Professional Documents

Culture Documents

Motorised Jack

Motorised Jack

Uploaded by

67 Nikam kunal sanjay0 ratings0% found this document useful (0 votes)

76 views15 pagesThe document presents a plan for a motorized car jack project. It includes an introduction describing car jacks and the benefits of a motorized system. The main components are listed as a lead screw jack, 12V DC motor, gearbox, switching mechanism, and metal structure. The working involves a motor transmitting power via gears to rotate a power screw and lift the vehicle. Specifications include a 500kg lifting capacity and 300mm maximum lift. Applications are for lifting vehicles for maintenance. Advantages include fast, safe operation without human effort. Disadvantages include potential battery drain. The conclusion discusses modifying an existing jack with a motor and gears to create a reliable, automated lifting system powered by a car battery.

Original Description:

Original Title

Motorised Jack Ppt

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document presents a plan for a motorized car jack project. It includes an introduction describing car jacks and the benefits of a motorized system. The main components are listed as a lead screw jack, 12V DC motor, gearbox, switching mechanism, and metal structure. The working involves a motor transmitting power via gears to rotate a power screw and lift the vehicle. Specifications include a 500kg lifting capacity and 300mm maximum lift. Applications are for lifting vehicles for maintenance. Advantages include fast, safe operation without human effort. Disadvantages include potential battery drain. The conclusion discusses modifying an existing jack with a motor and gears to create a reliable, automated lifting system powered by a car battery.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

76 views15 pagesMotorised Jack

Motorised Jack

Uploaded by

67 Nikam kunal sanjayThe document presents a plan for a motorized car jack project. It includes an introduction describing car jacks and the benefits of a motorized system. The main components are listed as a lead screw jack, 12V DC motor, gearbox, switching mechanism, and metal structure. The working involves a motor transmitting power via gears to rotate a power screw and lift the vehicle. Specifications include a 500kg lifting capacity and 300mm maximum lift. Applications are for lifting vehicles for maintenance. Advantages include fast, safe operation without human effort. Disadvantages include potential battery drain. The conclusion discusses modifying an existing jack with a motor and gears to create a reliable, automated lifting system powered by a car battery.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 15

CAPSTONE PROJECT PLANNING

Presentation

MOTORISED CAR JACK

Presented By,

67. KUNAL NIKAM

35. AVINASH JAGTAP

109. RAHUL SABLE.

97. SURAJ TARDE

INTRODUCTION

Jack is a mechanical device used to lift heavy loads or

apply great forces. A mechanical jack employs a square

thread for lifting heavy equipment. The most common

form is a car jack, floor jack or garage jack which lifts

vehicles so that maintenance can be performed.

To reduce the risk of getting injury in the case of

malfunctioning of the device the motorized jacking

system enables operator to be at a safe distance during

the jacking process

A mechanical toggle jack is operated by rotation of

lead screw. In this case of a jack, a small force applied

in the horizontal plane is used to lift very large weight.

The compressive force of jackscrew is obtained through

the tension force applied by its lead screw.

COMPONENTS

Lead Screw jack= 2 ton.

High torque 12v dc motor.

Gearbox.

Switching mechanism.

Metal structure.

WORKING OF ELECTRIC JACK

The electric jack will lift a vehicle chassis in contact with the top

section in working condition, when the power screw is rotated through

its connecting gear with the pinion after electrical power applied to the

motor when plugged to the 12V battery in car. Motor transmits its

rotating power to the pinion gear meshing with the bigger gear

connected to the power screw to be rotated with required speed

reduction and increased torque to drive the power screw connected with

it. The power screw rotates within the threaded bore of side member in

the clockwise direction that will cause the links to be goes along the

threaded portion towards each other during load-lifting process and vice

versa. Initially the jack will first be placed below the vehicle to be lifted

such that at least a small clearance will exist between the top plate and

the vehicle chassis to be lifted. Then after power screw will be turned so

that the top section makes contact with the car chassis and the

clearance space will be eliminated. As contact is made with car, load of

car will be increasingly shifted to the top plate and cause forces to be

developed in and transmitted through links and side member of the

electric jack. The force transmitted through the side member will be

transferred on threads of screw of electric jack. By switching circuit

connected to the motor we can regulate the rising and lowering process

of car.

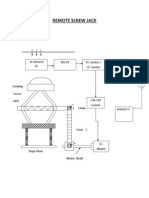

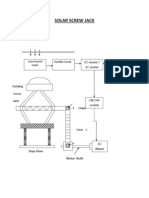

BLOCK DIAGRAM

METHODOLOGY

As per group discussion, we prepared

presentation and report of motorized car jack.

We purchase the required parts as per list.

Then we construct motorized jack according

to the design.

Test the all parts of jack.

Manufactured the required parts.

Done some welding, cutting, grinding & drilling

process to complete the work as per design.

Made all the electrical connection to run the

motor

GEARS

Gearing system-A gear is a rotating machine part having cut teeth which

mesh with another toothed part in order to transmit torque, in most cases

with teeth on the one gear being of identical shape, and often also with that

shape on the other gear. Two or more gears working in tandem are called a

transmission and can produce a mechanical advantage through a gear ratio

and thus may be considered a simple machine. Geared devices can change

the speed, torque, and direction of a power source. When two gears mesh,

and one gear is bigger than the other (even though the size of the teeth

must match), a mechanical advantage is produced, with the rotational

speeds and the torques of the two gears differing in an inverse relationship.

Electric motor-As we are going to use car Battery the motor used should

essentially be a 12V DC motor with sufficient torque to overcome the thread

friction and to raise the load.

A bidirectional DC motor circuit-We can build a DC motor circuit which is

capable of spinning forward and in reverse with the flip of a switch, so that

the motor can spin forwards or backwards when we want it to. To build a

bidirectional DC motor circuit, we need to use a switch, so that we can go

back and forth when we want between forward motion and reverse motion.

SPECIFICATIONS

It is having following specifications:-

Drive ; worm and worm gear

• Capacity : 500 Kg of concentrated load with concentrated centre of

gravity.

• Unit Weight ;-15 kg

• Maximum Lift ; 300 mm from the ground level.

• Minimum ground clearance required ; 150 mm from the ground.

APPLICATIONS

This equipment is mainly used for lifting an

vehicles for maintenance purpose.

Can be used to lift any object with in the

lifting capacity.

ADVANTAGES

Fast operation

No human efforts required

No risk to human as it is operated from safe

distance in case of slippage of jack.

Easy to operate no skilled person required.

Low operation cost.

DISADVANTAGES

Electrical supply of 12v is required from

vehicle battery which can drain the battery

of the vehicle.

CONCLUSION

The existing mechanical toggle jack was

modified by making small adjustment and

making use of an electric motor to drive power

screw, connecting gears with the pinion

mounted on the shaft of motor. The

automobile 12V battery source is used to

operate prime mover (motor), to shallow

weight lifting easier. The aspiration is to design

a car jack that is reliable, free from danger

and able to lift and lower the level, to design

and develop a car jack that is powered by car

battery is self and automated by button system

Thank You

You might also like

- Dynapac RelayDocument16 pagesDynapac RelayDaniel Cabral67% (6)

- Lab 1 Pneumatic FullDocument22 pagesLab 1 Pneumatic Fullbella100% (12)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- English S60 Operators Guide 6SE484 062906Document155 pagesEnglish S60 Operators Guide 6SE484 062906Massahiro FilhoNo ratings yet

- 15 PowerplantDocument26 pages15 PowerplantBlueSkyMaster100% (5)

- Car JackDocument8 pagesCar JackJamal Yusof0% (1)

- Automatic Side StandDocument23 pagesAutomatic Side StandShekhar Sawant0% (1)

- Chevelle Performance Projects: 1964-1972From EverandChevelle Performance Projects: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (2)

- Rov CourseDocument6 pagesRov CoursekasminahNo ratings yet

- Automatic Screw Jack Project ReportDocument12 pagesAutomatic Screw Jack Project ReportKaran Bansal67% (3)

- Solar Power Motorized Jack SynopsisDocument6 pagesSolar Power Motorized Jack SynopsisAnonymous j0aO95fgNo ratings yet

- Chapter 1Document27 pagesChapter 1chalaNo ratings yet

- Proposal On Design and Fabrication of Motorized Screw JackDocument9 pagesProposal On Design and Fabrication of Motorized Screw Jackcobra2919100% (2)

- DCP073 Fabrication of Bevel Gear Drive Screw JackDocument5 pagesDCP073 Fabrication of Bevel Gear Drive Screw JackANAND KRISHNAN100% (1)

- Bevel Gear Drive Screw Jack 6000Document5 pagesBevel Gear Drive Screw Jack 6000Elias YeshiwasNo ratings yet

- Project PPT Final - CerfDocument15 pagesProject PPT Final - CerfKailas DNo ratings yet

- Automated Car Jack - PDFDocument3 pagesAutomated Car Jack - PDFleena175No ratings yet

- Capstonproject Synopsis Presentation: Title: Hydro Power Electric Mechanical JackDocument6 pagesCapstonproject Synopsis Presentation: Title: Hydro Power Electric Mechanical JackHàrđik ĶharkhandiNo ratings yet

- Car JackDocument9 pagesCar Jackdeepak GuptaNo ratings yet

- Motorized Screw JackDocument19 pagesMotorized Screw JackPushpendra Kumar33% (3)

- Project PPT FinalDocument15 pagesProject PPT FinalKailas DNo ratings yet

- Irjet V8i3334Document3 pagesIrjet V8i3334Shahid AnwarNo ratings yet

- Chapter III - Electrical Power Generation Using Speed Breaker - Jefferson BeloDocument6 pagesChapter III - Electrical Power Generation Using Speed Breaker - Jefferson BeloJefferson BeloNo ratings yet

- Remote Controlled Screw Jack 2014 AcDocument58 pagesRemote Controlled Screw Jack 2014 AcChockalingam AthilingamNo ratings yet

- Design and Fabrication of Motorized Hydraulic JackDocument5 pagesDesign and Fabrication of Motorized Hydraulic JackAmar AglaveNo ratings yet

- Project PPT FinaldDocument15 pagesProject PPT FinaldKailas DNo ratings yet

- Solid Works Design & Simulation of Power Generating Speed BreakersDocument3 pagesSolid Works Design & Simulation of Power Generating Speed BreakersAVINASH BHUSARENo ratings yet

- Project WorkDocument15 pagesProject Workakif akifnaimNo ratings yet

- Button Operated Gear Changing System For Two WheelerDocument4 pagesButton Operated Gear Changing System For Two WheelerVikalp GuptaNo ratings yet

- Remote Screw JackDocument5 pagesRemote Screw JackJeevan Landge PatilNo ratings yet

- Solar Screw JackDocument6 pagesSolar Screw JackJeevan Landge PatilNo ratings yet

- Zigzag LifDocument4 pagesZigzag Lifvishnu kumarNo ratings yet

- Mec 28Document1 pageMec 28KoluNo ratings yet

- Instiute of Technology and Sciences, Rajampet (Autonomous) : AnnamacharyaDocument18 pagesInstiute of Technology and Sciences, Rajampet (Autonomous) : AnnamacharyaSushanth reddyNo ratings yet

- Double Acting Hacksaw Machine Using Scotch Yoke MechanismDocument32 pagesDouble Acting Hacksaw Machine Using Scotch Yoke Mechanismbalaji67% (12)

- Universal Power Automatic JackDocument4 pagesUniversal Power Automatic JackSenthilraj Sarangapani100% (1)

- Sand Ramming FullDocument15 pagesSand Ramming FullAlmubeenNo ratings yet

- Project: Design and Fabrication of Reverse Locking Mechanism For Heavy VehiclesDocument47 pagesProject: Design and Fabrication of Reverse Locking Mechanism For Heavy VehiclesarunNo ratings yet

- Electrical Loco Shed, Ghaziabad: Industrial TrainingDocument24 pagesElectrical Loco Shed, Ghaziabad: Industrial TrainingJoy ChakrabortyNo ratings yet

- Motorized Screw JackDocument19 pagesMotorized Screw JackmkkfakesNo ratings yet

- Design and Fabrication of Remote Controlled Scissor JackDocument19 pagesDesign and Fabrication of Remote Controlled Scissor Jackkalyanram33% (3)

- Push Button Operated Gear Shifting Mechanism For Two WheelerDocument19 pagesPush Button Operated Gear Shifting Mechanism For Two Wheelersabareesh91mechNo ratings yet

- Performance - Analysis - of - Motorized - Object AaaaaDocument14 pagesPerformance - Analysis - of - Motorized - Object Aaaaadagim zeynuNo ratings yet

- Design and Analysis of Center Jack For Cars: Related PapersDocument5 pagesDesign and Analysis of Center Jack For Cars: Related PapersUğur KoyunNo ratings yet

- AC Drives Lead The Technical Revolution of Electric ForkliftsDocument7 pagesAC Drives Lead The Technical Revolution of Electric ForkliftsahmadNo ratings yet

- Power Generation From Speed Breaker: by Nitesh RDocument16 pagesPower Generation From Speed Breaker: by Nitesh RSatish HSNo ratings yet

- Power Generation From Speed Breaker: by Nitesh RDocument16 pagesPower Generation From Speed Breaker: by Nitesh RSatish HSNo ratings yet

- Motorized Hydraulic JackDocument17 pagesMotorized Hydraulic JackAMBAR APTURKARNo ratings yet

- Automatic Screw JackDocument8 pagesAutomatic Screw JackShah0% (2)

- Industrialtraining 131119065512 Phpapp 02784896Document24 pagesIndustrialtraining 131119065512 Phpapp 02784896Deepak AsokanNo ratings yet

- Design and Fabrication of Electric Skating Cycle: AbstractDocument3 pagesDesign and Fabrication of Electric Skating Cycle: AbstractVickyNo ratings yet

- 12 Motorized Screw JackDocument5 pages12 Motorized Screw JackSaravanan ViswakarmaNo ratings yet

- Fabrication of Overhead CraneDocument45 pagesFabrication of Overhead CraneWORLD360No ratings yet

- Design and Fabrication of MotorisedDocument28 pagesDesign and Fabrication of Motorisedvickram jainNo ratings yet

- Design of Fabrication of Railway Track Power GenerationDocument5 pagesDesign of Fabrication of Railway Track Power GenerationVickyNo ratings yet

- Remote Controlled Motorized Hydraulic JackDocument72 pagesRemote Controlled Motorized Hydraulic JackSushil KumarNo ratings yet

- Supervised By: Dr. MD - Tazul Islam Profeesor, Department of Me Cuet Rahat Ahammed ID:1203030Document15 pagesSupervised By: Dr. MD - Tazul Islam Profeesor, Department of Me Cuet Rahat Ahammed ID:1203030Rahat AhammedNo ratings yet

- Design and Fabrication of Pneumatic Jack - 1604659939Document3 pagesDesign and Fabrication of Pneumatic Jack - 1604659939kavib8718No ratings yet

- Fabrication of Automatic Side Stand Braking Mechanism For Two WheelerDocument28 pagesFabrication of Automatic Side Stand Braking Mechanism For Two Wheelergnana muruganNo ratings yet

- Dil - Iii-1Document37 pagesDil - Iii-1Nikhil SreenivasanNo ratings yet

- DC MotorDocument3 pagesDC MotorShubham AgrawalNo ratings yet

- Welcome: Introducing Our ProjectDocument16 pagesWelcome: Introducing Our Projectpratik patilNo ratings yet

- Hydraulic JackDocument19 pagesHydraulic Jackaryan agrawalNo ratings yet

- Chapter 3Document24 pagesChapter 3Kapeel KumarNo ratings yet

- List MSDSDocument2 pagesList MSDSiffah nurfaizNo ratings yet

- Elmo Rletschle V-VC 202 User ManualDocument32 pagesElmo Rletschle V-VC 202 User ManualFirdhaus JaniNo ratings yet

- MCQ No - 4Document6 pagesMCQ No - 4satya prakashNo ratings yet

- The Kinematic Analysis of Ravigneaux Planetary Gear Set: ArticleDocument7 pagesThe Kinematic Analysis of Ravigneaux Planetary Gear Set: ArticleDia ZsilaNo ratings yet

- Fsaee Data Acquisition System: ECE 445 Senior DesignDocument27 pagesFsaee Data Acquisition System: ECE 445 Senior DesignMuhammad AnsarNo ratings yet

- Electric ENDocument23 pagesElectric ENBraulioNo ratings yet

- Module 4Document22 pagesModule 4Sushanth MNo ratings yet

- Volvo v70 Xc70 Xc90 2003 Wiring DiagramDocument20 pagesVolvo v70 Xc70 Xc90 2003 Wiring Diagramjoseph100% (62)

- User Manual of 5axis Breakout Board: SavebaseDocument12 pagesUser Manual of 5axis Breakout Board: SavebaseAbdennour MenkouchaNo ratings yet

- Instalacion 4100ESDocument262 pagesInstalacion 4100ESRaviNo ratings yet

- The Mesh Type Earthing Design of 66Kv Tatosan Substation: D 5MTRDocument1 pageThe Mesh Type Earthing Design of 66Kv Tatosan Substation: D 5MTRzaheeruddin_mohdNo ratings yet

- Slew BearingDocument1 pageSlew BearingRTG Mechanical EnggNo ratings yet

- Drawing RecordDocument24 pagesDrawing RecordKumud RanjanNo ratings yet

- Midea Atom B Series VRF 8 To 16kw ENDocument2 pagesMidea Atom B Series VRF 8 To 16kw ENa.guessoum.hvacNo ratings yet

- I32ZD-O2-K5P0: Large Format Projected Capacitive Touch DisplaysDocument1 pageI32ZD-O2-K5P0: Large Format Projected Capacitive Touch DisplaysSirzarumanAsNo ratings yet

- How To Interface HX711 Balance Module With Load CeDocument8 pagesHow To Interface HX711 Balance Module With Load CeEl Gil R GNo ratings yet

- MSS SP-82 1992Document7 pagesMSS SP-82 1992Marcelo PiresNo ratings yet

- 5c. STP Monthly Log BookDocument1 page5c. STP Monthly Log BookNISHANTH GANESHNo ratings yet

- VFD Wiring Diagram With Motor, Switches, and External Devices - ETechnoGDocument4 pagesVFD Wiring Diagram With Motor, Switches, and External Devices - ETechnoGTakesure MarizaniNo ratings yet

- 1N5XXXDocument2 pages1N5XXXpoke kmNo ratings yet

- APP 751A: SEL-751A Feeder Protection RelayDocument5 pagesAPP 751A: SEL-751A Feeder Protection RelayBouazzaNo ratings yet

- 14.5 Lifting Condensate and Contaminated CondensateDocument4 pages14.5 Lifting Condensate and Contaminated CondensateJose VerdezotoNo ratings yet

- b78b0977-b084-480e-a320-7ec15a7e8502Document28 pagesb78b0977-b084-480e-a320-7ec15a7e8502meyyiti01No ratings yet

- Atari 800 Operating System Manual, Part 1 of 4Document34 pagesAtari 800 Operating System Manual, Part 1 of 4rybagzNo ratings yet

- Teaching & Examination SchemeDocument28 pagesTeaching & Examination SchemeSHYAM SUNDAR OJHA SHYAMNo ratings yet