Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

47 viewsInitial Problem Perception

Initial Problem Perception

Uploaded by

ardinaawlThe document discusses issues with stock distribution and output cutting. It notes that stock distribution is over 5 days and output cutting is not always aligned with sewing needs. It also notes that distribution requests often pull forward the cutting plan date to fulfill sewing requirements. This leads to high work-in-process and stock at distribution. The real problem is that changes to the production plan every two weeks with each new PPCM release are causing inconsistency and an unsmooth process between cutting and distribution, resulting in high stock levels. The point of cause is determined to be the inconsistent PPCM releases.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- APLUS 121 User GuideDocument928 pagesAPLUS 121 User GuideJuan Pablo AriasNo ratings yet

- LSS - Case Study - 1 - Improving Call Center Operations v1.0Document7 pagesLSS - Case Study - 1 - Improving Call Center Operations v1.0Calvin VernonNo ratings yet

- JJJDocument9 pagesJJJKaantDenisNo ratings yet

- Handbook On Unani Medicines With Formulae, Processes, Uses and AnalysisDocument5 pagesHandbook On Unani Medicines With Formulae, Processes, Uses and Analysismy_khan20027195100% (3)

- Exercise Visualization Using ChartsDocument17 pagesExercise Visualization Using ChartsGOURAV SHRIVASTAVA Student, Jaipuria IndoreNo ratings yet

- New PPT DeckDocument5 pagesNew PPT Deckrahul kumarNo ratings yet

- Case DataDocument13 pagesCase DataKajal singhNo ratings yet

- Edi RecoveryDocument8 pagesEdi RecoveryEstmarg EstmargNo ratings yet

- Recording Ayam BroilerDocument7 pagesRecording Ayam BroilerlaataiasNo ratings yet

- PG FoilsDocument63 pagesPG FoilsvidyaNo ratings yet

- Projections World Trail-FinalDocument26 pagesProjections World Trail-FinalUppada SareesNo ratings yet

- Megacard CorporationDocument6 pagesMegacard CorporationJanit SethiNo ratings yet

- Experiment No. 4, Group 6Document12 pagesExperiment No. 4, Group 6Aman NagraleNo ratings yet

- Solar Savings CorrectDocument22 pagesSolar Savings CorrectRudraksh ShivhareNo ratings yet

- Draf Nota DinasDocument3 pagesDraf Nota Dinasagus susantoNo ratings yet

- Presentation ReportsDocument8 pagesPresentation ReportsNorhan AmmarNo ratings yet

- Excel Perhitungan Tugas Besar SCM - Kelompok-7 - TI4207Document49 pagesExcel Perhitungan Tugas Besar SCM - Kelompok-7 - TI4207FADILLA ZARA LARASHATINo ratings yet

- Blue BookDocument241 pagesBlue Bookeng_muhammad88No ratings yet

- En Un Banco O en Tu Casa Tendras El Mismo Capital O Menos en Un AñoDocument2 pagesEn Un Banco O en Tu Casa Tendras El Mismo Capital O Menos en Un AñoJose CarloNo ratings yet

- Consumo Vapor AASA 2019Document12 pagesConsumo Vapor AASA 2019ingearroyoNo ratings yet

- Ipm Assignment 01 (Fa18-Baf-084)Document5 pagesIpm Assignment 01 (Fa18-Baf-084)Yasir AhmadNo ratings yet

- 1 Mock Test Giảng PracticeDocument229 pages1 Mock Test Giảng PracticeHoài LinhNo ratings yet

- Datos F'C Fy Factor de Reducción (Ø) : 250 kg/cm2 4200 kg/cm2 0.9 2388000 KG-CMDocument50 pagesDatos F'C Fy Factor de Reducción (Ø) : 250 kg/cm2 4200 kg/cm2 0.9 2388000 KG-CMRobsonOrtizNo ratings yet

- Laporan Pengukuran Topografi Dan Bathimetri PT - Tei Lokasi Pulau Rimau - Banyuasin ExelDocument21 pagesLaporan Pengukuran Topografi Dan Bathimetri PT - Tei Lokasi Pulau Rimau - Banyuasin ExelTatanyaAndiRaditNo ratings yet

- Resource 5e85c2740f5e5963197435 PDFDocument133 pagesResource 5e85c2740f5e5963197435 PDFTooniNo ratings yet

- S. S. Crushers: Particulars Amount Cost of The ProjectDocument11 pagesS. S. Crushers: Particulars Amount Cost of The Projectpatan nazeerNo ratings yet

- Section TableDocument52 pagesSection TableNurin Irdina RoslanNo ratings yet

- 3i Part 5Document4 pages3i Part 5Ethan AbadNo ratings yet

- Sectional Properties of SteelDocument72 pagesSectional Properties of Steeladera1No ratings yet

- Analysis of Factors Behind Rise of Home Prices Across USDocument19 pagesAnalysis of Factors Behind Rise of Home Prices Across USrajNo ratings yet

- Instructions:: This Is An Online, Closed Book ExaminationDocument18 pagesInstructions:: This Is An Online, Closed Book ExaminationChandan SahNo ratings yet

- Sample IAS 29 COS ComputationDocument29 pagesSample IAS 29 COS ComputationShingirai CynthiaNo ratings yet

- An Application of Dmaic and Statistical Process Control Methodology For Minimizing Defect Percentage in Rotocast Area of Pt. XiDocument42 pagesAn Application of Dmaic and Statistical Process Control Methodology For Minimizing Defect Percentage in Rotocast Area of Pt. XiDhiniiee d'DienzzNo ratings yet

- Handbook of Structural Steelwork EE 55 13 Unlocked Pages 168 182Document51 pagesHandbook of Structural Steelwork EE 55 13 Unlocked Pages 168 182Ibrahim AbdiNo ratings yet

- SKDN Krktug 2012 - 2Document21 pagesSKDN Krktug 2012 - 2faridaNo ratings yet

- Week # Covered Period Cases Total 7K Special Total Billing Harvest 13K Regular 13K Special Class B & CDocument5 pagesWeek # Covered Period Cases Total 7K Special Total Billing Harvest 13K Regular 13K Special Class B & CShang BugayongNo ratings yet

- Pormalejo Construction and Survey OfficeDocument14 pagesPormalejo Construction and Survey OfficeSelene BrondialNo ratings yet

- Sheets Sheet Type Description Links Model List Exp Waitt Satisfaction Fte Vol Rev Salesp Other Calc Piv CheckDocument35 pagesSheets Sheet Type Description Links Model List Exp Waitt Satisfaction Fte Vol Rev Salesp Other Calc Piv CheckDemand SupplyNo ratings yet

- ML Project - Jupyter NotebookDocument5 pagesML Project - Jupyter NotebookJAISURYA S B.Sc.AIDANo ratings yet

- FQM - Assingment - 5 - Aviral Rai - PRN - 33Document22 pagesFQM - Assingment - 5 - Aviral Rai - PRN - 33sadkid alertNo ratings yet

- Plaxis - Finite Element Code For Soil and Rock AnalysesDocument1 pagePlaxis - Finite Element Code For Soil and Rock AnalysesYulius HendraNo ratings yet

- Tele MypracticeDocument18 pagesTele MypracticeSnehanshu SumanNo ratings yet

- ZurnDocument34 pagesZurnLight saberNo ratings yet

- Universal Beam Section PropertiesDocument4 pagesUniversal Beam Section Propertiesloft diamondNo ratings yet

- Cycle TimeDocument4 pagesCycle TimeMega watiNo ratings yet

- Muhammad Abdullah 30352Document11 pagesMuhammad Abdullah 30352maryamNo ratings yet

- Number of Periods: Data Weight Period Number Indicates Which Cells in Column To The Right Need A FormulaDocument6 pagesNumber of Periods: Data Weight Period Number Indicates Which Cells in Column To The Right Need A Formulankirich richuNo ratings yet

- Farmers Market Single QueueDocument10 pagesFarmers Market Single Queueisna rahayuNo ratings yet

- Course WorkDocument20 pagesCourse WorkKonesi RonaldNo ratings yet

- Asset Depreciation Information: HP Omni PC's Depreciation ScheduleDocument14 pagesAsset Depreciation Information: HP Omni PC's Depreciation ScheduleMuhammad HafeezNo ratings yet

- BS Section PDFDocument96 pagesBS Section PDFUpendra WalinjkarNo ratings yet

- مهارة التسجيل دراسة فاطمة انورDocument28 pagesمهارة التسجيل دراسة فاطمة انورdr fawziaNo ratings yet

- Mod FunctionDocument10 pagesMod FunctionNanda CmaNo ratings yet

- N2+o2 01.03.2023Document83 pagesN2+o2 01.03.2023anNo ratings yet

- Financial Model TemplateDocument295 pagesFinancial Model TemplategautammoreyNo ratings yet

- Daily Sales January 2007 2006: Total ValenciaDocument45 pagesDaily Sales January 2007 2006: Total Valenciaapi-19650311No ratings yet

- Usujk LSDocument15 pagesUsujk LSya ssmineNo ratings yet

- Demanda: MesesDocument16 pagesDemanda: MesesFrancisco CervantesNo ratings yet

- SUMMARYDocument8 pagesSUMMARYJEAN KATHLEEN SORIANONo ratings yet

- Carnet de Piquetage Réseau Kirzidi 2Document6 pagesCarnet de Piquetage Réseau Kirzidi 2rolandboulibessalaNo ratings yet

- Professional WorkingDocument8 pagesProfessional WorkingArslan RammayNo ratings yet

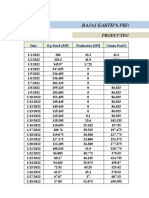

- Bajaj Earth's Stock (Jan 2022)Document60 pagesBajaj Earth's Stock (Jan 2022)nasir ahmedNo ratings yet

- Monitoring Stock PPCM 14 Januari 2021Document3,619 pagesMonitoring Stock PPCM 14 Januari 2021ardinaawlNo ratings yet

- Project Charter: Business Case Problem (Opportunity) StatementDocument3 pagesProject Charter: Business Case Problem (Opportunity) StatementardinaawlNo ratings yet

- Pemipaan Gas Bumi - Disain Dan Konstruksi (1) - Rev 2019Document47 pagesPemipaan Gas Bumi - Disain Dan Konstruksi (1) - Rev 2019ardinaawlNo ratings yet

- Modul 0 IntroDocument16 pagesModul 0 IntroardinaawlNo ratings yet

- PERMAS 01 (Reg Senin Rabu) PERMAS 02 (Reg Senin Selasa) PERMAS O3 (Par)Document3 pagesPERMAS 01 (Reg Senin Rabu) PERMAS 02 (Reg Senin Selasa) PERMAS O3 (Par)ardinaawlNo ratings yet

- Caso CEMEX MarianoDocument2 pagesCaso CEMEX MarianoMariano LopezNo ratings yet

- Civil Courts Acts 1958Document15 pagesCivil Courts Acts 1958Pratyush GuptaNo ratings yet

- 3rd International Conference On The Application of Superabsorben 2020Document275 pages3rd International Conference On The Application of Superabsorben 20204919404No ratings yet

- Lab Class Routine Spring 2020 Semester - 2Document1 pageLab Class Routine Spring 2020 Semester - 2Al-jubaer Bin Jihad PlabonNo ratings yet

- Gmail - Days Inn Hotels Confirmed Reservation NotificationDocument2 pagesGmail - Days Inn Hotels Confirmed Reservation Notificationapi-75518386No ratings yet

- Commands ListDocument11 pagesCommands ListAll SubscribeNo ratings yet

- Annotated Bibliography On Land Research in Nepal (2011)Document50 pagesAnnotated Bibliography On Land Research in Nepal (2011)Kristoff Sven100% (1)

- Dell Precision M4800 ParametryDocument2 pagesDell Precision M4800 ParametryWilsonLópezNo ratings yet

- Anhang Amel 55Document12 pagesAnhang Amel 55frankNo ratings yet

- Bacolod Brewery: Additive and Deductive Works: Material Diameter LengthDocument1 pageBacolod Brewery: Additive and Deductive Works: Material Diameter LengthWilliam Jefferson RañadaNo ratings yet

- Cluster Coordinators Csos Contact ListDocument1 pageCluster Coordinators Csos Contact ListAbdishakur Mohamud HassanNo ratings yet

- 55 Gold FeverDocument5 pages55 Gold FeverACasey101No ratings yet

- 2nd Year Civil Engineering Course Detail of IOE, TU NepalDocument20 pages2nd Year Civil Engineering Course Detail of IOE, TU NepalSunil Kharbuja100% (1)

- En 300 330 V2.1.0 PDFDocument74 pagesEn 300 330 V2.1.0 PDFSosialNo ratings yet

- Ansys ModelDocument11 pagesAnsys Modelsrini_meha100% (1)

- Self Declaration CertificateDocument1 pageSelf Declaration CertificatePuran SinghNo ratings yet

- Land LawDocument19 pagesLand LawRitesh KumaiNo ratings yet

- PLC Lader LogicDocument53 pagesPLC Lader LogicKamaraju DaviliNo ratings yet

- 04.1 S4 VAT PPT AquinoDocument112 pages04.1 S4 VAT PPT Aquinosaeloun hrdNo ratings yet

- Rotary Screw Compressors Models XJS/XJF 95 Through 151: E70-510 SPC/JAN 97Document4 pagesRotary Screw Compressors Models XJS/XJF 95 Through 151: E70-510 SPC/JAN 97dfmolinaNo ratings yet

- Pas Airpack 2 Pi 9046599 en GBDocument8 pagesPas Airpack 2 Pi 9046599 en GBForum PompieriiNo ratings yet

- P Servo-EDocument64 pagesP Servo-EÉder Camargo100% (1)

- Strings: Python For Informatics: Exploring InformationDocument31 pagesStrings: Python For Informatics: Exploring InformationKevin SahalaNo ratings yet

- Sav 4222Document30 pagesSav 4222tlidia100% (1)

- March 19, 2015Document10 pagesMarch 19, 2015The Delphos HeraldNo ratings yet

- Mercedes Benz Brocure Mb900Document16 pagesMercedes Benz Brocure Mb900ramsi17No ratings yet

Initial Problem Perception

Initial Problem Perception

Uploaded by

ardinaawl0 ratings0% found this document useful (0 votes)

47 views12 pagesThe document discusses issues with stock distribution and output cutting. It notes that stock distribution is over 5 days and output cutting is not always aligned with sewing needs. It also notes that distribution requests often pull forward the cutting plan date to fulfill sewing requirements. This leads to high work-in-process and stock at distribution. The real problem is that changes to the production plan every two weeks with each new PPCM release are causing inconsistency and an unsmooth process between cutting and distribution, resulting in high stock levels. The point of cause is determined to be the inconsistent PPCM releases.

Original Description:

Initial Problem Perception

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses issues with stock distribution and output cutting. It notes that stock distribution is over 5 days and output cutting is not always aligned with sewing needs. It also notes that distribution requests often pull forward the cutting plan date to fulfill sewing requirements. This leads to high work-in-process and stock at distribution. The real problem is that changes to the production plan every two weeks with each new PPCM release are causing inconsistency and an unsmooth process between cutting and distribution, resulting in high stock levels. The point of cause is determined to be the inconsistent PPCM releases.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

47 views12 pagesInitial Problem Perception

Initial Problem Perception

Uploaded by

ardinaawlThe document discusses issues with stock distribution and output cutting. It notes that stock distribution is over 5 days and output cutting is not always aligned with sewing needs. It also notes that distribution requests often pull forward the cutting plan date to fulfill sewing requirements. This leads to high work-in-process and stock at distribution. The real problem is that changes to the production plan every two weeks with each new PPCM release are causing inconsistency and an unsmooth process between cutting and distribution, resulting in high stock levels. The point of cause is determined to be the inconsistent PPCM releases.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 12

Clarify the problem

• Stock distribution (December 2020)

Clarify the problem

• Output cutting

DATE PLAN QTY ACTUAL QTY MENIT MENIT effisiensi

OUTPUT OUTPUT PLAN ACTUAL

01-Dec 35,938 36,545 40,726 45,288 99%

02-Dec 42,285 46,028 45,227 50,664 111%

03-Dec 35,494 38,296 44,657 43,932 96%

04-Dec 40,319 47,066 43,571 48,349 106%

07-Dec 49,531 33,690 53,917 40,868 90%

08-Dec 43,878 48,594 50,596 52,474 115%

10-Dec 79,700 33,617 82,453 40,526 89%

11-Dec 58,137 40,414 64,303 43,958 96%

14-Dec 43,885 44,469 47,587 46,394 102%

15-Dec 42,351 46,599 42,351 56,038 123%

16-Dec 44,839 43,519 44,839 48,963 107%

17-Dec 21,675 37,161 26,224 45,411 115%

18-Dec 13,677 44,436 15,805 52,192 125%

21-Dec 40,210 46,611 48,865 51,614 129%

22-Dec 33,592 36,524 33,485 40,164 110%

23-Dec 25,463 32,012 30,901 36,696 101%

28-Dec 33,504 37,313 42,271 41,386 113%

29-Dec 43,856 36,285 47,292 43,833 120%

30-Dec 66,360 24,385 51,357.00 33,446 92%

Clarify the Problem

• Distribution request pull forward plan cutting date

Date 1-Dec 3-Dec 7-Dec 8-Dec 10-Dec 11-Dec 14-Dec 18-Dec 21-Dec 22-Dec 23-Dec 28-Dec 29-Dec 30-Dec

PO 11 15 11 13 4 11 7 6 7 7 10 14 5 7

Qty Order (Pcs) 5,963 20,778 18,151 8,612 3,207 3,932 1,805 17,666 10,090 30,494 51,606 14,549 4,452 5,691

Initial Problem Perception

• High WIP or Stock in distribution, High Output cutting, but everyday

distribution Request pull forward plan cutting date to fulfill sewing

need.

Clarify the Problem

What actually happen What should be happen

• Stock distribution over than 5 • Stock distribution Distribution

days Stock ready 2 days and stock

• Not all output cutting is same as unready 3 days.

with needed • Output cutting should be the

• Distribution request pull forward same as with sewing needed

for cutting plan to fulfill sewing

need

Breakdwon

• PPCM Release every two weeks, every PPCM release there are

changes plan to start sewing. if the start to sewing is pull back, it

would increase work in process or stock at distribution, while if the

start to sewing is pulled forward it would make pull forward for plan

cutting date. And once it happens it would be made unsmooth

process between cutting and distribution.

Tabel jumlah maju mundur ppcm, table

jumlah pull forward pcd

Real Problem

• The changes every PPCM release caused a high stock in distribution

and led to unsmooth process between distribution and cutting

Point of Cause (PoC)

• Locate Area

Flow process

Based on trackback, the PoC is PPCM, the caused of this problem is

inconsistency PPCM

Point of Cause (PoC)

• Grasp situation at PoC

Point of Cause (PoC)

• Direct cause

You might also like

- APLUS 121 User GuideDocument928 pagesAPLUS 121 User GuideJuan Pablo AriasNo ratings yet

- LSS - Case Study - 1 - Improving Call Center Operations v1.0Document7 pagesLSS - Case Study - 1 - Improving Call Center Operations v1.0Calvin VernonNo ratings yet

- JJJDocument9 pagesJJJKaantDenisNo ratings yet

- Handbook On Unani Medicines With Formulae, Processes, Uses and AnalysisDocument5 pagesHandbook On Unani Medicines With Formulae, Processes, Uses and Analysismy_khan20027195100% (3)

- Exercise Visualization Using ChartsDocument17 pagesExercise Visualization Using ChartsGOURAV SHRIVASTAVA Student, Jaipuria IndoreNo ratings yet

- New PPT DeckDocument5 pagesNew PPT Deckrahul kumarNo ratings yet

- Case DataDocument13 pagesCase DataKajal singhNo ratings yet

- Edi RecoveryDocument8 pagesEdi RecoveryEstmarg EstmargNo ratings yet

- Recording Ayam BroilerDocument7 pagesRecording Ayam BroilerlaataiasNo ratings yet

- PG FoilsDocument63 pagesPG FoilsvidyaNo ratings yet

- Projections World Trail-FinalDocument26 pagesProjections World Trail-FinalUppada SareesNo ratings yet

- Megacard CorporationDocument6 pagesMegacard CorporationJanit SethiNo ratings yet

- Experiment No. 4, Group 6Document12 pagesExperiment No. 4, Group 6Aman NagraleNo ratings yet

- Solar Savings CorrectDocument22 pagesSolar Savings CorrectRudraksh ShivhareNo ratings yet

- Draf Nota DinasDocument3 pagesDraf Nota Dinasagus susantoNo ratings yet

- Presentation ReportsDocument8 pagesPresentation ReportsNorhan AmmarNo ratings yet

- Excel Perhitungan Tugas Besar SCM - Kelompok-7 - TI4207Document49 pagesExcel Perhitungan Tugas Besar SCM - Kelompok-7 - TI4207FADILLA ZARA LARASHATINo ratings yet

- Blue BookDocument241 pagesBlue Bookeng_muhammad88No ratings yet

- En Un Banco O en Tu Casa Tendras El Mismo Capital O Menos en Un AñoDocument2 pagesEn Un Banco O en Tu Casa Tendras El Mismo Capital O Menos en Un AñoJose CarloNo ratings yet

- Consumo Vapor AASA 2019Document12 pagesConsumo Vapor AASA 2019ingearroyoNo ratings yet

- Ipm Assignment 01 (Fa18-Baf-084)Document5 pagesIpm Assignment 01 (Fa18-Baf-084)Yasir AhmadNo ratings yet

- 1 Mock Test Giảng PracticeDocument229 pages1 Mock Test Giảng PracticeHoài LinhNo ratings yet

- Datos F'C Fy Factor de Reducción (Ø) : 250 kg/cm2 4200 kg/cm2 0.9 2388000 KG-CMDocument50 pagesDatos F'C Fy Factor de Reducción (Ø) : 250 kg/cm2 4200 kg/cm2 0.9 2388000 KG-CMRobsonOrtizNo ratings yet

- Laporan Pengukuran Topografi Dan Bathimetri PT - Tei Lokasi Pulau Rimau - Banyuasin ExelDocument21 pagesLaporan Pengukuran Topografi Dan Bathimetri PT - Tei Lokasi Pulau Rimau - Banyuasin ExelTatanyaAndiRaditNo ratings yet

- Resource 5e85c2740f5e5963197435 PDFDocument133 pagesResource 5e85c2740f5e5963197435 PDFTooniNo ratings yet

- S. S. Crushers: Particulars Amount Cost of The ProjectDocument11 pagesS. S. Crushers: Particulars Amount Cost of The Projectpatan nazeerNo ratings yet

- Section TableDocument52 pagesSection TableNurin Irdina RoslanNo ratings yet

- 3i Part 5Document4 pages3i Part 5Ethan AbadNo ratings yet

- Sectional Properties of SteelDocument72 pagesSectional Properties of Steeladera1No ratings yet

- Analysis of Factors Behind Rise of Home Prices Across USDocument19 pagesAnalysis of Factors Behind Rise of Home Prices Across USrajNo ratings yet

- Instructions:: This Is An Online, Closed Book ExaminationDocument18 pagesInstructions:: This Is An Online, Closed Book ExaminationChandan SahNo ratings yet

- Sample IAS 29 COS ComputationDocument29 pagesSample IAS 29 COS ComputationShingirai CynthiaNo ratings yet

- An Application of Dmaic and Statistical Process Control Methodology For Minimizing Defect Percentage in Rotocast Area of Pt. XiDocument42 pagesAn Application of Dmaic and Statistical Process Control Methodology For Minimizing Defect Percentage in Rotocast Area of Pt. XiDhiniiee d'DienzzNo ratings yet

- Handbook of Structural Steelwork EE 55 13 Unlocked Pages 168 182Document51 pagesHandbook of Structural Steelwork EE 55 13 Unlocked Pages 168 182Ibrahim AbdiNo ratings yet

- SKDN Krktug 2012 - 2Document21 pagesSKDN Krktug 2012 - 2faridaNo ratings yet

- Week # Covered Period Cases Total 7K Special Total Billing Harvest 13K Regular 13K Special Class B & CDocument5 pagesWeek # Covered Period Cases Total 7K Special Total Billing Harvest 13K Regular 13K Special Class B & CShang BugayongNo ratings yet

- Pormalejo Construction and Survey OfficeDocument14 pagesPormalejo Construction and Survey OfficeSelene BrondialNo ratings yet

- Sheets Sheet Type Description Links Model List Exp Waitt Satisfaction Fte Vol Rev Salesp Other Calc Piv CheckDocument35 pagesSheets Sheet Type Description Links Model List Exp Waitt Satisfaction Fte Vol Rev Salesp Other Calc Piv CheckDemand SupplyNo ratings yet

- ML Project - Jupyter NotebookDocument5 pagesML Project - Jupyter NotebookJAISURYA S B.Sc.AIDANo ratings yet

- FQM - Assingment - 5 - Aviral Rai - PRN - 33Document22 pagesFQM - Assingment - 5 - Aviral Rai - PRN - 33sadkid alertNo ratings yet

- Plaxis - Finite Element Code For Soil and Rock AnalysesDocument1 pagePlaxis - Finite Element Code For Soil and Rock AnalysesYulius HendraNo ratings yet

- Tele MypracticeDocument18 pagesTele MypracticeSnehanshu SumanNo ratings yet

- ZurnDocument34 pagesZurnLight saberNo ratings yet

- Universal Beam Section PropertiesDocument4 pagesUniversal Beam Section Propertiesloft diamondNo ratings yet

- Cycle TimeDocument4 pagesCycle TimeMega watiNo ratings yet

- Muhammad Abdullah 30352Document11 pagesMuhammad Abdullah 30352maryamNo ratings yet

- Number of Periods: Data Weight Period Number Indicates Which Cells in Column To The Right Need A FormulaDocument6 pagesNumber of Periods: Data Weight Period Number Indicates Which Cells in Column To The Right Need A Formulankirich richuNo ratings yet

- Farmers Market Single QueueDocument10 pagesFarmers Market Single Queueisna rahayuNo ratings yet

- Course WorkDocument20 pagesCourse WorkKonesi RonaldNo ratings yet

- Asset Depreciation Information: HP Omni PC's Depreciation ScheduleDocument14 pagesAsset Depreciation Information: HP Omni PC's Depreciation ScheduleMuhammad HafeezNo ratings yet

- BS Section PDFDocument96 pagesBS Section PDFUpendra WalinjkarNo ratings yet

- مهارة التسجيل دراسة فاطمة انورDocument28 pagesمهارة التسجيل دراسة فاطمة انورdr fawziaNo ratings yet

- Mod FunctionDocument10 pagesMod FunctionNanda CmaNo ratings yet

- N2+o2 01.03.2023Document83 pagesN2+o2 01.03.2023anNo ratings yet

- Financial Model TemplateDocument295 pagesFinancial Model TemplategautammoreyNo ratings yet

- Daily Sales January 2007 2006: Total ValenciaDocument45 pagesDaily Sales January 2007 2006: Total Valenciaapi-19650311No ratings yet

- Usujk LSDocument15 pagesUsujk LSya ssmineNo ratings yet

- Demanda: MesesDocument16 pagesDemanda: MesesFrancisco CervantesNo ratings yet

- SUMMARYDocument8 pagesSUMMARYJEAN KATHLEEN SORIANONo ratings yet

- Carnet de Piquetage Réseau Kirzidi 2Document6 pagesCarnet de Piquetage Réseau Kirzidi 2rolandboulibessalaNo ratings yet

- Professional WorkingDocument8 pagesProfessional WorkingArslan RammayNo ratings yet

- Bajaj Earth's Stock (Jan 2022)Document60 pagesBajaj Earth's Stock (Jan 2022)nasir ahmedNo ratings yet

- Monitoring Stock PPCM 14 Januari 2021Document3,619 pagesMonitoring Stock PPCM 14 Januari 2021ardinaawlNo ratings yet

- Project Charter: Business Case Problem (Opportunity) StatementDocument3 pagesProject Charter: Business Case Problem (Opportunity) StatementardinaawlNo ratings yet

- Pemipaan Gas Bumi - Disain Dan Konstruksi (1) - Rev 2019Document47 pagesPemipaan Gas Bumi - Disain Dan Konstruksi (1) - Rev 2019ardinaawlNo ratings yet

- Modul 0 IntroDocument16 pagesModul 0 IntroardinaawlNo ratings yet

- PERMAS 01 (Reg Senin Rabu) PERMAS 02 (Reg Senin Selasa) PERMAS O3 (Par)Document3 pagesPERMAS 01 (Reg Senin Rabu) PERMAS 02 (Reg Senin Selasa) PERMAS O3 (Par)ardinaawlNo ratings yet

- Caso CEMEX MarianoDocument2 pagesCaso CEMEX MarianoMariano LopezNo ratings yet

- Civil Courts Acts 1958Document15 pagesCivil Courts Acts 1958Pratyush GuptaNo ratings yet

- 3rd International Conference On The Application of Superabsorben 2020Document275 pages3rd International Conference On The Application of Superabsorben 20204919404No ratings yet

- Lab Class Routine Spring 2020 Semester - 2Document1 pageLab Class Routine Spring 2020 Semester - 2Al-jubaer Bin Jihad PlabonNo ratings yet

- Gmail - Days Inn Hotels Confirmed Reservation NotificationDocument2 pagesGmail - Days Inn Hotels Confirmed Reservation Notificationapi-75518386No ratings yet

- Commands ListDocument11 pagesCommands ListAll SubscribeNo ratings yet

- Annotated Bibliography On Land Research in Nepal (2011)Document50 pagesAnnotated Bibliography On Land Research in Nepal (2011)Kristoff Sven100% (1)

- Dell Precision M4800 ParametryDocument2 pagesDell Precision M4800 ParametryWilsonLópezNo ratings yet

- Anhang Amel 55Document12 pagesAnhang Amel 55frankNo ratings yet

- Bacolod Brewery: Additive and Deductive Works: Material Diameter LengthDocument1 pageBacolod Brewery: Additive and Deductive Works: Material Diameter LengthWilliam Jefferson RañadaNo ratings yet

- Cluster Coordinators Csos Contact ListDocument1 pageCluster Coordinators Csos Contact ListAbdishakur Mohamud HassanNo ratings yet

- 55 Gold FeverDocument5 pages55 Gold FeverACasey101No ratings yet

- 2nd Year Civil Engineering Course Detail of IOE, TU NepalDocument20 pages2nd Year Civil Engineering Course Detail of IOE, TU NepalSunil Kharbuja100% (1)

- En 300 330 V2.1.0 PDFDocument74 pagesEn 300 330 V2.1.0 PDFSosialNo ratings yet

- Ansys ModelDocument11 pagesAnsys Modelsrini_meha100% (1)

- Self Declaration CertificateDocument1 pageSelf Declaration CertificatePuran SinghNo ratings yet

- Land LawDocument19 pagesLand LawRitesh KumaiNo ratings yet

- PLC Lader LogicDocument53 pagesPLC Lader LogicKamaraju DaviliNo ratings yet

- 04.1 S4 VAT PPT AquinoDocument112 pages04.1 S4 VAT PPT Aquinosaeloun hrdNo ratings yet

- Rotary Screw Compressors Models XJS/XJF 95 Through 151: E70-510 SPC/JAN 97Document4 pagesRotary Screw Compressors Models XJS/XJF 95 Through 151: E70-510 SPC/JAN 97dfmolinaNo ratings yet

- Pas Airpack 2 Pi 9046599 en GBDocument8 pagesPas Airpack 2 Pi 9046599 en GBForum PompieriiNo ratings yet

- P Servo-EDocument64 pagesP Servo-EÉder Camargo100% (1)

- Strings: Python For Informatics: Exploring InformationDocument31 pagesStrings: Python For Informatics: Exploring InformationKevin SahalaNo ratings yet

- Sav 4222Document30 pagesSav 4222tlidia100% (1)

- March 19, 2015Document10 pagesMarch 19, 2015The Delphos HeraldNo ratings yet

- Mercedes Benz Brocure Mb900Document16 pagesMercedes Benz Brocure Mb900ramsi17No ratings yet