Professional Documents

Culture Documents

ERD Well Design Using IDM - Training Course: WWW - Choate.co - Uk

ERD Well Design Using IDM - Training Course: WWW - Choate.co - Uk

Uploaded by

Thomas DuCopyright:

Available Formats

You might also like

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- IAS - Chemistry - SB1 - Mark Scheme - T4 PDFDocument4 pagesIAS - Chemistry - SB1 - Mark Scheme - T4 PDFLoh Jun XianNo ratings yet

- Burt Word Recognition TestDocument8 pagesBurt Word Recognition TestYiwen Wu100% (1)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Numerical-Hoisting, Ton MilesDocument15 pagesNumerical-Hoisting, Ton MilesPuneet SinghNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Well Engineering, Rig EquipmentDocument38 pagesWell Engineering, Rig EquipmentJishnu Sudhir100% (1)

- Well Head Fatigue PresDocument17 pagesWell Head Fatigue PresdeeperdrillerNo ratings yet

- Foundation Design and Construction HK - Lecture SlidesDocument20 pagesFoundation Design and Construction HK - Lecture SlidesScott DownsNo ratings yet

- ProTech1Ch10 PDFDocument23 pagesProTech1Ch10 PDFweldsvNo ratings yet

- Extended Reached DrillingDocument34 pagesExtended Reached DrillingAhmad Advin100% (4)

- Lecture - 4 - Course Notes PDFDocument90 pagesLecture - 4 - Course Notes PDFFaraj NabiyevNo ratings yet

- Part 4 Hoisting SystemDocument35 pagesPart 4 Hoisting SystemJood SultanNo ratings yet

- CT Basics and Applications For StudentDocument230 pagesCT Basics and Applications For Studentanon_969492799No ratings yet

- Petroleum Engineering Summer Course 2015Document34 pagesPetroleum Engineering Summer Course 2015Radu ChibzuiNo ratings yet

- Well PlanningDocument86 pagesWell PlanningK SanjayaNo ratings yet

- DESIGNDocument2 pagesDESIGNStalin Chicaiza DagoNo ratings yet

- 1,2 - Well Planning Objective & Rig Sizing and SelectionDocument30 pages1,2 - Well Planning Objective & Rig Sizing and SelectionYassir Hindi100% (1)

- Rotary SystemDocument9 pagesRotary SystemHomam MohammadNo ratings yet

- Day 1 Practical ExamplesDocument23 pagesDay 1 Practical ExamplesRadu ChibzuiNo ratings yet

- 12 - Horizontal Well CompletionDocument21 pages12 - Horizontal Well CompletionMaximiliano GonzalezNo ratings yet

- Pumping Station Design For OperatorsDocument74 pagesPumping Station Design For OperatorsFrank RiveraNo ratings yet

- Presentation Pipeline DesignDocument47 pagesPresentation Pipeline DesignEdy Erwanto100% (2)

- PIPELINE PresentDocument47 pagesPIPELINE Presentromvos8469100% (1)

- Mud Hydraulics, DrillingDocument23 pagesMud Hydraulics, DrillingVladut FagarasNo ratings yet

- Tema 6 - HP Axial Flow TurbineDocument104 pagesTema 6 - HP Axial Flow Turbinefdsfsdfdsfsf100% (1)

- SPE 134586 Casing Drilling Application WDocument17 pagesSPE 134586 Casing Drilling Application WAmine MimoNo ratings yet

- 06 - PDA - Is It A Good Pile Test (Prof Harry Tan)Document47 pages06 - PDA - Is It A Good Pile Test (Prof Harry Tan)Yasonsky Captain100% (1)

- UAS Drill String Design and Hole ProblemDocument37 pagesUAS Drill String Design and Hole Problemsbaluwel100% (1)

- RheologyDocument37 pagesRheologyVassilios Kelessidis0% (1)

- ClosingLecture ME4521Document41 pagesClosingLecture ME4521eugene.commerellNo ratings yet

- Recent Development in Pile Instrumentation Technology For Driven, Jacked-In and Bored Cast-In-Place PilesDocument25 pagesRecent Development in Pile Instrumentation Technology For Driven, Jacked-In and Bored Cast-In-Place Pileszzz_monsterNo ratings yet

- Faculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageDocument26 pagesFaculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageOmer IkhlasNo ratings yet

- Misurata University Faculty of Engineering Petroleum DepartmentDocument30 pagesMisurata University Faculty of Engineering Petroleum DepartmentMohammed AmerNo ratings yet

- Transformer Life ManagementDocument20 pagesTransformer Life ManagementwiyatnoNo ratings yet

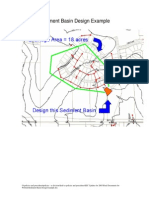

- Sediment Basin ExampleDocument8 pagesSediment Basin ExampleastarnasNo ratings yet

- Overview of Drilling Operations MAY 2011 SEMDocument48 pagesOverview of Drilling Operations MAY 2011 SEMdatug100% (1)

- Pipe Repair Case StudyDocument15 pagesPipe Repair Case StudyAnyanele Nnamdi Felix100% (1)

- Ultra Low Head TurbineDocument29 pagesUltra Low Head TurbinelonelypratikNo ratings yet

- Helical Design Theory and Applications: by Darin Willis, P.EDocument55 pagesHelical Design Theory and Applications: by Darin Willis, P.Eahmedmohammad28No ratings yet

- Eletrical Motor OffshoreDocument38 pagesEletrical Motor OffshoreandreisraelNo ratings yet

- Week 2 Dump FloodDocument20 pagesWeek 2 Dump FloodMuhamad HairulNo ratings yet

- Faculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageDocument14 pagesFaculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageOmer IkhlasNo ratings yet

- Pipeline Design and ConstructionDocument47 pagesPipeline Design and ConstructionSaber Abdel Moreid100% (5)

- S3 P1 Sites, Rigs, Derricks & Mast-CzyDocument6 pagesS3 P1 Sites, Rigs, Derricks & Mast-CzyHunterNo ratings yet

- MKPP2513: Petroleum Production EngineeringDocument15 pagesMKPP2513: Petroleum Production EngineeringhenryNo ratings yet

- SUbsea Pipeline InstallationDocument54 pagesSUbsea Pipeline InstallationShaiful Hizan100% (1)

- Well Foundation - RVNLDocument9 pagesWell Foundation - RVNLVenkateswarlu DanduNo ratings yet

- Nomenclature PresentationDocument34 pagesNomenclature PresentationAnonymous pVoSWn8yh0No ratings yet

- SEA PresentationDocument56 pagesSEA PresentationAliBenamerNo ratings yet

- Introduction To Coiled Tubing Equipment and ApplicationDocument43 pagesIntroduction To Coiled Tubing Equipment and ApplicationAhmed ElkashifNo ratings yet

- Wel Come To Our Presentation On Manufacturing and Testing of Over Flow Type Treadle PumpDocument33 pagesWel Come To Our Presentation On Manufacturing and Testing of Over Flow Type Treadle PumpKirubel MogesNo ratings yet

- Featools Intro Webinar Scripted For IntergraphDocument58 pagesFeatools Intro Webinar Scripted For IntergraphJimmy Alexander Avila100% (1)

- Zuudee BYD Titanium Subsea PipelineDocument51 pagesZuudee BYD Titanium Subsea PipelineZhu Daniel100% (1)

- Engineering the CMOS Library: Enhancing Digital Design Kits for Competitive SiliconFrom EverandEngineering the CMOS Library: Enhancing Digital Design Kits for Competitive SiliconRating: 1 out of 5 stars1/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- OPM10207-13 WellaheadDocument125 pagesOPM10207-13 WellaheadThomas DuNo ratings yet

- IDM Basic Training - ModrillDocument30 pagesIDM Basic Training - ModrillThomas Du100% (1)

- IDM Basic Training - EzCleanDocument22 pagesIDM Basic Training - EzCleanThomas DuNo ratings yet

- IDM IntroductionDocument33 pagesIDM IntroductionThomas DuNo ratings yet

- Global EDM Training Programme: Shell Exploration & ProductionDocument22 pagesGlobal EDM Training Programme: Shell Exploration & ProductionThomas DuNo ratings yet

- Day 1 Advanced IDM-ERDDocument58 pagesDay 1 Advanced IDM-ERDThomas DuNo ratings yet

- Typical Land Rig: National Oilwell VarcoDocument1 pageTypical Land Rig: National Oilwell VarcoThomas DuNo ratings yet

- CasingSeat2003.16.1.0Training Manual161780CDocument124 pagesCasingSeat2003.16.1.0Training Manual161780CThomas DuNo ratings yet

- APS BHA Vibration PaperDocument15 pagesAPS BHA Vibration PaperThomas DuNo ratings yet

- AC Motors PCIDocument30 pagesAC Motors PCIThomas DuNo ratings yet

- RBI & Remote MonitoringDocument4 pagesRBI & Remote MonitoringAkshat AgrawalNo ratings yet

- Equivalents of Carbon Steel QualitiesDocument6 pagesEquivalents of Carbon Steel QualitiesTushar KasabeNo ratings yet

- ChangelogDocument45 pagesChangeloggodcapuzNo ratings yet

- Day 3 SBL Practice To PassDocument20 pagesDay 3 SBL Practice To PassRaqib MalikNo ratings yet

- Datasheet Kalrez - 6221 PDFDocument2 pagesDatasheet Kalrez - 6221 PDFVictor Flores ResendizNo ratings yet

- 8 DMT Mix MN - Ryan (10!1!24) Ratio N ProportionDocument1 page8 DMT Mix MN - Ryan (10!1!24) Ratio N ProportionRohan MehtaNo ratings yet

- Genbio Mod 2Document10 pagesGenbio Mod 2ScionNo ratings yet

- Laser Range Meter PD-I: Technical Data ApplicationsDocument1 pageLaser Range Meter PD-I: Technical Data ApplicationsBiprojit HoreNo ratings yet

- English Code Phonics Book 2Document51 pagesEnglish Code Phonics Book 2Jezabel Escobar100% (1)

- LS Maths 7 Learner Book Answers - PDF - Mathematics - Arithmetic 2Document8 pagesLS Maths 7 Learner Book Answers - PDF - Mathematics - Arithmetic 2sonnyteohNo ratings yet

- Final GEUDP Waesano ESIA Document - Bahasa PDFDocument317 pagesFinal GEUDP Waesano ESIA Document - Bahasa PDFVenan HaryantoNo ratings yet

- Classroom Observation Tool COTDocument4 pagesClassroom Observation Tool COTRudy ClariñoNo ratings yet

- Be Curious 4 Projects Teachers GuideDocument7 pagesBe Curious 4 Projects Teachers GuideValeria Valentina Valenzuela HinojosaNo ratings yet

- Smart Buildings: John Smiciklas Director, BOMA Canada Jsmiciklas@bomacanada - CaDocument24 pagesSmart Buildings: John Smiciklas Director, BOMA Canada Jsmiciklas@bomacanada - Catest testNo ratings yet

- The Tritonet Approach To Music Theory PDFDocument30 pagesThe Tritonet Approach To Music Theory PDFSelçuk Canberk DağtekinNo ratings yet

- 7TCA083670R0648 lk243 10tDocument3 pages7TCA083670R0648 lk243 10tGeorge TheodosiouNo ratings yet

- Effect of Coco Peat Particle Size For The Optimum Growth of Nursery Plant of Greenhouse VegetablesDocument8 pagesEffect of Coco Peat Particle Size For The Optimum Growth of Nursery Plant of Greenhouse VegetablesGeofrey GodfreyNo ratings yet

- Murad MuminovDocument2 pagesMurad Muminovmurodmuminov1221No ratings yet

- A-Rev - PG - 307-Article Text-538-1-4-20190816 Rev 270919Document9 pagesA-Rev - PG - 307-Article Text-538-1-4-20190816 Rev 270919Oman AbdurahmanNo ratings yet

- 2 Coordinating ConjunctionDocument37 pages2 Coordinating ConjunctionRea Jane GarciaNo ratings yet

- A Workshop On Using Your Superpower of InfluenceDocument71 pagesA Workshop On Using Your Superpower of InfluenceChandra HaasNo ratings yet

- Non-Tin Catalysts For Alkoxy Silane Polymers: Silicone Chemis TryDocument8 pagesNon-Tin Catalysts For Alkoxy Silane Polymers: Silicone Chemis TryŞafakNo ratings yet

- Grammar Review: My School FriendsDocument2 pagesGrammar Review: My School Friendsлюдмила ветроваNo ratings yet

- Daily Lesson LOG: The Learners Demonstrate An Understanding Of: The Learners Shall Be Able ToDocument4 pagesDaily Lesson LOG: The Learners Demonstrate An Understanding Of: The Learners Shall Be Able ToJennyNo ratings yet

- Full Chapter Repetition and Creation Poetics of Autotextuality 1St Edition Radosvet Kolarov PDFDocument53 pagesFull Chapter Repetition and Creation Poetics of Autotextuality 1St Edition Radosvet Kolarov PDFclarence.nance336100% (8)

- Mod01 L02Document12 pagesMod01 L02Pankaj Kumar SainiNo ratings yet

- Python-2 - Unit-6,7,8 - Game DevelopmentDocument38 pagesPython-2 - Unit-6,7,8 - Game DevelopmentPalak RathoreNo ratings yet

- Accumulation of Heavy Metals in SpinaciaDocument12 pagesAccumulation of Heavy Metals in SpinaciaSachin SrivastavaNo ratings yet

ERD Well Design Using IDM - Training Course: WWW - Choate.co - Uk

ERD Well Design Using IDM - Training Course: WWW - Choate.co - Uk

Uploaded by

Thomas DuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ERD Well Design Using IDM - Training Course: WWW - Choate.co - Uk

ERD Well Design Using IDM - Training Course: WWW - Choate.co - Uk

Uploaded by

Thomas DuCopyright:

Available Formats

Day 3

ERD Well Design

Using IDM

- Training Course

www.choate.co.uk Well Engineering Geomechanics Software

Checkpoint

• At Checkpoints like this during the presentation,

you can

ask questions :

raise your hand

wait for a microphone

Press CTRL to speak

But raise your hand immediately if you lose audio / other connection

You may also be asked to confirm your connection with a tick

www.choate.co.uk Well Engineering Geomechanics Software

Agenda

• Day 1 - Course objectives and pre-requisites

- Role of IDM, MoDrill/EzClean internals

- Introduce demo ERD well

- Exercises : MoDrill cases A) to D)

• Day 2 - Review exercises from Day 1

- Complete the demonstration well

- Exercises: MoDrill cases E) to L)

• Day 3 - Review exercises from Day 2

and implications for ERD design

- Demonstrate use of Stabor (time permitting)

• Day 4 - “ERD Clinic” to review real field cases

www.choate.co.uk Well Engineering Geomechanics Software

Summary of 26” and 16” Hole Sections

( i.e. Day 1 Exercises)

• Drilling 26” Hole Section

– Buckling (reduce WOB), Hole cleaning (HCI<0.75), High ECD with

cuttings loading

• Running 18 5/8” Casing

– Rotation is impossible, >700lbf rig hoist capacity required to POOH

• Drilling 16” Hole Section

– Standpipe pressure highest at 370 bar. Mud motor pressure drip

increases substantially if stuck in chalk. Hole cleaning still a critical issue

(HCI~0.75)

• Running 13 3/8” Casing

– Low Set Down Weight (18MT). Near buckling limit. Options: Use heavier

casing in top, floatation. Not feasible to POOH

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• E) Drilling 12 1/4” Hole Section

– Drill String Saver plot

– Pipe Loads (stresses and make up torque)

– Buckling limits (hint: check effective

tension)

– Annulus and drill pipe pressures

– Equivalent circulating density (ECD)

– Hole cleaning index (HCI)

– Drill string saver plot

www.choate.co.uk Well Engineering Geomechanics Software

E) Drilling 12 1/4” Hole Section: Drill String Saver

The string is too weak to resolve a

yield envelope.

Overcoming friction when drilling

this high inclination section with

seawater in this fractured

limestone formation could present

an insurmountable challenge.

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• E) Drilling 12 1/4” Hole Section

– Drill String Saver

• Friction and inclination too high to resolve yield envelope

– Pipe Loads (stresses and make up torque)

– Bucking

– Buckling limits (hint: check effective tension)

– Annulus and drill pipe pressures

– Equivalent circulating density (ECD)

– Hole cleaning index (HCI)

– Drill string saver plot

www.choate.co.uk Well Engineering Geomechanics Software

E) Drilling 12 1/4” Hole : Pipe Stresses

www.choate.co.uk Well Engineering Geomechanics Software

E) Drilling 12 1/4” : MUT

www.choate.co.uk Well Engineering Geomechanics Software

E) Drilling 12 1/4” : Custom Graph

Use Custom Graph to

examine sensitivity of

make up torque to

friction factors

www.choate.co.uk Well Engineering Geomechanics Software

E) Drilling 12 ¼” : Custom Graph

Use Custom Graph to

examine sensitivity of

make up torque to

Make up torque

friction factors

exceeded even

for FF=0.2

(CMC=0.25).

Use WT56

(66kft-lb)

connectors with

FF=0.4

www.choate.co.uk Well Engineering Geomechanics Software

E) Drilling 12 ¼” : Drill String Saver

www.choate.co.uk Well Engineering Geomechanics Software

Checkpoint

• If you have a

question, please

raise your hand

Next topic: Continue review Drilling 12 ¼ “

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• E) Drilling 12 1/4” Hole Section

– Drill String Saver

• Friction and inclination too high to resolve yield envelope

– Pipe Loads (stresses and make up torque)

• Pipe yield stress and connector make up torque exceeded

• Use Wedge Thread WT56 connectors with CMC & FF=0.4

• Margin of bit overpull < 50MT. No slack off capacity.

• Max Hook Load = 246MT. Add 150MT to get 1Mlb rig requirement

– Buckling

• OK

– Annulus and drill pipe pressures

• Sliding: 239 bars. Room to increase flow rate to raise HCI

– Equivalent circulating density (ECD)

• OK, but addition of CMC to prevent losses could raise ECD

– Hole cleaning index (HCI)

• Maintain circulation and rotation and increase flow rate

www.choate.co.uk Well Engineering Geomechanics Software

E) Drilling 12 1/4” : Effective Tension

Buckling limit is

NOT exceeded

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• E) Drilling 12 1/4” Hole Section

– Drill String Saver

• Friction and inclination too high to resolve yield envelope

– Pipe Loads (stresses and make up torque)

• Pipe yield stress and connector make up torque exceeded

• Use Wedge Thread WT56 connectors with CMC & FF=0.4

• Margin of bit overpull < 50MT. No slack off capacity.

• Max Hook Load = 246MT. Add 150MT to get 1Mlb rig requirement

– Buckling

• OK

– Annulus and drill pipe pressures

• Sliding: 239 bars. Room to increase flow rate to raise HCI

– Equivalent circulating density (ECD)

• OK, but addition of CMC to prevent losses could raise ECD

– Hole cleaning index (HCI)

• Maintain circulation and rotation and increase flow rate

www.choate.co.uk Well Engineering Geomechanics Software

E) Drilling 12 ¼” : Standpipe Pressure

Sliding:

239 bars

Plot not

shown in

manual

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• E) Drilling 12 1/4” Hole Section

– Drill String Saver

• Friction and inclination too high to resolve yield envelope

– Pipe Loads (stresses and make up torque)

• Pipe yield stress and connector make up torque exceeded

• Use Wedge Thread WT56 connectors with CMC & FF=0.4

• Margin of bit overpull < 50MT. No slack off capacity.

• Max Hook Load = 246MT. Add 150MT to get 1Mlb rig requirement

– Buckling

• OK

– Annulus and drill pipe pressures

• Sliding: 239 bars : Room to increase flowrate to increase HCI

– Equivalent circulating density (ECD)

– Hole cleaning index (HCI)

www.choate.co.uk Well Engineering Geomechanics Software

E) Drilling 12 ¼” : ECD

www.choate.co.uk Well Engineering Geomechanics Software

Checkpoint

• Please confirm your

connection by pressing

the tick button now

• If you have a

question, please

raise your hand

Next topic: Continue review Drilling 12 ¼ “

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• E) Drilling 12 1/4” Hole Section

– Drill String Saver

• Friction and inclination too high to resolve yield envelope

– Pipe Loads (stresses and make up torque)

• Pipe yield stress and connector make up torque exceeded

• Use Wedge Thread WT56 connectors with CMC & FF=0.4

• Margin of bit overpull < 50MT. No slack off capacity.

• Max Hook Load = 246MT. Add 150MT to get 1Mlb rig requirement

– Buckling

• OK

– Annulus and drill pipe pressures

• Sliding: 239 bars : Room to increase flowrate to increase HCI

– Equivalent circulating density (ECD)

• OK, but addition of CMC to prevent losses could raise ECD

– Hole cleaning index (HCI)

www.choate.co.uk Well Engineering Geomechanics Software

E) Drilling 12 ¼” : Hole Cleaning Index

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• E) Drilling 12 1/4” Hole Section

– Drill String Saver

• Friction and inclination too high to resolve yield envelope

– Pipe Loads (stresses and make up torque)

• Pipe yield stress and connector make up torque exceeded

• Use Wedge Thread WT56 connectors with CMC & FF=0.4

• Margin of bit overpull < 50MT. No slack off capacity.

• Max Hook Load = 246MT. Add 150MT to get 1Mlb rig requirement

– Buckling

• OK

– Annulus and drill pipe pressures

• Sliding: 239 bars: Room to increase flowrate to increase HCI

– Equivalent circulating density (ECD)

• OK, but addition of CMC to prevent losses could raise ECD

– Hole cleaning index (HCI)

• Maintain circulation and rotation and increase flow rate

– ECD

www.choate.co.uk Well Engineering Geomechanics Software

E) Drilling 12 1/4” : ECD

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• E) Drilling 12 1/4” Hole Section

– Drill String Saver

• Friction and inclination too high to resolve yield envelope

– Pipe Loads (stresses and make up torque)

• Pipe yield stress and connector make up torque exceeded

• Use Wedge Thread WT56 connectors with CMC & FF=0.4

• Margin of bit overpull < 50MT. No slack off capacity.

• Max Hook Load = 246MT. Add 150MT to get 1Mlb rig requirement

– Buckling

• OK

– Annulus and drill pipe pressures

• Sliding: 239 bars: Room to increase flowrate to increase HCI

– Equivalent circulating density (ECD)

• OK, but addition of CMC to prevent losses could raise ECD

– Hole cleaning index (HCI)

• Maintain circulation and rotation and increase flow rate

– ECD

• But make sure ECD does not exceed formation strength

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• E) Drilling 12 1/4” Hole Section

– Calibrating Friction Factors

www.choate.co.uk Well Engineering Geomechanics Software

E) Drilling 12 1/4” : Calibrating Friction Factors

www.choate.co.uk Well Engineering Geomechanics Software

Checkpoint

• If you have a

question, please

raise your hand

www.choate.co.uk Well Engineering Geomechanics Software

Coffee Break

Let’s meet back here

in 10 minutes

Next topic: Review Running 9 5/8 “ Casing

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• F) Running 9 5/8” Casing

– Set down weight (SDW) (hint: drag chart)

– Pipe loads and buckling limits

– Axial loads on connectors

– Torsional stresses on connectors

– Hoist capacity requirement for pulling this casing

string

– ECDs

www.choate.co.uk Well Engineering Geomechanics Software

Running 9 5/8 ” : Set Down Weight

www.choate.co.uk Well Engineering Geomechanics Software

Running 9 5/8 ” : Effective Tension

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• F) Running 9 5/8” Casing

– Set down weight (SDW) (hint: drag chart)

• Negative! Minus 50MT, Buckled string

– Extreme floating option case

– Pipe loads and buckling limits

– Axial loads on connectors

– Torsional stresses on connectors

– Hoist capacity requirement for pulling this casing

string

– ECDs

www.choate.co.uk Well Engineering Geomechanics Software

Running 9 5/8 ” : Floating Option Input

www.choate.co.uk Well Engineering Geomechanics Software

Running 9 5/8 ” : Floating Option Results

www.choate.co.uk Well Engineering Geomechanics Software

Running 9 5/8 ” : Floating Option Results

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• F) Running 9 5/8” Casing

– Set down weight (SDW) (hint: drag chart)

• Negative! Minus 50MT

– Extreme floating option case

• Even this solution is only just feasible, plus rotation is

impossible

– Run 9 5/8” liner on a drill pipe

– Pipe loads and buckling limits

– Axial loads on connectors

– Torsional stresses on connectors

– Hoist capacity requirement for pulling this casing string

– ECDs

www.choate.co.uk Well Engineering Geomechanics Software

9 5/8” Liner Option: Set down weight

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• F) Running 9 5/8” Casing

– Set down weight (SDW) (hint: drag chart)

• Negative! Minus 50MT

– Extreme floating option case

• Even this solution is only just feasible, plus rotation is

impossible

– Run 9 5/8” liner on a drill pipe

• Set down weight 25MT

– Pipe stresses Axial loads on connectors

– Torsional stresses on connectors

– Hoist capacity requirement for pulling this casing string

– ECDs

www.choate.co.uk Well Engineering Geomechanics Software

9 5/8” Liner Option: Pipe Stress

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• F) Running 9 5/8” Casing

– Set down weight (SDW) (hint: drag chart)

• Negative! Minus 50MT

– Extreme floating option case

• Even this solution is only just feasible, plus rotation is

impossible

– Run 9 5/8” liner on a drill pipe

• Set down weight 25MT

– 9 5/8” liner Pipe stresses

• Drillpipe yields

– 9 5/8” liner make up torque

www.choate.co.uk Well Engineering Geomechanics Software

9 5/8” Liner Option: Pipe Stress

www.choate.co.uk Well Engineering Geomechanics Software

Checkpoint

• If you have a

question, please

raise your hand

Next topic: Review 9 5/8” Liner floating option

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• F) Running 9 5/8” Casing

– Set down weight (SDW) (hint: drag chart)

• Negative! Minus 50MT

– Extreme floating option case

• Even this solution is only just feasible, plus rotation

is impossible

– Run 9 5/8” liner on a drill pipe

• Set down weight 25MT

– 9 5/8” liner pipe stresses

• Drillpipe yields

– 9 5/8” liner make up torque

• Exceeded for drill pipe and liner top

– 9 5/8” liner floating option

www.choate.co.uk Well Engineering Geomechanics Software

9 5/8” Floating Liner Option: Drag Chart

www.choate.co.uk Well Engineering Geomechanics Software

9 5/8” Floating Liner Option: Pipe Stress

www.choate.co.uk Well Engineering Geomechanics Software

9 5/8” Floating Liner Option: Torque – New

VAM

www.choate.co.uk Well Engineering Geomechanics Software

9 5/8” Floating Liner Option: Torque – Tenaris

Blue

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• F) Running 9 5/8” Casing

– Set down weight (SDW) (hint: drag chart)

• Negative! Minus 50MT

– Extreme floating option case

• Even this solution is only just feasible, plus rotation is

impossible

– Run 9 5/8” liner on a drill pipe

• Set down weight 25MT

– 9 5/8” liner pipe stresses

• Drillpipe yields

– 9 5/8” liner make up torque: Drag

• Exceeded for drill pipe and liner top

– 9 5/8” liner floating option

• Drag & pipe stress OK, but liner top torque is just met by Tenaris

Blue connectors

– Casing Design

www.choate.co.uk Well Engineering Geomechanics Software

9 5/8” Floating Liner Option: Casing Design

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• F) Running 9 5/8” Casing

– Set down weight (SDW) (hint: drag chart)

• Negative! Minus 50MT

– Extreme floating option case

• Even this solution is only just feasible, plus rotation is impossible

– Run 9 5/8” liner on a drill pipe

• Set down weight 25MT

– 9 5/8” liner pipe stresses

• Drillpipe yields

– 9 5/8” liner make up torque: Drag

• Exceeded for drill pipe and liner top

– 9 5/8” liner floating option

• Drag & pipe stress OK, but liner top torque is just met by Tenaris

Blue connectors. Use a swivel? Liner top connectors?

– Casing Design

• OK

www.choate.co.uk Well Engineering Geomechanics Software

Checkpoint

• If you have a

question,

please raise

your hand

www.choate.co.uk Well Engineering Geomechanics Software

Coffee Break

Let’s meet back here

in 10 minutes

Next topic: Review Drilling 8 ½ ”

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• G) 8 1/2” Hole Drilling

– Hole Cleaning Index

– ECD

– ECD

www.choate.co.uk Well Engineering Geomechanics Software

Drilling 8 ½ ” : Hole Cleaning Index

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• G) 8 1/2” Hole Drilling

– Hole Cleaning Index

• Far less of an issue, especially with rotation

– ECD

www.choate.co.uk Well Engineering Geomechanics Software

Drilling 8 ½ ” : ECD

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• G) 8 1/2” Hole Drilling

– Hole Cleaning Index

• Far less of an issue, especially with rotation

– ECD

• Likely exceeds formation strength. If flow rate is

reduced, then hole cleaning becomes an issue.

www.choate.co.uk Well Engineering Geomechanics Software

Checkpoint

• If you have a

question,

please raise

your hand

Next topic: Review 7” Liner Running

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• H) 7” Liner Running

– Set down weight

– Make up torque

www.choate.co.uk Well Engineering Geomechanics Software

7” Liner Running: Drag

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• H) 7” Liner Running

– Set down weight

• Higher at 40MT

– Make up torque

www.choate.co.uk Well Engineering Geomechanics Software

7” Liner Running: Torque

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• H) 7” Liner Running

– Set down weight

• Higher at 40MT

– Make up torque

• Liner top torque could be an issue. MoDrill does

not include a liner top or a liner swivel component.

www.choate.co.uk Well Engineering Geomechanics Software

Checkpoint

• If you have a

question,

please raise

your hand

Next topic: Review Drilling 6” Hole

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• I) 6” Hole Drilling

– Calculation

– Pipe stresses, make up torque and string

buckling

www.choate.co.uk Well Engineering Geomechanics Software

6” Hole Drilling: Lockup

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• I) 6” Hole Drilling

– Calculations

• String lockup

– Pipe stresses, make up torque and string

buckling

www.choate.co.uk Well Engineering Geomechanics Software

6” Hole Drilling: Pipe Stress

www.choate.co.uk Well Engineering Geomechanics Software

6” Hole Drilling: Torque

www.choate.co.uk Well Engineering Geomechanics Software

6” Hole Drilling: Effective Tension

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• I) 6” Hole Drilling

– Calculations

• String lockup

– Pipe stresses, make up torque and string

buckling

• All limits exceeded

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• J) 5” Liner Running

– Set Down Weight

www.choate.co.uk Well Engineering Geomechanics Software

5” Liner Running: Effective Tension

www.choate.co.uk Well Engineering Geomechanics Software

Review of Day 2 Exercise

• J) 5” Liner Running

– Set Down Weight

• More feasible than drilling 6” hole itself

www.choate.co.uk Well Engineering Geomechanics Software

Checkpoint!

• Please confirm you are wide awake

with a good connection by

pressing the tick button now

• If you have a question,

please raise your hand

Next, we will have a 30-min “stepout” session for you to work on the example ERD well. The instructor will indicate he is

not available during these breaks by clicking on the stepout button

You may do the same.

When you are back in, click the button again

www.choate.co.uk Well Engineering Geomechanics Software

Day 3 Exercise 1

Please make your own summary of the

complete set of results for all hole

sections and drilling and casing/liner

strings for this well.

What are your overall conclusions?

Can you suggest alternatives?

Let’s meet back here

in 30 minutes to

review!

www.choate.co.uk Well Engineering Geomechanics Software

Summary of 26” and 16” Hole Sections

• Drilling 26” Hole Section

– Buckling (reduce WOB), Hole cleaning (HCI<0.75), High ECD

with cuttings loading

• Running 18 5/8” Casing

– Rotation is impossible, >700lbf rig hoist capacity required to

POOH

• Drilling 16” Hole Section

– Standpipe pressure highest at 370 bar. Mud motor pressure drip

increases substantially if stuck in chalk. Hole cleaning still a

critical issue (HCI~0.75)

• Running 13 3/8” Casing

– Low Set Down Weight (18MT). Near buckling limit. Options: Use

heavier casing in top, floatation. Not feasible to POOH

www.choate.co.uk Well Engineering Geomechanics Software

Summary of 12 1/4” and 8 1/2” Hole Sections

• Drilling 12 1/4” Hole Section

– High torque, use WT connectors and reduce friction to FF< 0.4.

(Seawater + CMC). Maintain circulation/rotation and increase

flow rate to ensure hole cleaning, but ECD will increase

• Running 9 5/8” Casing

– Negative Set Down Weight (minus 50MT). Floating not feasible.

Only option to run as a liner, but pipe yield stress and liner top

torque are exceeded. Floating a liner is feasible with Tenaris

connectors, but liner top torque may be exceeded. Collapse OK.

• Drilling 8 1/2” Hole Section

– Hole cleaning is OK if rotating, but ECD is likely to be exceeded.

Reducing flowrate could compromise hole cleaning

• Running 7” Liner

– Set Down Weight at TD is 40MT (less above TD), but liner top

torque could be an issue.

www.choate.co.uk Well Engineering Geomechanics Software

Summary of 6” Hole Sections, Tubing

and Workstring

• Drilling 6” Hole Section

– String locks up, all stress and make up torque limits are

exceeded

• Running 5” Liner

– More feasible than drilling the 6” hole

• Running 5” Tubing

– Locks up at 1726m

• Running 2 7/8” Workstring

– String locks up with WT26 connectors

www.choate.co.uk Well Engineering Geomechanics Software

Overall Conclusions

• It would not be possible to drill and

complete this well

• Options are:

– Reconfigure well design: Use one size up hole

sizes (e.g. 16” replaced 12 1/4” etc.)

– Modify the wellpath

www.choate.co.uk Well Engineering Geomechanics Software

Homework!

• Redo all the

preceeding

calculations with the

following wellpath

• What are your overall

conclusions?

www.choate.co.uk Well Engineering Geomechanics Software

Homework!

www.choate.co.uk Well Engineering Geomechanics Software

Homework!

www.choate.co.uk Well Engineering Geomechanics Software

Checkpoint

• If you have a

question,

please raise

your hand

Next topic: Borehole Stability demo

www.choate.co.uk Well Engineering Geomechanics Software

Stabor Borehole Stability Demo

• Run Stabor and open the following case:

– SG) 8 1/2” Hole Stability

• Demonstration of input and output only

– Instructions as per Chapter 7 in the manual

www.choate.co.uk Well Engineering Geomechanics Software

We’ve Reached the End of Day 2 !

• Are we still afloat?

• Any heart attacks?

• Tomorrow we take a look at

some real field cases

www.choate.co.uk Well Engineering Geomechanics Software

See you tomorrow,

End of Day 3

getting deeper into the subject...

www.choate.co.uk Well Engineering Geomechanics Software

You might also like

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- IAS - Chemistry - SB1 - Mark Scheme - T4 PDFDocument4 pagesIAS - Chemistry - SB1 - Mark Scheme - T4 PDFLoh Jun XianNo ratings yet

- Burt Word Recognition TestDocument8 pagesBurt Word Recognition TestYiwen Wu100% (1)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Numerical-Hoisting, Ton MilesDocument15 pagesNumerical-Hoisting, Ton MilesPuneet SinghNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Well Engineering, Rig EquipmentDocument38 pagesWell Engineering, Rig EquipmentJishnu Sudhir100% (1)

- Well Head Fatigue PresDocument17 pagesWell Head Fatigue PresdeeperdrillerNo ratings yet

- Foundation Design and Construction HK - Lecture SlidesDocument20 pagesFoundation Design and Construction HK - Lecture SlidesScott DownsNo ratings yet

- ProTech1Ch10 PDFDocument23 pagesProTech1Ch10 PDFweldsvNo ratings yet

- Extended Reached DrillingDocument34 pagesExtended Reached DrillingAhmad Advin100% (4)

- Lecture - 4 - Course Notes PDFDocument90 pagesLecture - 4 - Course Notes PDFFaraj NabiyevNo ratings yet

- Part 4 Hoisting SystemDocument35 pagesPart 4 Hoisting SystemJood SultanNo ratings yet

- CT Basics and Applications For StudentDocument230 pagesCT Basics and Applications For Studentanon_969492799No ratings yet

- Petroleum Engineering Summer Course 2015Document34 pagesPetroleum Engineering Summer Course 2015Radu ChibzuiNo ratings yet

- Well PlanningDocument86 pagesWell PlanningK SanjayaNo ratings yet

- DESIGNDocument2 pagesDESIGNStalin Chicaiza DagoNo ratings yet

- 1,2 - Well Planning Objective & Rig Sizing and SelectionDocument30 pages1,2 - Well Planning Objective & Rig Sizing and SelectionYassir Hindi100% (1)

- Rotary SystemDocument9 pagesRotary SystemHomam MohammadNo ratings yet

- Day 1 Practical ExamplesDocument23 pagesDay 1 Practical ExamplesRadu ChibzuiNo ratings yet

- 12 - Horizontal Well CompletionDocument21 pages12 - Horizontal Well CompletionMaximiliano GonzalezNo ratings yet

- Pumping Station Design For OperatorsDocument74 pagesPumping Station Design For OperatorsFrank RiveraNo ratings yet

- Presentation Pipeline DesignDocument47 pagesPresentation Pipeline DesignEdy Erwanto100% (2)

- PIPELINE PresentDocument47 pagesPIPELINE Presentromvos8469100% (1)

- Mud Hydraulics, DrillingDocument23 pagesMud Hydraulics, DrillingVladut FagarasNo ratings yet

- Tema 6 - HP Axial Flow TurbineDocument104 pagesTema 6 - HP Axial Flow Turbinefdsfsdfdsfsf100% (1)

- SPE 134586 Casing Drilling Application WDocument17 pagesSPE 134586 Casing Drilling Application WAmine MimoNo ratings yet

- 06 - PDA - Is It A Good Pile Test (Prof Harry Tan)Document47 pages06 - PDA - Is It A Good Pile Test (Prof Harry Tan)Yasonsky Captain100% (1)

- UAS Drill String Design and Hole ProblemDocument37 pagesUAS Drill String Design and Hole Problemsbaluwel100% (1)

- RheologyDocument37 pagesRheologyVassilios Kelessidis0% (1)

- ClosingLecture ME4521Document41 pagesClosingLecture ME4521eugene.commerellNo ratings yet

- Recent Development in Pile Instrumentation Technology For Driven, Jacked-In and Bored Cast-In-Place PilesDocument25 pagesRecent Development in Pile Instrumentation Technology For Driven, Jacked-In and Bored Cast-In-Place Pileszzz_monsterNo ratings yet

- Faculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageDocument26 pagesFaculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageOmer IkhlasNo ratings yet

- Misurata University Faculty of Engineering Petroleum DepartmentDocument30 pagesMisurata University Faculty of Engineering Petroleum DepartmentMohammed AmerNo ratings yet

- Transformer Life ManagementDocument20 pagesTransformer Life ManagementwiyatnoNo ratings yet

- Sediment Basin ExampleDocument8 pagesSediment Basin ExampleastarnasNo ratings yet

- Overview of Drilling Operations MAY 2011 SEMDocument48 pagesOverview of Drilling Operations MAY 2011 SEMdatug100% (1)

- Pipe Repair Case StudyDocument15 pagesPipe Repair Case StudyAnyanele Nnamdi Felix100% (1)

- Ultra Low Head TurbineDocument29 pagesUltra Low Head TurbinelonelypratikNo ratings yet

- Helical Design Theory and Applications: by Darin Willis, P.EDocument55 pagesHelical Design Theory and Applications: by Darin Willis, P.Eahmedmohammad28No ratings yet

- Eletrical Motor OffshoreDocument38 pagesEletrical Motor OffshoreandreisraelNo ratings yet

- Week 2 Dump FloodDocument20 pagesWeek 2 Dump FloodMuhamad HairulNo ratings yet

- Faculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageDocument14 pagesFaculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageOmer IkhlasNo ratings yet

- Pipeline Design and ConstructionDocument47 pagesPipeline Design and ConstructionSaber Abdel Moreid100% (5)

- S3 P1 Sites, Rigs, Derricks & Mast-CzyDocument6 pagesS3 P1 Sites, Rigs, Derricks & Mast-CzyHunterNo ratings yet

- MKPP2513: Petroleum Production EngineeringDocument15 pagesMKPP2513: Petroleum Production EngineeringhenryNo ratings yet

- SUbsea Pipeline InstallationDocument54 pagesSUbsea Pipeline InstallationShaiful Hizan100% (1)

- Well Foundation - RVNLDocument9 pagesWell Foundation - RVNLVenkateswarlu DanduNo ratings yet

- Nomenclature PresentationDocument34 pagesNomenclature PresentationAnonymous pVoSWn8yh0No ratings yet

- SEA PresentationDocument56 pagesSEA PresentationAliBenamerNo ratings yet

- Introduction To Coiled Tubing Equipment and ApplicationDocument43 pagesIntroduction To Coiled Tubing Equipment and ApplicationAhmed ElkashifNo ratings yet

- Wel Come To Our Presentation On Manufacturing and Testing of Over Flow Type Treadle PumpDocument33 pagesWel Come To Our Presentation On Manufacturing and Testing of Over Flow Type Treadle PumpKirubel MogesNo ratings yet

- Featools Intro Webinar Scripted For IntergraphDocument58 pagesFeatools Intro Webinar Scripted For IntergraphJimmy Alexander Avila100% (1)

- Zuudee BYD Titanium Subsea PipelineDocument51 pagesZuudee BYD Titanium Subsea PipelineZhu Daniel100% (1)

- Engineering the CMOS Library: Enhancing Digital Design Kits for Competitive SiliconFrom EverandEngineering the CMOS Library: Enhancing Digital Design Kits for Competitive SiliconRating: 1 out of 5 stars1/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- OPM10207-13 WellaheadDocument125 pagesOPM10207-13 WellaheadThomas DuNo ratings yet

- IDM Basic Training - ModrillDocument30 pagesIDM Basic Training - ModrillThomas Du100% (1)

- IDM Basic Training - EzCleanDocument22 pagesIDM Basic Training - EzCleanThomas DuNo ratings yet

- IDM IntroductionDocument33 pagesIDM IntroductionThomas DuNo ratings yet

- Global EDM Training Programme: Shell Exploration & ProductionDocument22 pagesGlobal EDM Training Programme: Shell Exploration & ProductionThomas DuNo ratings yet

- Day 1 Advanced IDM-ERDDocument58 pagesDay 1 Advanced IDM-ERDThomas DuNo ratings yet

- Typical Land Rig: National Oilwell VarcoDocument1 pageTypical Land Rig: National Oilwell VarcoThomas DuNo ratings yet

- CasingSeat2003.16.1.0Training Manual161780CDocument124 pagesCasingSeat2003.16.1.0Training Manual161780CThomas DuNo ratings yet

- APS BHA Vibration PaperDocument15 pagesAPS BHA Vibration PaperThomas DuNo ratings yet

- AC Motors PCIDocument30 pagesAC Motors PCIThomas DuNo ratings yet

- RBI & Remote MonitoringDocument4 pagesRBI & Remote MonitoringAkshat AgrawalNo ratings yet

- Equivalents of Carbon Steel QualitiesDocument6 pagesEquivalents of Carbon Steel QualitiesTushar KasabeNo ratings yet

- ChangelogDocument45 pagesChangeloggodcapuzNo ratings yet

- Day 3 SBL Practice To PassDocument20 pagesDay 3 SBL Practice To PassRaqib MalikNo ratings yet

- Datasheet Kalrez - 6221 PDFDocument2 pagesDatasheet Kalrez - 6221 PDFVictor Flores ResendizNo ratings yet

- 8 DMT Mix MN - Ryan (10!1!24) Ratio N ProportionDocument1 page8 DMT Mix MN - Ryan (10!1!24) Ratio N ProportionRohan MehtaNo ratings yet

- Genbio Mod 2Document10 pagesGenbio Mod 2ScionNo ratings yet

- Laser Range Meter PD-I: Technical Data ApplicationsDocument1 pageLaser Range Meter PD-I: Technical Data ApplicationsBiprojit HoreNo ratings yet

- English Code Phonics Book 2Document51 pagesEnglish Code Phonics Book 2Jezabel Escobar100% (1)

- LS Maths 7 Learner Book Answers - PDF - Mathematics - Arithmetic 2Document8 pagesLS Maths 7 Learner Book Answers - PDF - Mathematics - Arithmetic 2sonnyteohNo ratings yet

- Final GEUDP Waesano ESIA Document - Bahasa PDFDocument317 pagesFinal GEUDP Waesano ESIA Document - Bahasa PDFVenan HaryantoNo ratings yet

- Classroom Observation Tool COTDocument4 pagesClassroom Observation Tool COTRudy ClariñoNo ratings yet

- Be Curious 4 Projects Teachers GuideDocument7 pagesBe Curious 4 Projects Teachers GuideValeria Valentina Valenzuela HinojosaNo ratings yet

- Smart Buildings: John Smiciklas Director, BOMA Canada Jsmiciklas@bomacanada - CaDocument24 pagesSmart Buildings: John Smiciklas Director, BOMA Canada Jsmiciklas@bomacanada - Catest testNo ratings yet

- The Tritonet Approach To Music Theory PDFDocument30 pagesThe Tritonet Approach To Music Theory PDFSelçuk Canberk DağtekinNo ratings yet

- 7TCA083670R0648 lk243 10tDocument3 pages7TCA083670R0648 lk243 10tGeorge TheodosiouNo ratings yet

- Effect of Coco Peat Particle Size For The Optimum Growth of Nursery Plant of Greenhouse VegetablesDocument8 pagesEffect of Coco Peat Particle Size For The Optimum Growth of Nursery Plant of Greenhouse VegetablesGeofrey GodfreyNo ratings yet

- Murad MuminovDocument2 pagesMurad Muminovmurodmuminov1221No ratings yet

- A-Rev - PG - 307-Article Text-538-1-4-20190816 Rev 270919Document9 pagesA-Rev - PG - 307-Article Text-538-1-4-20190816 Rev 270919Oman AbdurahmanNo ratings yet

- 2 Coordinating ConjunctionDocument37 pages2 Coordinating ConjunctionRea Jane GarciaNo ratings yet

- A Workshop On Using Your Superpower of InfluenceDocument71 pagesA Workshop On Using Your Superpower of InfluenceChandra HaasNo ratings yet

- Non-Tin Catalysts For Alkoxy Silane Polymers: Silicone Chemis TryDocument8 pagesNon-Tin Catalysts For Alkoxy Silane Polymers: Silicone Chemis TryŞafakNo ratings yet

- Grammar Review: My School FriendsDocument2 pagesGrammar Review: My School Friendsлюдмила ветроваNo ratings yet

- Daily Lesson LOG: The Learners Demonstrate An Understanding Of: The Learners Shall Be Able ToDocument4 pagesDaily Lesson LOG: The Learners Demonstrate An Understanding Of: The Learners Shall Be Able ToJennyNo ratings yet

- Full Chapter Repetition and Creation Poetics of Autotextuality 1St Edition Radosvet Kolarov PDFDocument53 pagesFull Chapter Repetition and Creation Poetics of Autotextuality 1St Edition Radosvet Kolarov PDFclarence.nance336100% (8)

- Mod01 L02Document12 pagesMod01 L02Pankaj Kumar SainiNo ratings yet

- Python-2 - Unit-6,7,8 - Game DevelopmentDocument38 pagesPython-2 - Unit-6,7,8 - Game DevelopmentPalak RathoreNo ratings yet

- Accumulation of Heavy Metals in SpinaciaDocument12 pagesAccumulation of Heavy Metals in SpinaciaSachin SrivastavaNo ratings yet