1Document11 pagesHmpe Manual Rev 1Kathrin KatsNo ratings yet

- ConveyorsDocument48 pagesConveyorsAd Man GeTigNo ratings yet

- Belt ConveyorDocument30 pagesBelt ConveyorajayNo ratings yet

- Materials HandlingDocument27 pagesMaterials HandlingPatricia de LeonNo ratings yet

- 1 Conveyorppt Course 2010Document36 pages1 Conveyorppt Course 2010sk3146No ratings yet

- Chain Conveyors: Prepared By: Yitagesu TesfayeDocument38 pagesChain Conveyors: Prepared By: Yitagesu Tesfayeይታገሡ ተሥፋዬNo ratings yet

- ConveyorDocument36 pagesConveyorapirakqNo ratings yet

- Tunnel and TunnelingDocument31 pagesTunnel and TunnelingPatel MeetNo ratings yet

- EBUYDocument51 pagesEBUYebuy100% (1)

- 1.5 Belt Conveyors: Maximum Slope Raw Material, Wet Slag Clinker Cement Coal/PetcokeDocument4 pages1.5 Belt Conveyors: Maximum Slope Raw Material, Wet Slag Clinker Cement Coal/Petcokesigit s81No ratings yet

- Introduction To Well ServiceDocument16 pagesIntroduction To Well ServiceDini Nur IslamiNo ratings yet

- 11.japan Pipe Belt Conveyor SystemDocument9 pages11.japan Pipe Belt Conveyor Systemshariq begNo ratings yet

- M 344 ContentDocument47 pagesM 344 ContentLoda LassanNo ratings yet

- Power - TransmissionDocument85 pagesPower - TransmissionSOURABH GANGWARNo ratings yet

- 3.conveyor Belt Selection-Design For High Speed ConveyorsDocument17 pages3.conveyor Belt Selection-Design For High Speed ConveyorsAshok KumarNo ratings yet

- 1567426110conveying EquipmentsDocument18 pages1567426110conveying Equipmentssoumya ranjan sahooNo ratings yet

- Belt Conveyors - RBLDocument141 pagesBelt Conveyors - RBLMigue Migue Salgado ZequedaNo ratings yet

- Chapter III Solid Handling PDFDocument44 pagesChapter III Solid Handling PDFnahom100% (1)

- TT 601practicalsDocument18 pagesTT 601practicalsHiba EjazNo ratings yet

- WOLKITE UNIVERSITY - PPT TexDocument98 pagesWOLKITE UNIVERSITY - PPT TexAbel TayeNo ratings yet

- PT32 09 PDFDocument3 pagesPT32 09 PDFGrandhi Venkata Satya KiranNo ratings yet

- Topic: Design of Centering System For Feed Belt Conveyors With Friction DriveDocument24 pagesTopic: Design of Centering System For Feed Belt Conveyors With Friction Drivesanjay devNo ratings yet

- Belt ConveyorDocument7 pagesBelt ConveyorPRABIR DATTANo ratings yet

- On Ropes and CordagesDocument30 pagesOn Ropes and CordagesHimanshu Verma100% (2)

- B.Tech Diploma Combined MIN - V - Factor of Safety.Document17 pagesB.Tech Diploma Combined MIN - V - Factor of Safety.shivam raiNo ratings yet

- Belt and ConveyorDocument9 pagesBelt and ConveyorYash Deep KumarNo ratings yet

- تقرير فاينل صناعية ١Document9 pagesتقرير فاينل صناعية ١سجاد المالكيNo ratings yet

- Conveyor BeltDocument54 pagesConveyor BeltDhruv PanchalNo ratings yet

- CEG 438 Assignment 1Document7 pagesCEG 438 Assignment 1Olusola OlagunjuNo ratings yet

- Tecco / Spider Systems Stabilize Slopes Using High-Tensile WireDocument12 pagesTecco / Spider Systems Stabilize Slopes Using High-Tensile WireMilton TeranNo ratings yet

- Conveyor BeltDocument50 pagesConveyor Belthimanchalmishra7No ratings yet

- Draglies&ClamshellDocument60 pagesDraglies&ClamshellAkshay Joshi100% (1)

- Lecture - 18-19 - Flat Belt DriveDocument31 pagesLecture - 18-19 - Flat Belt DriveM.Abdullah RiazNo ratings yet

- Aerial Ropeway: Vipin Kumar PandeyDocument22 pagesAerial Ropeway: Vipin Kumar PandeyMPS Tutorials and Tech.100% (2)

- AGV & RopesDocument48 pagesAGV & RopesSaru ArjunanNo ratings yet

- Unit 3Document163 pagesUnit 3Sid SNo ratings yet

- Installation Manual UPP PipingDocument68 pagesInstallation Manual UPP Pipingnitroxx7100% (1)

- Textile Reinforced - Cold Splice - Final 14 MRCH 2018Document25 pagesTextile Reinforced - Cold Splice - Final 14 MRCH 2018Shariq KhanNo ratings yet

- Materials Handling (3) : Ir. Edy Sanwani MT., Phd. Dr. Eng. Nurulhuda Halim ST., MTDocument27 pagesMaterials Handling (3) : Ir. Edy Sanwani MT., Phd. Dr. Eng. Nurulhuda Halim ST., MTOlivia SophieNo ratings yet

- Chapter Four Storage and Transportation of Solids in Bulk: Chemical Engineering DepartmentDocument30 pagesChapter Four Storage and Transportation of Solids in Bulk: Chemical Engineering DepartmentYohannes EndaleNo ratings yet

- Belt Conveyor (V1)[1]Document45 pagesBelt Conveyor (V1)[1]alaa59mahmoudNo ratings yet

- Chap 3MHDocument43 pagesChap 3MHAnonymous HzaFK17Kb100% (1)

- Aerial Ropeways1Document60 pagesAerial Ropeways1Anshul yadavNo ratings yet

- WINDINGDocument56 pagesWINDINGSaul GoodmanNo ratings yet

- The Knot Book - Knots, Bends and Hitches - A Guide for Sailors, Adventurers and HobbyistsFrom EverandThe Knot Book - Knots, Bends and Hitches - A Guide for Sailors, Adventurers and HobbyistsNo ratings yet

- Advisory Regarding Revision of Safe Axle PDFDocument7 pagesAdvisory Regarding Revision of Safe Axle PDFashish kumarNo ratings yet

- Century in Flight - AirfoilsDocument3 pagesCentury in Flight - AirfoilsJoelNo ratings yet

- Capital Region: County Structurally Deficient BridgesDocument4 pagesCapital Region: County Structurally Deficient BridgesElizabeth BenjaminNo ratings yet

- Media ReportDocument70 pagesMedia ReportAndrew AB BurgoonNo ratings yet

- Understanding Crude Oil and Product Markets Primer Low PDFDocument39 pagesUnderstanding Crude Oil and Product Markets Primer Low PDFrohanpujari100% (1)

- Chennai Metro Rail Accessibility 2014 POA VISUAL GUIDEDocument30 pagesChennai Metro Rail Accessibility 2014 POA VISUAL GUIDEVaishnavi JayakumarNo ratings yet

- LưU Ý Khi LàM DạNg MapDocument7 pagesLưU Ý Khi LàM DạNg MapIsave SavannahNo ratings yet

- Clinicians Guide To Assessing and Counseling Older Drivers Sep 2020Document282 pagesClinicians Guide To Assessing and Counseling Older Drivers Sep 2020lucia.oliveiraNo ratings yet

- Diagrama Arranque Mazda 3 2006Document2 pagesDiagrama Arranque Mazda 3 2006Jhon ConnorNo ratings yet

- Previous Lease & Aircraft Valuation AnalysisDocument9 pagesPrevious Lease & Aircraft Valuation AnalysisAdyb A SiddiqueeNo ratings yet

- UTILITIES Annie Assignment 15 ElevatorDocument9 pagesUTILITIES Annie Assignment 15 ElevatorVanz Farrizze VergaraNo ratings yet

- Beijing Subway.20140531.114616Document6 pagesBeijing Subway.20140531.114616liver61jeepNo ratings yet

- Catalogo Cartas Atualizacao 30setembro2023Document174 pagesCatalogo Cartas Atualizacao 30setembro2023joaosaraiva1307No ratings yet

- Final ProjectDocument21 pagesFinal ProjectAhmed ShararaNo ratings yet

- Resolution No. 10488: Campaign Activity From 29 March Campaign Activity On Thursday)Document9 pagesResolution No. 10488: Campaign Activity From 29 March Campaign Activity On Thursday)Taga BukidNo ratings yet

- SPELLING BEE CONTEST - ENGLISH 1 y 2 - CATEGORIA ADocument3 pagesSPELLING BEE CONTEST - ENGLISH 1 y 2 - CATEGORIA ACamilo CortesNo ratings yet

- Demand Drivers of LogisticsDocument7 pagesDemand Drivers of Logisticssuyash1987No ratings yet

- Storm Drainage Spec - enDocument16 pagesStorm Drainage Spec - enNgoc Ba NguyenNo ratings yet

- BMW Clips FastenersDocument3 pagesBMW Clips FastenersMike CappsNo ratings yet

- Transmission: Lesson 7.1 - Power Train TransmissionDocument40 pagesTransmission: Lesson 7.1 - Power Train TransmissionJoel Carvajal ArayaNo ratings yet

- BC Newcomers Guide PDFDocument122 pagesBC Newcomers Guide PDFoakfedNo ratings yet

- Vibration Assessment Report PDFDocument51 pagesVibration Assessment Report PDFHung NguyentheNo ratings yet

- Right Forms of VerbDocument6 pagesRight Forms of VerbMr Double RNo ratings yet

- Obama Presidential Center PresentationDocument84 pagesObama Presidential Center PresentationThe Daily LineNo ratings yet

- Travel Reservation July 25 For FRANCISCO GUTIERREZDocument2 pagesTravel Reservation July 25 For FRANCISCO GUTIERREZJose HerreraNo ratings yet

- Design of Catamaran Ship Main Deck and Bulkhead To Withstand The Crane LoadDocument11 pagesDesign of Catamaran Ship Main Deck and Bulkhead To Withstand The Crane Loadghulam mohi ud dinNo ratings yet

- Iot-Driven Road Safety System: Abstract-Roads Are Integral Part of Human Civilization. TheyDocument5 pagesIot-Driven Road Safety System: Abstract-Roads Are Integral Part of Human Civilization. TheyLicence Spécialisée Idbd EnsakNo ratings yet

- Steady Aircraft Flight and Aircraft PerformanceDocument203 pagesSteady Aircraft Flight and Aircraft PerformanceJack58No ratings yet

MBM Engineering College Jodhpur: Belt Conveyor System

MBM Engineering College Jodhpur: Belt Conveyor System

Uploaded by

narendra lamba0 ratings0% found this document useful (0 votes)

37 views11 pagesThe document discusses belt conveyor systems used for material transportation in surface and underground mines. It describes the main components of belt conveyors including the belt itself, idlers, supporting structures, and drive systems. The belt is an endless woven fabric covered in rubber or plastic. Idlers are long pulleys that provide shape and support. The document also covers advantages like adaptability and noiseless operation, as well as disadvantages like need for monitoring and difficulty cleaning sticky materials. Formulas are provided for calculating capacity and number of belt plies based on factors like speed, material properties, and tensile strength.

Original Description:

Original Title

belt conveyor

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses belt conveyor systems used for material transportation in surface and underground mines. It describes the main components of belt conveyors including the belt itself, idlers, supporting structures, and drive systems. The belt is an endless woven fabric covered in rubber or plastic. Idlers are long pulleys that provide shape and support. The document also covers advantages like adaptability and noiseless operation, as well as disadvantages like need for monitoring and difficulty cleaning sticky materials. Formulas are provided for calculating capacity and number of belt plies based on factors like speed, material properties, and tensile strength.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

37 views11 pagesMBM Engineering College Jodhpur: Belt Conveyor System

MBM Engineering College Jodhpur: Belt Conveyor System

Uploaded by

narendra lambaThe document discusses belt conveyor systems used for material transportation in surface and underground mines. It describes the main components of belt conveyors including the belt itself, idlers, supporting structures, and drive systems. The belt is an endless woven fabric covered in rubber or plastic. Idlers are long pulleys that provide shape and support. The document also covers advantages like adaptability and noiseless operation, as well as disadvantages like need for monitoring and difficulty cleaning sticky materials. Formulas are provided for calculating capacity and number of belt plies based on factors like speed, material properties, and tensile strength.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 11

MBM ENGINEERING COLLEGE JODHPUR

BELT CONVEYOR SYSTEM

CONTENT

• INTRODUCTION

• THE BELT

• CARE OF BELT

• IDLERS AND SUPPORTING STRUCTURES

• COMPONENTS

• NUMERICAL ANALYSIS

• ADVANTAGES AND DISADVANTAGES

INTRODUCTION

• It is used for material transportation in surface

as well as underground mines.

• The principal types of conveyor used in mines

are:

1: Belt conveyor

2: Scraper conveyor

3: Shaker conveyor

THE BELT

• The belt is an endless thick flat strip of woven cotton

,rayon or nylon fabric laid up in plies.

• The surface and sides are covered by rubber plastic or

pvc.

• The belt conveyor works on a straight roadway which

may be level , inclined or partially inclined.

• The speed of belt varies from 0.75m/s to 2.5m/s.

• Belt width

surface mines: 0.6m to 1.5 m

underground mines: 0.6 to 1m

CARE OF BELT

1: Protect belt from direct sunlight and keep it away

from steam pipes.

2: Use drive drums and delivery as well as tail end drums

of adequate size so that sharp bending avoided.

3: During handling do not subject the belt to many

bending or wrappings.

4: Prevent the belt from rubbing against any prop.

5: For troughted belt inclination of side rollers should

not exceed 30 degree.

IDLERS AND SUPPORTING STRUCTURES

• The idler is a long pulley moving on its own axle

and ball bearings and filled with grease.

• The belt travels on idlers placed an interval of

1.5m to 2.1m.

• It provides troughed shape for handling loose

and broken material.

• The idlers are supported on channel iron

framework and the members of such framework

are 3 to 4m long.

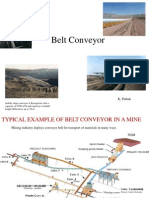

COMPONENTS

FIG: BELT CONVEYOR

NUMERICAL ANALYSIS

1: CAPACITY(T)= a*b*v

where T=the carrying capacity(tonne/sec)

a=avg. Cross sectional area of material(m^2)

b= the bulk density(te/m^3)

v= speed of conveyor belt

2: NUMBER OF PLIES=(RSmax)/BKt

where as Smax=Maximum belt tension in in kg

R= factor of safety in the range of 8-10

B=Belt width in cm

Kt=Ultimate tensile strength /cm

ADVANTAGES DISADVANTAGES

• It can be applied in surface and

underground mines • Continuous or periodic monitoring

• Noiseless operation. of belt is necessary

• Large length of conveying path

• The normal design of a belt

• Lower power consumption.

conveyor is opened. If your product

• Long life. needs to be contained, covers and

• Adaptability to different types of or drip pans can become expensive

goods. and cumbersome.

• Ability to carry almost any bulk

• If the material is sticky, belt

material

cleaning can be difficult and

• High reliability of operation.

generally not very successful.

• Can transport material in any direction.

• Heating effect of belt material

REFERENCES

1:D J DESHMUKH VOLUME 3

2: R R TATIYA

3: GOOGLE IMAGE

THANK YOU

You might also like

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Fabric Properties and Their Relevance in End UsesDocument77 pagesFabric Properties and Their Relevance in End UsesBhupendra Singh ButolaNo ratings yet

- Splintered City - SeattleDocument82 pagesSplintered City - SeattleSelurinhe100% (8)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Unit 13 - Queuing Analysis (Part 1)Document4 pagesUnit 13 - Queuing Analysis (Part 1)Joshua John JulioNo ratings yet

- Belt ConveyorDocument11 pagesBelt Conveyornarendra lambaNo ratings yet

- Belt Conveyor Lecture Notes Up To 08.02.2024Document22 pagesBelt Conveyor Lecture Notes Up To 08.02.2024Abhinav GanveerNo ratings yet

- BMHE Lecture Notes 3 0Document18 pagesBMHE Lecture Notes 3 022je0398No ratings yet

- Beltconveyor PDFDocument24 pagesBeltconveyor PDFrao159951No ratings yet

- Beltconveyor 170407133414Document24 pagesBeltconveyor 170407133414Ganesh Sakhalkar GSNo ratings yet

- Lecture 4 - Conveyor BeltsDocument55 pagesLecture 4 - Conveyor BeltsGRAHAM KUNDAI DENGEZANo ratings yet

- IPE 309 Lecture 7 and 8Document40 pagesIPE 309 Lecture 7 and 8Mamunur Rashid MashukNo ratings yet

- Presentación Equipo 2Document62 pagesPresentación Equipo 2Ruben Lopez RicoNo ratings yet

- MHE (Sirawdink Getachew)Document8 pagesMHE (Sirawdink Getachew)sirawdinkgetachew15No ratings yet

- Belt Conveyor by Alok VardhanDocument30 pagesBelt Conveyor by Alok VardhanLOKENDRA9150% (2)

- CeRyEx Conveyor Belt PDSDocument1 pageCeRyEx Conveyor Belt PDSMejía Mendoza Jaime EfraínNo ratings yet

- Mining System Lec 3Document26 pagesMining System Lec 3shoaib ahmedNo ratings yet

- Hmpe Manual Rev 1Document11 pagesHmpe Manual Rev 1Kathrin KatsNo ratings yet

- ConveyorsDocument48 pagesConveyorsAd Man GeTigNo ratings yet

- Belt ConveyorDocument30 pagesBelt ConveyorajayNo ratings yet

- Materials HandlingDocument27 pagesMaterials HandlingPatricia de LeonNo ratings yet

- 1 Conveyorppt Course 2010Document36 pages1 Conveyorppt Course 2010sk3146No ratings yet

- Chain Conveyors: Prepared By: Yitagesu TesfayeDocument38 pagesChain Conveyors: Prepared By: Yitagesu Tesfayeይታገሡ ተሥፋዬNo ratings yet

- ConveyorDocument36 pagesConveyorapirakqNo ratings yet

- Tunnel and TunnelingDocument31 pagesTunnel and TunnelingPatel MeetNo ratings yet

- EBUYDocument51 pagesEBUYebuy100% (1)

- 1.5 Belt Conveyors: Maximum Slope Raw Material, Wet Slag Clinker Cement Coal/PetcokeDocument4 pages1.5 Belt Conveyors: Maximum Slope Raw Material, Wet Slag Clinker Cement Coal/Petcokesigit s81No ratings yet

- Introduction To Well ServiceDocument16 pagesIntroduction To Well ServiceDini Nur IslamiNo ratings yet

- 11.japan Pipe Belt Conveyor SystemDocument9 pages11.japan Pipe Belt Conveyor Systemshariq begNo ratings yet

- M 344 ContentDocument47 pagesM 344 ContentLoda LassanNo ratings yet

- Power - TransmissionDocument85 pagesPower - TransmissionSOURABH GANGWARNo ratings yet

- 3.conveyor Belt Selection-Design For High Speed ConveyorsDocument17 pages3.conveyor Belt Selection-Design For High Speed ConveyorsAshok KumarNo ratings yet

- 1567426110conveying EquipmentsDocument18 pages1567426110conveying Equipmentssoumya ranjan sahooNo ratings yet

- Belt Conveyors - RBLDocument141 pagesBelt Conveyors - RBLMigue Migue Salgado ZequedaNo ratings yet

- Chapter III Solid Handling PDFDocument44 pagesChapter III Solid Handling PDFnahom100% (1)

- TT 601practicalsDocument18 pagesTT 601practicalsHiba EjazNo ratings yet

- WOLKITE UNIVERSITY - PPT TexDocument98 pagesWOLKITE UNIVERSITY - PPT TexAbel TayeNo ratings yet

- PT32 09 PDFDocument3 pagesPT32 09 PDFGrandhi Venkata Satya KiranNo ratings yet

- Topic: Design of Centering System For Feed Belt Conveyors With Friction DriveDocument24 pagesTopic: Design of Centering System For Feed Belt Conveyors With Friction Drivesanjay devNo ratings yet

- Belt ConveyorDocument7 pagesBelt ConveyorPRABIR DATTANo ratings yet

- On Ropes and CordagesDocument30 pagesOn Ropes and CordagesHimanshu Verma100% (2)

- B.Tech Diploma Combined MIN - V - Factor of Safety.Document17 pagesB.Tech Diploma Combined MIN - V - Factor of Safety.shivam raiNo ratings yet

- Belt and ConveyorDocument9 pagesBelt and ConveyorYash Deep KumarNo ratings yet

- تقرير فاينل صناعية ١Document9 pagesتقرير فاينل صناعية ١سجاد المالكيNo ratings yet

- Conveyor BeltDocument54 pagesConveyor BeltDhruv PanchalNo ratings yet

- CEG 438 Assignment 1Document7 pagesCEG 438 Assignment 1Olusola OlagunjuNo ratings yet

- Tecco / Spider Systems Stabilize Slopes Using High-Tensile WireDocument12 pagesTecco / Spider Systems Stabilize Slopes Using High-Tensile WireMilton TeranNo ratings yet

- Conveyor BeltDocument50 pagesConveyor Belthimanchalmishra7No ratings yet

- Draglies&ClamshellDocument60 pagesDraglies&ClamshellAkshay Joshi100% (1)

- Lecture - 18-19 - Flat Belt DriveDocument31 pagesLecture - 18-19 - Flat Belt DriveM.Abdullah RiazNo ratings yet

- Aerial Ropeway: Vipin Kumar PandeyDocument22 pagesAerial Ropeway: Vipin Kumar PandeyMPS Tutorials and Tech.100% (2)

- AGV & RopesDocument48 pagesAGV & RopesSaru ArjunanNo ratings yet

- Unit 3Document163 pagesUnit 3Sid SNo ratings yet

- Installation Manual UPP PipingDocument68 pagesInstallation Manual UPP Pipingnitroxx7100% (1)

- Textile Reinforced - Cold Splice - Final 14 MRCH 2018Document25 pagesTextile Reinforced - Cold Splice - Final 14 MRCH 2018Shariq KhanNo ratings yet

- Materials Handling (3) : Ir. Edy Sanwani MT., Phd. Dr. Eng. Nurulhuda Halim ST., MTDocument27 pagesMaterials Handling (3) : Ir. Edy Sanwani MT., Phd. Dr. Eng. Nurulhuda Halim ST., MTOlivia SophieNo ratings yet

- Chapter Four Storage and Transportation of Solids in Bulk: Chemical Engineering DepartmentDocument30 pagesChapter Four Storage and Transportation of Solids in Bulk: Chemical Engineering DepartmentYohannes EndaleNo ratings yet

- Belt Conveyor (V1)[1]Document45 pagesBelt Conveyor (V1)[1]alaa59mahmoudNo ratings yet

- Chap 3MHDocument43 pagesChap 3MHAnonymous HzaFK17Kb100% (1)

- Aerial Ropeways1Document60 pagesAerial Ropeways1Anshul yadavNo ratings yet

- WINDINGDocument56 pagesWINDINGSaul GoodmanNo ratings yet

- The Knot Book - Knots, Bends and Hitches - A Guide for Sailors, Adventurers and HobbyistsFrom EverandThe Knot Book - Knots, Bends and Hitches - A Guide for Sailors, Adventurers and HobbyistsNo ratings yet

- Advisory Regarding Revision of Safe Axle PDFDocument7 pagesAdvisory Regarding Revision of Safe Axle PDFashish kumarNo ratings yet

- Century in Flight - AirfoilsDocument3 pagesCentury in Flight - AirfoilsJoelNo ratings yet

- Capital Region: County Structurally Deficient BridgesDocument4 pagesCapital Region: County Structurally Deficient BridgesElizabeth BenjaminNo ratings yet

- Media ReportDocument70 pagesMedia ReportAndrew AB BurgoonNo ratings yet

- Understanding Crude Oil and Product Markets Primer Low PDFDocument39 pagesUnderstanding Crude Oil and Product Markets Primer Low PDFrohanpujari100% (1)

- Chennai Metro Rail Accessibility 2014 POA VISUAL GUIDEDocument30 pagesChennai Metro Rail Accessibility 2014 POA VISUAL GUIDEVaishnavi JayakumarNo ratings yet

- LưU Ý Khi LàM DạNg MapDocument7 pagesLưU Ý Khi LàM DạNg MapIsave SavannahNo ratings yet

- Clinicians Guide To Assessing and Counseling Older Drivers Sep 2020Document282 pagesClinicians Guide To Assessing and Counseling Older Drivers Sep 2020lucia.oliveiraNo ratings yet

- Diagrama Arranque Mazda 3 2006Document2 pagesDiagrama Arranque Mazda 3 2006Jhon ConnorNo ratings yet

- Previous Lease & Aircraft Valuation AnalysisDocument9 pagesPrevious Lease & Aircraft Valuation AnalysisAdyb A SiddiqueeNo ratings yet

- UTILITIES Annie Assignment 15 ElevatorDocument9 pagesUTILITIES Annie Assignment 15 ElevatorVanz Farrizze VergaraNo ratings yet

- Beijing Subway.20140531.114616Document6 pagesBeijing Subway.20140531.114616liver61jeepNo ratings yet

- Catalogo Cartas Atualizacao 30setembro2023Document174 pagesCatalogo Cartas Atualizacao 30setembro2023joaosaraiva1307No ratings yet

- Final ProjectDocument21 pagesFinal ProjectAhmed ShararaNo ratings yet

- Resolution No. 10488: Campaign Activity From 29 March Campaign Activity On Thursday)Document9 pagesResolution No. 10488: Campaign Activity From 29 March Campaign Activity On Thursday)Taga BukidNo ratings yet

- SPELLING BEE CONTEST - ENGLISH 1 y 2 - CATEGORIA ADocument3 pagesSPELLING BEE CONTEST - ENGLISH 1 y 2 - CATEGORIA ACamilo CortesNo ratings yet

- Demand Drivers of LogisticsDocument7 pagesDemand Drivers of Logisticssuyash1987No ratings yet

- Storm Drainage Spec - enDocument16 pagesStorm Drainage Spec - enNgoc Ba NguyenNo ratings yet

- BMW Clips FastenersDocument3 pagesBMW Clips FastenersMike CappsNo ratings yet

- Transmission: Lesson 7.1 - Power Train TransmissionDocument40 pagesTransmission: Lesson 7.1 - Power Train TransmissionJoel Carvajal ArayaNo ratings yet

- BC Newcomers Guide PDFDocument122 pagesBC Newcomers Guide PDFoakfedNo ratings yet

- Vibration Assessment Report PDFDocument51 pagesVibration Assessment Report PDFHung NguyentheNo ratings yet

- Right Forms of VerbDocument6 pagesRight Forms of VerbMr Double RNo ratings yet

- Obama Presidential Center PresentationDocument84 pagesObama Presidential Center PresentationThe Daily LineNo ratings yet

- Travel Reservation July 25 For FRANCISCO GUTIERREZDocument2 pagesTravel Reservation July 25 For FRANCISCO GUTIERREZJose HerreraNo ratings yet

- Design of Catamaran Ship Main Deck and Bulkhead To Withstand The Crane LoadDocument11 pagesDesign of Catamaran Ship Main Deck and Bulkhead To Withstand The Crane Loadghulam mohi ud dinNo ratings yet

- Iot-Driven Road Safety System: Abstract-Roads Are Integral Part of Human Civilization. TheyDocument5 pagesIot-Driven Road Safety System: Abstract-Roads Are Integral Part of Human Civilization. TheyLicence Spécialisée Idbd EnsakNo ratings yet

- Steady Aircraft Flight and Aircraft PerformanceDocument203 pagesSteady Aircraft Flight and Aircraft PerformanceJack58No ratings yet

![Belt Conveyor (V1)[1]](https://imgv2-2-f.scribdassets.com/img/document/747882384/149x198/684dce487d/1720099833?v=1)