Professional Documents

Culture Documents

Fundamentals of Materials: Behavior and Manufacturing Properties

Fundamentals of Materials: Behavior and Manufacturing Properties

Uploaded by

Hamed Mirabi0 ratings0% found this document useful (0 votes)

14 views37 pagesThis chapter discusses the structure, properties, and applications of polymers. It describes how polymers are formed from monomers using polymerization reactions and how their molecular structure, including linear, branched, and cross-linked configurations, influences properties. The chapter outlines the key differences between thermoplastics and thermosetting plastics and examines how temperature affects polymer behavior and characteristics. It also explores various polymer types and their common uses.

Original Description:

Original Title

ch07a

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis chapter discusses the structure, properties, and applications of polymers. It describes how polymers are formed from monomers using polymerization reactions and how their molecular structure, including linear, branched, and cross-linked configurations, influences properties. The chapter outlines the key differences between thermoplastics and thermosetting plastics and examines how temperature affects polymer behavior and characteristics. It also explores various polymer types and their common uses.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

14 views37 pagesFundamentals of Materials: Behavior and Manufacturing Properties

Fundamentals of Materials: Behavior and Manufacturing Properties

Uploaded by

Hamed MirabiThis chapter discusses the structure, properties, and applications of polymers. It describes how polymers are formed from monomers using polymerization reactions and how their molecular structure, including linear, branched, and cross-linked configurations, influences properties. The chapter outlines the key differences between thermoplastics and thermosetting plastics and examines how temperature affects polymer behavior and characteristics. It also explores various polymer types and their common uses.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 37

Manufacturing Engineering and Technology

Fundamentals of Materials: Behavior and

Manufacturing Properties

1. The Structure of Metals

2. Mechanical Behavior, Testing and

Manufacturing Properties of Materials

3. Physical Properties of Materials

4. Metal Alloys: Structure and Strengthening by

Heat Treatment

5. Ferrous Metals and Alloys: Production,

General Properties and Applications

2005 Pearson Education South Asia Pte Ltd

Manufacturing Engineering and Technology

Fundamentals of Materials: Behavior and

Manufacturing Properties

6. Nonferrous Metals and Alloys: Production,

General Properties and Applications

7. Polymers: Structure, General Properties and

Applications

8. Ceramics, Graphite and Diamond: Structure,

General Properties and Applications

9. Composite Materials: Structure, General

Properties, and Applications

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

Chapter Objectives

• Structure of polymers, polymerization processes, crystallinity, and glass-

transition temperature.

• How temperature and deformation rate affect the properties of

thermoplastics.

• Differences between thermoplastics and thermosets.

• Properties and applications of polymers, their advantages and limitations.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

Chapter Outline

1. Introduction

2. The Structure of Polymers

3. Thermoplastics

4. Thermosetting Plastics

5. Additives in Plastics

6. General Properties and Applications of Thermoplastics

7. General Properties and Applications of Thermosetting Plastics

8. Biodegradable Plastics

9. Elastomers (Rubbers)

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.1 Introduction

• Plastics are one of numerous polymeric materials and have extremely large molecules (macromolecules or giant molecules).

• The advantages of polymers in terms of the following characteristics:

• Corrosion resistance and resistance to chemicals

• Low electrical and thermal conductivity

• Low density

• High strength-to-weight ratio (particularly when reinforced)

• Noise reduction

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.1 Introduction

• Noise reduction

• Ease of manufacturing and complexity of design possibilities

• Relatively low cost

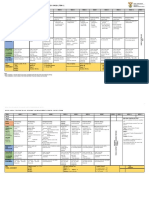

• Other characteristics that may or may not be desirable (depending on the application), such as low strength

and stiffness (Table 7.1), high coefficient of thermal expansion, low useful-temperature range—up to about

350°C, and lower dimensional stability in service over a period of time.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.1 Introduction

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.1 Introduction

• Plastics can be formed, machined, cast, and joined into various shapes with relative ease.

• Plastics are available commercially as film, sheet, plate, rods, and tubing of various cross-sections.

• An outline of the basic process of making various synthetic polymers is given in Fig. 7.1.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.1 Introduction

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

• The properties of polymers depend largely on the structures of individual polymer molecules, molecule shape and size, and

how molecules are arranged to form a polymer structure.

• Polymers are long-chain molecules that are formed by polymerization (that is, by the linking and cross-linking of different

monomers).

• A monomer is the basic building block of a polymer.

• The word mer (from the Greek meros, meaning part) indicates the smallest repetitive unit; its use is similar to that of the term

unit cell in crystal structures of metals.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

• The term polymer means many mers (or units), generally repeated

hundreds or thousands of times in a chainlike structure.

• Fig 7.2 shows the molecular structure of various polymers. These

are examples of the basic building blocks for plastics.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

• In condensation polymerization polymers are produced by the formation of bonds

between two types of reacting mers.

• Fig 7.3 shows the examples of polymerization. (a) Condensation polymerization of

nylon 6,6 and (b) addition polymerization of polyethylene molecules from ethylene

mers.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

• This process is also known as step-growth or step-reaction polymerization,

because the polymer molecule grows step-by-step until all of one reactant is

consumed.

• In addition polymerization (also called chain-growth or chain-reaction

polymerization), bonding takes place without reaction by-products,

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

Molecular Weight

• The sum of the molecular weights of the mers in a representative chain is known as the molecular weight of

the polymer.

• The spread of the molecular weights in a chain is referred to as the molecular weight distribution (MWD).

• A polymer’s molecular weight and its MWD have a strong influence on its properties.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

Molecular Weight

• Fig 7.4 shows the effect of molecular weight and degree of

polymerization on the strength and viscosity of polymers.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

Degree of Polymerization

• It is convenient to express the size of a polymer chain in terms of the degree of polymerization (DP), which

is defined as the ratio of the molecular weight of the polymer to the molecular weight of the repeating unit.

• The higher the DP, the higher is the polymer’s viscosity or its resistance to flow.

• High viscosity adversely affects the ease of shaping and, thus, raises the overall cost of processing.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

Bonding

• During polymerization, the monomers are linked together by covalent bonds, forming a polymer chain.

• Because of their strength, covalent bonds also are called primary bonds.

• The polymer chains are, in turn, held together by secondary bonds, such as van der Waals bonds, hydrogen

bonds, and ionic bonds.

• Secondary bonds are weaker than primary bonds by one to two orders of magnitude.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

Linear Polymers

• The chain-like polymers shown in Fig. 7.2 are called linear polymers because of their sequential structure.

• Fig 7.5 shows the schematic illustration of polymer chains. (a) Linear structure— thermoplastics such as acrylics, nylons,

polyethylene, and polyvinyl chloride have linear structures. (b) Branched structure, such as in polyethylene. (c) Cross-

linked structure—many rubbers or elastomers have this structure, and the vulcanization of rubber produces this structure.

(d) Network structure, which is basically highly cross-linked—examples are thermosetting plastics, such as epoxies and

phenolics.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

Branched Polymers

• The properties of a polymer depend not only on the type of monomers but also on their

arrangement in the molecular structure.

• In branched polymers (Fig. 7.5b), side-branch chains are attached to the main chain

during the synthesis of the polymer.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

Cross-linked Polymers

• Generally three-dimensional in structure, cross-linked polymers have adjacent chains linked by covalent bonds

(Fig. 7.5c).

• Polymers with a cross-linked chain structure are called thermosets, or thermosetting plastics.

• Fig 7.6 shows the behavior of polymers as a function of temperature and (a) degree of crystallinity and (b) cross-

linking. The combined elastic and viscous behavior of polymers is known as viscoelasticity.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

Network polymers

• These polymers consist of spatial (three-dimensional) networks of three

or more active covalent bonds (Fig. 7.5d).

• A highly cross-linked polymer also is considered a network polymer.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2 The Structure of Polymers

Copolymers and terpolymers

• If the repeating units in a polymer chain are all of the same type, the molecule is called a homopolymer.

• Copolymers contain two types of polymers (for example, styrene-butadiene, which is used widely for

automobile tires).

• Terpolymers contain three types (for example, ABS (acrylonitrilebutadiene-styrene), which is used for

helmets, telephones, and refrigerator liners).

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

Example 7.1 Dental and medical bone cement

Polymethylmethacrylate (PMMA) is an acrylic polymer commonly

used in dental and medical applications as an adhesive and

commonly is referred to as bone cement. There are a number of

forms of PMMA, but this example describes one common form

involving an addition-polymerization reaction. PMMA is delivered

in two parts: a powder and a liquid, which are mixed by hand. The

liquid wets and partially dissolves the powder, resulting in a liquid

with viscosity on the order of 0.1 Ns/m 2 similar to that of vegetable

oil. The viscosity increases markedly until a “dough” state is

reached in about five minutes and fully hardens from the dough

state in an additional five minutes.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

Example 7.1 Dental and medical bone cement

The powder consists of high molecular weight

poly[(methylmethacrylate)- costyrene] particles of about 50 micro-

meter in diameter, containing a small volume fraction of benzoyl

peroxide. The liquid consists of a methyl methacrylate (MMA)

monomer, with a small amount of dissolved n,n dimethyl-p-

toluidine (DMPT). When the liquid and powder are mixed, the

MMA wets the particles (dissolving a surface layer of the PMMA

particles) and the DMPT cleaves the benzoyl peroxide molecule

into

two parts to form a catalyst with a free electron (sometimes

referred to as a free radical). The resulting catalyst causes rapid

growth of PMMA from the MMA mers, so that the final material is

a composite of high molecular weight PMMA particles

interconnected by PMMA chains. A schematic diagram of fully set

bone cement is shown in Fig. 7.7.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

Example 7.1 Dental and medical bone cement

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2.2 Crystallinity

• Polymers such as polymethylmethacrylate, polycarbonate, and polystyrene are generally amorphous; that is,

the polymer chains exist without long-range order.

• The crystalline regions in polymers are called crystallites.

• Fig 7.8 shows the amorphous and crystalline regions in a polymer.

• The crystalline region (crystallite) has an orderly arrangement of molecules. The higher the crystallinity, the

harder, stiffer, and less ductile the polymer.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2.2 Crystallinity

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2.2 Crystallinity

• These crystals are formed when the long molecules arrange themselves in an orderly manner, similar to

the folding of a fire hose in a cabinet or of facial tissues in a box.

• A partially crystalline (semi-crystalline) polymer can be regarded as a two-phase material, one phase

being crystalline and the other amorphous.

• By controlling the rate of solidification during cooling and the chain structure, it is possible to impart

different degrees of crystallinity to polymers, although never 100%.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2.2 Crystallinity

Effects of crystallinity

• The mechanical and physical properties of polymers are greatly influenced by the degree of crystallinity:

as crystallinity increases, polymers become stiffer, harder, less ductile, more dense, less rubbery, and

more resistant to solvents and heat (Fig. 7.6).

• The increase in density with increasing crystallinity is called crystallization shrinkage and is caused by a

more efficient packing of the molecules in the crystal lattice.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2.3 Glass-transition temperature

• The temperature at which a transition occurs is called the glass-transition temperature, T g, also called the glass point or

glass temperature.

• To determine Tg, the specific volume of the polymer is determined and plotted against temperature, and marked by a sharp

change in the slope of the curve.

• Fig 7.9 shows the Specific volume of polymers as a function of temperature. Amorphous polymers, such as acrylic and

polycarbonate, have a glass-transition temperature, but do not have a specific melting point, Partly crystalline polymers, such

as polyethylene and nylons, contract sharply while passing through their melting temperatures during cooling.

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2.3 Glass-transition temperature

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2.3 Glass-transition temperature

• The glass-transition temperature varies with different

polymers (Table 7.2).

2005 Pearson Education South Asia Pte Ltd

7. Polymers: Structure, General Properties and Applications

7.2.4 Polymer Blends

• The brittle behavior of amorphous polymers below their glass-transition temperature can be reduced by blending them—

usually with small quantities of an elastomer.

• These polymer blends are known as rubber modified polymers.

• Advances in blending involve several components, creating polyblends that utilize the favorable properties of different

polymers.

• Miscible blends (mixing without separation of two phases) are created by a process similar to the alloying of metals that

enables polymer blends to become more ductile.

2005 Pearson Education South Asia Pte Ltd

You might also like

- Orange Juice SongbookDocument60 pagesOrange Juice SongbookLewis BlossNo ratings yet

- Making Plastics From Monomer To Polymer CEP Sep 2015Document6 pagesMaking Plastics From Monomer To Polymer CEP Sep 2015Juan Sebastian SánchezNo ratings yet

- QPDEC2010 Sem 1Document16 pagesQPDEC2010 Sem 1Vishal KanojiyaNo ratings yet

- Chapter 3 Polymers Thermoplastics and AdditivesDocument23 pagesChapter 3 Polymers Thermoplastics and AdditivesRusydi JamainNo ratings yet

- PolymersDocument86 pagesPolymersShrutiNo ratings yet

- Blue Print Concepts11Document104 pagesBlue Print Concepts11Nati DerNo ratings yet

- Material Science: Prof. Satish V. KailasDocument27 pagesMaterial Science: Prof. Satish V. KailasAsif KhanNo ratings yet

- Mat Unit 3Document56 pagesMat Unit 3Nisha JaiswalNo ratings yet

- Guide To Compositesv5webpdfDocument73 pagesGuide To Compositesv5webpdfImamRNNo ratings yet

- App 8400001 TXN 105421794 TMPLT 8400004Document22 pagesApp 8400001 TXN 105421794 TMPLT 8400004Rajasekaran NNo ratings yet

- Notes Class 1Document9 pagesNotes Class 1Mahir MahmoodNo ratings yet

- Polymers 2Document46 pagesPolymers 2Omed. HNo ratings yet

- 1.8 Exercises: 1.8.1 QuestionsDocument13 pages1.8 Exercises: 1.8.1 QuestionsJenniifer Neniithaw GNo ratings yet

- Classnote 1 PDFDocument78 pagesClassnote 1 PDFCJ SpencerNo ratings yet

- Overview of Polymer-Characterization & AnalysisDocument22 pagesOverview of Polymer-Characterization & AnalysiskhaledNo ratings yet

- Polymers, Ceramics & Composites: DR Yehia M. YoussefDocument27 pagesPolymers, Ceramics & Composites: DR Yehia M. YoussefAlaa MohamedNo ratings yet

- A Composite Is Any Material Made of More Than One ComponentDocument10 pagesA Composite Is Any Material Made of More Than One ComponentKingchemNo ratings yet

- Plastic Molding BaseDocument98 pagesPlastic Molding BaseKodhansNo ratings yet

- Polymers and Composite Materials: Review QuestionsDocument8 pagesPolymers and Composite Materials: Review QuestionsKhaled ShaabanNo ratings yet

- Gurit Guide To CompositesDocument74 pagesGurit Guide To CompositesSibin SaseendranNo ratings yet

- Module-3 Additive Manufacturing 18 SchemeDocument62 pagesModule-3 Additive Manufacturing 18 SchemeSANTOSHNo ratings yet

- Elective Course (2) - Composite Materials MET 443Document16 pagesElective Course (2) - Composite Materials MET 443يوسف عادل حسانينNo ratings yet

- Polymer Science and Technology 2Document93 pagesPolymer Science and Technology 2xnzrjp55tsNo ratings yet

- Pe Mids PDFDocument242 pagesPe Mids PDFAfaq Mehmood AlmaniNo ratings yet

- 13 PolimerDocument54 pages13 PolimerJhonsonNo ratings yet

- Assignment 03 by AlemuDocument11 pagesAssignment 03 by AlemuAlemu MergaNo ratings yet

- UnitV - Functional MaterialsDocument24 pagesUnitV - Functional MaterialsAppu MadanNo ratings yet

- Polymers NEWDocument70 pagesPolymers NEWHisham TaherNo ratings yet

- PDFDocument32 pagesPDFEngr Qaisar NazeerNo ratings yet

- SLG Chem 3 LG 5.10 Classifications and Properties of PolymersDocument7 pagesSLG Chem 3 LG 5.10 Classifications and Properties of PolymersfranzachilleslindayagNo ratings yet

- 1 PolymerDocument55 pages1 Polymerbt21102047 Vishwajeet YadavNo ratings yet

- Introduction To Polymer Composites: Mohamed Mahmoud Abdul-MonemDocument29 pagesIntroduction To Polymer Composites: Mohamed Mahmoud Abdul-Monemمصطفى باسم هادي B1No ratings yet

- Composite Materials CZ2BDocument20 pagesComposite Materials CZ2BVahid KamraninejadNo ratings yet

- Unit-Iv Part-ADocument7 pagesUnit-Iv Part-AParameswara RajaNo ratings yet

- Polymers: - Me YouthDocument37 pagesPolymers: - Me YouthJOSEPH REFUERZONo ratings yet

- PolymersDocument72 pagesPolymersThe Private DetectiveNo ratings yet

- Polymer and CompositesDocument105 pagesPolymer and Compositesbatur42No ratings yet

- Nanoparticles Effect On FRP Filament-Winded Composites PerformanceDocument13 pagesNanoparticles Effect On FRP Filament-Winded Composites PerformanceUday MavooriNo ratings yet

- SP Guide To CompositesDocument69 pagesSP Guide To CompositesCefirel_grifonNo ratings yet

- CHM 408 Polymer Chemistry UneditedDocument73 pagesCHM 408 Polymer Chemistry UneditedDemir YurdakulNo ratings yet

- Lesson #4: The Polymer Materials and Products Learning ObjectivesDocument14 pagesLesson #4: The Polymer Materials and Products Learning ObjectivesMartin John RamirezNo ratings yet

- R20 Applied Chemistry - UNIT-1 (Ref-2) - NewDocument21 pagesR20 Applied Chemistry - UNIT-1 (Ref-2) - NewGopl KuppaNo ratings yet

- Delamination of Sandwich CompositesDocument25 pagesDelamination of Sandwich CompositesK@l¡to$No ratings yet

- Hybrid PolymerDocument21 pagesHybrid PolymerVikram Pratap ChauhanNo ratings yet

- SA Unit 5 POLYMER AND ORGANOMETALLIC COMPOUNDSDocument34 pagesSA Unit 5 POLYMER AND ORGANOMETALLIC COMPOUNDSguptaneha8700003783No ratings yet

- 10 - Chapter 1 PDFDocument95 pages10 - Chapter 1 PDFFlávio AmaralNo ratings yet

- Subtopic 6.1: Polymers: MaterialsDocument32 pagesSubtopic 6.1: Polymers: MaterialschiggsNo ratings yet

- Ploy MerDocument17 pagesPloy MerAnonymous fdyyOfNo ratings yet

- 1Document55 pages1Shamil GadaNo ratings yet

- ProposalDocument4 pagesProposalOlawale John AdeotiNo ratings yet

- CH 08Document62 pagesCH 08Engr Fazal AkbarNo ratings yet

- POLYMERSDocument36 pagesPOLYMERSJimboy Macalinao BlazaNo ratings yet

- Materi Komposit - Prof. Anne ZulfiaDocument59 pagesMateri Komposit - Prof. Anne ZulfiaMuhammad ThohariNo ratings yet

- Composite Materials (Structures, Properties, Applications)Document19 pagesComposite Materials (Structures, Properties, Applications)Ridwan HakimNo ratings yet

- Complex Macromolecular Architectures: Synthesis, Characterization, and Self-AssemblyFrom EverandComplex Macromolecular Architectures: Synthesis, Characterization, and Self-AssemblyNo ratings yet

- Polyoxymethylene Handbook: Structure, Properties, Applications and their NanocompositesFrom EverandPolyoxymethylene Handbook: Structure, Properties, Applications and their NanocompositesNo ratings yet

- Polymer Nanotubes Nanocomposites: Synthesis, Properties and ApplicationsFrom EverandPolymer Nanotubes Nanocomposites: Synthesis, Properties and ApplicationsNo ratings yet

- Andrea Reaction Paper FinalDocument3 pagesAndrea Reaction Paper FinalIrene SabidNo ratings yet

- CBN BrochureDocument16 pagesCBN BrochuredunnyhalitionNo ratings yet

- 1.630 ATP 2023-24 GR 9 EMS FinalDocument4 pages1.630 ATP 2023-24 GR 9 EMS FinalNeliNo ratings yet

- PCC221 Recovery BoilerDocument4 pagesPCC221 Recovery BoilerHEMANT RAMJINo ratings yet

- University of Tripoli HS120: - C. - D. Dense Regular Connective TissueDocument4 pagesUniversity of Tripoli HS120: - C. - D. Dense Regular Connective TissueAnn AnooshNo ratings yet

- Altizer - Godhead and The NothingDocument180 pagesAltizer - Godhead and The NothingRocabatus100% (1)

- Nidhi Gupta Resume UpdatedDocument4 pagesNidhi Gupta Resume Updatedshannbaby22No ratings yet

- Aluminum 2024-T4-2024-T351Document3 pagesAluminum 2024-T4-2024-T351Raj EklureNo ratings yet

- Woodrats and Cholla-Dependence of A Small MammalDocument5 pagesWoodrats and Cholla-Dependence of A Small MammalDylan PeroNo ratings yet

- Annotated BibliographyDocument2 pagesAnnotated Bibliographyapi-254427588No ratings yet

- BlusatranspassadaAriadne Top 123-1-3Document32 pagesBlusatranspassadaAriadne Top 123-1-3Nadiele MoraesNo ratings yet

- MeetingsDocument3 pagesMeetingsTom SchmitNo ratings yet

- Articulo Sordo CegueraDocument11 pagesArticulo Sordo CegueraIsidoraBelénRojasTorresNo ratings yet

- Islam Managment AssigmentDocument30 pagesIslam Managment AssigmentNurul FarahidaNo ratings yet

- QMP 15 Identification and TraceabilityDocument6 pagesQMP 15 Identification and Traceabilityom cncNo ratings yet

- Thermal Efficiency Fired HeaterDocument5 pagesThermal Efficiency Fired Heatermuhammad_asim_10No ratings yet

- Ethics of Student Final PDFDocument15 pagesEthics of Student Final PDFAmtul KafiNo ratings yet

- Threat Modeling Tool 2016 User GuideDocument59 pagesThreat Modeling Tool 2016 User GuideSenthilkumarmoorthyNo ratings yet

- Proposal NewDocument19 pagesProposal NewAzimSyahmiNo ratings yet

- CES522 A 02 - Topic 2a - 3. ShearDocument7 pagesCES522 A 02 - Topic 2a - 3. ShearAizuddinNo ratings yet

- Digital Storage Oscilloscopes: TDS210 TDS220 TDS224Document4 pagesDigital Storage Oscilloscopes: TDS210 TDS220 TDS224Jime SiepeNo ratings yet

- Chapter 1 Introduction: 1.1 Purpose of The Manual For Micro-Hydro DevelopmentDocument7 pagesChapter 1 Introduction: 1.1 Purpose of The Manual For Micro-Hydro DevelopmentAde Y SaputraNo ratings yet

- SAP Mega DriveDocument17 pagesSAP Mega DriveSakthi FriendNo ratings yet

- 2 Hernandez Et Al 2005 Polychaeta BiogeographyDocument11 pages2 Hernandez Et Al 2005 Polychaeta BiogeographyViskar RyuuNo ratings yet

- Lecture 12Document11 pagesLecture 12hafsaah46No ratings yet

- Test of SignificanceDocument22 pagesTest of SignificanceKathiravan GopalanNo ratings yet

- Dramaturgies of Change: Greek Theatre Now: EditorialDocument6 pagesDramaturgies of Change: Greek Theatre Now: EditorialElsa TsiafidouNo ratings yet

- Christian Anarchy - Jesus Primacy Over The Powers PDFDocument208 pagesChristian Anarchy - Jesus Primacy Over The Powers PDFJohn Wesley BarkerNo ratings yet