Professional Documents

Culture Documents

Quality Induction Training-No 1

Quality Induction Training-No 1

Uploaded by

Kannan MurugesanCopyright:

Available Formats

You might also like

- 5CO01 - Assessment BriefDocument10 pages5CO01 - Assessment BriefEmmanuel KingsNo ratings yet

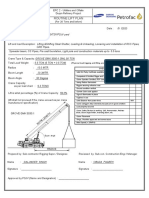

- Routine Lift Plan For All Crane-Grove GMK 50 TonDocument1 pageRoutine Lift Plan For All Crane-Grove GMK 50 TonKannan Murugesan100% (1)

- VanGogh EbookDocument288 pagesVanGogh EbookDragan Cvetkovic88% (8)

- Quality Management Review Agenda and MinutesDocument4 pagesQuality Management Review Agenda and MinutesKannan MurugesanNo ratings yet

- Quality Walk Report FormatDocument14 pagesQuality Walk Report FormatAmar KolachinaNo ratings yet

- Inspection & Test Plan (Itp) : False FlooringDocument1 pageInspection & Test Plan (Itp) : False FlooringLOPA THANDARNo ratings yet

- U07754QOSM - Project O & M Manual TemplateDocument12 pagesU07754QOSM - Project O & M Manual TemplateRithesh ShettyNo ratings yet

- Trimble Precision IQ GFX 750 OptimizedDocument319 pagesTrimble Precision IQ GFX 750 OptimizedireneuszNo ratings yet

- Quality InductionDocument15 pagesQuality InductionaleemmurtazaNo ratings yet

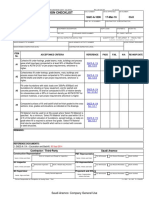

- ITP Check List For Metal Deck InstallationDocument2 pagesITP Check List For Metal Deck InstallationJoyce Gordonio0% (1)

- Inspection and Test Plan: Contract NoDocument2 pagesInspection and Test Plan: Contract NoAhmed Samir SalimNo ratings yet

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilJagdishNo ratings yet

- Plaster Check ListDocument1 pagePlaster Check Listsankuj5354No ratings yet

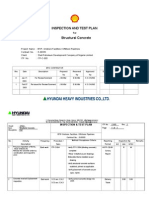

- ITP C 005 (Structural Concrete)Document4 pagesITP C 005 (Structural Concrete)segun ajibolaNo ratings yet

- Itp For Installation of FormworksDocument1 pageItp For Installation of FormworksImho TepNo ratings yet

- SBS Waterproofing ITP & ChecklistDocument27 pagesSBS Waterproofing ITP & Checklistlike saddamNo ratings yet

- Itp - EifsDocument22 pagesItp - Eifssathiyaprasath100% (1)

- SAIC-A-1006 - Final Fill InspectionDocument1 pageSAIC-A-1006 - Final Fill InspectionwalidNo ratings yet

- Gf-Ohtl2-Q-Pl-2001 - 0 Inspection Test Plan For Civil and Structural Steel Code A PDFDocument33 pagesGf-Ohtl2-Q-Pl-2001 - 0 Inspection Test Plan For Civil and Structural Steel Code A PDFAhmed Mohsin100% (1)

- Lesson 10 Project Quality PlanningDocument51 pagesLesson 10 Project Quality PlanningDevjit MandalNo ratings yet

- Presentation On QA QC Faisal Ali ShaikhDocument14 pagesPresentation On QA QC Faisal Ali ShaikhFaisal Ali ShaikhNo ratings yet

- Quality TrainingDocument16 pagesQuality Trainingyushma ghimireNo ratings yet

- QES PEVC-ENG237 - Checklist For PSS Fencing DetailsDocument2 pagesQES PEVC-ENG237 - Checklist For PSS Fencing DetailsRupesh Khandekar100% (1)

- Inspection and Test Plan - Wooden Wall Panel InstallationDocument2 pagesInspection and Test Plan - Wooden Wall Panel Installationexia1992No ratings yet

- Method Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01Document9 pagesMethod Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01hammad21100% (1)

- Quality Plan AuditDocument5 pagesQuality Plan AuditRajan100% (1)

- VECO-QM-PRO-0001 Project Quality Audit Procedure, Rev. 0Document10 pagesVECO-QM-PRO-0001 Project Quality Audit Procedure, Rev. 0hymerchmidtNo ratings yet

- Method Statement of Mass Concrete Block Precast WorksDocument41 pagesMethod Statement of Mass Concrete Block Precast WorksShams JogNo ratings yet

- Quality System Process Map: Customer RequirementsDocument1 pageQuality System Process Map: Customer RequirementsDaniel PradityaNo ratings yet

- Reference Document. Inspection / Testing Frequency Testing Requirement/ Surveillance Points Disc Oneic AawDocument3 pagesReference Document. Inspection / Testing Frequency Testing Requirement/ Surveillance Points Disc Oneic AawPresanna Rajasekaran100% (2)

- Acmc-Qaqc-001 - Quality Observation Report Form - QorDocument12 pagesAcmc-Qaqc-001 - Quality Observation Report Form - QorerwinNo ratings yet

- 5.Ms-Internal Plaster WorkDocument8 pages5.Ms-Internal Plaster WorkShenbagaraja PandianNo ratings yet

- Quality Requirements of ContractorsDocument15 pagesQuality Requirements of ContractorsRoshin99No ratings yet

- QCS 2010 AmmendmentsDocument6 pagesQCS 2010 AmmendmentsPuneeth DevadigaNo ratings yet

- ITP Fencing Rev - 00 PDFDocument3 pagesITP Fencing Rev - 00 PDFanon_987276020No ratings yet

- SLPG Q 0000 24001 019 001 4 0Document15 pagesSLPG Q 0000 24001 019 001 4 0sivagnanamNo ratings yet

- Project Quality Plan-SF5TA20-UT LSTKDocument25 pagesProject Quality Plan-SF5TA20-UT LSTKReehan Aslam100% (1)

- Inspection Test Plan For ISBL 1Document59 pagesInspection Test Plan For ISBL 1Sharat SahaNo ratings yet

- Saudi Oger Ltd. (Project Name) : PlasteringDocument1 pageSaudi Oger Ltd. (Project Name) : PlasteringAnthony AngelesNo ratings yet

- Quality Control - Works Inspection: Acoustic Board PanellingDocument1 pageQuality Control - Works Inspection: Acoustic Board PanellingParasNo ratings yet

- ER288-Rebar Test PlanDocument4 pagesER288-Rebar Test PlanalfieNo ratings yet

- Quality Plan 2 PDF FreeDocument21 pagesQuality Plan 2 PDF FreeEng.arifNo ratings yet

- Itp BuildingDocument42 pagesItp BuildingHaekal RamadhanNo ratings yet

- PQP EpldtDocument8 pagesPQP Epldtmartin leeNo ratings yet

- Presentation - QUALITY (SCHEDULE 'Q' REQUIREMENTS)Document55 pagesPresentation - QUALITY (SCHEDULE 'Q' REQUIREMENTS)kbldamNo ratings yet

- CS P12 Drawing Control ProcedureDocument4 pagesCS P12 Drawing Control Procedurerichard nagilusNo ratings yet

- EGA2 Lessons Learned QualityDocument4 pagesEGA2 Lessons Learned QualityfaizanAkhtar100% (3)

- Fencing Checklist Rev 1Document2 pagesFencing Checklist Rev 1Candice KallooNo ratings yet

- Contractor Monthly) : Quality Report (CMQRDocument11 pagesContractor Monthly) : Quality Report (CMQRKarthik KumarNo ratings yet

- Emulsion Paint ChecklistDocument2 pagesEmulsion Paint Checklistmesmerize59No ratings yet

- PQP Flow ChartDocument1 pagePQP Flow ChartFIRMANSYAHNo ratings yet

- Flowchart QC-QCDocument13 pagesFlowchart QC-QCDevid Peri Sonefel100% (1)

- WMS Concrete Repair WorkDocument8 pagesWMS Concrete Repair WorkRepl microsoft, PuneNo ratings yet

- Itp For Gravel Surfacing and Dust PreventionDocument7 pagesItp For Gravel Surfacing and Dust PreventionShewale PravinNo ratings yet

- Civils - Trenching - ExcavationsDocument2 pagesCivils - Trenching - Excavationsmitendra singhNo ratings yet

- AAA-Project Quality Plan (Rev.0-2015)Document8 pagesAAA-Project Quality Plan (Rev.0-2015)Behroze ShabirNo ratings yet

- Appendix E: Checklist For Kerbstone Works Location / Identification: Drawing No.: No. Description Yes No N/ADocument2 pagesAppendix E: Checklist For Kerbstone Works Location / Identification: Drawing No.: No. Description Yes No N/AJericFuentesNo ratings yet

- 1.SRO-QPITP - Mechanical WorksDocument2 pages1.SRO-QPITP - Mechanical Worksachusanachu100% (1)

- Civil Quality Control Plan EarthworksDocument3 pagesCivil Quality Control Plan Earthworksroekyat hendrawanNo ratings yet

- Programme On Quality Control & Assurance: Sankha Bhattacharya, Housing Devolopment LimitedDocument25 pagesProgramme On Quality Control & Assurance: Sankha Bhattacharya, Housing Devolopment Limitedsankha07No ratings yet

- Kc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationDocument2 pagesKc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationMitendra Kumar ChauhanNo ratings yet

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFDocument53 pagesA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONNo ratings yet

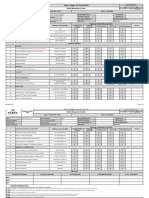

- 02 Civil & Structure - Rev - 01Document24 pages02 Civil & Structure - Rev - 01Yasir MehmoodNo ratings yet

- 044 ITP For Installation of Gypsum Board Buildings PDFDocument10 pages044 ITP For Installation of Gypsum Board Buildings PDFHarshvardhan PathakNo ratings yet

- Tullymurdoch Windfarm Concrete Pour Toolbox Talk PDFDocument18 pagesTullymurdoch Windfarm Concrete Pour Toolbox Talk PDFDragu SorinNo ratings yet

- Qa QC Duties and ResponsibilityDocument3 pagesQa QC Duties and ResponsibilityKannan MurugesanNo ratings yet

- Sample Test report-HDPEDocument1 pageSample Test report-HDPEKannan MurugesanNo ratings yet

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNo ratings yet

- 24-10-2020 Sample Quality Walk ThroughDocument3 pages24-10-2020 Sample Quality Walk ThroughKannan MurugesanNo ratings yet

- Masterflow Solutions BASF ProfileDocument8 pagesMasterflow Solutions BASF ProfileKannan MurugesanNo ratings yet

- Base Plate and Anchor Rod DesignDocument2 pagesBase Plate and Anchor Rod DesignKannan MurugesanNo ratings yet

- Chemical Store: 8" Dia Pipe OwsDocument1 pageChemical Store: 8" Dia Pipe OwsKannan MurugesanNo ratings yet

- Curing TrackerDocument1 pageCuring TrackerKannan MurugesanNo ratings yet

- Consumable Control Procedure-Slpg-S-000-0069-H22-001-001-4-0-Code-2Document27 pagesConsumable Control Procedure-Slpg-S-000-0069-H22-001-001-4-0-Code-2Kannan MurugesanNo ratings yet

- Survey Inspection Record: PEC-QU-ITR-X-11083 Rev 2Document1 pageSurvey Inspection Record: PEC-QU-ITR-X-11083 Rev 2Kannan MurugesanNo ratings yet

- Unit 680 Pipe Supports PS057, 062 BBSDocument6 pagesUnit 680 Pipe Supports PS057, 062 BBSKannan MurugesanNo ratings yet

- G.O (MS) No.221 7.5 Reservation - Amount Sanction G.ODocument10 pagesG.O (MS) No.221 7.5 Reservation - Amount Sanction G.OKannan MurugesanNo ratings yet

- Air Ticket Kochi MaleDocument1 pageAir Ticket Kochi MaleKannan MurugesanNo ratings yet

- Course Appraisal Form (1 Tutor)Document3 pagesCourse Appraisal Form (1 Tutor)Kannan MurugesanNo ratings yet

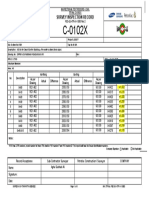

- Compressive Test Strength of ConcreteDocument1 pageCompressive Test Strength of ConcreteKannan MurugesanNo ratings yet

- Air India Web Booking ETicket (J3ZGV) - ThangarajuDocument2 pagesAir India Web Booking ETicket (J3ZGV) - ThangarajuKannan MurugesanNo ratings yet

- PP9 Biodiversity of PlantsDocument93 pagesPP9 Biodiversity of PlantsRorisang MotsamaiNo ratings yet

- Ideas For The Philosophy of The History of Mankind 1St Edition Johann Gottfried Herder Full ChapterDocument67 pagesIdeas For The Philosophy of The History of Mankind 1St Edition Johann Gottfried Herder Full Chaptersusan.long892100% (12)

- Physics (From: Physik (Epist Mē)Document1 pagePhysics (From: Physik (Epist Mē)annmarieNo ratings yet

- CV Rinaldi Setiawan Welder 2Document14 pagesCV Rinaldi Setiawan Welder 2myudi20182No ratings yet

- Comenzi LinuxDocument6 pagesComenzi LinuxDOMA TANIELNo ratings yet

- 2008olbrycht Alex OpisDocument23 pages2008olbrycht Alex OpisHamid Reza SorouriNo ratings yet

- Lecture 2A - (MMW) VariablesDocument4 pagesLecture 2A - (MMW) VariablesShannen DionioNo ratings yet

- Petitioner vs. vs. Respondents Primo O. Orellan Jose M. KimpoDocument5 pagesPetitioner vs. vs. Respondents Primo O. Orellan Jose M. Kimpogenel marquezNo ratings yet

- 30 IELTS Writing Band 8.0Document31 pages30 IELTS Writing Band 8.0Elize WillyNo ratings yet

- Discourse AnalysisDocument3 pagesDiscourse AnalysisPrashant KushwahNo ratings yet

- Window & Door System: Let'S Build A Better FutureDocument4 pagesWindow & Door System: Let'S Build A Better FutureAmir AlićNo ratings yet

- Top of FormDocument28 pagesTop of Formsybell8No ratings yet

- CumiDocument56 pagesCumiRahul NairNo ratings yet

- Fellowship Cover LetterDocument5 pagesFellowship Cover Letterxjfahwegf100% (1)

- EZ Pilot Pro RTF Instruction Manual-V2.1Document27 pagesEZ Pilot Pro RTF Instruction Manual-V2.1abuk5566No ratings yet

- Solutions ME Chapter 1Document7 pagesSolutions ME Chapter 1Puji Hikmah100% (3)

- Tony Robbins NotesDocument3 pagesTony Robbins Notesrationalgaze0% (2)

- Prep 1st Term 2021 PDFDocument8 pagesPrep 1st Term 2021 PDFWajid Jamil100% (4)

- Panaguiton, Jr. Vs DOJ - G.R. No. 167571 - Nov 25, 2008Document9 pagesPanaguiton, Jr. Vs DOJ - G.R. No. 167571 - Nov 25, 2008Boogie San JuanNo ratings yet

- Villanueva v. Sps. BranocoDocument14 pagesVillanueva v. Sps. Branocobrida athenaNo ratings yet

- Day 1 - 3D 4D 5D BIM For Supporting Industry 4 - 0 BIM - Wika Rev1Document69 pagesDay 1 - 3D 4D 5D BIM For Supporting Industry 4 - 0 BIM - Wika Rev1Ernie SitanggangNo ratings yet

- Slide Pentaksiran Holistik - Konsep Dan AmalanDocument15 pagesSlide Pentaksiran Holistik - Konsep Dan AmalanNURFARIESYAH NAJWA BINTI NURUL HISHAMNo ratings yet

- MS Access - Working With QueriesDocument69 pagesMS Access - Working With QueriesbogsbestNo ratings yet

- LED Lighting Design & Specifi Cation Guide: Considerations For Harsh and Hazardous Area ApplicationsDocument20 pagesLED Lighting Design & Specifi Cation Guide: Considerations For Harsh and Hazardous Area ApplicationsSarvesh AhluwaliaNo ratings yet

- Sop QubDocument2 pagesSop QubAMRUD GAMINGNo ratings yet

- Chevron Corrective Action OrderDocument8 pagesChevron Corrective Action OrderThe Salt Lake TribuneNo ratings yet

- Mini CNC Machine Arduino Based Adafruit Driver MotDocument9 pagesMini CNC Machine Arduino Based Adafruit Driver Motrafael rosalesNo ratings yet

Quality Induction Training-No 1

Quality Induction Training-No 1

Uploaded by

Kannan MurugesanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Induction Training-No 1

Quality Induction Training-No 1

Uploaded by

Kannan MurugesanCopyright:

Available Formats

TARGET LLC

WELCOME

QUALITY INDUCTION

COMMITTED TO BUILD OMAN’S TOMORROW 1

Project Details

Name of the Project:EPC Works for Permanent Staff Accommodation at Nimr.

Client :Oman Gas Company.

Consultant :NEO.

MEP Sub-Contractor: Al Rafa

COMMITTED TO BUILD OMAN’S TOMORROW 2

OGC Specification Details

1.SP 1279-Specification for Civil and Building Construction.

2.SP 1282-Specificaion for Reinforced Concrete.

3.SP 1274-Specification for Civil Engineering materials.

4.SP 1275-Specification for design of Civil &Building works.

COMMITTED TO BUILD OMAN’S TOMORROW 3

Basic requirements in Reinforcement

Grade of Steel :High yield strength-500 n/mm2.

Importance of concrete cover

Concrete cover for reinforcement is required

to protect the rebar against corrosion and to

provide resistance against fire. The thickness

of coverdepends on environmental

conditions and type of structural member.

COMMITTED TO BUILD OMAN’S TOMORROW 4

Required Cover For Various Elements

COMMITTED TO BUILD OMAN’S TOMORROW 5

Minimum Lap/Splice length =50 d means 50 x diameter of bar.

1.Butterfly tie should provide.

2.Binding wire:16Gauge black annealed wire.

3.Avoid binding wire knots in cover zone area.

4.Rebar Cleaning.

5.No kink/joggling without permission.

COMMITTED TO BUILD OMAN’S TOMORROW 6

Reinforcement Works Do’s &don’t’s

Avoid gas cutting &

welding of

reinforcement

Do not stack

reinforcement

steel on the bare

ground

COMMITTED TO BUILD OMAN’S TOMORROW 7

Excavation & Back filling works

Prior to Excavation check for Approved drawing for Survey Coordinates.

Back filling shall be of Type-B Material of PDO Standard.

All back fill materials Borrow pits has to be witnessed by OGC Site team

before using at site.

Backfilling has to be carried out in layers of 150mm thick.

COMMITTED TO BUILD OMAN’S TOMORROW 8

FORM WORK

Approved Formwork system to be used.

COMMITTED TO BUILD OMAN’S TOMORROW 9

Formwork

1. Formwork for concrete shall be rigidly constructed with an approved

material and shall be true to both shape and dimensions specified.

2. Joints shall be sufficiently tight to prevent leakage of cement grout and to

avoid formation of fins or other blemishes.

3. 25 mm chamfers shall be formed on all external exposed

corners of concrete members.

4. Formwork shall be cleared out of all dust, wood shavings, dirt and other

extraneous material near blowing-out with compressed air before any

concrete is placed.

5. Mould oil approved by the Company shall be applied to faces of formwork

to prevent adherence of concrete.

COMMITTED TO BUILD OMAN’S TOMORROW 10

Do’s:

As per Scheme / form work drawings.

Clean the formwork & ply surfaces before being used.

Remove the concrete laitance if any from the shutter surface

Apply form release oil on shutters adequately using sponge rollers or

sprayer.

Check for plumb, level and alignment of formwork.

Ensure tightness of tie rods, supports, bracings etc.

Thoroughly remove all ply pieces, saw dust and other wastes.

Plug all openings and gaps using adhesive tape or by plywood piece.

COMMITTED TO BUILD OMAN’S TOMORROW 11

Don’ts

Do not deviate from scheme drawings .

Do not Use damage or warped shutters.

Do not rest supports on loose earth and or over the temporary

supports

Do not apply excess oil on plywood surface

Do not use hessian cloths, gunny bags or empty cement bags to

plug openings and gaps.

Do not cut wood / plywood on form works.

COMMITTED TO BUILD OMAN’S TOMORROW 12

CONCRETE

COMMITTED TO BUILD OMAN’S TOMORROW 13

CONCRETE VIBRATION

Proper Needle Should be used for vibration.

60mm needle to be used for concrete and 40mm

used only for section having less than 250mm.

Concrete should be placed in layers not more than

300mm.

Vibrators shall be inserted vertically and the

spacing shall be 450mm for 60mm needle and

300mm for 40mm needle.

Vibrator shall not kept more than 10-15seconds in

a place.

While second layer vibration half of the previous

layer thickness vibrator to be inserted.

COMMITTED TO BUILD OMAN’S TOMORROW 14

COMMITTED TO BUILD OMAN’S TOMORROW 15

CONCRETE CURING

All freshly deposited concrete shall be protected

from premature drying and rapid temperature

change by the use of hessian cloth or protective

membrane for minimum 7 days.Casting dates

are mentioned to ensure.

During the curing period, and thereafter as

conditions may require, concrete shall be

protected from mechanical damage,

disturbance,

For the sides of columns, beams and walls, on

removal of formwork, the concrete shall

beclosely wrapped with wet Hessian and

enclosed with pigmented polythene sheeting.

COMMITTED TO BUILD OMAN’S TOMORROW 16

BLOCK WORK

Do’s and Don’ts

COMMITTED TO BUILD OMAN’S TOMORROW 17

COMMITTED TO BUILD OMAN’S TOMORROW 18

Lessons learned are the documented information that reflects both the positive

and negative experiences of a project. They represent the organization's commitment

to project management excellence and the project manager's opportunity to learn

from the actual experiences of others. And the mistakes and errors can be avoided in the

future projects.

COMMITTED TO BUILD OMAN’S TOMORROW 19

COMMITTED TO BUILD OMAN’S TOMORROW 20

COMMITTED TO BUILD OMAN’S TOMORROW 21

Remember !

Quality is in our hands

THANK YOU

COMMITTED TO BUILD OMAN’S TOMORROW 22

You might also like

- 5CO01 - Assessment BriefDocument10 pages5CO01 - Assessment BriefEmmanuel KingsNo ratings yet

- Routine Lift Plan For All Crane-Grove GMK 50 TonDocument1 pageRoutine Lift Plan For All Crane-Grove GMK 50 TonKannan Murugesan100% (1)

- VanGogh EbookDocument288 pagesVanGogh EbookDragan Cvetkovic88% (8)

- Quality Management Review Agenda and MinutesDocument4 pagesQuality Management Review Agenda and MinutesKannan MurugesanNo ratings yet

- Quality Walk Report FormatDocument14 pagesQuality Walk Report FormatAmar KolachinaNo ratings yet

- Inspection & Test Plan (Itp) : False FlooringDocument1 pageInspection & Test Plan (Itp) : False FlooringLOPA THANDARNo ratings yet

- U07754QOSM - Project O & M Manual TemplateDocument12 pagesU07754QOSM - Project O & M Manual TemplateRithesh ShettyNo ratings yet

- Trimble Precision IQ GFX 750 OptimizedDocument319 pagesTrimble Precision IQ GFX 750 OptimizedireneuszNo ratings yet

- Quality InductionDocument15 pagesQuality InductionaleemmurtazaNo ratings yet

- ITP Check List For Metal Deck InstallationDocument2 pagesITP Check List For Metal Deck InstallationJoyce Gordonio0% (1)

- Inspection and Test Plan: Contract NoDocument2 pagesInspection and Test Plan: Contract NoAhmed Samir SalimNo ratings yet

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilJagdishNo ratings yet

- Plaster Check ListDocument1 pagePlaster Check Listsankuj5354No ratings yet

- ITP C 005 (Structural Concrete)Document4 pagesITP C 005 (Structural Concrete)segun ajibolaNo ratings yet

- Itp For Installation of FormworksDocument1 pageItp For Installation of FormworksImho TepNo ratings yet

- SBS Waterproofing ITP & ChecklistDocument27 pagesSBS Waterproofing ITP & Checklistlike saddamNo ratings yet

- Itp - EifsDocument22 pagesItp - Eifssathiyaprasath100% (1)

- SAIC-A-1006 - Final Fill InspectionDocument1 pageSAIC-A-1006 - Final Fill InspectionwalidNo ratings yet

- Gf-Ohtl2-Q-Pl-2001 - 0 Inspection Test Plan For Civil and Structural Steel Code A PDFDocument33 pagesGf-Ohtl2-Q-Pl-2001 - 0 Inspection Test Plan For Civil and Structural Steel Code A PDFAhmed Mohsin100% (1)

- Lesson 10 Project Quality PlanningDocument51 pagesLesson 10 Project Quality PlanningDevjit MandalNo ratings yet

- Presentation On QA QC Faisal Ali ShaikhDocument14 pagesPresentation On QA QC Faisal Ali ShaikhFaisal Ali ShaikhNo ratings yet

- Quality TrainingDocument16 pagesQuality Trainingyushma ghimireNo ratings yet

- QES PEVC-ENG237 - Checklist For PSS Fencing DetailsDocument2 pagesQES PEVC-ENG237 - Checklist For PSS Fencing DetailsRupesh Khandekar100% (1)

- Inspection and Test Plan - Wooden Wall Panel InstallationDocument2 pagesInspection and Test Plan - Wooden Wall Panel Installationexia1992No ratings yet

- Method Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01Document9 pagesMethod Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01hammad21100% (1)

- Quality Plan AuditDocument5 pagesQuality Plan AuditRajan100% (1)

- VECO-QM-PRO-0001 Project Quality Audit Procedure, Rev. 0Document10 pagesVECO-QM-PRO-0001 Project Quality Audit Procedure, Rev. 0hymerchmidtNo ratings yet

- Method Statement of Mass Concrete Block Precast WorksDocument41 pagesMethod Statement of Mass Concrete Block Precast WorksShams JogNo ratings yet

- Quality System Process Map: Customer RequirementsDocument1 pageQuality System Process Map: Customer RequirementsDaniel PradityaNo ratings yet

- Reference Document. Inspection / Testing Frequency Testing Requirement/ Surveillance Points Disc Oneic AawDocument3 pagesReference Document. Inspection / Testing Frequency Testing Requirement/ Surveillance Points Disc Oneic AawPresanna Rajasekaran100% (2)

- Acmc-Qaqc-001 - Quality Observation Report Form - QorDocument12 pagesAcmc-Qaqc-001 - Quality Observation Report Form - QorerwinNo ratings yet

- 5.Ms-Internal Plaster WorkDocument8 pages5.Ms-Internal Plaster WorkShenbagaraja PandianNo ratings yet

- Quality Requirements of ContractorsDocument15 pagesQuality Requirements of ContractorsRoshin99No ratings yet

- QCS 2010 AmmendmentsDocument6 pagesQCS 2010 AmmendmentsPuneeth DevadigaNo ratings yet

- ITP Fencing Rev - 00 PDFDocument3 pagesITP Fencing Rev - 00 PDFanon_987276020No ratings yet

- SLPG Q 0000 24001 019 001 4 0Document15 pagesSLPG Q 0000 24001 019 001 4 0sivagnanamNo ratings yet

- Project Quality Plan-SF5TA20-UT LSTKDocument25 pagesProject Quality Plan-SF5TA20-UT LSTKReehan Aslam100% (1)

- Inspection Test Plan For ISBL 1Document59 pagesInspection Test Plan For ISBL 1Sharat SahaNo ratings yet

- Saudi Oger Ltd. (Project Name) : PlasteringDocument1 pageSaudi Oger Ltd. (Project Name) : PlasteringAnthony AngelesNo ratings yet

- Quality Control - Works Inspection: Acoustic Board PanellingDocument1 pageQuality Control - Works Inspection: Acoustic Board PanellingParasNo ratings yet

- ER288-Rebar Test PlanDocument4 pagesER288-Rebar Test PlanalfieNo ratings yet

- Quality Plan 2 PDF FreeDocument21 pagesQuality Plan 2 PDF FreeEng.arifNo ratings yet

- Itp BuildingDocument42 pagesItp BuildingHaekal RamadhanNo ratings yet

- PQP EpldtDocument8 pagesPQP Epldtmartin leeNo ratings yet

- Presentation - QUALITY (SCHEDULE 'Q' REQUIREMENTS)Document55 pagesPresentation - QUALITY (SCHEDULE 'Q' REQUIREMENTS)kbldamNo ratings yet

- CS P12 Drawing Control ProcedureDocument4 pagesCS P12 Drawing Control Procedurerichard nagilusNo ratings yet

- EGA2 Lessons Learned QualityDocument4 pagesEGA2 Lessons Learned QualityfaizanAkhtar100% (3)

- Fencing Checklist Rev 1Document2 pagesFencing Checklist Rev 1Candice KallooNo ratings yet

- Contractor Monthly) : Quality Report (CMQRDocument11 pagesContractor Monthly) : Quality Report (CMQRKarthik KumarNo ratings yet

- Emulsion Paint ChecklistDocument2 pagesEmulsion Paint Checklistmesmerize59No ratings yet

- PQP Flow ChartDocument1 pagePQP Flow ChartFIRMANSYAHNo ratings yet

- Flowchart QC-QCDocument13 pagesFlowchart QC-QCDevid Peri Sonefel100% (1)

- WMS Concrete Repair WorkDocument8 pagesWMS Concrete Repair WorkRepl microsoft, PuneNo ratings yet

- Itp For Gravel Surfacing and Dust PreventionDocument7 pagesItp For Gravel Surfacing and Dust PreventionShewale PravinNo ratings yet

- Civils - Trenching - ExcavationsDocument2 pagesCivils - Trenching - Excavationsmitendra singhNo ratings yet

- AAA-Project Quality Plan (Rev.0-2015)Document8 pagesAAA-Project Quality Plan (Rev.0-2015)Behroze ShabirNo ratings yet

- Appendix E: Checklist For Kerbstone Works Location / Identification: Drawing No.: No. Description Yes No N/ADocument2 pagesAppendix E: Checklist For Kerbstone Works Location / Identification: Drawing No.: No. Description Yes No N/AJericFuentesNo ratings yet

- 1.SRO-QPITP - Mechanical WorksDocument2 pages1.SRO-QPITP - Mechanical Worksachusanachu100% (1)

- Civil Quality Control Plan EarthworksDocument3 pagesCivil Quality Control Plan Earthworksroekyat hendrawanNo ratings yet

- Programme On Quality Control & Assurance: Sankha Bhattacharya, Housing Devolopment LimitedDocument25 pagesProgramme On Quality Control & Assurance: Sankha Bhattacharya, Housing Devolopment Limitedsankha07No ratings yet

- Kc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationDocument2 pagesKc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationMitendra Kumar ChauhanNo ratings yet

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFDocument53 pagesA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONNo ratings yet

- 02 Civil & Structure - Rev - 01Document24 pages02 Civil & Structure - Rev - 01Yasir MehmoodNo ratings yet

- 044 ITP For Installation of Gypsum Board Buildings PDFDocument10 pages044 ITP For Installation of Gypsum Board Buildings PDFHarshvardhan PathakNo ratings yet

- Tullymurdoch Windfarm Concrete Pour Toolbox Talk PDFDocument18 pagesTullymurdoch Windfarm Concrete Pour Toolbox Talk PDFDragu SorinNo ratings yet

- Qa QC Duties and ResponsibilityDocument3 pagesQa QC Duties and ResponsibilityKannan MurugesanNo ratings yet

- Sample Test report-HDPEDocument1 pageSample Test report-HDPEKannan MurugesanNo ratings yet

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNo ratings yet

- 24-10-2020 Sample Quality Walk ThroughDocument3 pages24-10-2020 Sample Quality Walk ThroughKannan MurugesanNo ratings yet

- Masterflow Solutions BASF ProfileDocument8 pagesMasterflow Solutions BASF ProfileKannan MurugesanNo ratings yet

- Base Plate and Anchor Rod DesignDocument2 pagesBase Plate and Anchor Rod DesignKannan MurugesanNo ratings yet

- Chemical Store: 8" Dia Pipe OwsDocument1 pageChemical Store: 8" Dia Pipe OwsKannan MurugesanNo ratings yet

- Curing TrackerDocument1 pageCuring TrackerKannan MurugesanNo ratings yet

- Consumable Control Procedure-Slpg-S-000-0069-H22-001-001-4-0-Code-2Document27 pagesConsumable Control Procedure-Slpg-S-000-0069-H22-001-001-4-0-Code-2Kannan MurugesanNo ratings yet

- Survey Inspection Record: PEC-QU-ITR-X-11083 Rev 2Document1 pageSurvey Inspection Record: PEC-QU-ITR-X-11083 Rev 2Kannan MurugesanNo ratings yet

- Unit 680 Pipe Supports PS057, 062 BBSDocument6 pagesUnit 680 Pipe Supports PS057, 062 BBSKannan MurugesanNo ratings yet

- G.O (MS) No.221 7.5 Reservation - Amount Sanction G.ODocument10 pagesG.O (MS) No.221 7.5 Reservation - Amount Sanction G.OKannan MurugesanNo ratings yet

- Air Ticket Kochi MaleDocument1 pageAir Ticket Kochi MaleKannan MurugesanNo ratings yet

- Course Appraisal Form (1 Tutor)Document3 pagesCourse Appraisal Form (1 Tutor)Kannan MurugesanNo ratings yet

- Compressive Test Strength of ConcreteDocument1 pageCompressive Test Strength of ConcreteKannan MurugesanNo ratings yet

- Air India Web Booking ETicket (J3ZGV) - ThangarajuDocument2 pagesAir India Web Booking ETicket (J3ZGV) - ThangarajuKannan MurugesanNo ratings yet

- PP9 Biodiversity of PlantsDocument93 pagesPP9 Biodiversity of PlantsRorisang MotsamaiNo ratings yet

- Ideas For The Philosophy of The History of Mankind 1St Edition Johann Gottfried Herder Full ChapterDocument67 pagesIdeas For The Philosophy of The History of Mankind 1St Edition Johann Gottfried Herder Full Chaptersusan.long892100% (12)

- Physics (From: Physik (Epist Mē)Document1 pagePhysics (From: Physik (Epist Mē)annmarieNo ratings yet

- CV Rinaldi Setiawan Welder 2Document14 pagesCV Rinaldi Setiawan Welder 2myudi20182No ratings yet

- Comenzi LinuxDocument6 pagesComenzi LinuxDOMA TANIELNo ratings yet

- 2008olbrycht Alex OpisDocument23 pages2008olbrycht Alex OpisHamid Reza SorouriNo ratings yet

- Lecture 2A - (MMW) VariablesDocument4 pagesLecture 2A - (MMW) VariablesShannen DionioNo ratings yet

- Petitioner vs. vs. Respondents Primo O. Orellan Jose M. KimpoDocument5 pagesPetitioner vs. vs. Respondents Primo O. Orellan Jose M. Kimpogenel marquezNo ratings yet

- 30 IELTS Writing Band 8.0Document31 pages30 IELTS Writing Band 8.0Elize WillyNo ratings yet

- Discourse AnalysisDocument3 pagesDiscourse AnalysisPrashant KushwahNo ratings yet

- Window & Door System: Let'S Build A Better FutureDocument4 pagesWindow & Door System: Let'S Build A Better FutureAmir AlićNo ratings yet

- Top of FormDocument28 pagesTop of Formsybell8No ratings yet

- CumiDocument56 pagesCumiRahul NairNo ratings yet

- Fellowship Cover LetterDocument5 pagesFellowship Cover Letterxjfahwegf100% (1)

- EZ Pilot Pro RTF Instruction Manual-V2.1Document27 pagesEZ Pilot Pro RTF Instruction Manual-V2.1abuk5566No ratings yet

- Solutions ME Chapter 1Document7 pagesSolutions ME Chapter 1Puji Hikmah100% (3)

- Tony Robbins NotesDocument3 pagesTony Robbins Notesrationalgaze0% (2)

- Prep 1st Term 2021 PDFDocument8 pagesPrep 1st Term 2021 PDFWajid Jamil100% (4)

- Panaguiton, Jr. Vs DOJ - G.R. No. 167571 - Nov 25, 2008Document9 pagesPanaguiton, Jr. Vs DOJ - G.R. No. 167571 - Nov 25, 2008Boogie San JuanNo ratings yet

- Villanueva v. Sps. BranocoDocument14 pagesVillanueva v. Sps. Branocobrida athenaNo ratings yet

- Day 1 - 3D 4D 5D BIM For Supporting Industry 4 - 0 BIM - Wika Rev1Document69 pagesDay 1 - 3D 4D 5D BIM For Supporting Industry 4 - 0 BIM - Wika Rev1Ernie SitanggangNo ratings yet

- Slide Pentaksiran Holistik - Konsep Dan AmalanDocument15 pagesSlide Pentaksiran Holistik - Konsep Dan AmalanNURFARIESYAH NAJWA BINTI NURUL HISHAMNo ratings yet

- MS Access - Working With QueriesDocument69 pagesMS Access - Working With QueriesbogsbestNo ratings yet

- LED Lighting Design & Specifi Cation Guide: Considerations For Harsh and Hazardous Area ApplicationsDocument20 pagesLED Lighting Design & Specifi Cation Guide: Considerations For Harsh and Hazardous Area ApplicationsSarvesh AhluwaliaNo ratings yet

- Sop QubDocument2 pagesSop QubAMRUD GAMINGNo ratings yet

- Chevron Corrective Action OrderDocument8 pagesChevron Corrective Action OrderThe Salt Lake TribuneNo ratings yet

- Mini CNC Machine Arduino Based Adafruit Driver MotDocument9 pagesMini CNC Machine Arduino Based Adafruit Driver Motrafael rosalesNo ratings yet