Professional Documents

Culture Documents

7232S1TKCE60632018 - Simulasi Proses - Pertemuan 10 - Materi Tambahan

7232S1TKCE60632018 - Simulasi Proses - Pertemuan 10 - Materi Tambahan

Uploaded by

amelia mardhotillah0 ratings0% found this document useful (0 votes)

12 views17 pagesCopyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

12 views17 pages7232S1TKCE60632018 - Simulasi Proses - Pertemuan 10 - Materi Tambahan

7232S1TKCE60632018 - Simulasi Proses - Pertemuan 10 - Materi Tambahan

Uploaded by

amelia mardhotillahCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 17

Distilasi

• Dibenzo(a.h)anthracene is a polycyclic aromatic

hydrocarbon (PAH) compound with the structural formula

shown below.

• Estimate its properties based on its structural formula

deisobuthanizer

• Cairan hidrocabon yang dihasilkan dari NGL

(natural gas liquid) dipisahkan kedalam ,

propane (C3), Isobuthane (CH4), normal

buthane (nC4) dan produk gasoline ( C5+ ).

Tahapan pertama yaitu memisahkan terlebih

dahulu antara isobutane dengan normal

buthane. Seperti gambar dibawah ini

0.001 gasoline (C5+)

Proses deethanizer

• Aliran gas dari proses demethanizer dialirkan ke

dalam distilator yang bertujuan untuk

menghilangkan kandungan ethane dalam gas. Gas

umpan meiliki komposisi seperti dalam tabel

dengan tekanan 2790 kpa dan temperatur 19.97 C.

Tekanan pada boiler sebesar 2792 kpa, pada

condenser sebesar 2725 kpa dengan presure drop

pada boiler sebesar 35 kpa. Hitung jumlah stage

minimum dan sebenarnya, reflux minimum dan

lokasi optimum umpan, serta diameter distilator,

SEPERATION STYRENE

• The organic phase (S21) contains around 70 mol% of styrene, 27.5 mol% of ethylbenzene, 2.2 mol%

of toluene, and minor amounts of benzene and other components. For modeling of the liquid–liquid

separator use a Three-Phase Separator. The flow of the vapor phase is zero in this case; therefore,

the vapor stream is hidden. As it results from the thermodynamic analysis of this mixture, its

separation to poor components is not very easy. Owing to low relative volatility of ethylbenzene to

styrene and toluene to ethylbenzene, a large number of theoretical stages can be expected and large

reflux ratios are required. For details on the specification of a distillation column in Aspen HYSYS,.

Use a partial condenser in the first distillation column. The number of theoretical stages can be set to

30, and the theoretical feed stage can be the 13th stage. Set both the condenser and the reboiler

pressure to 5 kPa (pressure drop in the column is not taken into account).As initial specifications of

the column, use the distillation rate that equals the molar flow of toluene in the feed stream (S21) and

the reflux ratio. After convergence of the column using initial specifications, define new

specifications: mole fraction of styrene and toluene in the bottom product of 0.999 and mole recovery

of styrene and ethylbenzene in the bottom product of 0.999. With these specifications, the reflux ratio

reaches values of around 17; however, the distillation rate is only around 1 kmol⋅h−1 so the reflux

flow rate is not very high. Separation of the styrene–ethylbenzene mixture is simulated in two

columns. In the first column, 80 mol% of styrene with the purity of 99.9% is recovered. To achieve

these requirements, a column with 60 theoretical stages and a reflux ratio of 7 has to be used. The

column pressure is 5 kPa. The second column with 40 theoretical stages and a reflux ratio of 6.8.

provides styrene recovery of 99.5 and purity of 99.9 mol%. Total styrene recoveryis 99.1%, and its

purity is 99.9%. If requirement for purity of styrene is decreased to 99 mol%, the value of reflux ratio

decreases to 4.1. The ethylbenzene stream is pumped back to the reactor.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Safavid Ceramics and Chinese InspirationDocument4 pagesSafavid Ceramics and Chinese InspirationGermanikNo ratings yet

- BS 57 (1951)Document23 pagesBS 57 (1951)dapsiduNo ratings yet

- Ebiz Steps PDFDocument59 pagesEbiz Steps PDFBathina Srinivasa RaoNo ratings yet

- Oracle Certified Professional Java Programmer (OCPJP 7) BookDocument38 pagesOracle Certified Professional Java Programmer (OCPJP 7) BookDhivya Ganesh100% (2)

- Building A Trading PlanDocument38 pagesBuilding A Trading Planamy100% (1)

- Chapter 6 Project ManagementDocument54 pagesChapter 6 Project ManagementSHAWN TAKAONANo ratings yet

- Lexico and GrammarDocument7 pagesLexico and Grammarphammaiphuong2k9No ratings yet

- GSM System Fundamental TrainingDocument144 pagesGSM System Fundamental Trainingmansonbazzokka100% (2)

- Home Assignment - JUNK BOND Subject: Corporate FinanceDocument3 pagesHome Assignment - JUNK BOND Subject: Corporate FinanceAsad Mazhar100% (1)

- PFW - Vol. 23, Issue 08 (August 18, 2008) Escape To New YorkDocument0 pagesPFW - Vol. 23, Issue 08 (August 18, 2008) Escape To New YorkskanzeniNo ratings yet

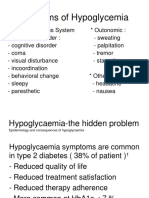

- Symptoms of HypoglycemiaDocument20 pagesSymptoms of Hypoglycemiakenny StefNo ratings yet

- Hellermann Tyton PDFDocument152 pagesHellermann Tyton PDFanon_34390801No ratings yet

- Experimental Investigation of Single Cylinder Diesel Engine Using Tyre Pyrolysis Oil (TPO) BlendsDocument6 pagesExperimental Investigation of Single Cylinder Diesel Engine Using Tyre Pyrolysis Oil (TPO) BlendsEditor IJRITCCNo ratings yet

- Indicator Development - SPICEDDocument1 pageIndicator Development - SPICEDRahman Surkhy100% (2)

- Full Send WhitepaperDocument12 pagesFull Send WhitepaperJoao VitorNo ratings yet

- CapacitorsDocument86 pagesCapacitorsarunNo ratings yet

- Mage Wars: Variant With No Dice: Basic RulesDocument8 pagesMage Wars: Variant With No Dice: Basic RulesMáté BoaNo ratings yet

- Smart Contracts: Functioning and Legal Enforceability in IndiaDocument14 pagesSmart Contracts: Functioning and Legal Enforceability in IndiaPrasanth Raju100% (1)

- Project WorkDocument6 pagesProject WorkNurbek YaxshimuratovNo ratings yet

- Primary School Planner Second Year of English: 11 - 20 WordsearchDocument0 pagesPrimary School Planner Second Year of English: 11 - 20 WordsearchJunaidi HamdiNo ratings yet

- A Generalization of Wilson's Theorem: R. Andrew Ohana June 3, 2009Document13 pagesA Generalization of Wilson's Theorem: R. Andrew Ohana June 3, 2009Ramón Darío CarrasqueroNo ratings yet

- The Silt Verses - Chapter 21 TranscriptDocument32 pagesThe Silt Verses - Chapter 21 TranscriptVictória MoraesNo ratings yet

- Assembly Language Lecture6Document10 pagesAssembly Language Lecture6bmas19692No ratings yet

- Pharmacology Notes: EliminationDocument14 pagesPharmacology Notes: EliminationHaifa ibrahimNo ratings yet

- Jurnal Anfar 2Document15 pagesJurnal Anfar 2Yulia YunaraNo ratings yet

- Case Study Emirates AirlinesDocument4 pagesCase Study Emirates Airlinesuzzmapk33% (9)

- 2020 Updated Resume FinalDocument2 pages2020 Updated Resume Finalapi-523816461No ratings yet

- BREAKDOWN TIMELINE - Rev1Document12 pagesBREAKDOWN TIMELINE - Rev1Dimas AndiNo ratings yet

- Strand A Ilp Lesson PlanDocument3 pagesStrand A Ilp Lesson PlanyoNo ratings yet