Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

450 viewsOn Preheating

On Preheating

Uploaded by

YYThe document discusses preheating in welding. Preheating involves heating the base metal to a specific temperature before welding to slow cooling rates and allow hydrogen to diffuse out, reducing cracking. It outlines four primary reasons for preheating: 1) slower cooling produces a more ductile structure, 2) allows hydrogen to diffuse out, 3) reduces shrinkage stresses, and 4) raises some steels above brittle temperatures. Determining the need for and level of preheating depends on codes, material thickness and properties, restraint, and risk of cracking. Guidelines are provided for selecting a preheat temperature when codes don't apply.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You might also like

- Procedure of PVC, FRP Welding and Jointing ProcedureDocument5 pagesProcedure of PVC, FRP Welding and Jointing ProcedureHasan AhmedNo ratings yet

- Bhel WPS For P91Document10 pagesBhel WPS For P91lightsonsNo ratings yet

- Method of SwagingDocument4 pagesMethod of Swagingjcarlos7411No ratings yet

- WPS, PQR 041Document21 pagesWPS, PQR 041swamykommula100% (1)

- Fundamentals of Welding TechDocument29 pagesFundamentals of Welding TechAshwani DograNo ratings yet

- Asme Ix - WPS - Gtaw Fcaw Gmaw PDFDocument1 pageAsme Ix - WPS - Gtaw Fcaw Gmaw PDFThe Welding Inspections CommunityNo ratings yet

- CSWIP Welding Inspection Notes and QuestionsDocument132 pagesCSWIP Welding Inspection Notes and QuestionsfahreezNo ratings yet

- Preheat and Interpass TempDocument2 pagesPreheat and Interpass TempUche UrchNo ratings yet

- Preheating and Post Weld Heat TreatmentsDocument3 pagesPreheating and Post Weld Heat TreatmentssubrataNo ratings yet

- Preheat RequirementsDocument3 pagesPreheat RequirementsVJG369No ratings yet

- Interpass Temperature WeldingDocument2 pagesInterpass Temperature Weldinghareesh13h100% (1)

- Ingenieria de La Soldadura PDFDocument11 pagesIngenieria de La Soldadura PDFedscesc10100% (1)

- Post Weld Heat TreatmentDocument10 pagesPost Weld Heat Treatmentcristian291011No ratings yet

- 5 Methods To Determine Preheat TemperatureDocument4 pages5 Methods To Determine Preheat TemperatureMohamed AtefNo ratings yet

- PWHTDocument79 pagesPWHTnguyenNo ratings yet

- PWHTDocument57 pagesPWHTssNo ratings yet

- Basic Points of P91Document4 pagesBasic Points of P91Asad Bin Ala Qatari100% (1)

- Ferrite Weld Test Procedure-1Document5 pagesFerrite Weld Test Procedure-1tedmer1No ratings yet

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaNo ratings yet

- CBB Exam Preparation CourseDocument2 pagesCBB Exam Preparation CourseaadmaadmNo ratings yet

- WPS - 006Document13 pagesWPS - 006MAT-LIONNo ratings yet

- Visual Inspection of Weld Joints Welding and NDTDocument7 pagesVisual Inspection of Weld Joints Welding and NDTALFA ENGINEERING100% (2)

- TDC Certificate PDFDocument2 pagesTDC Certificate PDFAlaxmi NarayanNo ratings yet

- PQR A106 HAL-1Document1 pagePQR A106 HAL-1Budi Setia RahmanNo ratings yet

- ABout Preheat Before WeldingDocument2 pagesABout Preheat Before WeldingHary Olya AdriansyahNo ratings yet

- PWHTDocument103 pagesPWHTsheikbbaNo ratings yet

- PWHTDocument103 pagesPWHTChetan B KapadiaNo ratings yet

- How To Read PWHTchartDocument10 pagesHow To Read PWHTchartAkhilesh Kumar100% (4)

- Heat Treatment of SteelsDocument9 pagesHeat Treatment of SteelsEhsan KhanNo ratings yet

- TWI Cswip 3.1wis 5 Welding Inspection Welding Symbols BSEN ISO 22553 /AWS A2Document68 pagesTWI Cswip 3.1wis 5 Welding Inspection Welding Symbols BSEN ISO 22553 /AWS A2Ali ClubistNo ratings yet

- Tube To Tube Sheet Mock UpDocument5 pagesTube To Tube Sheet Mock UpKushalNo ratings yet

- Strip CladingDocument26 pagesStrip Cladingviswamanoj100% (1)

- Welding TerminologyDocument18 pagesWelding Terminologymahi1437100% (1)

- Pressure Plate MaterialDocument5 pagesPressure Plate MaterialBhavani PrasadNo ratings yet

- National Iranian Gas Company IGAT 5 Gas Compressor Stations: 602-106-TSH-VD-015 Rev. 0 PWHT ProcedureDocument9 pagesNational Iranian Gas Company IGAT 5 Gas Compressor Stations: 602-106-TSH-VD-015 Rev. 0 PWHT ProcedurewiNo ratings yet

- Dissimilar Base Metal ThicknessDocument5 pagesDissimilar Base Metal ThicknessFERNANDO MIRANDA100% (2)

- Note 1 Approving Welding Procedure - Process FlowDocument26 pagesNote 1 Approving Welding Procedure - Process FlowMohamad Yusuf HelmiNo ratings yet

- ASME Section IX Welding Procedure Qualification: Antonius P. BramonoDocument50 pagesASME Section IX Welding Procedure Qualification: Antonius P. BramonoHAKANNo ratings yet

- Acceptable Grade of Plate Material (API 650)Document1 pageAcceptable Grade of Plate Material (API 650)juantamad02No ratings yet

- PWHT of Dissimilar: Metal WeldsDocument48 pagesPWHT of Dissimilar: Metal WeldswchavezbNo ratings yet

- PWHTDocument3 pagesPWHTharishcsharmaNo ratings yet

- ASME 9 - CalculatorDocument2 pagesASME 9 - CalculatorEmel Besir100% (1)

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- Specification For WeldingDocument67 pagesSpecification For WeldingMehdi NouriNo ratings yet

- WPSASMEDocument76 pagesWPSASMERama TamaNo ratings yet

- Welding QuestionnairesDocument2 pagesWelding Questionnairesasif712100% (2)

- P01-Welding Consm ControlDocument5 pagesP01-Welding Consm ControlvenkateshNo ratings yet

- Submerged Arc Welding: by L D PoyyaraDocument29 pagesSubmerged Arc Welding: by L D PoyyaraSapan KansaraNo ratings yet

- Sa 387Document29 pagesSa 387Ali VarmazyarNo ratings yet

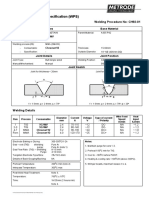

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- Critical Observations During A Shut Down Audit of A PF BoilerDocument9 pagesCritical Observations During A Shut Down Audit of A PF Boilerparthi20065768No ratings yet

- WPS Steps of MakingDocument51 pagesWPS Steps of MakingSaut Maruli Tua Samosir100% (1)

- Welding InspectionDocument43 pagesWelding Inspectionzubairsarwar912No ratings yet

- WPS Qualify To DNV-OS-C401 - SampleDocument12 pagesWPS Qualify To DNV-OS-C401 - SampleBien NguyenDuyNo ratings yet

- PWHTDocument25 pagesPWHTBruce leeNo ratings yet

- Heat Treatment PDFDocument22 pagesHeat Treatment PDFravi00098No ratings yet

- Welding PreheatDocument2 pagesWelding PreheatsjmudaNo ratings yet

- What Is PreheatDocument4 pagesWhat Is PreheatahmedNo ratings yet

- Fundamentals of PreheatDocument2 pagesFundamentals of PreheatErivaldo ConstantNo ratings yet

- Qa-Rkm-Techdoc-Ht-A6 - PreheatDocument3 pagesQa-Rkm-Techdoc-Ht-A6 - PreheatmiteshNo ratings yet

- PreheatDocument2 pagesPreheatZoe ToNo ratings yet

- A Primer Weldment Preheating Interpass Temperature: On andDocument4 pagesA Primer Weldment Preheating Interpass Temperature: On andMuhammed Hisham HNo ratings yet

- SMAW7 Mod4 Evaluate Hazards and Risks V3Document19 pagesSMAW7 Mod4 Evaluate Hazards and Risks V3Kurt Valentine LopezNo ratings yet

- 12 SMAW W 1 - Types of Welding PositionsDocument10 pages12 SMAW W 1 - Types of Welding PositionsNelPalalonNo ratings yet

- Lesson Plan Smaw2Document4 pagesLesson Plan Smaw2Junet Bombeat CanqueNo ratings yet

- Elimination of Crack Formation in Stainless Steel After Tig Welding - 2-427-151816990575-79Document5 pagesElimination of Crack Formation in Stainless Steel After Tig Welding - 2-427-151816990575-79arjun prajapatiNo ratings yet

- Plate and Pipe Groove and Fillet WeldingDocument1 pagePlate and Pipe Groove and Fillet WeldingYASH BARDHAN SinghNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- GB8410 2006 enDocument46 pagesGB8410 2006 enDiego Camargo100% (1)

- Batch - 3 Project Report CorrectedDocument40 pagesBatch - 3 Project Report CorrectedT2L KISHORENo ratings yet

- Effects of MN, P, S, Si, VDocument2 pagesEffects of MN, P, S, Si, Vfaizalzol0% (1)

- The Evolution of Shielding GasDocument3 pagesThe Evolution of Shielding GasSharad ShahNo ratings yet

- Force - Fitness For Service Evaluation of Hydrotest ExemptionDocument24 pagesForce - Fitness For Service Evaluation of Hydrotest ExemptionFaiz BokhadiNo ratings yet

- Azing Procedure Weld Copper WaterstopDocument5 pagesAzing Procedure Weld Copper Waterstopzhuxueyun55No ratings yet

- ASME & AWS Welding Codes-Similarities and DifferencesDocument7 pagesASME & AWS Welding Codes-Similarities and DifferencesMnttoMecNo ratings yet

- Paper 3Document4 pagesPaper 3maani7zeroNo ratings yet

- Welddefects & Quality ControlDocument50 pagesWelddefects & Quality ControlAmirtha Thiyagaraajan AlagesanNo ratings yet

- Operating Instructions: Diesel Engine 12V2000M93 16V2000M93Document163 pagesOperating Instructions: Diesel Engine 12V2000M93 16V2000M93Renato MagalhãesNo ratings yet

- DatabaseDocument235 pagesDatabasejosephruNo ratings yet

- User Manual Kullanim Kilavuzu: Rs 350 M - MW Rs 400 M - MW Rs 500 M - MWDocument88 pagesUser Manual Kullanim Kilavuzu: Rs 350 M - MW Rs 400 M - MW Rs 500 M - MWSerhan AysanNo ratings yet

- Plant Register TemplateDocument4 pagesPlant Register TemplateimamtaNo ratings yet

- Asme Code For Ultrasonic Testing The Knowledge Sinequation: Ashok J. TrivediDocument7 pagesAsme Code For Ultrasonic Testing The Knowledge Sinequation: Ashok J. TrivediAli Ben AmorNo ratings yet

- API 570 Study Guide 2010 Chevron Angola May 2010 PDFDocument316 pagesAPI 570 Study Guide 2010 Chevron Angola May 2010 PDFkbpatel123100% (1)

- Sawyer MFG BrochureDocument24 pagesSawyer MFG BrochureDiego RNo ratings yet

- Aquavolt 2: High Precision Moisture AnalyzerDocument2 pagesAquavolt 2: High Precision Moisture AnalyzerDoge CaptainNo ratings yet

- Plastics WeldingDocument4 pagesPlastics Weldingmehdi7891No ratings yet

- Standard Operating Procedure (Straightning) : Prepared By: Checked by Approved byDocument2 pagesStandard Operating Procedure (Straightning) : Prepared By: Checked by Approved bysbmmlaNo ratings yet

- Komatsu Excavator Pc300 7 Pc300lc 7 Pc350 7 Pc350lc 7 Shop ManualDocument20 pagesKomatsu Excavator Pc300 7 Pc300lc 7 Pc350 7 Pc350lc 7 Shop Manualcharlie100% (53)

- C - SPEC of Order 22.83 (EURU505293-505459) - 2022-11-15 PDFDocument7 pagesC - SPEC of Order 22.83 (EURU505293-505459) - 2022-11-15 PDFRod SantosNo ratings yet

- 1.introduction To SMAWDocument74 pages1.introduction To SMAWRumman Ul AhsanNo ratings yet

On Preheating

On Preheating

Uploaded by

YY0 ratings0% found this document useful (0 votes)

450 views22 pagesThe document discusses preheating in welding. Preheating involves heating the base metal to a specific temperature before welding to slow cooling rates and allow hydrogen to diffuse out, reducing cracking. It outlines four primary reasons for preheating: 1) slower cooling produces a more ductile structure, 2) allows hydrogen to diffuse out, 3) reduces shrinkage stresses, and 4) raises some steels above brittle temperatures. Determining the need for and level of preheating depends on codes, material thickness and properties, restraint, and risk of cracking. Guidelines are provided for selecting a preheat temperature when codes don't apply.

Original Description:

Covers the salient features for requirement of preheating, type, method, advantages, disadvantages

Original Title

ppt on preheating

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses preheating in welding. Preheating involves heating the base metal to a specific temperature before welding to slow cooling rates and allow hydrogen to diffuse out, reducing cracking. It outlines four primary reasons for preheating: 1) slower cooling produces a more ductile structure, 2) allows hydrogen to diffuse out, 3) reduces shrinkage stresses, and 4) raises some steels above brittle temperatures. Determining the need for and level of preheating depends on codes, material thickness and properties, restraint, and risk of cracking. Guidelines are provided for selecting a preheat temperature when codes don't apply.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

450 views22 pagesOn Preheating

On Preheating

Uploaded by

YYThe document discusses preheating in welding. Preheating involves heating the base metal to a specific temperature before welding to slow cooling rates and allow hydrogen to diffuse out, reducing cracking. It outlines four primary reasons for preheating: 1) slower cooling produces a more ductile structure, 2) allows hydrogen to diffuse out, 3) reduces shrinkage stresses, and 4) raises some steels above brittle temperatures. Determining the need for and level of preheating depends on codes, material thickness and properties, restraint, and risk of cracking. Guidelines are provided for selecting a preheat temperature when codes don't apply.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 22

Preheating

•Preheating involves heating the base metal, either

in its entirety or just the region surrounding the

joint, to a specific desired temperature, called the

preheat temperature, prior to welding.

•Heating may be continued during the welding

process, but frequently the heat from welding is

sufficient to maintain the desired temperature

without a continuation of the external heat source.

Preheating

•The interpass temperature, defined as the base

metal temperature at the time when welding is to

be performed between the first and last welding

passes, cannot be permitted to fall below the

preheat temperature.

•Interpass temperature will not be discussed

further here; however, it will be the subject of a

future column.

Preheating

•Preheating can produce many beneficial effects;

however, without a working knowledge of the

fundamentals involved, one risks wasting money,

or even worse, degrading the integrity of the

weldment.

Reasons to Preheat

•There are four primary reasons to utilize preheat:

(1)it slows the cooling rate in the weld metal and

base metal, producing a more ductile metallurgical

structure with greater resistance to cracking;

(2)The slower cooling rate provides an opportunity

for hydrogen that may be present to diffuse out

harmlessly, reducing the potential for cracking.

Reasons to Preheat

(3) it reduces the shrinkage stresses in the weld

and adjacent base metal, which is especially

important in highly restrained joints; and

(4) it raises some steels above the temperature at

which brittle fracture would occur in fabrication.

Additionally, preheat can be used to help ensure

specific mechanical properties, such as weld metal

notch toughness.

Reasons to Preheat

In determining whether or not to preheat, the

following should be considered:

•code requirements,

•section thickness,

•base metal chemistry,

•restraint,

•ambient temperature,

•filler metal hydrogen content and

•previous cracking problems.

Requirement to Preheat

•If a welding code must be followed, then the code

generally will specify the minimum preheat

temperature for a given base metal, welding

process and section thickness.

•This minimum value must be attained regardless

of the restraint or variation in base metal

chemistry; however, the minimum value may be

increased if necessary.

Requirement to Preheat

•When there are no codes governing the welding,

one must determine whether preheat is required,

and if so, what preheat temperature will be

appropriate.

•In general, preheat usually is not required on low

carbon steels less than 1 in (25 mm) thick.

•However, as the chemistry, diffusible hydrogen

level of the weld metal, restraint or section

thickness increases, the need for preheat also

increases.

Requirement to Preheat

•Welding codes generally specify minimum values

for the preheat temperature,which may or may not

be adequate to prohibit cracking in every

application. For example, if a beamto- column

connection made of ASTM A572-Gr50 jumbo

sections (thicknesses ranging from 4 to 5 in [100-

125 mm]) is to be fabricated with a lowhydrogen

electrode, then a minimum prequalified preheat of

225°F (107°C) is required (AWS D1.1-96, Table

3.2).

Requirement to Preheat

•However, for making butt splices in jumbo

sections, it is advisable to increase the preheat

temperature beyond the minimum prequalified

level to that required by AISC for making butt

splices in jumbo sections, namely 350°F (175°C)

(AISC LRFD J2.8). This conservative

recommendation acknowledges that the minimum

preheat requirements prescribed by AWSD1.1

may not be adequate for these highly restrained

connections.

Requirement to Preheat

When no welding code is specified, and the need for

preheat has been established, how does one determine an

appropriate preheat temperature? Consider AWS D1.1-96,

Annex XI: “Guideline on Alternative Methods for

Determining Preheat” which presents two procedures for

establishing a preheat temperature developed primarily

from laboratory cracking tests. These techniques are

beneficial when the risk of cracking is increased due to the

chemical composition, a greater degree of restraint, higher

levels of hydrogen or lower welding heat input.

Requirement to Preheat

• The two methods outlined in Annex XI of AWS D1.1-96

are:

• (1) heat affected zone (HAZ) hardness control and

• (2) hydrogen control.

• The HAZ hardness control method, which is restricted to

fillet welds, is based on the assumption that cracking will

not occur if the hardness of the HAZ is kept below some

critical value. This is achieved by controlling the cooling

rate. The critical cooling rate for a given hardness can be

related to the carbon equivalent of the steel, which is

defined as

• CE=C + (Mn + Si)/6+(Cr + Mo + V)/5+(Ni + Cu)/15

Requirement to Preheat

• From the critical cooling rate, a minimum preheat

temperature can then be calculated. AWS D1.1-96 states that

“Although the method can be used to determine a preheat

level, its main value is in determining the minimum heat input

(and hence minimum weld size) that prevents excessive

hardening”

• The hydrogen control method is based on the assumption

that cracking will not occur if the amount of hydrogen

remaining in the joint after it has cooled down to about 120°F

(50°C) does not exceed a critical value dependent on the

composition of the steel and the restraint. This procedure is

extremely useful for high strength, low-alloy steels that have

high hardenability. However, the calculated preheat may be

somewhat conservative for carbon steels

Requirement to Preheat

The three basic steps of the hydrogen control method are:

(1) Calculate a composition parameter similar to the carbon

equivalent; (2) Calculate a susceptibility index as a function

of the composition parameter and the filler metal diffusible

hydrogen content; and (3) Determine the minimum preheat

temperature from the restraint level, material thickness, and

susceptibility index.

Application of Preheat

The material thickness, size of the weldment and available

heating equipment should be considered when choosing a

method for applying preheat. For example, small production

assemblies may be heated most effectively in a furnace.

However, large structural components often require banks

of heating torches, electrical strip heaters, or induction or

radiant heaters.

Application of Preheat

Preheating carbon steel to a precise temperature generally

is not required. Although it is important that the work be

heated to a minimum temperature, it usually is acceptable

to exceed that temperature by approximately 100°F (40°C).

However, this is not the case for some quenched and

tempered (Q&T) steels such as A514 or A517, since

welding on overheated Q&T steels may be detrimental in

the heat affected zone. Therefore, Q&T steels require that

maximum and minimum preheat temperatures be

established and closely followed.

Application of Preheat

When heating the joint to be welded, the AWS D1.1 code

requires that the minimum preheat temperature be

established at a distance that is at least equal to the

thickness of the thickest member, but not less than 3 in (75

mm) in all directions from the point of welding. To ensure

that thefull material volume surrounding the joint is heated,

it is recommended practice to heat the side opposite of that

which is to be welded and to measure the surface

temperature adjacent to the joint. Finally, the interpass

temperature should be checked to verify that the minimum

preheat temperature has been maintained just prior to

initiating the arc for each pass.

Benefits of Preheat

• Preheat can minimize cracking and/or ensure specific

mechanical properties such as notch toughness.

• • Preheat must be used whenever applicable codes so

specify; when no codes apply to a given situation, the

welding engineer must determine whether or not preheat

is needed, and what temperature will be required for a

given base metal and section thickness.

Benefits of Preheat

• Annex XI of AWS D1.1-96 provides guidelines for

alternative methods of determining proper amounts of

preheat: the HAZ hardness control method, or the

hydrogen control method.

• • Preheat may be applied in a furnace, or by using

heating torches, electrical strip heaters, or induction or

radiant heaters. Carbon steels do not require precise

temperature accuracy, but maximum and minimum

preheat temperatures must be followed closely for

quenched and tempered steels.

Any Question ??

THANKS

You might also like

- Procedure of PVC, FRP Welding and Jointing ProcedureDocument5 pagesProcedure of PVC, FRP Welding and Jointing ProcedureHasan AhmedNo ratings yet

- Bhel WPS For P91Document10 pagesBhel WPS For P91lightsonsNo ratings yet

- Method of SwagingDocument4 pagesMethod of Swagingjcarlos7411No ratings yet

- WPS, PQR 041Document21 pagesWPS, PQR 041swamykommula100% (1)

- Fundamentals of Welding TechDocument29 pagesFundamentals of Welding TechAshwani DograNo ratings yet

- Asme Ix - WPS - Gtaw Fcaw Gmaw PDFDocument1 pageAsme Ix - WPS - Gtaw Fcaw Gmaw PDFThe Welding Inspections CommunityNo ratings yet

- CSWIP Welding Inspection Notes and QuestionsDocument132 pagesCSWIP Welding Inspection Notes and QuestionsfahreezNo ratings yet

- Preheat and Interpass TempDocument2 pagesPreheat and Interpass TempUche UrchNo ratings yet

- Preheating and Post Weld Heat TreatmentsDocument3 pagesPreheating and Post Weld Heat TreatmentssubrataNo ratings yet

- Preheat RequirementsDocument3 pagesPreheat RequirementsVJG369No ratings yet

- Interpass Temperature WeldingDocument2 pagesInterpass Temperature Weldinghareesh13h100% (1)

- Ingenieria de La Soldadura PDFDocument11 pagesIngenieria de La Soldadura PDFedscesc10100% (1)

- Post Weld Heat TreatmentDocument10 pagesPost Weld Heat Treatmentcristian291011No ratings yet

- 5 Methods To Determine Preheat TemperatureDocument4 pages5 Methods To Determine Preheat TemperatureMohamed AtefNo ratings yet

- PWHTDocument79 pagesPWHTnguyenNo ratings yet

- PWHTDocument57 pagesPWHTssNo ratings yet

- Basic Points of P91Document4 pagesBasic Points of P91Asad Bin Ala Qatari100% (1)

- Ferrite Weld Test Procedure-1Document5 pagesFerrite Weld Test Procedure-1tedmer1No ratings yet

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaNo ratings yet

- CBB Exam Preparation CourseDocument2 pagesCBB Exam Preparation CourseaadmaadmNo ratings yet

- WPS - 006Document13 pagesWPS - 006MAT-LIONNo ratings yet

- Visual Inspection of Weld Joints Welding and NDTDocument7 pagesVisual Inspection of Weld Joints Welding and NDTALFA ENGINEERING100% (2)

- TDC Certificate PDFDocument2 pagesTDC Certificate PDFAlaxmi NarayanNo ratings yet

- PQR A106 HAL-1Document1 pagePQR A106 HAL-1Budi Setia RahmanNo ratings yet

- ABout Preheat Before WeldingDocument2 pagesABout Preheat Before WeldingHary Olya AdriansyahNo ratings yet

- PWHTDocument103 pagesPWHTsheikbbaNo ratings yet

- PWHTDocument103 pagesPWHTChetan B KapadiaNo ratings yet

- How To Read PWHTchartDocument10 pagesHow To Read PWHTchartAkhilesh Kumar100% (4)

- Heat Treatment of SteelsDocument9 pagesHeat Treatment of SteelsEhsan KhanNo ratings yet

- TWI Cswip 3.1wis 5 Welding Inspection Welding Symbols BSEN ISO 22553 /AWS A2Document68 pagesTWI Cswip 3.1wis 5 Welding Inspection Welding Symbols BSEN ISO 22553 /AWS A2Ali ClubistNo ratings yet

- Tube To Tube Sheet Mock UpDocument5 pagesTube To Tube Sheet Mock UpKushalNo ratings yet

- Strip CladingDocument26 pagesStrip Cladingviswamanoj100% (1)

- Welding TerminologyDocument18 pagesWelding Terminologymahi1437100% (1)

- Pressure Plate MaterialDocument5 pagesPressure Plate MaterialBhavani PrasadNo ratings yet

- National Iranian Gas Company IGAT 5 Gas Compressor Stations: 602-106-TSH-VD-015 Rev. 0 PWHT ProcedureDocument9 pagesNational Iranian Gas Company IGAT 5 Gas Compressor Stations: 602-106-TSH-VD-015 Rev. 0 PWHT ProcedurewiNo ratings yet

- Dissimilar Base Metal ThicknessDocument5 pagesDissimilar Base Metal ThicknessFERNANDO MIRANDA100% (2)

- Note 1 Approving Welding Procedure - Process FlowDocument26 pagesNote 1 Approving Welding Procedure - Process FlowMohamad Yusuf HelmiNo ratings yet

- ASME Section IX Welding Procedure Qualification: Antonius P. BramonoDocument50 pagesASME Section IX Welding Procedure Qualification: Antonius P. BramonoHAKANNo ratings yet

- Acceptable Grade of Plate Material (API 650)Document1 pageAcceptable Grade of Plate Material (API 650)juantamad02No ratings yet

- PWHT of Dissimilar: Metal WeldsDocument48 pagesPWHT of Dissimilar: Metal WeldswchavezbNo ratings yet

- PWHTDocument3 pagesPWHTharishcsharmaNo ratings yet

- ASME 9 - CalculatorDocument2 pagesASME 9 - CalculatorEmel Besir100% (1)

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- Specification For WeldingDocument67 pagesSpecification For WeldingMehdi NouriNo ratings yet

- WPSASMEDocument76 pagesWPSASMERama TamaNo ratings yet

- Welding QuestionnairesDocument2 pagesWelding Questionnairesasif712100% (2)

- P01-Welding Consm ControlDocument5 pagesP01-Welding Consm ControlvenkateshNo ratings yet

- Submerged Arc Welding: by L D PoyyaraDocument29 pagesSubmerged Arc Welding: by L D PoyyaraSapan KansaraNo ratings yet

- Sa 387Document29 pagesSa 387Ali VarmazyarNo ratings yet

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- Critical Observations During A Shut Down Audit of A PF BoilerDocument9 pagesCritical Observations During A Shut Down Audit of A PF Boilerparthi20065768No ratings yet

- WPS Steps of MakingDocument51 pagesWPS Steps of MakingSaut Maruli Tua Samosir100% (1)

- Welding InspectionDocument43 pagesWelding Inspectionzubairsarwar912No ratings yet

- WPS Qualify To DNV-OS-C401 - SampleDocument12 pagesWPS Qualify To DNV-OS-C401 - SampleBien NguyenDuyNo ratings yet

- PWHTDocument25 pagesPWHTBruce leeNo ratings yet

- Heat Treatment PDFDocument22 pagesHeat Treatment PDFravi00098No ratings yet

- Welding PreheatDocument2 pagesWelding PreheatsjmudaNo ratings yet

- What Is PreheatDocument4 pagesWhat Is PreheatahmedNo ratings yet

- Fundamentals of PreheatDocument2 pagesFundamentals of PreheatErivaldo ConstantNo ratings yet

- Qa-Rkm-Techdoc-Ht-A6 - PreheatDocument3 pagesQa-Rkm-Techdoc-Ht-A6 - PreheatmiteshNo ratings yet

- PreheatDocument2 pagesPreheatZoe ToNo ratings yet

- A Primer Weldment Preheating Interpass Temperature: On andDocument4 pagesA Primer Weldment Preheating Interpass Temperature: On andMuhammed Hisham HNo ratings yet

- SMAW7 Mod4 Evaluate Hazards and Risks V3Document19 pagesSMAW7 Mod4 Evaluate Hazards and Risks V3Kurt Valentine LopezNo ratings yet

- 12 SMAW W 1 - Types of Welding PositionsDocument10 pages12 SMAW W 1 - Types of Welding PositionsNelPalalonNo ratings yet

- Lesson Plan Smaw2Document4 pagesLesson Plan Smaw2Junet Bombeat CanqueNo ratings yet

- Elimination of Crack Formation in Stainless Steel After Tig Welding - 2-427-151816990575-79Document5 pagesElimination of Crack Formation in Stainless Steel After Tig Welding - 2-427-151816990575-79arjun prajapatiNo ratings yet

- Plate and Pipe Groove and Fillet WeldingDocument1 pagePlate and Pipe Groove and Fillet WeldingYASH BARDHAN SinghNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- GB8410 2006 enDocument46 pagesGB8410 2006 enDiego Camargo100% (1)

- Batch - 3 Project Report CorrectedDocument40 pagesBatch - 3 Project Report CorrectedT2L KISHORENo ratings yet

- Effects of MN, P, S, Si, VDocument2 pagesEffects of MN, P, S, Si, Vfaizalzol0% (1)

- The Evolution of Shielding GasDocument3 pagesThe Evolution of Shielding GasSharad ShahNo ratings yet

- Force - Fitness For Service Evaluation of Hydrotest ExemptionDocument24 pagesForce - Fitness For Service Evaluation of Hydrotest ExemptionFaiz BokhadiNo ratings yet

- Azing Procedure Weld Copper WaterstopDocument5 pagesAzing Procedure Weld Copper Waterstopzhuxueyun55No ratings yet

- ASME & AWS Welding Codes-Similarities and DifferencesDocument7 pagesASME & AWS Welding Codes-Similarities and DifferencesMnttoMecNo ratings yet

- Paper 3Document4 pagesPaper 3maani7zeroNo ratings yet

- Welddefects & Quality ControlDocument50 pagesWelddefects & Quality ControlAmirtha Thiyagaraajan AlagesanNo ratings yet

- Operating Instructions: Diesel Engine 12V2000M93 16V2000M93Document163 pagesOperating Instructions: Diesel Engine 12V2000M93 16V2000M93Renato MagalhãesNo ratings yet

- DatabaseDocument235 pagesDatabasejosephruNo ratings yet

- User Manual Kullanim Kilavuzu: Rs 350 M - MW Rs 400 M - MW Rs 500 M - MWDocument88 pagesUser Manual Kullanim Kilavuzu: Rs 350 M - MW Rs 400 M - MW Rs 500 M - MWSerhan AysanNo ratings yet

- Plant Register TemplateDocument4 pagesPlant Register TemplateimamtaNo ratings yet

- Asme Code For Ultrasonic Testing The Knowledge Sinequation: Ashok J. TrivediDocument7 pagesAsme Code For Ultrasonic Testing The Knowledge Sinequation: Ashok J. TrivediAli Ben AmorNo ratings yet

- API 570 Study Guide 2010 Chevron Angola May 2010 PDFDocument316 pagesAPI 570 Study Guide 2010 Chevron Angola May 2010 PDFkbpatel123100% (1)

- Sawyer MFG BrochureDocument24 pagesSawyer MFG BrochureDiego RNo ratings yet

- Aquavolt 2: High Precision Moisture AnalyzerDocument2 pagesAquavolt 2: High Precision Moisture AnalyzerDoge CaptainNo ratings yet

- Plastics WeldingDocument4 pagesPlastics Weldingmehdi7891No ratings yet

- Standard Operating Procedure (Straightning) : Prepared By: Checked by Approved byDocument2 pagesStandard Operating Procedure (Straightning) : Prepared By: Checked by Approved bysbmmlaNo ratings yet

- Komatsu Excavator Pc300 7 Pc300lc 7 Pc350 7 Pc350lc 7 Shop ManualDocument20 pagesKomatsu Excavator Pc300 7 Pc300lc 7 Pc350 7 Pc350lc 7 Shop Manualcharlie100% (53)

- C - SPEC of Order 22.83 (EURU505293-505459) - 2022-11-15 PDFDocument7 pagesC - SPEC of Order 22.83 (EURU505293-505459) - 2022-11-15 PDFRod SantosNo ratings yet

- 1.introduction To SMAWDocument74 pages1.introduction To SMAWRumman Ul AhsanNo ratings yet