Professional Documents

Culture Documents

ME307 Energy Conversion Devices: Assignment - 6 Topic - Cavitation in Hydroturbomachines

ME307 Energy Conversion Devices: Assignment - 6 Topic - Cavitation in Hydroturbomachines

Uploaded by

Awantika Singh0 ratings0% found this document useful (0 votes)

3 views6 pages1) The document discusses how to check for cavitation in pump systems using the vapor pressure of liquids.

2) It explains that if the pressure curve crosses below the vapor pressure line, cavitation will occur as the pressure will drop below the vapor pressure of the liquid.

3) Conversely, if the pressure curve does not cross the vapor pressure line, the system is correctly designed and cavitation will not occur as the pressure will remain above the vapor pressure.

Original Description:

Original Title

A6_B18163

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) The document discusses how to check for cavitation in pump systems using the vapor pressure of liquids.

2) It explains that if the pressure curve crosses below the vapor pressure line, cavitation will occur as the pressure will drop below the vapor pressure of the liquid.

3) Conversely, if the pressure curve does not cross the vapor pressure line, the system is correctly designed and cavitation will not occur as the pressure will remain above the vapor pressure.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

3 views6 pagesME307 Energy Conversion Devices: Assignment - 6 Topic - Cavitation in Hydroturbomachines

ME307 Energy Conversion Devices: Assignment - 6 Topic - Cavitation in Hydroturbomachines

Uploaded by

Awantika Singh1) The document discusses how to check for cavitation in pump systems using the vapor pressure of liquids.

2) It explains that if the pressure curve crosses below the vapor pressure line, cavitation will occur as the pressure will drop below the vapor pressure of the liquid.

3) Conversely, if the pressure curve does not cross the vapor pressure line, the system is correctly designed and cavitation will not occur as the pressure will remain above the vapor pressure.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 6

ME307

Energy Conversion Devices

Assignment – 6

Topic – Cavitation in Hydroturbomachines

Name – Awantika Singh

Roll No. – B18163

Question:

• How to check whether a pump system is

correctly designed and cavitation will not occur

using the vapor pressure of the liquids ?

Answer:

• The pressure varies at different positions in a pump. The

pressure through the pump firstly drops and then increases up

to a certain level nearby the outlet. It is due to the fact that

the diameter of the impeller is small as compared to the

suction pipe, and the pump impeller is adding energy to the

liquid, thereby increasing its pressure. Hence this diagram

shows the variation of pressure through an impeller.

• In figure 2 the black line (represents vapor pressure) parallel to

x - axis cuts the graph. It signifies that at this position the

pressure will be less than the vapor pressure (Vp) of the liquid

which flows inside the pump. This means that the system in

which this pump is installed is not providing sufficient NPSHa

(Net positive suction head available) since it depends on the

vapor pressure of the liquid and hence cavitation will occur.

• In figure 3 the Vp (vapor pressure) line doesn’t cut the curve at

any point. This shows that there is sufficient NPSHa and the

pressure will not drop below the vapor pressure of the liquid.

Hence, this system is designed properly and cavitation will not

occur here.

• Hence, this is how by using the known property of a liquid i.e.

vapor pressure (Vp) which is related to NPSHa one can observe

and tell whether cavitation will occur or not in a pump system.

It is necessary to ensure that NPSHa is available so that the

fluid remains above the vapor pressure and cavitation can be

avoided. There are other things also which need to be

considered to avoid cavitation like vapor pressure of the liquid

which I have mentioned here.

You might also like

- Pumps (Questions & Answers)Document14 pagesPumps (Questions & Answers)SriRaman Pathakgaru100% (5)

- How To Find Pump Size and Pump Head CalculationDocument8 pagesHow To Find Pump Size and Pump Head Calculationprosper100% (1)

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNo ratings yet

- Diesel Common Rail Injection Electronic Components ExplainedFrom EverandDiesel Common Rail Injection Electronic Components ExplainedRating: 3.5 out of 5 stars3.5/5 (7)

- Pid Presentation 1Document11 pagesPid Presentation 1SahilNo ratings yet

- Controlling Centrifugal PumpsDocument12 pagesControlling Centrifugal PumpsDan AngheleaNo ratings yet

- Artificial LiftDocument35 pagesArtificial LiftVladan Prigara100% (1)

- Artificial Lift: by Sekar Learning Advisor - ProcessDocument35 pagesArtificial Lift: by Sekar Learning Advisor - ProcessYsaías Samanez VeraNo ratings yet

- Pumps OverviewDocument12 pagesPumps OverviewHesham ZaghloulNo ratings yet

- Net Positive Suction HeadDocument2 pagesNet Positive Suction Headanwerosama0% (1)

- NPSHA For PumpDocument11 pagesNPSHA For PumpHariharan KandasamyNo ratings yet

- Net Positive Suction Head or NPSHDocument4 pagesNet Positive Suction Head or NPSHSathish Lingam100% (1)

- How To Size A Pump Blackmonk Engineering PDFDocument9 pagesHow To Size A Pump Blackmonk Engineering PDFRajesh KrishnamoorthyNo ratings yet

- What Is NPSHDocument10 pagesWhat Is NPSHgyousafNo ratings yet

- Melab Act2Document2 pagesMelab Act2Theo AlapanNo ratings yet

- Natalie Portmans Shaved Head Glossary of Firefighting Equipment#n Talk PageDocument34 pagesNatalie Portmans Shaved Head Glossary of Firefighting Equipment#n Talk PageMikelaNo ratings yet

- NPSH Is An: Acronym Hydraulic Vapor PressureDocument5 pagesNPSH Is An: Acronym Hydraulic Vapor PressureSantosh Yellappa SulebhavikarNo ratings yet

- Pump ReportDocument12 pagesPump ReportHesham Zaghloul100% (1)

- 60 (Pumps & Compressors)Document17 pages60 (Pumps & Compressors)Vu TranNo ratings yet

- NPSHDocument5 pagesNPSHmbakhshi2No ratings yet

- Pump Head CalculationsDocument65 pagesPump Head CalculationsAnonymous TjdHCuNo ratings yet

- Centrifugal Pumps NPSHDocument6 pagesCentrifugal Pumps NPSHSubrata MukherjeeNo ratings yet

- 400 Bad Request 400 Bad Request Nginx/1.2.9Document64 pages400 Bad Request 400 Bad Request Nginx/1.2.9aminNo ratings yet

- Centrifugal PumpDocument12 pagesCentrifugal PumppertmasterNo ratings yet

- Logics PumpsDocument155 pagesLogics PumpsKashif ChaudhryNo ratings yet

- Acceleration Head For Centrifugal Pumps: Pulsing Flow Requires More NPSHDocument1 pageAcceleration Head For Centrifugal Pumps: Pulsing Flow Requires More NPSHnirmal_subudhiNo ratings yet

- NPSH Old PDFDocument3 pagesNPSH Old PDFMalik JunaidNo ratings yet

- 7 - Pumps (Part 2)Document27 pages7 - Pumps (Part 2)AmpNo ratings yet

- Centrifugal Pump SystemsDocument92 pagesCentrifugal Pump Systemsvijay kumarNo ratings yet

- Pump Basics PDFDocument43 pagesPump Basics PDFtsrinivasan5083No ratings yet

- Lec01 Process Design of Pipe Process Equipment Design Chemical EngineeringDocument11 pagesLec01 Process Design of Pipe Process Equipment Design Chemical EngineeringLuis Enrique Flores ValenzuelaNo ratings yet

- Sizing Pulsation Dampeners Is Critical To Effectiveness P47E11 010Document6 pagesSizing Pulsation Dampeners Is Critical To Effectiveness P47E11 010Othoniel KanoNo ratings yet

- NPSH1Document8 pagesNPSH1koyasrujanaNo ratings yet

- Pumps Design and PerformanceDocument27 pagesPumps Design and PerformanceJefferson SmithNo ratings yet

- How Does Pump Suction Limit The FlowDocument6 pagesHow Does Pump Suction Limit The FlowNilesh GohelNo ratings yet

- Pump Stuff GuidelinesDocument37 pagesPump Stuff GuidelinesBogdan ChivulescuNo ratings yet

- NSS & NPSHRDocument3 pagesNSS & NPSHRmariasofiarossiNo ratings yet

- NPSHDocument7 pagesNPSHsateesh chand100% (1)

- A Look at Centrifugal Pump Suction Hydraulic - Part 1Document4 pagesA Look at Centrifugal Pump Suction Hydraulic - Part 1Said Ahmed SalemNo ratings yet

- How To Size A PumpDocument6 pagesHow To Size A PumpSoe T. Htun100% (1)

- PumpsDocument6 pagesPumpsSalehAfadlehNo ratings yet

- Frequently Asked Questions On PumpsDocument4 pagesFrequently Asked Questions On PumpsujghvfkjNo ratings yet

- NPSHDocument6 pagesNPSHAnsari SuhailNo ratings yet

- NPSHDocument1 pageNPSHssabih75No ratings yet

- Understanding Net Positive Suction Head - Short Notes For GATE Mechanical EngineeringDocument4 pagesUnderstanding Net Positive Suction Head - Short Notes For GATE Mechanical EngineeringBharat BhushanNo ratings yet

- Me151 MidtermsDocument18 pagesMe151 MidtermsJohnNo ratings yet

- A Look at Centrifugal Pump Suction Hydraulic - Part 2Document3 pagesA Look at Centrifugal Pump Suction Hydraulic - Part 2Said Ahmed SalemNo ratings yet

- NPSH CalculationDocument19 pagesNPSH CalculationPatilea Daniela100% (1)

- True Operating Flow Range of A Centrifugal PumpsDocument2 pagesTrue Operating Flow Range of A Centrifugal PumpsmishraenggNo ratings yet

- Schema Booster MetanoDocument10 pagesSchema Booster MetanoMario Rabe GalbiatiNo ratings yet

- Pumps and Pumping Stations: 3.2.1 Q-H CurveDocument10 pagesPumps and Pumping Stations: 3.2.1 Q-H CurveOlanrewaju OlawaleNo ratings yet

- TURBOMACHINES: Pumps PerformanceDocument35 pagesTURBOMACHINES: Pumps PerformanceBaber H. ElahiNo ratings yet

- Guide To Reading A Positive Displacement Pump CurveDocument10 pagesGuide To Reading A Positive Displacement Pump CurveLluís Vidales SerresNo ratings yet

- Chapter 5 Rotating EquipmentDocument32 pagesChapter 5 Rotating EquipmentAeffandii SamawiNo ratings yet

- Accelertion Head PDFDocument5 pagesAccelertion Head PDFEng AlfNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Squealer Tips (Tips With Either Cooling Slots or Seals) Are Used ToDocument4 pagesSquealer Tips (Tips With Either Cooling Slots or Seals) Are Used ToAwantika SinghNo ratings yet

- Metals Have A Sharp Freezing Point While Alloys Freeze Over A Range of TemperatureDocument6 pagesMetals Have A Sharp Freezing Point While Alloys Freeze Over A Range of TemperatureAwantika SinghNo ratings yet

- Resist Structure - Electroplating - Resist Strip - Metal MoldDocument2 pagesResist Structure - Electroplating - Resist Strip - Metal MoldAwantika SinghNo ratings yet

- ME307 Energy Conversion Devices: Assignment - 4 TopicDocument5 pagesME307 Energy Conversion Devices: Assignment - 4 TopicAwantika SinghNo ratings yet

- Gas Turbine:: CombustorDocument3 pagesGas Turbine:: CombustorAwantika SinghNo ratings yet

- Spin Coating 2. Baking 3. UV Exposure 4. Developing 5. InspectionDocument2 pagesSpin Coating 2. Baking 3. UV Exposure 4. Developing 5. InspectionAwantika SinghNo ratings yet

- Solar Cell: Photovoltaics: Solar Cells Function Based OnDocument3 pagesSolar Cell: Photovoltaics: Solar Cells Function Based OnAwantika SinghNo ratings yet

- Blades: Most Important Parts That Convert The Energy: HP and IPDocument5 pagesBlades: Most Important Parts That Convert The Energy: HP and IPAwantika SinghNo ratings yet

- Microstructure: The Arrangement ofDocument4 pagesMicrostructure: The Arrangement ofAwantika SinghNo ratings yet

- Disc and Drum: Tow TypesDocument4 pagesDisc and Drum: Tow TypesAwantika SinghNo ratings yet

- Basic Properties Influencing Manufacturability: Indentation Tests For HardnessDocument5 pagesBasic Properties Influencing Manufacturability: Indentation Tests For HardnessAwantika SinghNo ratings yet

- ME307 Energy Conversion Devices: Assignment - 2 Topic - Pumping SystemsDocument7 pagesME307 Energy Conversion Devices: Assignment - 2 Topic - Pumping SystemsAwantika SinghNo ratings yet

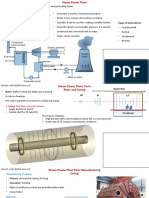

- Types of Steam Plants:: Stack Combustion Gases To StackDocument3 pagesTypes of Steam Plants:: Stack Combustion Gases To StackAwantika SinghNo ratings yet

- Examples: Casting, Forging, Rolling, Milling, Drilling, Drawing, Sintering, Sheet MetalDocument6 pagesExamples: Casting, Forging, Rolling, Milling, Drilling, Drawing, Sintering, Sheet MetalAwantika SinghNo ratings yet

- ME307 Energy Conversion Devices: Assignment - 9 Topic - Steam and Gas TurbinesDocument6 pagesME307 Energy Conversion Devices: Assignment - 9 Topic - Steam and Gas TurbinesAwantika SinghNo ratings yet

- ME307 Energy Conversion Devices: Assignment - 7 Topic - Basics of Compressible FlowDocument6 pagesME307 Energy Conversion Devices: Assignment - 7 Topic - Basics of Compressible FlowAwantika SinghNo ratings yet

- ME307 Energy Conversion Devices: Assignment - 2 Topic - Pumping SystemsDocument7 pagesME307 Energy Conversion Devices: Assignment - 2 Topic - Pumping SystemsAwantika SinghNo ratings yet

- ME307 Energy Conversion Devices: Assignment - 8 Topic - Steam and Gas TurbinesDocument6 pagesME307 Energy Conversion Devices: Assignment - 8 Topic - Steam and Gas TurbinesAwantika SinghNo ratings yet

- ME307 Energy Conversion Devices: Assignment - 5 TopicDocument6 pagesME307 Energy Conversion Devices: Assignment - 5 TopicAwantika SinghNo ratings yet

- Latex Demo Class: Awantika Singh May 25, 2019Document1 pageLatex Demo Class: Awantika Singh May 25, 2019Awantika SinghNo ratings yet

- Energy Conversion Devices: TopicDocument18 pagesEnergy Conversion Devices: TopicAwantika SinghNo ratings yet

- Précis Writing or RestatementDocument1 pagePrécis Writing or RestatementAwantika SinghNo ratings yet

- Automatic Blackboard CleanerDocument25 pagesAutomatic Blackboard CleanerAwantika SinghNo ratings yet