Professional Documents

Culture Documents

IENG 475 Lecture 05

IENG 475 Lecture 05

Uploaded by

Zain TahirCopyright:

Available Formats

You might also like

- Lathe 3Document30 pagesLathe 3redflavenNo ratings yet

- IENG 475 Lecture 05Document27 pagesIENG 475 Lecture 05John VincentNo ratings yet

- Lathe and Drilling OperationsDocument58 pagesLathe and Drilling OperationsPalak NaikNo ratings yet

- IENG 475 Lecture 06Document22 pagesIENG 475 Lecture 06patlninadNo ratings yet

- Milling MachineDocument22 pagesMilling MachineSheikh Zakir100% (1)

- Chapter 21-Theory of Metal MachiningDocument50 pagesChapter 21-Theory of Metal MachiningFaizanNo ratings yet

- Chapter 21-Theory of Metal MachiningDocument50 pagesChapter 21-Theory of Metal Machiningasifayaz120100% (2)

- Chapter 1Document68 pagesChapter 1gashawletaNo ratings yet

- Chapter 6 NursalbiahDocument109 pagesChapter 6 NursalbiahMohd Sayyid Mu'ammarNo ratings yet

- NTM 2 CompleteDocument21 pagesNTM 2 CompleteHatim Dailaimi100% (1)

- Week 11 Ch21 22 Machining OperationsDocument37 pagesWeek 11 Ch21 22 Machining OperationsJay Dee11No ratings yet

- M3 - MFG Science and Tooling - Theory of Metal Cutting-4Document172 pagesM3 - MFG Science and Tooling - Theory of Metal Cutting-4Grishma BalgiNo ratings yet

- Unit I - Theory of Metal CuttingDocument106 pagesUnit I - Theory of Metal CuttingRamesh Kumar ANo ratings yet

- Lec - 9 - Milling-Gear Cutting-CNCDocument38 pagesLec - 9 - Milling-Gear Cutting-CNCsaxadi4814No ratings yet

- CH 22 ADocument81 pagesCH 22 AThiran Boy LingamNo ratings yet

- Metal Cutting: Machining & Machining Tools Unit-1Document90 pagesMetal Cutting: Machining & Machining Tools Unit-1Joao PedroNo ratings yet

- 3rd Edition Anthony J. Wheeler Ahmad R.Document58 pages3rd Edition Anthony J. Wheeler Ahmad R.Ahmad IkhwanNo ratings yet

- Lec MillingDocument42 pagesLec Millingmuhammad sabihNo ratings yet

- Manufacturing Processes (2), Ie-352 Ahmed M El-Sherbeeny, PHD Spring 2018Document37 pagesManufacturing Processes (2), Ie-352 Ahmed M El-Sherbeeny, PHD Spring 2018Sid SharmaNo ratings yet

- 2Document77 pages2Pothuri SuneeldathNo ratings yet

- Manuf. Tech. - Machining OperationsDocument49 pagesManuf. Tech. - Machining OperationsManuel Tikongyin WundengbaNo ratings yet

- mp1 170302175707Document60 pagesmp1 170302175707uday245No ratings yet

- Lecture Objectives: To Develop An Understanding ofDocument24 pagesLecture Objectives: To Develop An Understanding ofMuhammad IrfanNo ratings yet

- Manufacturing Technology I - Material Removal Process 2Document164 pagesManufacturing Technology I - Material Removal Process 2Ayush KishoreNo ratings yet

- 03 - Ch1 To Ch4 - FinalDocument106 pages03 - Ch1 To Ch4 - FinalAhmed Sobhi l أحمد صبحيNo ratings yet

- Theory of Metal CuttingDocument89 pagesTheory of Metal CuttingRaj KumarNo ratings yet

- 04) Manufacturing Processes 1 PDFDocument63 pages04) Manufacturing Processes 1 PDFCharish ManimtimNo ratings yet

- MTM 1Document30 pagesMTM 1Abdul Moeed AhmedNo ratings yet

- Manufacturing Engineering II Chapter 1.1Document23 pagesManufacturing Engineering II Chapter 1.1Layike Alemayehu100% (1)

- Assignment Report1Document20 pagesAssignment Report1Keshav GopaulNo ratings yet

- Theory of Metal MachiningDocument63 pagesTheory of Metal MachiningThiran Boy LingamNo ratings yet

- Manufacturing Processes I - Machining ProcessesDocument57 pagesManufacturing Processes I - Machining ProcessesImtiajur Rahman AyonNo ratings yet

- Automation Chapter 6 PDFDocument240 pagesAutomation Chapter 6 PDFRaed Al Ma'aniNo ratings yet

- 04) Manufacturing Processes 1Document63 pages04) Manufacturing Processes 1mohamedabdallah2849728No ratings yet

- Lecture 4Document21 pagesLecture 4Muhammad Ali BakhtNo ratings yet

- Metal MachiningDocument23 pagesMetal MachiningAnas Anwar ArainNo ratings yet

- Chapter 22-Machining Operations IDocument79 pagesChapter 22-Machining Operations Iasifayaz120No ratings yet

- CH-1 MachiningDocument29 pagesCH-1 MachiningAbreham DerejeNo ratings yet

- Machining Operation IDocument40 pagesMachining Operation ICaleb QuaynorNo ratings yet

- Lec 1-Machining Operations IIDocument51 pagesLec 1-Machining Operations IIHammad RazaNo ratings yet

- SEMINARDocument17 pagesSEMINARAbin BrothersNo ratings yet

- Metal Cutting: BTME-405Document111 pagesMetal Cutting: BTME-405Yuvraaj Singh100% (1)

- Senario, Mary Angelie T. - LAB - Activity No. 8Document3 pagesSenario, Mary Angelie T. - LAB - Activity No. 8Mary Angelie SenarioNo ratings yet

- Unit 1Document106 pagesUnit 1anandNo ratings yet

- Machining Process - IDocument30 pagesMachining Process - INajshhsNo ratings yet

- Lecture 01 Chapter 21 Theory of Metal Machining GrooverDocument64 pagesLecture 01 Chapter 21 Theory of Metal Machining GrooverOttoman Empire “Ottoman Empire wars”No ratings yet

- Module 3 - Metal Removal Processes Fall2023Document203 pagesModule 3 - Metal Removal Processes Fall2023Amna OmerNo ratings yet

- Unit I - Theory of Metal CuttingDocument111 pagesUnit I - Theory of Metal CuttingSaravana KumarNo ratings yet

- Module 2 - Machining Processes and Machine Tools - Fall 2022Document203 pagesModule 2 - Machining Processes and Machine Tools - Fall 2022chemical labNo ratings yet

- Fundamentals of Metal Cutting and Machining Processes: Lecture 6-7Document150 pagesFundamentals of Metal Cutting and Machining Processes: Lecture 6-7Sibu SibuNo ratings yet

- Manufacturing Process - 2: Sot, PdpuDocument114 pagesManufacturing Process - 2: Sot, PdpuDipen KNo ratings yet

- Chap. 1Document49 pagesChap. 1Fabinus BinusNo ratings yet

- Turning Vs Milling ReadingDocument6 pagesTurning Vs Milling ReadingEnri JaénNo ratings yet

- Machining ProcessesDocument44 pagesMachining Processesregassa rajiNo ratings yet

- Theory of Metal Cutting-Module 1Document116 pagesTheory of Metal Cutting-Module 1rejeesh_rajendranNo ratings yet

- Machine Tools - 2022Document44 pagesMachine Tools - 2022Robert AggreyNo ratings yet

- CH 21Document45 pagesCH 21Anonymous p0mg44xNo ratings yet

- CH 22Document8 pagesCH 22Hari PrasadNo ratings yet

- Lecture 7 (Machining Operations, Planing, Shaping)Document29 pagesLecture 7 (Machining Operations, Planing, Shaping)hashir siddiquiNo ratings yet

- Maker Gallery DesignDocument1 pageMaker Gallery DesignSimran LakhwaniNo ratings yet

- Aws 13Document28 pagesAws 13sprasadn66No ratings yet

- Digital Iq Social Benchmark 2022Document24 pagesDigital Iq Social Benchmark 2022Andrius JaquesNo ratings yet

- Remax India - External Case StudyDocument1 pageRemax India - External Case StudyremaxyoungaceleadsNo ratings yet

- RMA Case StudyDocument8 pagesRMA Case StudyJohnny NguyenNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationIndira MukherjeeNo ratings yet

- Chapter 1 - Cost Accounting FundamentalsDocument16 pagesChapter 1 - Cost Accounting FundamentalsPrincess Jay NacorNo ratings yet

- Materials Management: DefinitionDocument3 pagesMaterials Management: DefinitionvijiNo ratings yet

- Supply Chain Management of BisleriDocument44 pagesSupply Chain Management of Bislerivipul suthar100% (1)

- FSM 002 Food Safety Quality Manual SummaryDocument8 pagesFSM 002 Food Safety Quality Manual SummaryAliNo ratings yet

- 1z0 982 PDFDocument51 pages1z0 982 PDFsuman dNo ratings yet

- Six Sigma: An Emerging Approach in Pharma Industry: I J P & A BDocument7 pagesSix Sigma: An Emerging Approach in Pharma Industry: I J P & A BRagavendra RagsNo ratings yet

- The Information Systems Life CycleDocument16 pagesThe Information Systems Life CycleVani AyyadevaraNo ratings yet

- A Review of Supply Chain Complexity Drivers PDFDocument6 pagesA Review of Supply Chain Complexity Drivers PDFar.chimedesNo ratings yet

- Case Study: How MERSEA Structures Its Marketing Funnel: Company BackgroundDocument5 pagesCase Study: How MERSEA Structures Its Marketing Funnel: Company BackgroundMANAV SAHUNo ratings yet

- Zahab Komal CV NewDocument3 pagesZahab Komal CV NewPasbanSaibanNo ratings yet

- By Harvinder Singh SainiDocument19 pagesBy Harvinder Singh Sainitara selfNo ratings yet

- PerformanceTask GROUP1Document2 pagesPerformanceTask GROUP1Shey BaraquioNo ratings yet

- Sales and Distribution Management Case PresentationDocument19 pagesSales and Distribution Management Case PresentationARPIT GILRANo ratings yet

- A Case Study of ERP ImplementationDocument24 pagesA Case Study of ERP ImplementationDevspringNo ratings yet

- New Supplier Survey FormDocument14 pagesNew Supplier Survey Formsutharitessh100% (1)

- Introduction To Enterprise Systems: Magal and Word - Integrated Business Processes With ERP Systems - © 2011Document36 pagesIntroduction To Enterprise Systems: Magal and Word - Integrated Business Processes With ERP Systems - © 2011M 3No ratings yet

- Cold Work Steels: Available Product VariantsDocument5 pagesCold Work Steels: Available Product VariantsAnonymous oyUAtpKNo ratings yet

- Industrial Training Report (Nor Aisyah Asyira Binti Nazli-2019475676)Document45 pagesIndustrial Training Report (Nor Aisyah Asyira Binti Nazli-2019475676)kun faridNo ratings yet

- Sydney Boys 2014 Business Studies Trials & SolutionsDocument25 pagesSydney Boys 2014 Business Studies Trials & SolutionsThomas SomyNo ratings yet

- High Speed MachiningDocument27 pagesHigh Speed MachiningSandeep Kumar100% (1)

- Supply Chain Security Risk Assessment FAQs 062510Document5 pagesSupply Chain Security Risk Assessment FAQs 062510Marco PeralNo ratings yet

- AF3112 Management Accounting 2: Process CostingDocument66 pagesAF3112 Management Accounting 2: Process Costing行歌No ratings yet

- Foundation in Management Accounting: FIA Level (MA1 + MA2)Document71 pagesFoundation in Management Accounting: FIA Level (MA1 + MA2)Trann NguyenNo ratings yet

- Omps Mim 5Document28 pagesOmps Mim 5Nicos AntoniadesNo ratings yet

IENG 475 Lecture 05

IENG 475 Lecture 05

Uploaded by

Zain TahirOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IENG 475 Lecture 05

IENG 475 Lecture 05

Uploaded by

Zain TahirCopyright:

Available Formats

IENG 475 - Lecture 05

Lathe Operations

10/26/20 IENG 475: Computer-Controlled 1

Manufacturing Systems

Bonus Quiz 1

Name the three primary parameters that

must be specified for a machining operation.

These three parameters allow us to decide if

we have the power to physically perform the

operation. What (three letters) calculation

can we get from the primary parameters to

begin to address the necessary power

requirements?

10/26/20 IENG 475: Computer-Controlled 3

Manufacturing Systems

Manufacturing Operations

Four classes of Processing Operations:

• Solidification Processes

• Particulate Processes

• Deformation Processes

• Material Removal Processes

Two classes of Assembly Operations:

• Mechanical Assembly

• Joining

10/26/20 IENG 475: Computer-Controlled 4

Manufacturing Systems

Machining

Variety of work materials can Wasteful of material

be machined • Chips generated in

• Most frequently applied to machining are wasted

metals material, at least in the

Variety of part shapes and unit operation

special geometry features Time consuming

possible, such as: • A machining operation

• Screw threads generally takes more time

• Accurate round holes to shape a given part than

• Very straight edges and flat alternative shaping

surfaces processes, such as

Good dimensional accuracy casting, powder

and surface finish metallurgy, or forming

10/26/20 IENG 475: Computer-Controlled 5

Manufacturing Systems

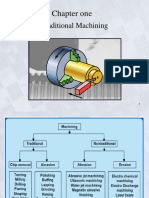

Machining Operations

Generally performed after other manufacturing processes

(casting, forging, …)

• Other processes create the general shape of the workpart

• Machining provides the final shape, dimensions, finish, and special

geometric details that other processes cannot create

Most important machining operations:

• Turning

• Drilling

• Milling

Other machining operations:

• Shaping and planing

• Broaching

• Sawing

10/26/20 IENG 475: Computer-Controlled 6

Manufacturing Systems

Primary Machining Parameters

Cutting Speed – (v)

• Primary motion

• Peripheral speed m/s ft/min

Feed – (f)

• Secondary motion

• Turning: mm/rev in/rev

• Milling: mm/tooth in/tooth

Depth of Cut – (d)

• Penetration of tool below original work surface

• Single parameter mm in

Resulting in Material Removal Rate – (MRR)

MRR = v f d mm3/s in3/min

where v = cutting speed; f = feed; d = depth of cut

10/26/20 IENG 475: Computer-Controlled 7

Manufacturing Systems

Turning Parameters Illustrated

Figure 22.5 ‑ Turning operation [Groover (2004), p.503]

10/26/20 IENG 475: Computer-Controlled 8

Manufacturing Systems

Drilling

Creates a round hole in

a workpart

Contrasts with boring

which can only enlarge

an existing hole

Cutting tool called a drill

or drill bit

Customarily performed

on a drill press

Figure 21.3 (b) drilling

[Groover (2004), p.501]

10/26/20 IENG 475: Computer-Controlled 9

Manufacturing Systems

Milling Parameters Illustrated

Figure 21.3 ‑ Two forms of milling:

[Groover (2004), p.516]

(a) peripheral milling, and (b) face milling

10/26/20 IENG 475: Computer-Controlled 10

Manufacturing Systems

Machining Operations &

Parameters

Operation Type Speed Feed Depth of Cut

Turning: Surface speed Parallel to the Tool penetration

(periphery) of workpiece axis* below original

workpiece rotates

workpiece (*except parting/grooving) work surface

single point cutting

Drilling: Surface speed Parallel to the Tool penetration

(periphery) of tool axis below original

tool rotates

tool work surface

single pass cutting (depth of hole)

Milling: Surface speed Perpendicular to Tool penetration

(periphery) of the tool axis below original

tool rotates

tool work surface

multi-point cutting

10/26/20 IENG 475: Computer-Controlled 11

Manufacturing Systems

Cut Types: Roughing &

Finishing

Number

Cut Type of Speed Feed Depth of Cut

Passes

Roughing: 1+ Low High High

removes large 0.4 - 1.25 mm/ 2.5 - 20 mm

amounts to get .015 - .050 in/ .100 - .750 in

close to shape

Finishing: 1-2 High Low Low

achieves final 0.125 - 0.4 mm/ 0.75 - 2.0 mm

dimensions, .005 - .015 in/ .030 - .075 in

tolerances, and

finish

10/26/20 IENG 475: Computer-Controlled 12

Manufacturing Systems

Turning

A single point cutting tool removes material from a

rotating workpiece to generate a rotationally

symmetric shape

Machine tool is called a lathe

Types of cuts:

• Facing

• Contour turning

• Chamfering

• Parting (Cut-off) / Grooving

• Threading

10/26/20 IENG 475: Computer-Controlled 13

Manufacturing Systems

Turning Parameters Illustrated

Figure 22.5 ‑ Turning operation [Groover (2004), p.503]

10/26/20 IENG 475: Computer-Controlled 14

Manufacturing Systems

Facing

Tool is fed

radially inward

Figure 22.6 (a) facing

10/26/20 IENG 475: Computer-Controlled 15

Manufacturing Systems

Contour Turning

Instead of feeding the

tool parallel to the axis

of rotation, tool follows a

contour that is not

necessarily straight

(thus creating a

contoured form).

Figure 22.6 (c) contour turning

10/26/20 IENG 475: Computer-Controlled 16

Manufacturing Systems

Right & Left Hand Tools

Right Hand Tool:

• Cuts from right to left

Left Hand Tool:

• Cuts from left to right

10/26/20 IENG 475: Computer-Controlled 17

Manufacturing Systems

Chamfering

Cutting edge

cuts an angle on

the corner of the

cylinder, forming

a "chamfer"

Figure 22.6 (e) chamfering

10/26/20 IENG 475: Computer-Controlled 18

Manufacturing Systems

Parting (Cutoff) / Grooving

Tool is fed radially

into rotating work

at some location

to cut off end of

part, or provide a

groove

Figure 22.6 (f) cutoff

10/26/20 IENG 475: Computer-Controlled 19

Manufacturing Systems

Threading

Pointed form tool is

fed linearly across

surface of rotating

workpart parallel to

axis of rotation at a

large feed rate, thus

creating threads

Figure 22.6 (g) threading

10/26/20 IENG 475: Computer-Controlled 20

Manufacturing Systems

Engine Lathe

Figure 22.7

Diagram of

an engine

lathe,

showing its

principal

components

10/26/20 IENG 475: Computer-Controlled 21

Manufacturing Systems

Chuck

Figure 22.8 (b) three‑jaw chuck

10/26/20 IENG 475: Computer-Controlled 22

Manufacturing Systems

Turret Lathe

Manual operation is replaced by a

“turret” that holds multiple tools

• Tools are rapidly brought into action by

indexing the turret

• Tool post is replaced by multi‑sided turret

to index multiple tools

• Applications: high production work that

requires a sequence of cuts on the part

10/26/20 IENG 475: Computer-Controlled 23

Manufacturing Systems

CNC Turret Lathe

Spindle Speed

Tool Turret

+ X-axis

Ways

+ Z-axis

Cross Slide

Spindle

10/26/20 IENG 475: Computer-Controlled 24

Manufacturing Systems

CNC Lathe: Air-Operated Chuck

Right Hand

Profile Tool

Chuck

10/26/20 IENG 475: Computer-Controlled 25

Manufacturing Systems

CNC Lathe: Tool Turret

Left Hand

Profile Tool

Tool Turret

Grooving /

Parting Tool

Tool Holder

Right Hand

Profile Tool

10/26/20 IENG 475: Computer-Controlled 26

Manufacturing Systems

Machining Calculations:

Turning

Spindle Speed - N v (rpm)

• v = cutting speed N

• Do = outer diameter π Do

Feed Rate - fr (mm/min -or- in/min)

• f = feed per rev fr N f

Depth of Cut - d Do Df (mm/rev -or- in/rev)

d

• Do = outer diameter 2

• Df = final diameter

Machining Time - Tm L (min)

Tm

• L = length of cut fr

Mat’l Removal Rate - MRR MRR v f d (mm3/min -or- in3/min)

10/26/20 IENG 475: Computer-Controlled 27

Manufacturing Systems

Questions & Issues

Finish Machining (Drilling & Milling) Next Week:

• Next Topic: Process Planning

• Following Week: Group Technology

Lab this week:

• Fixturing (manual tools & drill press)

Lab next week:

• Manual Lathe & Mill Operations:

• Rough & Finish Profiling Cuts

• Facing Cuts

• Parting Cuts

• Tool Changes

• Touch-Off

10/26/20 IENG 475: Computer-Controlled 28

Manufacturing Systems

You might also like

- Lathe 3Document30 pagesLathe 3redflavenNo ratings yet

- IENG 475 Lecture 05Document27 pagesIENG 475 Lecture 05John VincentNo ratings yet

- Lathe and Drilling OperationsDocument58 pagesLathe and Drilling OperationsPalak NaikNo ratings yet

- IENG 475 Lecture 06Document22 pagesIENG 475 Lecture 06patlninadNo ratings yet

- Milling MachineDocument22 pagesMilling MachineSheikh Zakir100% (1)

- Chapter 21-Theory of Metal MachiningDocument50 pagesChapter 21-Theory of Metal MachiningFaizanNo ratings yet

- Chapter 21-Theory of Metal MachiningDocument50 pagesChapter 21-Theory of Metal Machiningasifayaz120100% (2)

- Chapter 1Document68 pagesChapter 1gashawletaNo ratings yet

- Chapter 6 NursalbiahDocument109 pagesChapter 6 NursalbiahMohd Sayyid Mu'ammarNo ratings yet

- NTM 2 CompleteDocument21 pagesNTM 2 CompleteHatim Dailaimi100% (1)

- Week 11 Ch21 22 Machining OperationsDocument37 pagesWeek 11 Ch21 22 Machining OperationsJay Dee11No ratings yet

- M3 - MFG Science and Tooling - Theory of Metal Cutting-4Document172 pagesM3 - MFG Science and Tooling - Theory of Metal Cutting-4Grishma BalgiNo ratings yet

- Unit I - Theory of Metal CuttingDocument106 pagesUnit I - Theory of Metal CuttingRamesh Kumar ANo ratings yet

- Lec - 9 - Milling-Gear Cutting-CNCDocument38 pagesLec - 9 - Milling-Gear Cutting-CNCsaxadi4814No ratings yet

- CH 22 ADocument81 pagesCH 22 AThiran Boy LingamNo ratings yet

- Metal Cutting: Machining & Machining Tools Unit-1Document90 pagesMetal Cutting: Machining & Machining Tools Unit-1Joao PedroNo ratings yet

- 3rd Edition Anthony J. Wheeler Ahmad R.Document58 pages3rd Edition Anthony J. Wheeler Ahmad R.Ahmad IkhwanNo ratings yet

- Lec MillingDocument42 pagesLec Millingmuhammad sabihNo ratings yet

- Manufacturing Processes (2), Ie-352 Ahmed M El-Sherbeeny, PHD Spring 2018Document37 pagesManufacturing Processes (2), Ie-352 Ahmed M El-Sherbeeny, PHD Spring 2018Sid SharmaNo ratings yet

- 2Document77 pages2Pothuri SuneeldathNo ratings yet

- Manuf. Tech. - Machining OperationsDocument49 pagesManuf. Tech. - Machining OperationsManuel Tikongyin WundengbaNo ratings yet

- mp1 170302175707Document60 pagesmp1 170302175707uday245No ratings yet

- Lecture Objectives: To Develop An Understanding ofDocument24 pagesLecture Objectives: To Develop An Understanding ofMuhammad IrfanNo ratings yet

- Manufacturing Technology I - Material Removal Process 2Document164 pagesManufacturing Technology I - Material Removal Process 2Ayush KishoreNo ratings yet

- 03 - Ch1 To Ch4 - FinalDocument106 pages03 - Ch1 To Ch4 - FinalAhmed Sobhi l أحمد صبحيNo ratings yet

- Theory of Metal CuttingDocument89 pagesTheory of Metal CuttingRaj KumarNo ratings yet

- 04) Manufacturing Processes 1 PDFDocument63 pages04) Manufacturing Processes 1 PDFCharish ManimtimNo ratings yet

- MTM 1Document30 pagesMTM 1Abdul Moeed AhmedNo ratings yet

- Manufacturing Engineering II Chapter 1.1Document23 pagesManufacturing Engineering II Chapter 1.1Layike Alemayehu100% (1)

- Assignment Report1Document20 pagesAssignment Report1Keshav GopaulNo ratings yet

- Theory of Metal MachiningDocument63 pagesTheory of Metal MachiningThiran Boy LingamNo ratings yet

- Manufacturing Processes I - Machining ProcessesDocument57 pagesManufacturing Processes I - Machining ProcessesImtiajur Rahman AyonNo ratings yet

- Automation Chapter 6 PDFDocument240 pagesAutomation Chapter 6 PDFRaed Al Ma'aniNo ratings yet

- 04) Manufacturing Processes 1Document63 pages04) Manufacturing Processes 1mohamedabdallah2849728No ratings yet

- Lecture 4Document21 pagesLecture 4Muhammad Ali BakhtNo ratings yet

- Metal MachiningDocument23 pagesMetal MachiningAnas Anwar ArainNo ratings yet

- Chapter 22-Machining Operations IDocument79 pagesChapter 22-Machining Operations Iasifayaz120No ratings yet

- CH-1 MachiningDocument29 pagesCH-1 MachiningAbreham DerejeNo ratings yet

- Machining Operation IDocument40 pagesMachining Operation ICaleb QuaynorNo ratings yet

- Lec 1-Machining Operations IIDocument51 pagesLec 1-Machining Operations IIHammad RazaNo ratings yet

- SEMINARDocument17 pagesSEMINARAbin BrothersNo ratings yet

- Metal Cutting: BTME-405Document111 pagesMetal Cutting: BTME-405Yuvraaj Singh100% (1)

- Senario, Mary Angelie T. - LAB - Activity No. 8Document3 pagesSenario, Mary Angelie T. - LAB - Activity No. 8Mary Angelie SenarioNo ratings yet

- Unit 1Document106 pagesUnit 1anandNo ratings yet

- Machining Process - IDocument30 pagesMachining Process - INajshhsNo ratings yet

- Lecture 01 Chapter 21 Theory of Metal Machining GrooverDocument64 pagesLecture 01 Chapter 21 Theory of Metal Machining GrooverOttoman Empire “Ottoman Empire wars”No ratings yet

- Module 3 - Metal Removal Processes Fall2023Document203 pagesModule 3 - Metal Removal Processes Fall2023Amna OmerNo ratings yet

- Unit I - Theory of Metal CuttingDocument111 pagesUnit I - Theory of Metal CuttingSaravana KumarNo ratings yet

- Module 2 - Machining Processes and Machine Tools - Fall 2022Document203 pagesModule 2 - Machining Processes and Machine Tools - Fall 2022chemical labNo ratings yet

- Fundamentals of Metal Cutting and Machining Processes: Lecture 6-7Document150 pagesFundamentals of Metal Cutting and Machining Processes: Lecture 6-7Sibu SibuNo ratings yet

- Manufacturing Process - 2: Sot, PdpuDocument114 pagesManufacturing Process - 2: Sot, PdpuDipen KNo ratings yet

- Chap. 1Document49 pagesChap. 1Fabinus BinusNo ratings yet

- Turning Vs Milling ReadingDocument6 pagesTurning Vs Milling ReadingEnri JaénNo ratings yet

- Machining ProcessesDocument44 pagesMachining Processesregassa rajiNo ratings yet

- Theory of Metal Cutting-Module 1Document116 pagesTheory of Metal Cutting-Module 1rejeesh_rajendranNo ratings yet

- Machine Tools - 2022Document44 pagesMachine Tools - 2022Robert AggreyNo ratings yet

- CH 21Document45 pagesCH 21Anonymous p0mg44xNo ratings yet

- CH 22Document8 pagesCH 22Hari PrasadNo ratings yet

- Lecture 7 (Machining Operations, Planing, Shaping)Document29 pagesLecture 7 (Machining Operations, Planing, Shaping)hashir siddiquiNo ratings yet

- Maker Gallery DesignDocument1 pageMaker Gallery DesignSimran LakhwaniNo ratings yet

- Aws 13Document28 pagesAws 13sprasadn66No ratings yet

- Digital Iq Social Benchmark 2022Document24 pagesDigital Iq Social Benchmark 2022Andrius JaquesNo ratings yet

- Remax India - External Case StudyDocument1 pageRemax India - External Case StudyremaxyoungaceleadsNo ratings yet

- RMA Case StudyDocument8 pagesRMA Case StudyJohnny NguyenNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationIndira MukherjeeNo ratings yet

- Chapter 1 - Cost Accounting FundamentalsDocument16 pagesChapter 1 - Cost Accounting FundamentalsPrincess Jay NacorNo ratings yet

- Materials Management: DefinitionDocument3 pagesMaterials Management: DefinitionvijiNo ratings yet

- Supply Chain Management of BisleriDocument44 pagesSupply Chain Management of Bislerivipul suthar100% (1)

- FSM 002 Food Safety Quality Manual SummaryDocument8 pagesFSM 002 Food Safety Quality Manual SummaryAliNo ratings yet

- 1z0 982 PDFDocument51 pages1z0 982 PDFsuman dNo ratings yet

- Six Sigma: An Emerging Approach in Pharma Industry: I J P & A BDocument7 pagesSix Sigma: An Emerging Approach in Pharma Industry: I J P & A BRagavendra RagsNo ratings yet

- The Information Systems Life CycleDocument16 pagesThe Information Systems Life CycleVani AyyadevaraNo ratings yet

- A Review of Supply Chain Complexity Drivers PDFDocument6 pagesA Review of Supply Chain Complexity Drivers PDFar.chimedesNo ratings yet

- Case Study: How MERSEA Structures Its Marketing Funnel: Company BackgroundDocument5 pagesCase Study: How MERSEA Structures Its Marketing Funnel: Company BackgroundMANAV SAHUNo ratings yet

- Zahab Komal CV NewDocument3 pagesZahab Komal CV NewPasbanSaibanNo ratings yet

- By Harvinder Singh SainiDocument19 pagesBy Harvinder Singh Sainitara selfNo ratings yet

- PerformanceTask GROUP1Document2 pagesPerformanceTask GROUP1Shey BaraquioNo ratings yet

- Sales and Distribution Management Case PresentationDocument19 pagesSales and Distribution Management Case PresentationARPIT GILRANo ratings yet

- A Case Study of ERP ImplementationDocument24 pagesA Case Study of ERP ImplementationDevspringNo ratings yet

- New Supplier Survey FormDocument14 pagesNew Supplier Survey Formsutharitessh100% (1)

- Introduction To Enterprise Systems: Magal and Word - Integrated Business Processes With ERP Systems - © 2011Document36 pagesIntroduction To Enterprise Systems: Magal and Word - Integrated Business Processes With ERP Systems - © 2011M 3No ratings yet

- Cold Work Steels: Available Product VariantsDocument5 pagesCold Work Steels: Available Product VariantsAnonymous oyUAtpKNo ratings yet

- Industrial Training Report (Nor Aisyah Asyira Binti Nazli-2019475676)Document45 pagesIndustrial Training Report (Nor Aisyah Asyira Binti Nazli-2019475676)kun faridNo ratings yet

- Sydney Boys 2014 Business Studies Trials & SolutionsDocument25 pagesSydney Boys 2014 Business Studies Trials & SolutionsThomas SomyNo ratings yet

- High Speed MachiningDocument27 pagesHigh Speed MachiningSandeep Kumar100% (1)

- Supply Chain Security Risk Assessment FAQs 062510Document5 pagesSupply Chain Security Risk Assessment FAQs 062510Marco PeralNo ratings yet

- AF3112 Management Accounting 2: Process CostingDocument66 pagesAF3112 Management Accounting 2: Process Costing行歌No ratings yet

- Foundation in Management Accounting: FIA Level (MA1 + MA2)Document71 pagesFoundation in Management Accounting: FIA Level (MA1 + MA2)Trann NguyenNo ratings yet

- Omps Mim 5Document28 pagesOmps Mim 5Nicos AntoniadesNo ratings yet