Professional Documents

Culture Documents

Partial Replacement of Cement by Ggbs Mini

Partial Replacement of Cement by Ggbs Mini

Uploaded by

Sai Ram0 ratings0% found this document useful (0 votes)

147 views15 pagesThis document summarizes an experimental study on replacing cement with ground granulated blast furnace slag (GGBS) in concrete. The study aims to evaluate the compressive strength of concrete with partial replacement of cement by GGBS. A mix design for M30 grade concrete was developed according to Indian standards. Concrete mixes with 0%, 10%, 20%, 30%, and 40% replacement of cement with GGBS were tested. Test results found that 10% replacement of cement with GGBS produced higher compressive strength than plain cement concrete. The study concluded that GGBS can effectively be used in concrete to improve strength while reducing costs and CO2 emissions from cement production.

Original Description:

Original Title

Partial replacement of cement by ggbs mini

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes an experimental study on replacing cement with ground granulated blast furnace slag (GGBS) in concrete. The study aims to evaluate the compressive strength of concrete with partial replacement of cement by GGBS. A mix design for M30 grade concrete was developed according to Indian standards. Concrete mixes with 0%, 10%, 20%, 30%, and 40% replacement of cement with GGBS were tested. Test results found that 10% replacement of cement with GGBS produced higher compressive strength than plain cement concrete. The study concluded that GGBS can effectively be used in concrete to improve strength while reducing costs and CO2 emissions from cement production.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

147 views15 pagesPartial Replacement of Cement by Ggbs Mini

Partial Replacement of Cement by Ggbs Mini

Uploaded by

Sai RamThis document summarizes an experimental study on replacing cement with ground granulated blast furnace slag (GGBS) in concrete. The study aims to evaluate the compressive strength of concrete with partial replacement of cement by GGBS. A mix design for M30 grade concrete was developed according to Indian standards. Concrete mixes with 0%, 10%, 20%, 30%, and 40% replacement of cement with GGBS were tested. Test results found that 10% replacement of cement with GGBS produced higher compressive strength than plain cement concrete. The study concluded that GGBS can effectively be used in concrete to improve strength while reducing costs and CO2 emissions from cement production.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 15

BATCH NO.

07 Date: 17-04-2020

AN EXPERIMENTAL STUDY ON

REPLACEMENT OF CEMENT BY

GGBS

Under the guidance of

Mrs. M. Sri Lakshmi M.Tech, (Ph.D)

Assistant Professor

Batch Members

N.S.N.SINDHUSHA : (17A31A0167)

R.S.MANASI: (17A31A0170) T.S.V.SIVA RAM:(17A31A01B3)

P.V.S SAI RAM: (17A31A01A5) G.V.V.DURGA PRASAD: (16A31A0183)

PRAGATI ENGINEERING COLLEGE

(Autonomous)

A Grade

DEPARTMENT OF CIVIL ENGINEERING

CONTENTS:

Abstract

Introduction

Objectives

Methodology

Desing Mix

Literature Review

Results and discussion

Conclusion

References

ABSTRACT:

In view of rapid constructions and huge cost of building materials there is

an urgency to reduce construction cost. The suitability and demand for usage

of different industrial wastes like GGBS (Ground Granulated Blast Furnace

Slag) is favoured to conserve the natural resources and reduction in

construction cost to attain sustainable development. Addition of GGBS to the

concrete improves the behaviour of concrete and strength.

In this experimental study the cement is partially replaced by GGBS. The

various materials used in this study are cement, fine aggregate, coarse

aggregate, GGBS. Different material tests will be conducted on each of the

materials, to achieve at the suitability of materials as per IS specifications. A

mix is designed for M30 grade concrete as per IS 10262:2009(Indian standard

code of practise).Trail mix is casted and tested for the adequacy. On arriving at

the designed mix of M30 grade, fresh and hardened properties of concrete are

determined. GGBS is partially replaced by 0%,10%,20%,30% and 40% by

weight of cement. For each of the concrete mixes, fresh and hardened

properties are determined. Then we arrive at the optimum mix.

INTRODUCTION:

Concrete is the main binding material which is used in the construction

industry.

The quality of concrete mainly depends upon the ingredients used.

Due to rapid growth in the infrastructure development and decline in

availability of natural aggregates the use of alternative materials are widely

used.

In this experimental study,we are replacing the cement and coarse

aggregate by GGBS and coconut shell

In 1862, GGBS was first discovered in Germany by Emil langers. Ground

Granulated blast furnance slag is a by product from the blast furnance

slag.

In India, we produce about 7.8 millions tons of Blast furnace slag.

GGBS is used to make durable concrete structures in combination with

Ordinary Portland cement and other pozzolanic cement.

OBJECTIVES:

The main objective of our project is to study the effect of partial

replacement of cement with ggbs under M30 grade concrete.

The aim of this project is to evaluate the compressive strength of concrete

by partially replacing of cement by GGBS.

To reduce the cost of concrete by using ggbs as partial replacement of

cement.

The partial replacement of opc with GGBS Improves the workability.

METHODOLOGY:

GGBS is collected from the steel manufacturing industry.

Preliminary tests are conducted for fine aggregate,coarse aggregate and

cement.

Using different percentage of GGBS for M30 grade of concrete mix will be

casted.

The casted concrete was removed from moulds and placed in curing tank.

In this experimental study cubes are designed to investigate the strength of

GGBS concrete.

Design Mix:

The design mix for M30 grade concrete is:-

STIPULATIONS FOR PROPORTIONING

1. Grade designation. : M30

2. Type of cement. : 53 grade

3. Max nominal size of aggregate. : 20 mm

4. Min cement content. : 320 kg/m3

5. Exposure condition. : Moderate

6. Max cement content. : 450 kg/m3

7. Specific gravity of cement. : 3.17

8. Specific gravity of fine aggregate : 2.65

9. Specific gravity of coarse aggregate : 2.58

Step-1:

f’ck=fck+1.65s

Where

f’ck=target average compressive strength at 28 days

fck=characteristic compressive strength at 28 days

s = standard deviation

From table no.1 of IS 10262:2009

S value of M30 grade=5

=30+1.65×5

=38.25 N/mm2

Step-2:

From table no.5 of IS 456:2000

Water cement ratio for reinforced concrete for moderate exposure condition = 0.40

Step-3:

From table no.2 of IS 10262:2009

Max water content for 20 mm size of aggregate = 186 lit (Acc to size of aggregate)

Step-4:

w/c ratio = 0.40

Cement content= weight of water/(w/c ratio)=186/0.40=465 kg/m3

We know that maximum cement content is 450 kg/m3but we got cement content is 465

kg/m3.

Hence we consider max cement content is 450 kg/m3

Step-5:

From table no.3 of IS 10262:2009

Volume of coarse aggregate for 20 mm size of coarse aggregate confining to zone 2 of fine

aggregate = 0.62

Then volume of fine aggregate = 1-0.62 =0.38

• Volume of concrete = 1 m3

• Volume of cement. =(450/3.17)×(1/1000)=0.141 m3

• Volume of water. =(186/1)×(1/1000)= 0.186m3

• Volume of all in aggregate=[volume of concrete-(volume of cement + volume of

water)]=1-(0.141+0.186)=0.673 m3

• Mass of coarse aggregate =e × volume of coarse aggregate × specific gravity of coarse

aggregate x 1000=0.673×0.62×2.58×1000=1076.53kg/m3

• Mass of fine aggregate =e × volume of fine aggregate × specific gravity of Coarse

aggregate × 1000=0.673×0.38×2.65×1000=677.71 kg/m3

Mix proportions:

=450:677.71:1076.53

=1:1.5:2.39

LITERATURE REVIEW:

Ecocem. “Ground Granulated Blast furnance slag (GGBS)”.Retrieved

2013-05-27.U.S. Federal Highway Administration. “Ground

Granulated Blast Furnance slag”. Archived from the original on 2007-

01-22. Retrieved 2007-01-24

B.Kaviya, R.Arjun, P.Rajkumar, S.Ramakrishnan,

S.Subash(study on partial replacement of cement by ground

granulated blast furnace slag) IJPAM (volume116,No.13,2017)

says that GGBS based concrete have acheived an increase in

strength for 30% replacement of cement at the age of 7 and 28

days.

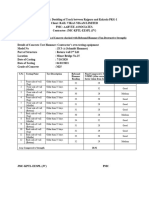

RESULTS AND DISCUSSIONS:

• Compression tests are used to determine the materials bahaviour under

applied crushing loads.

• Test for compressive strength is carried out on cube.

• Compressive strength is taken on the average of Atwo cubes test results.

• At 10 percent GGBS gives more compressive strength than opc.

CONCLUSION:

• Higher the percentage of cement replaced by GGBS,longer will be the

initial setting time.

• The usage of GGBS in concrete highly improves the strength.

• From the above results,it can be concluded that GGBS can be effectively

used in concrete.

• The usage of GGBS in concrete as replacement of cement material will

lessen the Co2 is being emitted during its manufacture and acts as an

ecofrienly material reducing the greenhouse effect.

REFERENCES:

• Ground granulated blast-furnace slag - Wikipedia, the free encyclopedia.

• IS: 456-2000 code of practice for plain and reinforced concrete.

• SP: 23-1982 hand book on concrete mixes.

• IS: 10262-2009 Indian standards recommended guidelines for concrete

mix design.

• IS: 516-1959 Indian standards methods of tests for strength of concrete.

• IS: 383-1970 specifications for coarse aggregate and fine aggregate.

THANK YOU

You might also like

- General Forms.1aDocument44 pagesGeneral Forms.1aNoli BenongoNo ratings yet

- Lifting Plan For Equipment - MMSPDocument14 pagesLifting Plan For Equipment - MMSPClifford100% (2)

- NRM 1 October 2021Document476 pagesNRM 1 October 2021Gamini KodikaraNo ratings yet

- Partial Replacement of Cement by GgbsDocument25 pagesPartial Replacement of Cement by GgbsSai Ram100% (1)

- Major Project PPT GGBSDocument20 pagesMajor Project PPT GGBSNaReN KumarNo ratings yet

- Artificial Neural Network For Concrete Mix DesignDocument11 pagesArtificial Neural Network For Concrete Mix DesignUmer Farooq100% (1)

- PV490-C Volume 3Document142 pagesPV490-C Volume 3sajid yaqoobNo ratings yet

- The Shard - London Case Study: "Working To A Deadline": Online Distance: Design ManagementDocument31 pagesThe Shard - London Case Study: "Working To A Deadline": Online Distance: Design ManagementkitstonNo ratings yet

- Ground Granulated Blast Furnace Slag (GGBS) : Effect of Particle Size and Dosage On Compressive Strength With Microstructural Analysis of ConcreteDocument8 pagesGround Granulated Blast Furnace Slag (GGBS) : Effect of Particle Size and Dosage On Compressive Strength With Microstructural Analysis of ConcreteIJRASETPublicationsNo ratings yet

- GGBSDocument20 pagesGGBSratnakar0% (1)

- Major Project GGBS-1Document49 pagesMajor Project GGBS-1NaReN Kumar0% (1)

- An Experimental Study On Strength of Concrete With Silica Fume and Partial Replacement of Cement by Brick PowderDocument5 pagesAn Experimental Study On Strength of Concrete With Silica Fume and Partial Replacement of Cement by Brick PowderInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Ground Granulated Blast Furnace Slag - Literature ReviewDocument20 pagesGround Granulated Blast Furnace Slag - Literature ReviewHetroSapiansNo ratings yet

- Compressive Strength of ConcreteDocument7 pagesCompressive Strength of ConcreteNick Genese100% (1)

- Final PPT An Experimental Study On Mechanical PropertiesDocument31 pagesFinal PPT An Experimental Study On Mechanical PropertiesMohd JunaidNo ratings yet

- Fly Ash For Cement ConcreteDocument48 pagesFly Ash For Cement Concreterashm006ranjanNo ratings yet

- Strength of Concrete Structure Partial Replacement of Sand by Copper SlagDocument6 pagesStrength of Concrete Structure Partial Replacement of Sand by Copper SlagEditor IJTSRDNo ratings yet

- Partial Replacement of Cement With GGBS in ConcreteDocument10 pagesPartial Replacement of Cement With GGBS in ConcreteE Hammam El MissiryNo ratings yet

- Partial Replacement of Cement by Saw Dust Ash in Constructional WorksDocument31 pagesPartial Replacement of Cement by Saw Dust Ash in Constructional WorksHariharasudhanNo ratings yet

- Pratial Replacement of Fine Aggregates With Copper SlagDocument18 pagesPratial Replacement of Fine Aggregates With Copper SlagSachin N100% (1)

- Development of A Mix Design Adjustment Method For Fiber ReinforceDocument154 pagesDevelopment of A Mix Design Adjustment Method For Fiber Reinforcebasel abduNo ratings yet

- Project ReportDocument41 pagesProject ReportAashu chaudhary100% (1)

- PPTDocument28 pagesPPTRama Arul SakthiNo ratings yet

- Mix Design M-40Document10 pagesMix Design M-40psjjoshiNo ratings yet

- Replacement of Cement by Red Mud in Paver BlockDocument20 pagesReplacement of Cement by Red Mud in Paver BlockRanjeeth KumarNo ratings yet

- NDT Rebound Hammer Test ReportsDocument7 pagesNDT Rebound Hammer Test ReportsPrasanta ParidaNo ratings yet

- Studies On Quarry Dust As Partial Replacement of Fine Aggregates in ConcreteDocument3 pagesStudies On Quarry Dust As Partial Replacement of Fine Aggregates in ConcreteEditor IJLTEMASNo ratings yet

- Fly Ash ConcreteDocument14 pagesFly Ash Concretenaveenthirumal67% (3)

- Comparative Study On The Strength and Durability Properties of Concrete With Manufactured SandDocument7 pagesComparative Study On The Strength and Durability Properties of Concrete With Manufactured SandyoussefNo ratings yet

- Exprimental Study On Permeable Concrete Pavement ForDocument28 pagesExprimental Study On Permeable Concrete Pavement ForVaidyanathan SivasubramanianNo ratings yet

- Mix Design M - 30 NEWDocument6 pagesMix Design M - 30 NEWRajeev ReddyNo ratings yet

- GGBS Usage in ConcreteDocument16 pagesGGBS Usage in Concretesuraj george kNo ratings yet

- Udaya C 1ms17cse27 Final Project ReportDocument77 pagesUdaya C 1ms17cse27 Final Project ReportalluayaanNo ratings yet

- Partial Replacement of Cement by Marble SlurryDocument31 pagesPartial Replacement of Cement by Marble SlurryDhanendra SinghNo ratings yet

- Mini Project Final Repot NSDocument12 pagesMini Project Final Repot NSNikhil Movie changerNo ratings yet

- Concrete Mix DesignDocument21 pagesConcrete Mix DesignPratyush Kumar DoraNo ratings yet

- 14cl113 Sadbhav ReportDocument21 pages14cl113 Sadbhav ReportYash VajaNo ratings yet

- Nano ConcreteDocument12 pagesNano ConcreteDvorah KahnNo ratings yet

- Brick Manufacturing Using Non Biodegradable WasteDocument8 pagesBrick Manufacturing Using Non Biodegradable WasteAnjana Kanwar RajawatNo ratings yet

- Fly Ash For Cement Concrete: NTPC LimitedDocument51 pagesFly Ash For Cement Concrete: NTPC LimitedMd AwesshadabNo ratings yet

- Mix Design M40 Grade Designed As Per IS 10262:2009 & IS 456:2000Document6 pagesMix Design M40 Grade Designed As Per IS 10262:2009 & IS 456:2000Sanjoy RoyNo ratings yet

- Mix DesignDocument27 pagesMix DesignSoni Mishra TiwariNo ratings yet

- An Experimental Study On Stabilization of Black Cotton Soil by Using Bio PolymersDocument4 pagesAn Experimental Study On Stabilization of Black Cotton Soil by Using Bio PolymersEditor IJTSRDNo ratings yet

- Experimental Investigation On Partial Replacement of Cement With Dolomite Powder PDFDocument9 pagesExperimental Investigation On Partial Replacement of Cement With Dolomite Powder PDFSalman AghariyaNo ratings yet

- Mix Design As Per IS 10262-2019Document18 pagesMix Design As Per IS 10262-2019Suchitra PandaNo ratings yet

- JULY Final Mtech ProjectDocument100 pagesJULY Final Mtech ProjectEpherem DanielNo ratings yet

- Experimental Study On Partial Replacement of Cement Using AlccofineDocument8 pagesExperimental Study On Partial Replacement of Cement Using AlccofineNavik BhandariNo ratings yet

- Minor ProjectDocument17 pagesMinor Projectपाँशुल जम्वाल राजपूतNo ratings yet

- Anwesh Project 1Document33 pagesAnwesh Project 1sunil kumarNo ratings yet

- Transparent Concrete SeminarDocument17 pagesTransparent Concrete Seminarimul100% (2)

- Rajarajeswari College of EngineeringDocument23 pagesRajarajeswari College of Engineeringchetan maitriNo ratings yet

- Geopolymer Concrete Sem 8 (GPC)Document21 pagesGeopolymer Concrete Sem 8 (GPC)daahdadaNo ratings yet

- Project 8th SemDocument21 pagesProject 8th Semamish rajNo ratings yet

- FerroDocument129 pagesFerrosureshrakesh0% (1)

- Building Materials Final Solution After Cor.Document64 pagesBuilding Materials Final Solution After Cor.TarunNo ratings yet

- Analysis of Compressive Strength of M-25 Grade Concrete Using Fly Ash As Partial Replacement of CementDocument49 pagesAnalysis of Compressive Strength of M-25 Grade Concrete Using Fly Ash As Partial Replacement of CementRais AlamNo ratings yet

- A Review Paper On Replacement of Fine AggregateDocument5 pagesA Review Paper On Replacement of Fine AggregateIJRASETPublicationsNo ratings yet

- High Performance ConcreteDocument79 pagesHigh Performance ConcreteShyam Prasad ThiraviamNo ratings yet

- Concrete Mix DesignDocument22 pagesConcrete Mix DesignIvo StanilovNo ratings yet

- NPTEL Concrete Engg and Tech Problem and Solved AnswersDocument5 pagesNPTEL Concrete Engg and Tech Problem and Solved AnswerssuranjanacNo ratings yet

- Project On Partial Replacement of Cement With Marble PowderDocument11 pagesProject On Partial Replacement of Cement With Marble PowderSaurabh Pandey100% (2)

- Experimental Study On Polypropylene Fiber Reinforcement Concrete With Mineral AdmixturesDocument9 pagesExperimental Study On Polypropylene Fiber Reinforcement Concrete With Mineral AdmixtureskannanNo ratings yet

- Analysis of Strength Characteristics of GGBS PDFDocument3 pagesAnalysis of Strength Characteristics of GGBS PDFSoundar PachiappanNo ratings yet

- GGBS As Partial Replacement of OPC in Cement Concrete - An Experimental StudyDocument3 pagesGGBS As Partial Replacement of OPC in Cement Concrete - An Experimental Studyபுருஷோத்தமன் சரவணன்No ratings yet

- Sustainable Consideration of Concrete Using GGBFS and Fly AshDocument9 pagesSustainable Consideration of Concrete Using GGBFS and Fly AshIJRASETPublicationsNo ratings yet

- TEC-033000.2-MET-DoR - (Method Statement For Constructions of Pile Caps, Lift Pit, Pipe Encasement Below Raft) (A)Document16 pagesTEC-033000.2-MET-DoR - (Method Statement For Constructions of Pile Caps, Lift Pit, Pipe Encasement Below Raft) (A)Haymanot BaynesagnNo ratings yet

- Eeo Officer ListDocument393 pagesEeo Officer ListSimon DaudaNo ratings yet

- Recent Complain Analysis 2019.06.28Document34 pagesRecent Complain Analysis 2019.06.28Yasndra AbeygunewardhaneNo ratings yet

- Qasim Sultan Dogar: Profile SummaryDocument4 pagesQasim Sultan Dogar: Profile SummaryQasim SultanNo ratings yet

- B2TBSPF102: All Dimension in Charts and Drawing Are in MillimetersDocument3 pagesB2TBSPF102: All Dimension in Charts and Drawing Are in Millimeterskhaled aliNo ratings yet

- 1 GRADE BEAM LAYOUT PLAN & REINF. DETAILS-ModelDocument1 page1 GRADE BEAM LAYOUT PLAN & REINF. DETAILS-ModelImran Hasan KibriaNo ratings yet

- Bomag - Google SearchDocument1 pageBomag - Google SearchMassimo CerulloNo ratings yet

- A10530 Te Whatu Ora Lakes Project Mauri Ora SoQ March 2023 Excel Spreadsheet NOT A Contract DocumentDocument262 pagesA10530 Te Whatu Ora Lakes Project Mauri Ora SoQ March 2023 Excel Spreadsheet NOT A Contract DocumentcesarNo ratings yet

- Coating Inspector - CV TADocument4 pagesCoating Inspector - CV TAkaleem malikNo ratings yet

- Brochure Block-MouldsDocument14 pagesBrochure Block-MouldsEphraim BarezNo ratings yet

- Transport For NSW (TFNSW) Qa Specification R23 Plastic Flexible PipesDocument20 pagesTransport For NSW (TFNSW) Qa Specification R23 Plastic Flexible PipesHenry HNo ratings yet

- Method Statement Installation of 11kv HV Switchgear PanelDocument7 pagesMethod Statement Installation of 11kv HV Switchgear Panelsyed fazluddin67% (3)

- Guide To Selecting The Best JCT Main Contract - AveburyDocument1 pageGuide To Selecting The Best JCT Main Contract - Aveburyraymond1066No ratings yet

- Sop Piling WorkDocument2 pagesSop Piling WorkamirNo ratings yet

- CID Foundation Only PermitDocument1 pageCID Foundation Only PermitOsvaldo CalderonUACJNo ratings yet

- Design and Manufacturing of Cobble StoneDocument18 pagesDesign and Manufacturing of Cobble StoneGetahunNo ratings yet

- Team: Sherlok: Akash SagarDocument8 pagesTeam: Sherlok: Akash SagarkartikNo ratings yet

- Itb - I-008Document12 pagesItb - I-008Godwin A.udo-akanNo ratings yet

- NVHomes Stratford Hall FloorplanDocument2 pagesNVHomes Stratford Hall FloorplanvoldyyyNo ratings yet

- Article On ECI Under NECDocument11 pagesArticle On ECI Under NECPvvg PrasadNo ratings yet

- SOP - Ready Mix Annual Facility AuditDocument2 pagesSOP - Ready Mix Annual Facility AuditTri widiyah VitantiNo ratings yet

- SCAFFOLDING & LADDER HSE ChecklistDocument2 pagesSCAFFOLDING & LADDER HSE Checklistvinil radhakrishnaNo ratings yet

- Preventing Catastrophic Events in ConstructionDocument220 pagesPreventing Catastrophic Events in ConstructionfmNo ratings yet

- Profile Guide: Corrugated Sheet & Foam FillersDocument275 pagesProfile Guide: Corrugated Sheet & Foam FillersnguyenanhtuanbNo ratings yet

- Spare Parts List Series M200LS: Effective Date: January 15, 2014 Supersedes: June 11, 2013Document16 pagesSpare Parts List Series M200LS: Effective Date: January 15, 2014 Supersedes: June 11, 2013Trần Quốc Đông100% (1)