Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

55 viewsChap017 - The Internet of Things and ERP

Chap017 - The Internet of Things and ERP

Uploaded by

murat kahramanThe Internet of Things and ERP

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- Integrated Marketing Communication: Tata Gluco Plus: Building The Brand IdentityDocument10 pagesIntegrated Marketing Communication: Tata Gluco Plus: Building The Brand Identityeira k67% (3)

- Mont Blanc - FinalDocument39 pagesMont Blanc - FinalSagar Shrikant Jalui20% (5)

- CRM Program Using Oracle EBS - Student GuideDocument589 pagesCRM Program Using Oracle EBS - Student GuideShakti NaiduNo ratings yet

- Erp 01Document38 pagesErp 01parkcasperkingNo ratings yet

- ERP Unit 12 Benefits of ERPDocument14 pagesERP Unit 12 Benefits of ERPAnonymous bTh744z7E60% (1)

- Enterprise Resource Planning (Erp) in Inventory ManagementDocument36 pagesEnterprise Resource Planning (Erp) in Inventory ManagementVicky VigneshNo ratings yet

- Bhupesh Negi (OM Articles)Document6 pagesBhupesh Negi (OM Articles)Bhupesh NegiNo ratings yet

- ERP Unit-5Document7 pagesERP Unit-5hrishikingNo ratings yet

- Erp Impact On OrganizationsDocument83 pagesErp Impact On Organizationsrameshmba100% (7)

- R12 Finance Student GuideDocument479 pagesR12 Finance Student Guidemandeeppathak100% (3)

- Erp SystemDocument13 pagesErp Systemrayan alnoaimiNo ratings yet

- Enterprise Resource and Planning - ERPDocument20 pagesEnterprise Resource and Planning - ERPyogendra reddyNo ratings yet

- An Approach To ERP ImplementationDocument16 pagesAn Approach To ERP ImplementationAvijit RoyNo ratings yet

- ERP Enterprise Resource PlaningDocument17 pagesERP Enterprise Resource PlaningAlejandro David Lopez VegaNo ratings yet

- Module5 (ERP)Document20 pagesModule5 (ERP)Sahil SharmaNo ratings yet

- Enterprise Resource PlanningDocument10 pagesEnterprise Resource PlanningKeyur ChudasamaNo ratings yet

- Information System & Basics of ERP: Prof. Sourabh SharmaDocument44 pagesInformation System & Basics of ERP: Prof. Sourabh Sharmarajani mahapatraNo ratings yet

- Introduction To Enterprise Systems For Management (T2, Chapter 1)Document30 pagesIntroduction To Enterprise Systems For Management (T2, Chapter 1)flying_alexutzaNo ratings yet

- Advanced Business System: Chap 5Document23 pagesAdvanced Business System: Chap 5Smita BorkarNo ratings yet

- Enterprise Resource Planning & Material Requirement PlanningDocument5 pagesEnterprise Resource Planning & Material Requirement PlanningEnnavy YongkolNo ratings yet

- Backbone OF E BusinessDocument15 pagesBackbone OF E BusinessAdarsh NairNo ratings yet

- Final ItDocument25 pagesFinal ItYatin MalhotraNo ratings yet

- Enterprise Resource Planning (ERP) : Presented By: Makansingh ChauhanDocument28 pagesEnterprise Resource Planning (ERP) : Presented By: Makansingh ChauhanGuru Darshan0% (1)

- Enterprise Resource Planning - ERP: Presented byDocument32 pagesEnterprise Resource Planning - ERP: Presented byMohit VatsNo ratings yet

- Erp 1Document39 pagesErp 1Samson GoaNo ratings yet

- Enterprise Resource Planning: Presented By:-Gurnoor Kaur (BFT/18/620) Snigdha Das (BFT/18/616)Document34 pagesEnterprise Resource Planning: Presented By:-Gurnoor Kaur (BFT/18/620) Snigdha Das (BFT/18/616)GURNOOR KAURNo ratings yet

- Chapter 1 - 2 WeeksDocument50 pagesChapter 1 - 2 WeeksNhư VũNo ratings yet

- Brief Analysis of Implementation of ErpDocument15 pagesBrief Analysis of Implementation of ErpYash Saxena KhiladiNo ratings yet

- Electronic Business Systems: Mcgraw-Hill/Irwin ©2008, The Mcgraw-Hill Companies, All Rights ReservedDocument69 pagesElectronic Business Systems: Mcgraw-Hill/Irwin ©2008, The Mcgraw-Hill Companies, All Rights ReservedOvesh ShethNo ratings yet

- VishalDocument8 pagesVishalVishal SharmaNo ratings yet

- Cross AllDocument66 pagesCross Allharshm_7No ratings yet

- ERP ConceptsDocument27 pagesERP ConceptsLaxmi Pai100% (1)

- ERPDocument62 pagesERPMukul DashaputreNo ratings yet

- Name: Roll No: Department: Section:: Madhusmita Mishra 1006247081 M.B.A (First Year) "B"Document17 pagesName: Roll No: Department: Section:: Madhusmita Mishra 1006247081 M.B.A (First Year) "B"Vivek KumarNo ratings yet

- Assignment NO4 OF ERPDocument9 pagesAssignment NO4 OF ERPAnkur SinghNo ratings yet

- ERP Case StudyDocument36 pagesERP Case StudyGaurav RanjanNo ratings yet

- Describe Any Five Enterprise Resource Planning Functionality or Modules in Software SystemsDocument16 pagesDescribe Any Five Enterprise Resource Planning Functionality or Modules in Software Systemslydia nsengaNo ratings yet

- ERPDocument49 pagesERPDeep MalaniNo ratings yet

- Chase - Shankar - JacobsDocument25 pagesChase - Shankar - JacobsSirsha PattanayakNo ratings yet

- Enterprise Resource Planning As A Business Solution (ERP) : Prepared By: Ibrahim M. EltahhanDocument24 pagesEnterprise Resource Planning As A Business Solution (ERP) : Prepared By: Ibrahim M. Eltahhan诺兰100% (1)

- Chapter 08 ERPDocument20 pagesChapter 08 ERPrazi haiderNo ratings yet

- Basic Introduction About SAP ERP ECC and FICODocument12 pagesBasic Introduction About SAP ERP ECC and FICOsurnis4onkarNo ratings yet

- Erp DiscussionDocument7 pagesErp DiscussionjumuelcNo ratings yet

- Enterprise Resource PlanningDocument12 pagesEnterprise Resource PlanningchristainoNo ratings yet

- Production Planning & Control: AssignmentDocument6 pagesProduction Planning & Control: AssignmenttalhaNo ratings yet

- Module - 5 - MIS - CSIT204Document10 pagesModule - 5 - MIS - CSIT204aakash sharmaNo ratings yet

- Mod 5 - MIS - CSIT204Document10 pagesMod 5 - MIS - CSIT204Shar MohdNo ratings yet

- ERP Complete Digital NotesDocument58 pagesERP Complete Digital NotesVishal Prasad.No ratings yet

- Edited - Module 1 - ERPDocument29 pagesEdited - Module 1 - ERPHazel SerranoNo ratings yet

- Chap 01Document57 pagesChap 01احمد نصار100% (1)

- SCM & ErpDocument31 pagesSCM & ErpVrinda MadhuNo ratings yet

- Ict PPT April 05 2024Document13 pagesIct PPT April 05 2024rumelrashid_seuNo ratings yet

- Ilovepdf MergedDocument212 pagesIlovepdf MergedsukeshNo ratings yet

- What Is An ERP System?: Prepare By: Dr. Usman Tariq 17 January 2020Document31 pagesWhat Is An ERP System?: Prepare By: Dr. Usman Tariq 17 January 2020Faisal AlharbiNo ratings yet

- MGSC 300 Week 10.2: Welcome To Management Information Systems!Document20 pagesMGSC 300 Week 10.2: Welcome To Management Information Systems!AnkitGoyalNo ratings yet

- SZABIST SCM Unit 6 - ERPDocument52 pagesSZABIST SCM Unit 6 - ERPRehan RashidNo ratings yet

- Enterprise Resource PlanningDocument12 pagesEnterprise Resource Planningapi-37457400% (1)

- Assignment 1 ErpDocument10 pagesAssignment 1 ErpAditya Dev100% (1)

- Introduction To ERPDocument61 pagesIntroduction To ERPRaghavendra RaoNo ratings yet

- ERPDocument33 pagesERPLovepreetSidhuNo ratings yet

- Summary of Nicole Forsgren PhD, Jez Humble & Gene Kim's AccelerateFrom EverandSummary of Nicole Forsgren PhD, Jez Humble & Gene Kim's AccelerateNo ratings yet

- Sustainable Cocoa Production Program (SCPP) : Case StudyDocument19 pagesSustainable Cocoa Production Program (SCPP) : Case StudyfrendystpNo ratings yet

- Company Analysis: Printage MediaDocument25 pagesCompany Analysis: Printage MediaizadNo ratings yet

- Goldensource Intellectual Property Assignment, Non-Compete, Non-Disclosure and Non-Solicitation AgreementDocument6 pagesGoldensource Intellectual Property Assignment, Non-Compete, Non-Disclosure and Non-Solicitation AgreementKeyur SakhareNo ratings yet

- FAR2 Assignment EID MUBARAKDocument6 pagesFAR2 Assignment EID MUBARAKAli nawazNo ratings yet

- Ash - MBA 500 Spring 2023 Course Exam - docx-edit-CWDocument10 pagesAsh - MBA 500 Spring 2023 Course Exam - docx-edit-CWChandra AShNo ratings yet

- Human Resource Management - Key Challenges For 21st CenturyDocument3 pagesHuman Resource Management - Key Challenges For 21st Centuryarcherselevators50% (2)

- PLO 1a: Our Graduates Will Be Able To Identify The Business Problem in A Given SituationDocument4 pagesPLO 1a: Our Graduates Will Be Able To Identify The Business Problem in A Given SituationMEENA J RCBSNo ratings yet

- Exercise Getting Started v1 0Document3 pagesExercise Getting Started v1 0AnandNo ratings yet

- AMA CafeDocument15 pagesAMA CafemilindNo ratings yet

- GES004Document24 pagesGES004nas_mech8208No ratings yet

- Micro and MacroDocument12 pagesMicro and Macro777priyankaNo ratings yet

- Materials Management ManualDocument346 pagesMaterials Management ManualAddis NurhussienNo ratings yet

- 04 Accounting For Service BusinessDocument37 pages04 Accounting For Service Businesscarlo bundalian100% (1)

- ExamDocument5 pagesExamMikee CimafrancaNo ratings yet

- Report Sample-Supplier Factory AuditDocument24 pagesReport Sample-Supplier Factory AuditCarlosSánchezNo ratings yet

- 05 AC212 Lecture 5-Marginal Costing and Absorption Costing PDFDocument22 pages05 AC212 Lecture 5-Marginal Costing and Absorption Costing PDFsengpisalNo ratings yet

- Project Innovation Egg FingersDocument11 pagesProject Innovation Egg FingersPpatrick Pingol CNo ratings yet

- Journal of The Asia Pacific Economy: Psychographic Segmentation of Indian Urban ConsumersDocument24 pagesJournal of The Asia Pacific Economy: Psychographic Segmentation of Indian Urban ConsumersNhi Nguyễn Lê ĐôngNo ratings yet

- Chapter 3Document38 pagesChapter 3shera samyNo ratings yet

- Offer Letter 27-Dec-2019 PDFDocument25 pagesOffer Letter 27-Dec-2019 PDFIonutz AsafteiNo ratings yet

- Business Plan 12 HarveyDocument11 pagesBusiness Plan 12 HarveyKhrystelle BarrionNo ratings yet

- Comparison and Selection Among Alternatives: Lecture Week (Chapter) 6Document30 pagesComparison and Selection Among Alternatives: Lecture Week (Chapter) 6deevik thiranNo ratings yet

- Risk Based-Opportunity Assurance Plan - Rev 1 Pearl VEO-1Document8 pagesRisk Based-Opportunity Assurance Plan - Rev 1 Pearl VEO-1odunze1100% (2)

- Inventory Management at HeritageDocument99 pagesInventory Management at Heritagemanagement commerce projectsNo ratings yet

- 0 +RFQ+ (ACU+Maintenance) + (Edited) Alm Abc+edit+docx+ (SGD)Document5 pages0 +RFQ+ (ACU+Maintenance) + (Edited) Alm Abc+edit+docx+ (SGD)ŔingoStarr Echavez OrilloNo ratings yet

- Long Term Growth Fund Fact SheetDocument2 pagesLong Term Growth Fund Fact SheetmaxamsterNo ratings yet

- Papers by C K PrahladDocument2 pagesPapers by C K PrahladSabyasachi SinhaNo ratings yet

- Harry Potter Case Study PDFDocument41 pagesHarry Potter Case Study PDFADNAN FAROOQNo ratings yet

Chap017 - The Internet of Things and ERP

Chap017 - The Internet of Things and ERP

Uploaded by

murat kahraman0 ratings0% found this document useful (0 votes)

55 views18 pagesThe Internet of Things and ERP

Original Title

Chap017_The Internet of Things and ERP

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe Internet of Things and ERP

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

55 views18 pagesChap017 - The Internet of Things and ERP

Chap017 - The Internet of Things and ERP

Uploaded by

murat kahramanThe Internet of Things and ERP

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 18

CHAPTER 17: THE INTERNET OF

THINGS AND ERP

LO17-1: Understand what an enterprise resource planning

(ERP) system is.

LO17-2: Explain how ERP integrates business units through

information sharing.

LO17-3: Illustrate how supply chain planning and control fits

within ERP.

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-1

or distribution without the prior written consent of McGraw-Hill Education.

ERP in the Cloud

• Internet of things (IoT) and ERP

• Computers, cell phone and iPad etc. all in sync all the time!

• You can be aware of your partner’s location at any time

• Talk to your dog

• Adjust your thermostat

• Check on your child in school

• Just to name a few

• Imagine at work

• Ability to check multiple things

• Progress of contracts

• Forecast demand for a new product launched recently etc.

• IoT with ERP can deliver on these and more..

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-2

or distribution without the prior written consent of McGraw-Hill Education.

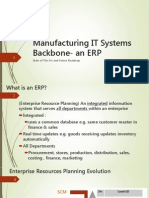

What is ERP?

• Managers

• ERP is a comprehensive software approach to support decisions

concurrent with planning and controlling the business

• IT Community

• ERP is a term describing a software system that integrates

application programs in finance, manufacturing, logistics, sales and

marketing, human resources, and other functions in a firm

• Accomplished through a database shared by all the functions and

data-processing applications

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-3

or distribution without the prior written consent of McGraw-Hill Education.

ERP

• ERP requires consistent numbers across all applications

• There are four aspects of ERP software that determine the

quality of an ERP system

1. The software should be multifunctional in scope

2. The software should be integrated

3. The software needs to be modular in structure

4. The software must facilitate basic planning and control activities

• Transaction processing: the posting and tracking of the

activities that document the business

• Efficient handling of the transactions as goods move through each step

of the process is the primary goal of an ERP system

• Decision support: the system helps the user make intelligent

judgments about how to run the business

• This is a second objective of an ERP system

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-4

or distribution without the prior written consent of McGraw-Hill Education.

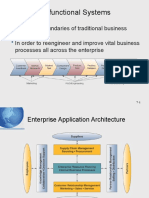

How ERP Connects the Functional Units

• A typical ERP system is made up of functionally oriented

and tightly integrated modules

• All the modules of the system use a common database

that is updated in real time

• ERP vendors are constantly looking for ways to improve

the functionality of their software, so new features are

often added

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-5

or distribution without the prior written consent of McGraw-Hill Education.

The Scope of ERP Applications

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-6

Exhibit 17.2 or distribution without the prior written consent of McGraw-Hill Education.

Typical ERP Modules

• Finance

• Automatic capture of basic accounting transactions at the source

• Manufacturing and Logistics

• Largest and most complex of the module categories

• Typical components include:

• Sales and operations planning

• Materials management

• Plant maintenance

• Quality management

• Production planning and control

• Project management

• Sales and Marketing

• Customer and sales management, forecasting, and so on

• Human Resources

• Supports the need to manage, schedule, pay, hire, and train people

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-7

or distribution without the prior written consent of McGraw-Hill Education.

Customized Software

• In addition to the standard application modules, many

companies utilize special add-on modules

• These link to the standard modules

• They tailor applications to specific needs

• These modules may be tailored to specific industries

• They may also provide special decision support functions

• Even with standard ERP packages, additional software

will usually be required

• Each company has a unique mix of products and services

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-8

or distribution without the prior written consent of McGraw-Hill Education.

Data Integration

• ERP works from a single database

• Transactions are processed in real time

• Data entered by one functional area updates all other

functional areas and the data are processed in real time

• Eliminates reposting of data (errors)

• Ensures a common vision instantly displayed

• Data warehouse: a special program that is designed to

automatically archive and process data for uses that are

outside the basic ERP system applications

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-9

or distribution without the prior written consent of McGraw-Hill Education.

How Supply Chain Planning and Control Fits Within

ERP

• ERP is concerned with all aspects of a supply chain

• Managing materials

• Scheduling machines and people

• Coordinating suppliers and key customers

• The coordination required for success runs across all

functional units in the firm

• An ERP system is designed to provide the information and decision

support needed to coordinate this

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-10

or distribution without the prior written consent of McGraw-Hill Education.

SAP Supply Chain Management

• SAP divides its supply chain software into four main

functions

1. Supply chain planning

2. Supply chain execution

3. Supply chain collaboration

4. Supply chain coordination

• Supply chain design module provides a centralized

overview of the entire supply chain and key performance

indicators

• Collaborative demand and supply planning helps match

demand to supply

• Materials management shares inventory and procurement

order information

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-11

or distribution without the prior written consent of McGraw-Hill Education.

SAP Supply Chain Management Continued

• Collaborative manufacturing shares information with

partners

• Collaborative fulfillment supports partnerships that can

intelligently commit to delivery dates in real time

• The inventory collaboration hub uses the Internet to gain

visibility to suppliers and manage the replenishment

process

• Collaborative replenishment planning allows

manufacturers to collaborate with their strategic retail

customers

• Vendor managed inventory (VMI) enables vendor-driven

inventory replenishment

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-12

or distribution without the prior written consent of McGraw-Hill Education.

SAP Supply Chain Management Concluded

• Enterprise portal gives users personalized access to a

range of information, applications, and services supported

by the system

• Mobile supply chain management allows people to plan,

execute, and monitor activity using mobile and remote

devices

• Supply chain event management monitors the execution

of supply chain events

• Supply chain performance management allows the firm to

monitor key performance indicators

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-13

or distribution without the prior written consent of McGraw-Hill Education.

Performance Metrics to Evaluate Integrated System

Effectiveness

• An ERP system can provide the data needed for a comprehensive set

of performance measures

• This allows the firm to evaluate strategic alignment of the various functions

with the firm’s strategy

• Three major functional areas make up the internal supply chain of a

manufacturing enterprise

1. Purchasing

2. Manufacturing

3. Sales and distribution

• Tight cooperation is required between these three functions for

effective manufacturing planning and control

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-14

Exhibit 17.2 or distribution without the prior written consent of McGraw-Hill Education.

The “Functional Silo” Approach

• Purchasing

• Responsible for buying all material to support manufacturing

operations

• Wishes to know what quantities are going to be needed over the

long term

• Solicits bids for the best price for each material

• The main criterion is simply the cost of the material

• Manufacturing

• Making the product at the lowest possible cost is classic metric

• Long production runs lead to lower unit costs and high inventories

• Distribution

• Job is moving product from the manufacturing site to the customer

at lowest possible cost

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-15

or distribution without the prior written consent of McGraw-Hill Education.

Implications if all Three Areas are Allowed to Work

Independently

• Purchasing will buy the largest quantities possible

• This results in large amounts of raw material inventory

• Manufacturing group desires to maximize production volumes

• Spread the fixed costs of production over as many units as possible

• Results in high WIP

• Time between batches increases

• Response time to unexpected demand increases

• Distribution will try to fully load every truck

• Minimize transportation cost

• Result in larges amount of inventory in distribution centers

• Sales group might sell product that cannot possibly be delivered

on time

• A more coordinated approach is facilitated by the use of an ERP

system

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-16

or distribution without the prior written consent of McGraw-Hill Education.

Summary

• ERP is a comprehensive software system that integrates

data from all functional areas of a business

• Benefits gained are better processes, information accuracy, and

responsiveness through the real-time information provided by the

system

• Typical ERP systems have application modules in finance,

manufacturing and logistics, sales and marketing, and

human resources

• The software modules connect to a common database that is

updated in real time

• Applications for supply chain activities are all included

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-17

or distribution without the prior written consent of McGraw-Hill Education.

Practice Exam

1. A computer system that links all areas of a company using

an integrated set of application programs and a common

database

2. The application programs are designed in accordance with

industry norms or _____

3. True/False: Implementing an ERP system is a simple

exercise that involves loading software on a computer

4. A term used for delivering ERP services on demand over the

Internet

5. The name of Microsoft’s ERP offering

6. Part of an ERP system that manages the activities within a

certain functional area

7. A set of processes to enable vendor-driven replenishment

Copyright ©2021 McGraw-Hill Education. All rights reserved. No reproduction 17-18

or distribution without the prior written consent of McGraw-Hill Education.

You might also like

- Integrated Marketing Communication: Tata Gluco Plus: Building The Brand IdentityDocument10 pagesIntegrated Marketing Communication: Tata Gluco Plus: Building The Brand Identityeira k67% (3)

- Mont Blanc - FinalDocument39 pagesMont Blanc - FinalSagar Shrikant Jalui20% (5)

- CRM Program Using Oracle EBS - Student GuideDocument589 pagesCRM Program Using Oracle EBS - Student GuideShakti NaiduNo ratings yet

- Erp 01Document38 pagesErp 01parkcasperkingNo ratings yet

- ERP Unit 12 Benefits of ERPDocument14 pagesERP Unit 12 Benefits of ERPAnonymous bTh744z7E60% (1)

- Enterprise Resource Planning (Erp) in Inventory ManagementDocument36 pagesEnterprise Resource Planning (Erp) in Inventory ManagementVicky VigneshNo ratings yet

- Bhupesh Negi (OM Articles)Document6 pagesBhupesh Negi (OM Articles)Bhupesh NegiNo ratings yet

- ERP Unit-5Document7 pagesERP Unit-5hrishikingNo ratings yet

- Erp Impact On OrganizationsDocument83 pagesErp Impact On Organizationsrameshmba100% (7)

- R12 Finance Student GuideDocument479 pagesR12 Finance Student Guidemandeeppathak100% (3)

- Erp SystemDocument13 pagesErp Systemrayan alnoaimiNo ratings yet

- Enterprise Resource and Planning - ERPDocument20 pagesEnterprise Resource and Planning - ERPyogendra reddyNo ratings yet

- An Approach To ERP ImplementationDocument16 pagesAn Approach To ERP ImplementationAvijit RoyNo ratings yet

- ERP Enterprise Resource PlaningDocument17 pagesERP Enterprise Resource PlaningAlejandro David Lopez VegaNo ratings yet

- Module5 (ERP)Document20 pagesModule5 (ERP)Sahil SharmaNo ratings yet

- Enterprise Resource PlanningDocument10 pagesEnterprise Resource PlanningKeyur ChudasamaNo ratings yet

- Information System & Basics of ERP: Prof. Sourabh SharmaDocument44 pagesInformation System & Basics of ERP: Prof. Sourabh Sharmarajani mahapatraNo ratings yet

- Introduction To Enterprise Systems For Management (T2, Chapter 1)Document30 pagesIntroduction To Enterprise Systems For Management (T2, Chapter 1)flying_alexutzaNo ratings yet

- Advanced Business System: Chap 5Document23 pagesAdvanced Business System: Chap 5Smita BorkarNo ratings yet

- Enterprise Resource Planning & Material Requirement PlanningDocument5 pagesEnterprise Resource Planning & Material Requirement PlanningEnnavy YongkolNo ratings yet

- Backbone OF E BusinessDocument15 pagesBackbone OF E BusinessAdarsh NairNo ratings yet

- Final ItDocument25 pagesFinal ItYatin MalhotraNo ratings yet

- Enterprise Resource Planning (ERP) : Presented By: Makansingh ChauhanDocument28 pagesEnterprise Resource Planning (ERP) : Presented By: Makansingh ChauhanGuru Darshan0% (1)

- Enterprise Resource Planning - ERP: Presented byDocument32 pagesEnterprise Resource Planning - ERP: Presented byMohit VatsNo ratings yet

- Erp 1Document39 pagesErp 1Samson GoaNo ratings yet

- Enterprise Resource Planning: Presented By:-Gurnoor Kaur (BFT/18/620) Snigdha Das (BFT/18/616)Document34 pagesEnterprise Resource Planning: Presented By:-Gurnoor Kaur (BFT/18/620) Snigdha Das (BFT/18/616)GURNOOR KAURNo ratings yet

- Chapter 1 - 2 WeeksDocument50 pagesChapter 1 - 2 WeeksNhư VũNo ratings yet

- Brief Analysis of Implementation of ErpDocument15 pagesBrief Analysis of Implementation of ErpYash Saxena KhiladiNo ratings yet

- Electronic Business Systems: Mcgraw-Hill/Irwin ©2008, The Mcgraw-Hill Companies, All Rights ReservedDocument69 pagesElectronic Business Systems: Mcgraw-Hill/Irwin ©2008, The Mcgraw-Hill Companies, All Rights ReservedOvesh ShethNo ratings yet

- VishalDocument8 pagesVishalVishal SharmaNo ratings yet

- Cross AllDocument66 pagesCross Allharshm_7No ratings yet

- ERP ConceptsDocument27 pagesERP ConceptsLaxmi Pai100% (1)

- ERPDocument62 pagesERPMukul DashaputreNo ratings yet

- Name: Roll No: Department: Section:: Madhusmita Mishra 1006247081 M.B.A (First Year) "B"Document17 pagesName: Roll No: Department: Section:: Madhusmita Mishra 1006247081 M.B.A (First Year) "B"Vivek KumarNo ratings yet

- Assignment NO4 OF ERPDocument9 pagesAssignment NO4 OF ERPAnkur SinghNo ratings yet

- ERP Case StudyDocument36 pagesERP Case StudyGaurav RanjanNo ratings yet

- Describe Any Five Enterprise Resource Planning Functionality or Modules in Software SystemsDocument16 pagesDescribe Any Five Enterprise Resource Planning Functionality or Modules in Software Systemslydia nsengaNo ratings yet

- ERPDocument49 pagesERPDeep MalaniNo ratings yet

- Chase - Shankar - JacobsDocument25 pagesChase - Shankar - JacobsSirsha PattanayakNo ratings yet

- Enterprise Resource Planning As A Business Solution (ERP) : Prepared By: Ibrahim M. EltahhanDocument24 pagesEnterprise Resource Planning As A Business Solution (ERP) : Prepared By: Ibrahim M. Eltahhan诺兰100% (1)

- Chapter 08 ERPDocument20 pagesChapter 08 ERPrazi haiderNo ratings yet

- Basic Introduction About SAP ERP ECC and FICODocument12 pagesBasic Introduction About SAP ERP ECC and FICOsurnis4onkarNo ratings yet

- Erp DiscussionDocument7 pagesErp DiscussionjumuelcNo ratings yet

- Enterprise Resource PlanningDocument12 pagesEnterprise Resource PlanningchristainoNo ratings yet

- Production Planning & Control: AssignmentDocument6 pagesProduction Planning & Control: AssignmenttalhaNo ratings yet

- Module - 5 - MIS - CSIT204Document10 pagesModule - 5 - MIS - CSIT204aakash sharmaNo ratings yet

- Mod 5 - MIS - CSIT204Document10 pagesMod 5 - MIS - CSIT204Shar MohdNo ratings yet

- ERP Complete Digital NotesDocument58 pagesERP Complete Digital NotesVishal Prasad.No ratings yet

- Edited - Module 1 - ERPDocument29 pagesEdited - Module 1 - ERPHazel SerranoNo ratings yet

- Chap 01Document57 pagesChap 01احمد نصار100% (1)

- SCM & ErpDocument31 pagesSCM & ErpVrinda MadhuNo ratings yet

- Ict PPT April 05 2024Document13 pagesIct PPT April 05 2024rumelrashid_seuNo ratings yet

- Ilovepdf MergedDocument212 pagesIlovepdf MergedsukeshNo ratings yet

- What Is An ERP System?: Prepare By: Dr. Usman Tariq 17 January 2020Document31 pagesWhat Is An ERP System?: Prepare By: Dr. Usman Tariq 17 January 2020Faisal AlharbiNo ratings yet

- MGSC 300 Week 10.2: Welcome To Management Information Systems!Document20 pagesMGSC 300 Week 10.2: Welcome To Management Information Systems!AnkitGoyalNo ratings yet

- SZABIST SCM Unit 6 - ERPDocument52 pagesSZABIST SCM Unit 6 - ERPRehan RashidNo ratings yet

- Enterprise Resource PlanningDocument12 pagesEnterprise Resource Planningapi-37457400% (1)

- Assignment 1 ErpDocument10 pagesAssignment 1 ErpAditya Dev100% (1)

- Introduction To ERPDocument61 pagesIntroduction To ERPRaghavendra RaoNo ratings yet

- ERPDocument33 pagesERPLovepreetSidhuNo ratings yet

- Summary of Nicole Forsgren PhD, Jez Humble & Gene Kim's AccelerateFrom EverandSummary of Nicole Forsgren PhD, Jez Humble & Gene Kim's AccelerateNo ratings yet

- Sustainable Cocoa Production Program (SCPP) : Case StudyDocument19 pagesSustainable Cocoa Production Program (SCPP) : Case StudyfrendystpNo ratings yet

- Company Analysis: Printage MediaDocument25 pagesCompany Analysis: Printage MediaizadNo ratings yet

- Goldensource Intellectual Property Assignment, Non-Compete, Non-Disclosure and Non-Solicitation AgreementDocument6 pagesGoldensource Intellectual Property Assignment, Non-Compete, Non-Disclosure and Non-Solicitation AgreementKeyur SakhareNo ratings yet

- FAR2 Assignment EID MUBARAKDocument6 pagesFAR2 Assignment EID MUBARAKAli nawazNo ratings yet

- Ash - MBA 500 Spring 2023 Course Exam - docx-edit-CWDocument10 pagesAsh - MBA 500 Spring 2023 Course Exam - docx-edit-CWChandra AShNo ratings yet

- Human Resource Management - Key Challenges For 21st CenturyDocument3 pagesHuman Resource Management - Key Challenges For 21st Centuryarcherselevators50% (2)

- PLO 1a: Our Graduates Will Be Able To Identify The Business Problem in A Given SituationDocument4 pagesPLO 1a: Our Graduates Will Be Able To Identify The Business Problem in A Given SituationMEENA J RCBSNo ratings yet

- Exercise Getting Started v1 0Document3 pagesExercise Getting Started v1 0AnandNo ratings yet

- AMA CafeDocument15 pagesAMA CafemilindNo ratings yet

- GES004Document24 pagesGES004nas_mech8208No ratings yet

- Micro and MacroDocument12 pagesMicro and Macro777priyankaNo ratings yet

- Materials Management ManualDocument346 pagesMaterials Management ManualAddis NurhussienNo ratings yet

- 04 Accounting For Service BusinessDocument37 pages04 Accounting For Service Businesscarlo bundalian100% (1)

- ExamDocument5 pagesExamMikee CimafrancaNo ratings yet

- Report Sample-Supplier Factory AuditDocument24 pagesReport Sample-Supplier Factory AuditCarlosSánchezNo ratings yet

- 05 AC212 Lecture 5-Marginal Costing and Absorption Costing PDFDocument22 pages05 AC212 Lecture 5-Marginal Costing and Absorption Costing PDFsengpisalNo ratings yet

- Project Innovation Egg FingersDocument11 pagesProject Innovation Egg FingersPpatrick Pingol CNo ratings yet

- Journal of The Asia Pacific Economy: Psychographic Segmentation of Indian Urban ConsumersDocument24 pagesJournal of The Asia Pacific Economy: Psychographic Segmentation of Indian Urban ConsumersNhi Nguyễn Lê ĐôngNo ratings yet

- Chapter 3Document38 pagesChapter 3shera samyNo ratings yet

- Offer Letter 27-Dec-2019 PDFDocument25 pagesOffer Letter 27-Dec-2019 PDFIonutz AsafteiNo ratings yet

- Business Plan 12 HarveyDocument11 pagesBusiness Plan 12 HarveyKhrystelle BarrionNo ratings yet

- Comparison and Selection Among Alternatives: Lecture Week (Chapter) 6Document30 pagesComparison and Selection Among Alternatives: Lecture Week (Chapter) 6deevik thiranNo ratings yet

- Risk Based-Opportunity Assurance Plan - Rev 1 Pearl VEO-1Document8 pagesRisk Based-Opportunity Assurance Plan - Rev 1 Pearl VEO-1odunze1100% (2)

- Inventory Management at HeritageDocument99 pagesInventory Management at Heritagemanagement commerce projectsNo ratings yet

- 0 +RFQ+ (ACU+Maintenance) + (Edited) Alm Abc+edit+docx+ (SGD)Document5 pages0 +RFQ+ (ACU+Maintenance) + (Edited) Alm Abc+edit+docx+ (SGD)ŔingoStarr Echavez OrilloNo ratings yet

- Long Term Growth Fund Fact SheetDocument2 pagesLong Term Growth Fund Fact SheetmaxamsterNo ratings yet

- Papers by C K PrahladDocument2 pagesPapers by C K PrahladSabyasachi SinhaNo ratings yet

- Harry Potter Case Study PDFDocument41 pagesHarry Potter Case Study PDFADNAN FAROOQNo ratings yet