Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

100 viewsBiomass Energy

Biomass Energy

Uploaded by

Jhon Lester KinakinThe document provides information on the three largest biomass power plants in Europe and biomass power development in the Philippines. The Ironbridge plant in the UK is the largest at 740 MW, previously a coal plant. The Alholmens Kraft plant in Finland is the second largest at 265 MW and supplies heat and power. The Polaniec plant in Poland is third largest at 205 MW using tree and agricultural waste. The document also lists 13 biomass power plants proposed or under construction in the Philippines ranging from 8.8 MW to 35 MW capacity.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- Energy FundamentalsDocument21 pagesEnergy FundamentalsIkmal Haziq Bin TalibNo ratings yet

- T&E Biomass ReportDocument10 pagesT&E Biomass ReportedienewsNo ratings yet

- Wood Pellet Final Report CM Nov07Document40 pagesWood Pellet Final Report CM Nov07muji7No ratings yet

- Pretreatment of Biomass by TorrefactionDocument7 pagesPretreatment of Biomass by Torrefactionluaweb123No ratings yet

- Different Power Plants in The PhilippinesDocument3 pagesDifferent Power Plants in The PhilippinesDenzen Isip71% (7)

- Effectiveness of ERDB Charcoal Briquette in Sequestrating CarbonDocument2 pagesEffectiveness of ERDB Charcoal Briquette in Sequestrating CarbonAnonymous VNSytXNo ratings yet

- Biomass Gasification For Electricity Generation and Production of Synthesis GasDocument15 pagesBiomass Gasification For Electricity Generation and Production of Synthesis GasSantosh DoddamaniNo ratings yet

- Building MorphologyDocument12 pagesBuilding MorphologyChan Siew ChongNo ratings yet

- Bionanocomposites Materials For Food Packaging Applications Concepts and Future Outlook PDFDocument9 pagesBionanocomposites Materials For Food Packaging Applications Concepts and Future Outlook PDFRadu ElenaNo ratings yet

- Production of Activated Carbon From Coconut Shell Optimization Using Response Surface MethodologyDocument9 pagesProduction of Activated Carbon From Coconut Shell Optimization Using Response Surface MethodologyyemresimsekNo ratings yet

- Coconut Wood Processing PDFDocument48 pagesCoconut Wood Processing PDFZoebairNo ratings yet

- Article From Coal To Biomass at MN PowerDocument3 pagesArticle From Coal To Biomass at MN PowerCory LukerNo ratings yet

- BambooDocument30 pagesBambooXtian Louie100% (1)

- Seminar ReportDocument17 pagesSeminar ReportVishnu RoyNo ratings yet

- CV of MAHESHWAR SHARON (42 PP)Document42 pagesCV of MAHESHWAR SHARON (42 PP)anislinek15No ratings yet

- 5.01 Biomass and Biofuels - IntroductionDocument9 pages5.01 Biomass and Biofuels - IntroductionRhita RayNo ratings yet

- September 1993: Biopolymers: Making Materials Nature's WayDocument86 pagesSeptember 1993: Biopolymers: Making Materials Nature's WaysaurabhNo ratings yet

- Biomass Energy: Sandip KC Roll: 11 Sushant Mahat Roll: 15Document38 pagesBiomass Energy: Sandip KC Roll: 11 Sushant Mahat Roll: 15ramesh pokhrelNo ratings yet

- Intro To Green ChemistryDocument44 pagesIntro To Green ChemistryAmann AwadNo ratings yet

- BiomassDocument36 pagesBiomassveenaNo ratings yet

- CPM BrochureDocument4 pagesCPM BrochureAlexandru IonescuNo ratings yet

- 4 - Microalgae - A Green Multiproduct Biorefinery For Future Industrial ProspectsDocument14 pages4 - Microalgae - A Green Multiproduct Biorefinery For Future Industrial ProspectsElena Rojo de BenitoNo ratings yet

- Biomass Gasification For Hydrogen ProductionDocument9 pagesBiomass Gasification For Hydrogen ProductionCris CrisNo ratings yet

- 06 Polystyrene StoryDocument67 pages06 Polystyrene StoryThe Outer MarkerNo ratings yet

- Biodegradable Polymers Bamboo Fiber BiocompositeDocument12 pagesBiodegradable Polymers Bamboo Fiber BiocompositekhuongdaihuynhNo ratings yet

- Fuel From FarmDocument168 pagesFuel From FarmKUKU100% (1)

- Factsheet Man-Made FibresDocument6 pagesFactsheet Man-Made FibresPrabaharan GunarajahNo ratings yet

- Water SplittingDocument7 pagesWater SplittingRommel BalceNo ratings yet

- Modified CelluloseDocument19 pagesModified CelluloseK V SATHEESHKUMAR MECHNo ratings yet

- Promising PDFDocument6 pagesPromising PDFGillian AmbaNo ratings yet

- Development of A Condenser For Marine Florae Pyrolysis ReactorDocument156 pagesDevelopment of A Condenser For Marine Florae Pyrolysis ReactorRichard Jess Chan100% (2)

- Agro Industrial Wastes.2012Document20 pagesAgro Industrial Wastes.2012Sadikul AminNo ratings yet

- 2009 - Review of Pyrolyisis Platform For Coproducing Bio-Oil and BiocharDocument16 pages2009 - Review of Pyrolyisis Platform For Coproducing Bio-Oil and BiocharapitbhuNo ratings yet

- Recent Developments in Crosslinking of ElastomersDocument31 pagesRecent Developments in Crosslinking of ElastomersAzizol WahabNo ratings yet

- Bioenergy Technology Roadmap For ColombiaDocument112 pagesBioenergy Technology Roadmap For ColombiaLaura JaimesNo ratings yet

- Wood Pellet Heat GuidebookDocument26 pagesWood Pellet Heat GuidebookSudhakar GanjikuntaNo ratings yet

- Life Cycle Assessment of Biochar As A Partial Replacement To Portland CementDocument6 pagesLife Cycle Assessment of Biochar As A Partial Replacement To Portland CementStephen John ClementeNo ratings yet

- Liquid Metal BatteriesDocument23 pagesLiquid Metal BatteriesmerrickNo ratings yet

- Biomass Power Plants Final2Document34 pagesBiomass Power Plants Final2Abdulhadi EliasNo ratings yet

- Agro CNGDocument14 pagesAgro CNGVinayak JaganureNo ratings yet

- Global Pellet Markets and Growth of Co-FiringDocument28 pagesGlobal Pellet Markets and Growth of Co-FiringNorzuriani Mohamed SeberiNo ratings yet

- Sonocrystallization - The Use of Ultrasound For Improved Industrial Crystallization PDFDocument10 pagesSonocrystallization - The Use of Ultrasound For Improved Industrial Crystallization PDFJessica FengkaiNo ratings yet

- Chapter 3c - Cellulose DerivativesDocument37 pagesChapter 3c - Cellulose DerivativesVanessa LimNo ratings yet

- Development of A Pedal-Operated Abaca Stripping Tool: Evelyn Bacarra-Tablante Angel T. SabusapDocument8 pagesDevelopment of A Pedal-Operated Abaca Stripping Tool: Evelyn Bacarra-Tablante Angel T. SabusapJordan PocaanNo ratings yet

- Last Chance To Donate To Wikipedia in 2009: Anaerobic DigestionDocument24 pagesLast Chance To Donate To Wikipedia in 2009: Anaerobic DigestionVincent Ekhator100% (1)

- Databook 2013Document309 pagesDatabook 2013Jan ZawiszaNo ratings yet

- Biomass Heating A Practical Guide For Potential Users (CTG012)Document94 pagesBiomass Heating A Practical Guide For Potential Users (CTG012)Prashant VaraNo ratings yet

- Biomass Gasification: The East African StudyDocument40 pagesBiomass Gasification: The East African StudyMoy DuekNo ratings yet

- Evaluating The Quality of Protein From Hemp Seed and Hemp Seed Products Through The Use of The Protein Digestibility Corrected Amino Acid Score MethodDocument44 pagesEvaluating The Quality of Protein From Hemp Seed and Hemp Seed Products Through The Use of The Protein Digestibility Corrected Amino Acid Score MethodRaphone Robert100% (1)

- Alexander2019 HomebiogasDocument11 pagesAlexander2019 HomebiogasSalvador Eduardo Vásquez DavalosNo ratings yet

- Crop DiseaseDocument17 pagesCrop DiseaseHanu MNo ratings yet

- Bio Based PolymersDocument16 pagesBio Based PolymersMisael Abdias Millan AlonzoNo ratings yet

- 2 - CHAPTER-Iv2 0Document30 pages2 - CHAPTER-Iv2 0GodisGood AlltheTimeNo ratings yet

- Tan Eng Hau - MBIC - Renewable EnergyDocument18 pagesTan Eng Hau - MBIC - Renewable EnergyLeonardo Alexander Renatus PaneNo ratings yet

- Characterization of Banana Peel Briquettes With The Variation of Binder ConcentrationDocument19 pagesCharacterization of Banana Peel Briquettes With The Variation of Binder ConcentrationSuriati Eka PutriNo ratings yet

- Economic Importance of Algae - BotanyDocument14 pagesEconomic Importance of Algae - BotanyWOWNo ratings yet

- Production of BioGas Using Kitchen WasteDocument6 pagesProduction of BioGas Using Kitchen Wastezonetrek100% (1)

- BiomassDocument3 pagesBiomassGi LantingNo ratings yet

- Different Power PlantsDocument3 pagesDifferent Power PlantsRenz Karl DeclaroNo ratings yet

- Understanding Biomass Energy - Importance of Biofuels | Biomass Energy for Kids | Children's Ecology BooksFrom EverandUnderstanding Biomass Energy - Importance of Biofuels | Biomass Energy for Kids | Children's Ecology BooksNo ratings yet

- Development Theories: Dr. Debashis DebnathDocument22 pagesDevelopment Theories: Dr. Debashis DebnathAnshul GuptaNo ratings yet

- Writ of Kalikasan and The Precautionary Principle and Disaster Risk Reduction and ManagementDocument5 pagesWrit of Kalikasan and The Precautionary Principle and Disaster Risk Reduction and ManagementDYbieNo ratings yet

- Wind Power For StudentsDocument33 pagesWind Power For StudentsFarah Sofhia Mohd ZinNo ratings yet

- 13 01018 Ful-Appeal Decision-420085Document6 pages13 01018 Ful-Appeal Decision-420085mwjNo ratings yet

- Project StakeholderManagement SustainabilityDocument22 pagesProject StakeholderManagement SustainabilityAZLAN AIYUBNo ratings yet

- ANZECC 1992 GuidelinesDocument171 pagesANZECC 1992 GuidelinespelimostroNo ratings yet

- Electric Flat Die Pellet Mill PDFDocument4 pagesElectric Flat Die Pellet Mill PDFpelletsmillmachinery0% (1)

- AC5 Material Science and EngineeringDocument8 pagesAC5 Material Science and EngineeringEdelson Mark GarciaNo ratings yet

- Ashol Lall: Beacon of Sustainable Architecture: IRRAD Gurgaon by Ashok B Lall ArchitectsDocument2 pagesAshol Lall: Beacon of Sustainable Architecture: IRRAD Gurgaon by Ashok B Lall ArchitectsMonisha100% (1)

- Parmanand Rastogi: B.Tech (ECE), M.Tech (Green Energy Technology) Personal DetailsDocument3 pagesParmanand Rastogi: B.Tech (ECE), M.Tech (Green Energy Technology) Personal DetailskrishnanandNo ratings yet

- Convergence-Building Towards Sustainable Management of WatershedsDocument54 pagesConvergence-Building Towards Sustainable Management of Watershedsfpe_scribdNo ratings yet

- Exploring The Perceptions of Tertiary Students' Perceptions and Attitudes Towards Environmental SustainabilityDocument10 pagesExploring The Perceptions of Tertiary Students' Perceptions and Attitudes Towards Environmental SustainabilitySEP-PublisherNo ratings yet

- Unesco Creative Cities Programme: For Sustainable DevelopmentDocument198 pagesUnesco Creative Cities Programme: For Sustainable DevelopmentYana ArsyadiNo ratings yet

- ESS 122 - L1 - Nature, Scope and History of Environmental LawDocument11 pagesESS 122 - L1 - Nature, Scope and History of Environmental LawJyotica Tandon0% (1)

- Sustainable Development: Polytechnic University of The Philppines Unisan, Quezon BranchDocument19 pagesSustainable Development: Polytechnic University of The Philppines Unisan, Quezon BranchMart Lemuel CalooyNo ratings yet

- Bio Energy PlantsDocument2 pagesBio Energy PlantsCurcudel AnastasiaNo ratings yet

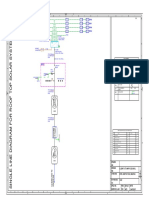

- STR-5 STR-7 STR-6: 2Rx1C X 4Sqmm DC Cu - Cable 740voc, 8.7amp Per StringDocument1 pageSTR-5 STR-7 STR-6: 2Rx1C X 4Sqmm DC Cu - Cable 740voc, 8.7amp Per StringSatishKumarMauryaNo ratings yet

- Problem-Solution Essay OutlineDocument2 pagesProblem-Solution Essay OutlineThrowaway TwoNo ratings yet

- Skill Development - 3BALIBDocument4 pagesSkill Development - 3BALIBPRERANA SRIMAAL School of Business Studies and Social SciencesNo ratings yet

- Presentation On Case Study IMTDocument4 pagesPresentation On Case Study IMTIshank Agarwal100% (1)

- PDF Environmental Policy New Directions For The Twenty First Century Norman J Vig Ebook Full ChapterDocument53 pagesPDF Environmental Policy New Directions For The Twenty First Century Norman J Vig Ebook Full Chaptergrace.hunter625100% (2)

- Impacts of TourismDocument7 pagesImpacts of TourismCarson FowlingNo ratings yet

- ENERGY EFFICIENCY IntroductionDocument13 pagesENERGY EFFICIENCY IntroductionAzmi HashimNo ratings yet

- Introduction To Systems Thinking Tools - EngDocument55 pagesIntroduction To Systems Thinking Tools - EngDan JecanNo ratings yet

- Q58 Rowlands and MedeleevDocument9 pagesQ58 Rowlands and MedeleevTow YeeNo ratings yet

- Thailand Human-Environment Interaction Issues PaperDocument4 pagesThailand Human-Environment Interaction Issues Paperapi-296686790No ratings yet

- Solar Energy Questions HandbookDocument17 pagesSolar Energy Questions HandbookMuhammadTouseefNo ratings yet

- 10 Steps To Setting Up Carbon Credits-2Document6 pages10 Steps To Setting Up Carbon Credits-2Marius Angara100% (1)

- NHP (2017-2021) - EngDocument46 pagesNHP (2017-2021) - Engmarcmyomyint1663No ratings yet

- Nepal2002 Water Resources Strategy-ExecSumDocument31 pagesNepal2002 Water Resources Strategy-ExecSumJulian YatesNo ratings yet

Biomass Energy

Biomass Energy

Uploaded by

Jhon Lester Kinakin0 ratings0% found this document useful (0 votes)

100 views14 pagesThe document provides information on the three largest biomass power plants in Europe and biomass power development in the Philippines. The Ironbridge plant in the UK is the largest at 740 MW, previously a coal plant. The Alholmens Kraft plant in Finland is the second largest at 265 MW and supplies heat and power. The Polaniec plant in Poland is third largest at 205 MW using tree and agricultural waste. The document also lists 13 biomass power plants proposed or under construction in the Philippines ranging from 8.8 MW to 35 MW capacity.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides information on the three largest biomass power plants in Europe and biomass power development in the Philippines. The Ironbridge plant in the UK is the largest at 740 MW, previously a coal plant. The Alholmens Kraft plant in Finland is the second largest at 265 MW and supplies heat and power. The Polaniec plant in Poland is third largest at 205 MW using tree and agricultural waste. The document also lists 13 biomass power plants proposed or under construction in the Philippines ranging from 8.8 MW to 35 MW capacity.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

100 views14 pagesBiomass Energy

Biomass Energy

Uploaded by

Jhon Lester KinakinThe document provides information on the three largest biomass power plants in Europe and biomass power development in the Philippines. The Ironbridge plant in the UK is the largest at 740 MW, previously a coal plant. The Alholmens Kraft plant in Finland is the second largest at 265 MW and supplies heat and power. The Polaniec plant in Poland is third largest at 205 MW using tree and agricultural waste. The document also lists 13 biomass power plants proposed or under construction in the Philippines ranging from 8.8 MW to 35 MW capacity.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 14

Ironbridge, United Kingdom – 740 MW

• Biggest biomass power plant

• located in Severn Gorge, UK

• previously a coal-fired power station

with a capacity of 1000 MW.

The plant was converted to generate

power from wood pellets

Alholmens Kraft, Finland – 265 MW

• Second biggest biomass power plant

• Operated since 2002

• Supplies 100 MW of heat for UPM paper

mill and 60 MW of district heating for

the inhabitants of Jakobstad.

Polaniec, Poland – 205 MW

• Third biggest biomass power plant

• Tree- farming and agricultural by-

products as fuel

• Operated since 2012

Biomass Power in the PHILIPPINES

Station Capacity Commissione Community Status

(MW) d

North Negros BioPower 24.9 2018 Manapla, Negros Proposed

Occ.

CLEAN GREEN Energy Corp 12 2017 Bagac, Bataan Under-Construction

Green Power Panay Phil Inc 35 2016 Mina, IloIlo Under-Construction

Green Power Bukidnon Phil Inc 35 2016 Maramag, Bukidnon Under-Construction

Green Power Alcala Phil Inc 35 2016 Alcala, Cagayan Under-Construction

Kalilangan Biomass Energy Corp 10 2017 TBA, Mindanao Under-Construction

Don Carlos Biomass Energy Corp 10 2017 TBA, Mindanao Under-Construction

Misamis Oriental Biomass Energy 12 2017 Misamis, Oriental Under-Construction

Corp

Aseagas Corporation 8.8 2015 Lian, Batangas Operational

San Carlos BioPower 19.9 2015 San Carlos City, Operational

Negros Occ.

Isabela Biomass Energy Corp 18 2015 Alicia, Isabela Operational

Asea One Power 42 2014 Aklan, Panay Operational

Working

Principle of

Biomass

How does a Biogas plant work?

1. Organic input materials such as food stuff remnants, fats or sludge can be fed into the biogas plant as

substrate.

2. Renewable resources such as corn, beets or grass serve as feed both for animals such as cows and pigs

as well as the micro organism in the biogas plant.

3. Manure and dung are also fed in the biogas plant.

4. In the fermented, heated to approximately 38-40°C, the substrate is decomposed by the

microorganisms under exclusion of light and oxygen.

5. Once the substrate has been fermented, it is transported to fermentation residue end storage

tank that can be retrieve from there for further utilization.

6. The residue can be utilised as high quality fertilizer.

7.But drying it subsequently using it as dry fertiliser is also an option.

8. The biogas generated is stored in roof of the tank

9. Biogas is burned in the combined heat and power plant (CHP) to generate electricity and heat.

10. The electric power is fed directly into the power grid.

11. The heat generated can be utilized to heat building or dry wood or harvest

products.

12. Processing of biogas.

13. Gas supply the national grid or gas filling stations.

CRYSTAL SUGAR

COMPANY INC

You might also like

- Energy FundamentalsDocument21 pagesEnergy FundamentalsIkmal Haziq Bin TalibNo ratings yet

- T&E Biomass ReportDocument10 pagesT&E Biomass ReportedienewsNo ratings yet

- Wood Pellet Final Report CM Nov07Document40 pagesWood Pellet Final Report CM Nov07muji7No ratings yet

- Pretreatment of Biomass by TorrefactionDocument7 pagesPretreatment of Biomass by Torrefactionluaweb123No ratings yet

- Different Power Plants in The PhilippinesDocument3 pagesDifferent Power Plants in The PhilippinesDenzen Isip71% (7)

- Effectiveness of ERDB Charcoal Briquette in Sequestrating CarbonDocument2 pagesEffectiveness of ERDB Charcoal Briquette in Sequestrating CarbonAnonymous VNSytXNo ratings yet

- Biomass Gasification For Electricity Generation and Production of Synthesis GasDocument15 pagesBiomass Gasification For Electricity Generation and Production of Synthesis GasSantosh DoddamaniNo ratings yet

- Building MorphologyDocument12 pagesBuilding MorphologyChan Siew ChongNo ratings yet

- Bionanocomposites Materials For Food Packaging Applications Concepts and Future Outlook PDFDocument9 pagesBionanocomposites Materials For Food Packaging Applications Concepts and Future Outlook PDFRadu ElenaNo ratings yet

- Production of Activated Carbon From Coconut Shell Optimization Using Response Surface MethodologyDocument9 pagesProduction of Activated Carbon From Coconut Shell Optimization Using Response Surface MethodologyyemresimsekNo ratings yet

- Coconut Wood Processing PDFDocument48 pagesCoconut Wood Processing PDFZoebairNo ratings yet

- Article From Coal To Biomass at MN PowerDocument3 pagesArticle From Coal To Biomass at MN PowerCory LukerNo ratings yet

- BambooDocument30 pagesBambooXtian Louie100% (1)

- Seminar ReportDocument17 pagesSeminar ReportVishnu RoyNo ratings yet

- CV of MAHESHWAR SHARON (42 PP)Document42 pagesCV of MAHESHWAR SHARON (42 PP)anislinek15No ratings yet

- 5.01 Biomass and Biofuels - IntroductionDocument9 pages5.01 Biomass and Biofuels - IntroductionRhita RayNo ratings yet

- September 1993: Biopolymers: Making Materials Nature's WayDocument86 pagesSeptember 1993: Biopolymers: Making Materials Nature's WaysaurabhNo ratings yet

- Biomass Energy: Sandip KC Roll: 11 Sushant Mahat Roll: 15Document38 pagesBiomass Energy: Sandip KC Roll: 11 Sushant Mahat Roll: 15ramesh pokhrelNo ratings yet

- Intro To Green ChemistryDocument44 pagesIntro To Green ChemistryAmann AwadNo ratings yet

- BiomassDocument36 pagesBiomassveenaNo ratings yet

- CPM BrochureDocument4 pagesCPM BrochureAlexandru IonescuNo ratings yet

- 4 - Microalgae - A Green Multiproduct Biorefinery For Future Industrial ProspectsDocument14 pages4 - Microalgae - A Green Multiproduct Biorefinery For Future Industrial ProspectsElena Rojo de BenitoNo ratings yet

- Biomass Gasification For Hydrogen ProductionDocument9 pagesBiomass Gasification For Hydrogen ProductionCris CrisNo ratings yet

- 06 Polystyrene StoryDocument67 pages06 Polystyrene StoryThe Outer MarkerNo ratings yet

- Biodegradable Polymers Bamboo Fiber BiocompositeDocument12 pagesBiodegradable Polymers Bamboo Fiber BiocompositekhuongdaihuynhNo ratings yet

- Fuel From FarmDocument168 pagesFuel From FarmKUKU100% (1)

- Factsheet Man-Made FibresDocument6 pagesFactsheet Man-Made FibresPrabaharan GunarajahNo ratings yet

- Water SplittingDocument7 pagesWater SplittingRommel BalceNo ratings yet

- Modified CelluloseDocument19 pagesModified CelluloseK V SATHEESHKUMAR MECHNo ratings yet

- Promising PDFDocument6 pagesPromising PDFGillian AmbaNo ratings yet

- Development of A Condenser For Marine Florae Pyrolysis ReactorDocument156 pagesDevelopment of A Condenser For Marine Florae Pyrolysis ReactorRichard Jess Chan100% (2)

- Agro Industrial Wastes.2012Document20 pagesAgro Industrial Wastes.2012Sadikul AminNo ratings yet

- 2009 - Review of Pyrolyisis Platform For Coproducing Bio-Oil and BiocharDocument16 pages2009 - Review of Pyrolyisis Platform For Coproducing Bio-Oil and BiocharapitbhuNo ratings yet

- Recent Developments in Crosslinking of ElastomersDocument31 pagesRecent Developments in Crosslinking of ElastomersAzizol WahabNo ratings yet

- Bioenergy Technology Roadmap For ColombiaDocument112 pagesBioenergy Technology Roadmap For ColombiaLaura JaimesNo ratings yet

- Wood Pellet Heat GuidebookDocument26 pagesWood Pellet Heat GuidebookSudhakar GanjikuntaNo ratings yet

- Life Cycle Assessment of Biochar As A Partial Replacement To Portland CementDocument6 pagesLife Cycle Assessment of Biochar As A Partial Replacement To Portland CementStephen John ClementeNo ratings yet

- Liquid Metal BatteriesDocument23 pagesLiquid Metal BatteriesmerrickNo ratings yet

- Biomass Power Plants Final2Document34 pagesBiomass Power Plants Final2Abdulhadi EliasNo ratings yet

- Agro CNGDocument14 pagesAgro CNGVinayak JaganureNo ratings yet

- Global Pellet Markets and Growth of Co-FiringDocument28 pagesGlobal Pellet Markets and Growth of Co-FiringNorzuriani Mohamed SeberiNo ratings yet

- Sonocrystallization - The Use of Ultrasound For Improved Industrial Crystallization PDFDocument10 pagesSonocrystallization - The Use of Ultrasound For Improved Industrial Crystallization PDFJessica FengkaiNo ratings yet

- Chapter 3c - Cellulose DerivativesDocument37 pagesChapter 3c - Cellulose DerivativesVanessa LimNo ratings yet

- Development of A Pedal-Operated Abaca Stripping Tool: Evelyn Bacarra-Tablante Angel T. SabusapDocument8 pagesDevelopment of A Pedal-Operated Abaca Stripping Tool: Evelyn Bacarra-Tablante Angel T. SabusapJordan PocaanNo ratings yet

- Last Chance To Donate To Wikipedia in 2009: Anaerobic DigestionDocument24 pagesLast Chance To Donate To Wikipedia in 2009: Anaerobic DigestionVincent Ekhator100% (1)

- Databook 2013Document309 pagesDatabook 2013Jan ZawiszaNo ratings yet

- Biomass Heating A Practical Guide For Potential Users (CTG012)Document94 pagesBiomass Heating A Practical Guide For Potential Users (CTG012)Prashant VaraNo ratings yet

- Biomass Gasification: The East African StudyDocument40 pagesBiomass Gasification: The East African StudyMoy DuekNo ratings yet

- Evaluating The Quality of Protein From Hemp Seed and Hemp Seed Products Through The Use of The Protein Digestibility Corrected Amino Acid Score MethodDocument44 pagesEvaluating The Quality of Protein From Hemp Seed and Hemp Seed Products Through The Use of The Protein Digestibility Corrected Amino Acid Score MethodRaphone Robert100% (1)

- Alexander2019 HomebiogasDocument11 pagesAlexander2019 HomebiogasSalvador Eduardo Vásquez DavalosNo ratings yet

- Crop DiseaseDocument17 pagesCrop DiseaseHanu MNo ratings yet

- Bio Based PolymersDocument16 pagesBio Based PolymersMisael Abdias Millan AlonzoNo ratings yet

- 2 - CHAPTER-Iv2 0Document30 pages2 - CHAPTER-Iv2 0GodisGood AlltheTimeNo ratings yet

- Tan Eng Hau - MBIC - Renewable EnergyDocument18 pagesTan Eng Hau - MBIC - Renewable EnergyLeonardo Alexander Renatus PaneNo ratings yet

- Characterization of Banana Peel Briquettes With The Variation of Binder ConcentrationDocument19 pagesCharacterization of Banana Peel Briquettes With The Variation of Binder ConcentrationSuriati Eka PutriNo ratings yet

- Economic Importance of Algae - BotanyDocument14 pagesEconomic Importance of Algae - BotanyWOWNo ratings yet

- Production of BioGas Using Kitchen WasteDocument6 pagesProduction of BioGas Using Kitchen Wastezonetrek100% (1)

- BiomassDocument3 pagesBiomassGi LantingNo ratings yet

- Different Power PlantsDocument3 pagesDifferent Power PlantsRenz Karl DeclaroNo ratings yet

- Understanding Biomass Energy - Importance of Biofuels | Biomass Energy for Kids | Children's Ecology BooksFrom EverandUnderstanding Biomass Energy - Importance of Biofuels | Biomass Energy for Kids | Children's Ecology BooksNo ratings yet

- Development Theories: Dr. Debashis DebnathDocument22 pagesDevelopment Theories: Dr. Debashis DebnathAnshul GuptaNo ratings yet

- Writ of Kalikasan and The Precautionary Principle and Disaster Risk Reduction and ManagementDocument5 pagesWrit of Kalikasan and The Precautionary Principle and Disaster Risk Reduction and ManagementDYbieNo ratings yet

- Wind Power For StudentsDocument33 pagesWind Power For StudentsFarah Sofhia Mohd ZinNo ratings yet

- 13 01018 Ful-Appeal Decision-420085Document6 pages13 01018 Ful-Appeal Decision-420085mwjNo ratings yet

- Project StakeholderManagement SustainabilityDocument22 pagesProject StakeholderManagement SustainabilityAZLAN AIYUBNo ratings yet

- ANZECC 1992 GuidelinesDocument171 pagesANZECC 1992 GuidelinespelimostroNo ratings yet

- Electric Flat Die Pellet Mill PDFDocument4 pagesElectric Flat Die Pellet Mill PDFpelletsmillmachinery0% (1)

- AC5 Material Science and EngineeringDocument8 pagesAC5 Material Science and EngineeringEdelson Mark GarciaNo ratings yet

- Ashol Lall: Beacon of Sustainable Architecture: IRRAD Gurgaon by Ashok B Lall ArchitectsDocument2 pagesAshol Lall: Beacon of Sustainable Architecture: IRRAD Gurgaon by Ashok B Lall ArchitectsMonisha100% (1)

- Parmanand Rastogi: B.Tech (ECE), M.Tech (Green Energy Technology) Personal DetailsDocument3 pagesParmanand Rastogi: B.Tech (ECE), M.Tech (Green Energy Technology) Personal DetailskrishnanandNo ratings yet

- Convergence-Building Towards Sustainable Management of WatershedsDocument54 pagesConvergence-Building Towards Sustainable Management of Watershedsfpe_scribdNo ratings yet

- Exploring The Perceptions of Tertiary Students' Perceptions and Attitudes Towards Environmental SustainabilityDocument10 pagesExploring The Perceptions of Tertiary Students' Perceptions and Attitudes Towards Environmental SustainabilitySEP-PublisherNo ratings yet

- Unesco Creative Cities Programme: For Sustainable DevelopmentDocument198 pagesUnesco Creative Cities Programme: For Sustainable DevelopmentYana ArsyadiNo ratings yet

- ESS 122 - L1 - Nature, Scope and History of Environmental LawDocument11 pagesESS 122 - L1 - Nature, Scope and History of Environmental LawJyotica Tandon0% (1)

- Sustainable Development: Polytechnic University of The Philppines Unisan, Quezon BranchDocument19 pagesSustainable Development: Polytechnic University of The Philppines Unisan, Quezon BranchMart Lemuel CalooyNo ratings yet

- Bio Energy PlantsDocument2 pagesBio Energy PlantsCurcudel AnastasiaNo ratings yet

- STR-5 STR-7 STR-6: 2Rx1C X 4Sqmm DC Cu - Cable 740voc, 8.7amp Per StringDocument1 pageSTR-5 STR-7 STR-6: 2Rx1C X 4Sqmm DC Cu - Cable 740voc, 8.7amp Per StringSatishKumarMauryaNo ratings yet

- Problem-Solution Essay OutlineDocument2 pagesProblem-Solution Essay OutlineThrowaway TwoNo ratings yet

- Skill Development - 3BALIBDocument4 pagesSkill Development - 3BALIBPRERANA SRIMAAL School of Business Studies and Social SciencesNo ratings yet

- Presentation On Case Study IMTDocument4 pagesPresentation On Case Study IMTIshank Agarwal100% (1)

- PDF Environmental Policy New Directions For The Twenty First Century Norman J Vig Ebook Full ChapterDocument53 pagesPDF Environmental Policy New Directions For The Twenty First Century Norman J Vig Ebook Full Chaptergrace.hunter625100% (2)

- Impacts of TourismDocument7 pagesImpacts of TourismCarson FowlingNo ratings yet

- ENERGY EFFICIENCY IntroductionDocument13 pagesENERGY EFFICIENCY IntroductionAzmi HashimNo ratings yet

- Introduction To Systems Thinking Tools - EngDocument55 pagesIntroduction To Systems Thinking Tools - EngDan JecanNo ratings yet

- Q58 Rowlands and MedeleevDocument9 pagesQ58 Rowlands and MedeleevTow YeeNo ratings yet

- Thailand Human-Environment Interaction Issues PaperDocument4 pagesThailand Human-Environment Interaction Issues Paperapi-296686790No ratings yet

- Solar Energy Questions HandbookDocument17 pagesSolar Energy Questions HandbookMuhammadTouseefNo ratings yet

- 10 Steps To Setting Up Carbon Credits-2Document6 pages10 Steps To Setting Up Carbon Credits-2Marius Angara100% (1)

- NHP (2017-2021) - EngDocument46 pagesNHP (2017-2021) - Engmarcmyomyint1663No ratings yet

- Nepal2002 Water Resources Strategy-ExecSumDocument31 pagesNepal2002 Water Resources Strategy-ExecSumJulian YatesNo ratings yet