Professional Documents

Culture Documents

Machine Tools (IPE 431) : Chip Formation

Machine Tools (IPE 431) : Chip Formation

Uploaded by

Farhan Haidary0 ratings0% found this document useful (0 votes)

23 views10 pagesThis document discusses the four main categories of chips formed during machining:

1) Discontinuous chips formed from brittle materials through fracturing.

2) Continuous or ribbon chips formed through continuous plastic deformation without fracturing ahead of the tool.

3) Continuous chips with a built-up edge (BUE) that protects the tool but causes poor surface finish.

4) Serrated chips with a saw-tooth appearance formed during high-speed machining of difficult materials like titanium alloys.

Original Description:

Original Title

Chip formation.pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses the four main categories of chips formed during machining:

1) Discontinuous chips formed from brittle materials through fracturing.

2) Continuous or ribbon chips formed through continuous plastic deformation without fracturing ahead of the tool.

3) Continuous chips with a built-up edge (BUE) that protects the tool but causes poor surface finish.

4) Serrated chips with a saw-tooth appearance formed during high-speed machining of difficult materials like titanium alloys.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

23 views10 pagesMachine Tools (IPE 431) : Chip Formation

Machine Tools (IPE 431) : Chip Formation

Uploaded by

Farhan HaidaryThis document discusses the four main categories of chips formed during machining:

1) Discontinuous chips formed from brittle materials through fracturing.

2) Continuous or ribbon chips formed through continuous plastic deformation without fracturing ahead of the tool.

3) Continuous chips with a built-up edge (BUE) that protects the tool but causes poor surface finish.

4) Serrated chips with a saw-tooth appearance formed during high-speed machining of difficult materials like titanium alloys.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 10

Machine Tools (IPE 431)

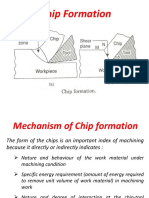

Chip formation

Farhan Mashuk Haidary

Lecturer (Adjunct Faculty)

Sonargaon Univeristy

Four main categories of chips

• 1) Discontinuous chips: These chips are small segments,

which adhere loosely to each other. They are formed

when the amount of deformation to which chips undergo

is limited by repeated fracturing. Hard and brittle

materials like bronze, brass and cast iron will produce

such chips.

• 2) Continuous or ribbon chips: In continuous chip formation, the

pressure of the work piece builds until the material fails by slip along

the plane. The inside on the chip displays steps produced by the

intermittent slip, but the outside is very smooth. It has its elements

bonded together in the form of long coils and is formed by the

continuous plastic deformation of material without fracture ahead of

the cutting edge of the tool and is followed by the smooth flow of

chip up the tool face.

• Conditions for continuous chips:

- Sharp cutting edges

- Low feed rate

- Large rake angle

- Ductile material

- High cutting speed

- Low friction at chip-tool interface

• 3) Continuous chips with Built-Up Edge (BUE): These types

of chips are very similar to that of continuous type, with the

difference that it is not as smooth as the previous one. This

type of chip is associated with poor surface finish, but protects

the cutting edge from wear due to movement of chips and the

action of heat causing the increase in tool life.

• Conditions for the formation of BUE are:

(i) machining of ductile materials

(ii) machining at relatively lower cutting speeds

(iii) work material having more than one phase

** Not observed when cutting pure metals

• 4) Serrated chips: These chips are semi-continuous in the

sense that they possess a saw-tooth appearance that is

produced by a cyclical chip formation of altering high shear

strain followed by low shear strain. This chip is most closely

associated with certain difficult-to-machine metals such as

titanium alloys, nickel-based super-alloys and aesthetic

stainless steels when they are machined at higher cutting

speeds. However, the phenomenon is also found with more

common work metals (e. g. steel), when they are cut at high

speeds

Assignment

You might also like

- Machine Tools and Digital Manufacturing (MTDM) : Machining ProcessDocument90 pagesMachine Tools and Digital Manufacturing (MTDM) : Machining ProcessLibin AbrahamNo ratings yet

- Machine Tools (IPE 431) : Chip FormationDocument10 pagesMachine Tools (IPE 431) : Chip FormationFarhan HaidaryNo ratings yet

- Types of Chips in Metal CuttingDocument5 pagesTypes of Chips in Metal CuttingMUKIIBI GERALDNo ratings yet

- Metal Cutting ProcessDocument26 pagesMetal Cutting Processমুকসেতিন আল রাজী রিফাতNo ratings yet

- 1f01bmctd Lab Manual Exp 8 - 2Document3 pages1f01bmctd Lab Manual Exp 8 - 2roses4happinessNo ratings yet

- Chips TypeDocument4 pagesChips TypeWajahat RasoolNo ratings yet

- CAT II - EMMU 7241 - Machine Tool Vibrations and Cutting Dynamics-Marking SchemeDocument14 pagesCAT II - EMMU 7241 - Machine Tool Vibrations and Cutting Dynamics-Marking SchemeCharles OndiekiNo ratings yet

- Theory of Metal CuttingDocument29 pagesTheory of Metal Cuttingvishnu anandNo ratings yet

- Assignment No - IDocument3 pagesAssignment No - Ivikas.thoratNo ratings yet

- Chipsformation 180405105837Document12 pagesChipsformation 180405105837xegeraj500No ratings yet

- Chip FromationDocument12 pagesChip FromationParag ParekhNo ratings yet

- TornoDocument201 pagesTornoLaura ROMERO TRUJILLONo ratings yet

- Chip Formation: Four Basic Type of Chips in Machining AreDocument14 pagesChip Formation: Four Basic Type of Chips in Machining ArejssrikantamurthyNo ratings yet

- Production Engineering Lecture 2Document16 pagesProduction Engineering Lecture 2AINAMANI AMOSNo ratings yet

- CF AsDocument12 pagesCF AsarulsivagiriNo ratings yet

- Chip FormationDocument27 pagesChip FormationJasvinder SinghNo ratings yet

- ME 6402 Manufacturing Technology II Unit - IDocument14 pagesME 6402 Manufacturing Technology II Unit - Iananda narayananNo ratings yet

- Lecture1 and 2Document23 pagesLecture1 and 2Sohan KumarNo ratings yet

- 3023 Machine Tools Notes Module 1Document22 pages3023 Machine Tools Notes Module 1Aswin SNo ratings yet

- L9 - Types of ChipsDocument36 pagesL9 - Types of Chipsudyadav3490No ratings yet

- L11 - Types of ChipsDocument36 pagesL11 - Types of ChipsAditya AdityaNo ratings yet

- 5 - Pembentukan GeramDocument21 pages5 - Pembentukan GeramHizkia OswariNo ratings yet

- MP6 Types of ChipsDocument35 pagesMP6 Types of ChipsLuv VermaniNo ratings yet

- Unit I ': Theory of Metal CuttingDocument14 pagesUnit I ': Theory of Metal CuttingramtwinsmeNo ratings yet

- Unit-I Theory of Metal CuttingDocument73 pagesUnit-I Theory of Metal CuttingSarvesh Kumarasamy100% (1)

- Unit 1 Me1203Document17 pagesUnit 1 Me1203Muthuvel M100% (1)

- Chip Formation and Tool LifeDocument37 pagesChip Formation and Tool LifeSquakx BescilNo ratings yet

- Unit I 4 Types of ChipsDocument6 pagesUnit I 4 Types of ChipsvelladuraiNo ratings yet

- Machining by CuttingDocument4 pagesMachining by CuttingSiddhi JainNo ratings yet

- 11th Machining IDocument23 pages11th Machining ISYED MUNEEBNo ratings yet

- Metal Swarf: Definition of ChippsDocument10 pagesMetal Swarf: Definition of ChippsabenezerNo ratings yet

- Chip Formation: Manufacturing Technology-IiDocument20 pagesChip Formation: Manufacturing Technology-IiSachin BharadwajNo ratings yet

- CHIPSDocument3 pagesCHIPSEmbati PhilliamNo ratings yet

- Chip Formation: IntroductionDocument5 pagesChip Formation: IntroductionDr.S.Ravi CITNo ratings yet

- Unit I ' Theory of Metal CuttingDocument19 pagesUnit I ' Theory of Metal CuttingThulasi RamNo ratings yet

- Theory of Metal CuttingDocument170 pagesTheory of Metal CuttingPreet DamaniNo ratings yet

- 3 Types of ChipsDocument35 pages3 Types of ChipsDhananjay SharmaNo ratings yet

- Chip Formation and Tool LifeDocument37 pagesChip Formation and Tool Lifeneelesh singh100% (10)

- 4 Types of Chips-1Document35 pages4 Types of Chips-1Kishan KashyapNo ratings yet

- Tipe ChipDocument3 pagesTipe ChipHary RespatiNo ratings yet

- 2 Metal CuttingDocument89 pages2 Metal CuttingYashraj patilNo ratings yet

- Model Answers On Some QuestionsDocument18 pagesModel Answers On Some QuestionsCharles OndiekiNo ratings yet

- Chapter 1Document38 pagesChapter 1Abhishek GramopadhyeNo ratings yet

- Chapter 4 Metal Removal ProcessesDocument66 pagesChapter 4 Metal Removal Processesdagimawgchew777No ratings yet

- 1 - Chapter 6 - 1 - 1 Material Removal Process - Introduction 21-1Document34 pages1 - Chapter 6 - 1 - 1 Material Removal Process - Introduction 21-1Fatin JoharNo ratings yet

- Types of Chips Waqas MTMDocument2 pagesTypes of Chips Waqas MTMirfan aminNo ratings yet

- Types of Chips Waqas MTMDocument2 pagesTypes of Chips Waqas MTMirfan aminNo ratings yet

- Sheet Production TechnologyDocument23 pagesSheet Production TechnologyOmar AlyNo ratings yet

- 2 Reading Matl CH - 6 Sheet Metal Parts MFG ProcessDocument62 pages2 Reading Matl CH - 6 Sheet Metal Parts MFG ProcessCaldwellNo ratings yet

- Theory of Metal Cutting PDFDocument47 pagesTheory of Metal Cutting PDFEmmanuel KutaniNo ratings yet

- Effect of Metal Cutting Parameters On Chip Reduction Co-EfficientDocument7 pagesEffect of Metal Cutting Parameters On Chip Reduction Co-EfficientDebarshibiswasNo ratings yet

- Conformado de Planchas 2Document44 pagesConformado de Planchas 2smartcad60No ratings yet

- Manufacturing Process - PresentationDocument15 pagesManufacturing Process - PresentationAnwesha PandaNo ratings yet

- Mechanism of Chip Formation Chip ModelingDocument26 pagesMechanism of Chip Formation Chip ModelingMukesh Muraleedharan NairNo ratings yet

- Me1008 Unit 3 Theory of Metal CuttingDocument39 pagesMe1008 Unit 3 Theory of Metal CuttingPruthviraj rathodNo ratings yet

- Theory of Metal CuttingDocument162 pagesTheory of Metal CuttingShrikrushna MaliNo ratings yet

- 1) - Introduction:: Metal Forming ProcessesDocument10 pages1) - Introduction:: Metal Forming Processesphysics a2No ratings yet

- Q. What Is Metal Cutting?Document12 pagesQ. What Is Metal Cutting?ThenarasumohanveluNo ratings yet

- An Introduction to Metal-Working (Illustrated)From EverandAn Introduction to Metal-Working (Illustrated)Rating: 2.5 out of 5 stars2.5/5 (2)

- Automation and FMSDocument12 pagesAutomation and FMSFarhan HaidaryNo ratings yet

- Machine Tools (IPE 431) : Jigs & FixturesDocument10 pagesMachine Tools (IPE 431) : Jigs & FixturesFarhan HaidaryNo ratings yet

- Machine Tools (IPE 431) : Grinding OperationsDocument17 pagesMachine Tools (IPE 431) : Grinding OperationsFarhan HaidaryNo ratings yet

- Machine Tools (IPE 431) : CNC MachinesDocument19 pagesMachine Tools (IPE 431) : CNC MachinesFarhan HaidaryNo ratings yet

- Machine Tools (IPE 431) : Chip FormationDocument10 pagesMachine Tools (IPE 431) : Chip FormationFarhan HaidaryNo ratings yet

- Machine Tools (IPE 431) : Automation and FMSDocument12 pagesMachine Tools (IPE 431) : Automation and FMSFarhan HaidaryNo ratings yet

- PUMP PP PDFDocument44 pagesPUMP PP PDFFarhan HaidaryNo ratings yet