Professional Documents

Culture Documents

This Time: Manufacturing & Materials: Manufacturing Is Undergoing A Revolution: Traditional Methods

This Time: Manufacturing & Materials: Manufacturing Is Undergoing A Revolution: Traditional Methods

Uploaded by

akabhinav320 ratings0% found this document useful (0 votes)

26 views20 pagesThis document discusses advances in manufacturing methods. Traditional manufacturing involves casting, molding, and other non-programmable methods, while newer computer numerical control (CNC) techniques like milling and lathing allow shapes to be programmed. Additive manufacturing such as 3D printing creates objects by adding layers of material and comes in various technologies like stereolithography, fused deposition modeling, and laminated object modeling. Overall, the text outlines how new manufacturing approaches now enable programmable shaping and complex geometries through techniques like CNC machines, laser cutting, and 3D printing.

Original Description:

Original Title

L-2 design realization

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses advances in manufacturing methods. Traditional manufacturing involves casting, molding, and other non-programmable methods, while newer computer numerical control (CNC) techniques like milling and lathing allow shapes to be programmed. Additive manufacturing such as 3D printing creates objects by adding layers of material and comes in various technologies like stereolithography, fused deposition modeling, and laminated object modeling. Overall, the text outlines how new manufacturing approaches now enable programmable shaping and complex geometries through techniques like CNC machines, laser cutting, and 3D printing.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

26 views20 pagesThis Time: Manufacturing & Materials: Manufacturing Is Undergoing A Revolution: Traditional Methods

This Time: Manufacturing & Materials: Manufacturing Is Undergoing A Revolution: Traditional Methods

Uploaded by

akabhinav32This document discusses advances in manufacturing methods. Traditional manufacturing involves casting, molding, and other non-programmable methods, while newer computer numerical control (CNC) techniques like milling and lathing allow shapes to be programmed. Additive manufacturing such as 3D printing creates objects by adding layers of material and comes in various technologies like stereolithography, fused deposition modeling, and laminated object modeling. Overall, the text outlines how new manufacturing approaches now enable programmable shaping and complex geometries through techniques like CNC machines, laser cutting, and 3D printing.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 20

This time: Manufacturing & Materials

Manufacturing is undergoing a revolution:

Traditional methods:

Casting, molding, fusing, slumping

Milling, lathing (non CNC-versions)

Stamping

Rolling, extrusion

Shape is “write-once” (not programmable) in

these methods.

Next-wave Manufacturing

Reprogramming shape:

CNC machining:

A computer outputs a path for a

cutting tool to create a specified

surface.

Not new, but now inexpensive,

PC-based.

Plastics, wood, metal, glass.

Flashcut 2000, XYZ-axes, 9x7x6.5”, $2895

Milling

Milling involves a moving XYZ head that cuts

into the workpiece:

Bits can achieve different

finishes.

Lathing

Lathes cut circularly symmetric parts.

Shafts, furniture, fasteners,… lenses.

Can also do grinding and polishing.

Milling Example

CNC milling example

(Deskproto web site)

Finish is quite smooth

ballnose cutting tool.

Lots of waste, but can

be recycled!

Next-wave Manufacturing

PC-boards:

Created with CAD tools.

Photographic reproduction:

• Low cost in volume.

• High complexity possible.

Multi-step process, BUT:

Web-based services have 24-hour turnaround,

low cost.

Next-wave Manufacturing

CNC Laser cutter:

X-Y axes control a powerful laser.

Fine line (0.007” or better).

Positioning to 1000 dpi,

Some control of depth:

• Engraving as

well as cutting.

Moderate cost:

$10,000 Versalaser

16x12” workspace.

Laser Cutter Capabilities

Precision is good enough to make smooth

sliding surfaces (gears).

Layering can be used to make

3D surfaces (very popular for

architectural models).

Can even make PCBs

by etching metal

from clear plastic!

Other 2D Cutting Technologies

Lasers can cut metal, but not

easily

Power limits, need to deal with

material removal.

Plasma cutters use an

electrically-generated plasma

jet to cut

Sweeps away material.

Plasma Cutters

Thin shapes in a variety of metals.

Torchmate 3 machine

is $10,000 for 4x8’

workspace.

Water Cutters

Similar idea to plasma but based on high-

pressure waterjet.

Cleaner method: water plus metal can be

collected.

Cost??

3D printers

A variety of 3D printing techniques have

appeared in the last few years.

SLA: Stereolithography: laser curing of

liquid plastic.

SLS: Selective Laser Sintering: similar, laser

fuses powder.

LOM: Layered Object Modeling: laser cuts

paper one layer at a time.

FDM: Fused Deposition Modeling: a thread

of plastic is melted through a moving head.

Stereolithography: SLA

Earliest 3D method, based on UV-set polymers.

Resolution quite good: 0.002” layers.

Curing needed before

part can be used.

LOM: Laminated Object Modelling

FDM: Fused Deposition Modelling

FDM is one of the most

versatile 3D methods

Many materials can be used:

solvent-based or thermo-

plastics.

Requires X-Y-X motion (like

a CNC machine).

Stratasys machines start at

$30,000

Roll-your-own 3D Printers

Material feeding heads are

commercial modules.

Microfab makes heads for

solvent-based and thermo-

plastics.

Add a CNC XYZ-stage to

create your own printer.

Roll-your-own 3D Printers

Polymer electronics is printable with microfab

heads, working on actuators.

Potential for printing complete electro-

mechanical systems.

Two prototype printers

at Berkeley.

3D Printer Disadvantages

Slow! Adding material is much slower than

removing it.

Speed scales very poorly with resolution:

double resolution and decrease speed by 8x.

Laser 3D methods faster (than other heads)

for equivalent resolution, but limited

materials.

3D Printing Data

The standard 3D printing format is “STL”.

Available as an output option for most CAD

tools, as a 3rd-party translator for Maya.

Then process-specific CAM software

(Computer-Aided Manufacturing) creates a

tool control file:

Tool path for milling and lathing.

Slices and support structures for 3D printers.

Summary

CNC machines provide shape programmability.

Lathes and mills provide traditional shaping.

Layered methods can create almost unlimited

shapes, but slowly.

2D and 3D shaping methods generally based

on CNC motion of an active head.

Architecture of shaping machines is open:

movement and heads are available separately.

You might also like

- Module-1 Additive Manufacturing 18 SchemeDocument47 pagesModule-1 Additive Manufacturing 18 SchemeSANTOSH100% (1)

- Concept ModellersDocument39 pagesConcept ModellersParth Modi83% (6)

- Embedded C Absolute Beginner-Compressed PDFDocument80 pagesEmbedded C Absolute Beginner-Compressed PDFakabhinav32No ratings yet

- Linking Words ExercisesDocument4 pagesLinking Words ExercisesNLBekvalac100% (1)

- Design Realization: John Canny 9/23/03Document22 pagesDesign Realization: John Canny 9/23/03Ricky SetyawanNo ratings yet

- Lec 9Document22 pagesLec 9Sreenivas BathinaNo ratings yet

- 3D Printing Introduction and Types PDFDocument83 pages3D Printing Introduction and Types PDFŤhåŕüñ Kūmæř GøwđNo ratings yet

- 3D PrintingDocument15 pages3D Printingstanley yNo ratings yet

- 3D PrintingDocument25 pages3D PrintingAnonymous PzbYdcEzNo ratings yet

- 3d PrintingDocument18 pages3d PrintingAnand Kumar YadavNo ratings yet

- IEEE Paper On 3d PrintingDocument4 pagesIEEE Paper On 3d PrintingSumit Rai91% (11)

- Rapid Prototyping (RP) : Compiled By:-Suwasit Dhiman Lelogix Design Solutions Pvt. LTDDocument23 pagesRapid Prototyping (RP) : Compiled By:-Suwasit Dhiman Lelogix Design Solutions Pvt. LTDmech430No ratings yet

- 3D PrintingDocument29 pages3D PrintingAbdul QualeqNo ratings yet

- By Joemics Ruban J Reg No:111617114036 Final Year Rmkcet: Seminar On 3d-PrintingDocument10 pagesBy Joemics Ruban J Reg No:111617114036 Final Year Rmkcet: Seminar On 3d-PrintingJoemics RubanNo ratings yet

- 3D Printing of Core and Cavity InsertsDocument15 pages3D Printing of Core and Cavity InsertsSushmaNo ratings yet

- Introduction To 3D PrinterDocument11 pagesIntroduction To 3D PrinterNilanka HarshaniNo ratings yet

- FINAL 3d Printing R M PowerPoint PresentationDocument20 pagesFINAL 3d Printing R M PowerPoint Presentationanugupta5354No ratings yet

- 3D Printing: Muhammed Ashiik S REG - NO 15040100 S5 ElectronicsDocument19 pages3D Printing: Muhammed Ashiik S REG - NO 15040100 S5 ElectronicsshadowhackerNo ratings yet

- Rapid Prototyping: Ashish Menon-13Bme0317 Sumit Sankhyan - 13bme0051 Siddhartha SARKAR - 13BME0281Document19 pagesRapid Prototyping: Ashish Menon-13Bme0317 Sumit Sankhyan - 13bme0051 Siddhartha SARKAR - 13BME0281AshishMenonNo ratings yet

- Additive Manufacturin Module 1 PPT NotesDocument46 pagesAdditive Manufacturin Module 1 PPT NotesMaaz AK100% (1)

- Seminar On: 3D PrintingDocument19 pagesSeminar On: 3D Printingdhanalakshmi k sNo ratings yet

- 3D Printing Technology: Design and Analysis of A Coil SPR For Different Materials Using Ansys With 3D Printing TechnologyDocument22 pages3D Printing Technology: Design and Analysis of A Coil SPR For Different Materials Using Ansys With 3D Printing TechnologySaiNo ratings yet

- Unit 3Document36 pagesUnit 3akshaymm1616No ratings yet

- 3D Printing and NanotechnologyDocument18 pages3D Printing and NanotechnologyJoyitaNo ratings yet

- 3D Printing SeminarDocument19 pages3D Printing SeminarManoj gowda kNo ratings yet

- 3D Printing Materials ReportDocument14 pages3D Printing Materials ReportKamal NabilNo ratings yet

- Rapid Prototyping and Surface Modification TechniquesDocument46 pagesRapid Prototyping and Surface Modification TechniquesmanuNo ratings yet

- 3D PrintingDocument18 pages3D PrintingkishanNo ratings yet

- 3D PrintingDocument19 pages3D PrintingMadhukar SamathamNo ratings yet

- Lect 3. Lean Manufacturing - 3d PrintingDocument66 pagesLect 3. Lean Manufacturing - 3d Printingraja harisNo ratings yet

- RTC Institute of Technology ANANDI, RANCHI-834 003Document27 pagesRTC Institute of Technology ANANDI, RANCHI-834 003bvnareshNo ratings yet

- Seminar On-3D Printing: Submitted By: Anju Dewangan Submitted To: Dr. G.K. Agrawal SirDocument23 pagesSeminar On-3D Printing: Submitted By: Anju Dewangan Submitted To: Dr. G.K. Agrawal SirTerminator941988No ratings yet

- Seminar On-3D Printing: Submitted By: Anju Dewangan Submitted To: Dr. G.K. Agrawal SirDocument23 pagesSeminar On-3D Printing: Submitted By: Anju Dewangan Submitted To: Dr. G.K. Agrawal SirTerminator941988No ratings yet

- Fabitor ContentDocument6 pagesFabitor ContentChandana SurthiNo ratings yet

- MSU6 Rapidprototypingtask 2Document27 pagesMSU6 Rapidprototypingtask 2adinamdarNo ratings yet

- 3D Printing: A SeminarDocument17 pages3D Printing: A SeminarRajesh SahuNo ratings yet

- Intro To AM ProcessesDocument71 pagesIntro To AM ProcessesChinmaya PadhyNo ratings yet

- 3D Printing & Prototyping: 2 Sem Lab Internal - Animesh SahooDocument15 pages3D Printing & Prototyping: 2 Sem Lab Internal - Animesh SahooAnimesh SahooNo ratings yet

- 3D PrintingDocument19 pages3D PrintingvindhNo ratings yet

- Sinhgad College of Engineering, Pune - 41Document11 pagesSinhgad College of Engineering, Pune - 41NikNo ratings yet

- RTC Institute of Technology ANANDI, RANCHI-834 003Document27 pagesRTC Institute of Technology ANANDI, RANCHI-834 003mecoolguysNo ratings yet

- 3D PrintingDocument21 pages3D PrintingOM PRAKASH SRIVASTAVANo ratings yet

- Module 1Document37 pagesModule 1Lokesh Lokesh D SNo ratings yet

- RTC Institute of Technology ANANDI, RANCHI-834 003Document27 pagesRTC Institute of Technology ANANDI, RANCHI-834 003B.AishwaryaNo ratings yet

- 3D PrintingDocument23 pages3D PrintingSrijan Upadhyay100% (1)

- Kaushalendra PDFDocument24 pagesKaushalendra PDFharshNo ratings yet

- 15ME82 Module 1Document72 pages15ME82 Module 1Machine BatteryNo ratings yet

- Makaut Question Banks SolutionDocument63 pagesMakaut Question Banks SolutionTirtha DasNo ratings yet

- Advances in 3D Printing: 1. Shubham Jain 2. Nitin Mamgai 3. Vinay KumarDocument9 pagesAdvances in 3D Printing: 1. Shubham Jain 2. Nitin Mamgai 3. Vinay KumarShubham JainNo ratings yet

- DR - Lakshmidevamma.M.M Department of Mechanical Engineering, Gec, KushalnagarDocument12 pagesDR - Lakshmidevamma.M.M Department of Mechanical Engineering, Gec, KushalnagarAKASHNo ratings yet

- Module 2 - CNC, 3d PrintingDocument5 pagesModule 2 - CNC, 3d Printingmahatosuraj078No ratings yet

- Computer Aided Design and Manufacturing Module 5 - Vikranth KannanthDocument35 pagesComputer Aided Design and Manufacturing Module 5 - Vikranth KannanthRavi Shankar mrNo ratings yet

- Tutorial: Rapid Prototyping TechnologiesDocument10 pagesTutorial: Rapid Prototyping TechnologiesFilip SvnikolicNo ratings yet

- Semester Project Presentation-SampleDocument17 pagesSemester Project Presentation-Samplek6561321No ratings yet

- 3d PrintingDocument74 pages3d PrintingDknargesh 2003No ratings yet

- 3D PrintingDocument16 pages3D Printingsagar_sgrNo ratings yet

- Guerrilla Guide To CNC Machining, Mold Making, and Resin CastingDocument106 pagesGuerrilla Guide To CNC Machining, Mold Making, and Resin CastingancientasmNo ratings yet

- 3dprintingppt 170825043023Document19 pages3dprintingppt 170825043023Terminator941988No ratings yet

- WWW - Oeclib.in: Seminar OnDocument19 pagesWWW - Oeclib.in: Seminar OnTerminator941988No ratings yet

- 3D PrintingDocument43 pages3D PrintingBheemesh GudelliNo ratings yet

- Desktop Manufacturing Use Machine Above This To Make ProductsFrom EverandDesktop Manufacturing Use Machine Above This To Make ProductsNo ratings yet

- Welding Processes 11Document97 pagesWelding Processes 11akabhinav32100% (2)

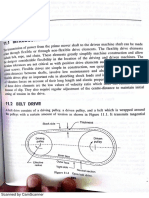

- Belt DriveDocument34 pagesBelt Driveakabhinav32No ratings yet

- L 4-MillingDocument27 pagesL 4-Millingakabhinav32No ratings yet

- L 2 Milling-01.09.2-15Document25 pagesL 2 Milling-01.09.2-15akabhinav32No ratings yet

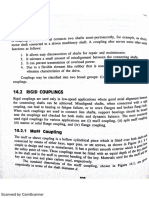

- Coupling PDFDocument19 pagesCoupling PDFakabhinav32No ratings yet

- L1-Shaper Slotter PlannerDocument47 pagesL1-Shaper Slotter Plannerakabhinav32No ratings yet

- Gears Manufacturing & Machine Tools & Machine ToolsDocument50 pagesGears Manufacturing & Machine Tools & Machine Toolsakabhinav32No ratings yet

- Applied Sciences: Extending Battery Lifetime by Avoiding High SOCDocument16 pagesApplied Sciences: Extending Battery Lifetime by Avoiding High SOCakabhinav32No ratings yet

- ME449 PracticeDocument98 pagesME449 Practiceakabhinav32No ratings yet

- Energies 12 00667 PDFDocument14 pagesEnergies 12 00667 PDFakabhinav32No ratings yet

- M2DC Series User Manual PDFDocument168 pagesM2DC Series User Manual PDFakabhinav32No ratings yet

- How To Mix Colors in Paint ProductionDocument17 pagesHow To Mix Colors in Paint ProductionBachir Ismail100% (1)

- WB4 Short Form - Dual Branding - 10-24-19Document2 pagesWB4 Short Form - Dual Branding - 10-24-19joseNo ratings yet

- API 650 FabricationDocument143 pagesAPI 650 Fabricationahmad_koros100% (1)

- A Detailed Study On Loss Processes in Solar CellsDocument11 pagesA Detailed Study On Loss Processes in Solar CellsFernando DiasNo ratings yet

- History of Sanskrit Language and Kerala Culture McqsDocument8 pagesHistory of Sanskrit Language and Kerala Culture Mcqsmuzu136055No ratings yet

- INSA312-Chapter 1Document40 pagesINSA312-Chapter 1alwkilmunirhNo ratings yet

- 21CLD Learning Activity Cover SheetDocument9 pages21CLD Learning Activity Cover SheetMariana VoloshynNo ratings yet

- CATIA - Human Builder & SimulationDocument2 pagesCATIA - Human Builder & Simulationguen_betonamuNo ratings yet

- Business Studies Project Class XIIDocument13 pagesBusiness Studies Project Class XIIKanishk Mehrotra67% (15)

- Index SSPC: SpecificationsDocument1 pageIndex SSPC: SpecificationsjosNo ratings yet

- Safety and CareDocument4 pagesSafety and CarePrince K. TaileyNo ratings yet

- Kingsley Cv2Document2 pagesKingsley Cv2akwue kingsleyNo ratings yet

- Business Environment ProjectDocument19 pagesBusiness Environment Projectaditi100% (1)

- BRAPDocument5 pagesBRAPrkkask01No ratings yet

- 3.3 Exam Style Questions Place Paper 1Document2 pages3.3 Exam Style Questions Place Paper 1Okan IsmailNo ratings yet

- Harpreet Kaur Gill SOP UKDocument2 pagesHarpreet Kaur Gill SOP UKSAHILPREET SINGHNo ratings yet

- Topic: Assessment of Rehman Medical College Students Attitude Towards Social Media Usage. AbstractDocument10 pagesTopic: Assessment of Rehman Medical College Students Attitude Towards Social Media Usage. AbstractKhalid Khan YousafzaiNo ratings yet

- Nw4install DHCPDocument10 pagesNw4install DHCPnitrorubyNo ratings yet

- Q1 Science 9 Module 3Document31 pagesQ1 Science 9 Module 3apudcrizarcellNo ratings yet

- Important Safeguards. Instrucciones Importantes de SeguridadDocument2 pagesImportant Safeguards. Instrucciones Importantes de SeguridadLUISA MALDONADO ROANo ratings yet

- Project Brief - Biometrio Earth - FinalDocument3 pagesProject Brief - Biometrio Earth - FinalMarcel JonathanNo ratings yet

- Definition of Research, Characteristics of Research, Research Process and Functions of Research Definition of ResearchDocument2 pagesDefinition of Research, Characteristics of Research, Research Process and Functions of Research Definition of ResearchNinda SNo ratings yet

- Crowell Smart Goal 18-19Document2 pagesCrowell Smart Goal 18-19api-335321754No ratings yet

- 2009 Tuffboom FlyerDocument2 pages2009 Tuffboom FlyerCarlos ReNo ratings yet

- advtJRF DIPAS212023Document4 pagesadvtJRF DIPAS212023Rathod Chandra SekharNo ratings yet

- Dissertation Auf DeutschDocument8 pagesDissertation Auf DeutschWriteMyPaperForMeSpringfield100% (1)

- Datron PRC-BC4 Multiple Battery Charger - Operator and Technical ManualDocument28 pagesDatron PRC-BC4 Multiple Battery Charger - Operator and Technical ManualAlexander J RokowetzNo ratings yet

- Project Based Learning And: Authentic AssessmentDocument52 pagesProject Based Learning And: Authentic Assessmentnancie8No ratings yet

- Flyer - Astm A252Document3 pagesFlyer - Astm A252PT. Pakuhaji Naga PerkasaNo ratings yet