Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

102 viewsChemical Reactor Design: 7 Sem, B.Tech. Chemical Engg

Chemical Reactor Design: 7 Sem, B.Tech. Chemical Engg

Uploaded by

Mohammad Ajaz DeshmukhThe document discusses the syllabus for a 7th semester chemical engineering course on chemical reactor design. The syllabus covers topics like fluid-particle reactions, fluid-fluid reactions, solid catalyzed reactions, gas-liquid reactions on solid catalysts, polymerization reaction systems, and steady state non-isothermal reactor design. It also lists reference books and provides examples of unit operations covered, including models for fluid-particle reactions like the progressive conversion model and shrinking unreacted core model.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- 2ND Term S2 Chemistry... - 2Document44 pages2ND Term S2 Chemistry... - 2Adelowo Daniel100% (2)

- Case Study 2 - The Role of Ethics in Social Science ResearchDocument4 pagesCase Study 2 - The Role of Ethics in Social Science ResearchSushma100% (1)

- Chemical Reactor Design: 7 Sem, B.Tech. Chemical EnggDocument16 pagesChemical Reactor Design: 7 Sem, B.Tech. Chemical EnggMohammad Ajaz DeshmukhNo ratings yet

- Chemical Reactor Design: 7 Sem, B.Tech. Chemical EnggDocument16 pagesChemical Reactor Design: 7 Sem, B.Tech. Chemical EnggMohammad Ajaz DeshmukhNo ratings yet

- Scanter 2001Document4 pagesScanter 2001anteysNo ratings yet

- High Rise Concrete Construction Vs High Rise Steel ConstructionDocument4 pagesHigh Rise Concrete Construction Vs High Rise Steel ConstructionnanamallowNo ratings yet

- Catalysis and AdsorptionDocument3 pagesCatalysis and AdsorptionGayathri GanesanNo ratings yet

- Chemical KineticsDocument26 pagesChemical KineticsyusrahgoldNo ratings yet

- Modeling of Noncatalytic Gas-Solid ReactionsDocument20 pagesModeling of Noncatalytic Gas-Solid ReactionsLuis PaletoNo ratings yet

- Unit Ii - Gas-Solid Non-Catalytic ReactorsDocument18 pagesUnit Ii - Gas-Solid Non-Catalytic ReactorsThirunavuk KarasuNo ratings yet

- Heterogeneous Reaction KineticDocument48 pagesHeterogeneous Reaction KineticChristian NwekeNo ratings yet

- Adsorption and Desorption Process in Lab For H20, CO2, CO and Mixture of H2O-CO2 On AU SampleDocument39 pagesAdsorption and Desorption Process in Lab For H20, CO2, CO and Mixture of H2O-CO2 On AU SamplegauriNo ratings yet

- Reactivity of Solids-2021Document43 pagesReactivity of Solids-2021Md Mehrab Alam ShayikhNo ratings yet

- CREII-Module-I - Lecture 1Document38 pagesCREII-Module-I - Lecture 1Aditya parasNo ratings yet

- Experiment 2: Molecules, Moles, and Chemical Reactions: Post-Lab Assignment or ReportDocument3 pagesExperiment 2: Molecules, Moles, and Chemical Reactions: Post-Lab Assignment or ReportJane DoeNo ratings yet

- ChI06 Rates of Reaction TMA B 0817Document21 pagesChI06 Rates of Reaction TMA B 0817Husnul YaqinNo ratings yet

- Fluid Partical Non Catalytic ReactionsDocument22 pagesFluid Partical Non Catalytic Reactionsعوض أمحمدNo ratings yet

- STEM Gen Chem 2 Q3 M3Document29 pagesSTEM Gen Chem 2 Q3 M3Roland AgraNo ratings yet

- Kinetic Modeling of Catalytic Reactions: Short Reference OnDocument24 pagesKinetic Modeling of Catalytic Reactions: Short Reference OnAmino AcidNo ratings yet

- Isothermal Kinetics in Solids - 1ADocument30 pagesIsothermal Kinetics in Solids - 1AGil RolunaNo ratings yet

- Chemical KineticsDocument6 pagesChemical KineticsCarla MagnayeNo ratings yet

- Jurnal Evap 121 PDFDocument8 pagesJurnal Evap 121 PDFanon_628260182No ratings yet

- CRE-II - Chapter-04 Fluid-Particle Systems - HKB 2.10.18Document42 pagesCRE-II - Chapter-04 Fluid-Particle Systems - HKB 2.10.18Ananya DaveNo ratings yet

- Rate ReactionDocument10 pagesRate ReactionTsabit AlbananiNo ratings yet

- CREII-Module-I - Lecture 1 PDFDocument36 pagesCREII-Module-I - Lecture 1 PDFshubhamNo ratings yet

- Chemical Reaction KineticsDocument15 pagesChemical Reaction Kineticsantonio giovannoNo ratings yet

- Chemical Reaction Engineering: Prepared By: Ma. Junallie F. Pomperada Che, Mengr.,Phdt.MDocument24 pagesChemical Reaction Engineering: Prepared By: Ma. Junallie F. Pomperada Che, Mengr.,Phdt.MReynaldo CalitinaNo ratings yet

- Reaction Notes-ChemistryDocument19 pagesReaction Notes-ChemistrySirupyEwe GamerNo ratings yet

- Rate NotesDocument16 pagesRate NotesMegan GohNo ratings yet

- Portfolio Chemical Phenomena 2022Document48 pagesPortfolio Chemical Phenomena 2022omarleyvagaNo ratings yet

- "Diffusive" Heat and Mass Transfer: NPTEL, IIT Kharagpur, Prof. Saikat Chakraborty, Department of Chemical EngineeringDocument7 pages"Diffusive" Heat and Mass Transfer: NPTEL, IIT Kharagpur, Prof. Saikat Chakraborty, Department of Chemical EngineeringShanmukShannuNo ratings yet

- Pdpu/Sot/5 Sem.B. Tech. Chemical EngineeringDocument11 pagesPdpu/Sot/5 Sem.B. Tech. Chemical EngineeringMeetNo ratings yet

- Fluid-Solid Non-Catalytic Reaction: Kinetics: Lecture OnDocument13 pagesFluid-Solid Non-Catalytic Reaction: Kinetics: Lecture OnshubhamNo ratings yet

- Chapter 6 Review SolutionsDocument3 pagesChapter 6 Review SolutionshelloblargNo ratings yet

- Compr Solid State Chemistry Questions and AnswersDocument44 pagesCompr Solid State Chemistry Questions and Answersد.حاتممرقهNo ratings yet

- Kinetika Kimia: Bambang WidionoDocument77 pagesKinetika Kimia: Bambang WidionoFardaawNo ratings yet

- Chemistry F5C1Document9 pagesChemistry F5C1Mohammad Nur SyafiqNo ratings yet

- Teaching Malte Behrens Solid State KineticsDocument38 pagesTeaching Malte Behrens Solid State KineticskgbabuNo ratings yet

- Unit 1 Reaction Kinetics NotesDocument24 pagesUnit 1 Reaction Kinetics NotescutecatmaryamNo ratings yet

- Chemical Kinetics 2023: Prof. Dr. Sahar A. El-MollaDocument36 pagesChemical Kinetics 2023: Prof. Dr. Sahar A. El-MollaMohamed KhaledNo ratings yet

- 20 March 2021, Solid Fluid Reactions SCMDocument6 pages20 March 2021, Solid Fluid Reactions SCMShailesh ChavanNo ratings yet

- Ana) Ysis of Reaction Products and Conversion Time in The Pyrolysis of Cellulose and Wood ParticlesDocument54 pagesAna) Ysis of Reaction Products and Conversion Time in The Pyrolysis of Cellulose and Wood ParticlesAhmad SubiyantoNo ratings yet

- M.sc. ChemistryDocument20 pagesM.sc. Chemistrykunalprabhu148No ratings yet

- Reactions Station LabDocument2 pagesReactions Station LabNyjai BruceNo ratings yet

- Heterogeneous CatalysisDocument38 pagesHeterogeneous CatalysisGnanaprakasam ANo ratings yet

- Rate of ReactionDocument16 pagesRate of ReactionRohmatul FaizahNo ratings yet

- PCh. 4 Fluid-Particle SystemsDocument42 pagesPCh. 4 Fluid-Particle SystemsAnanya DaveNo ratings yet

- Module 7Document20 pagesModule 7Arlene OribelloNo ratings yet

- Achapter7 8TextbookSolutionDocument91 pagesAchapter7 8TextbookSolutionjimNo ratings yet

- A6. Collision TheoryDocument118 pagesA6. Collision TheoryMJ Madredijo SadpcsNo ratings yet

- Bab 1 TRKDocument21 pagesBab 1 TRKfiNo ratings yet

- Chemical Reaction TITANIUMDocument19 pagesChemical Reaction TITANIUMAashishNo ratings yet

- CC 8 SyllabusDocument3 pagesCC 8 SyllabusSANKARA RAO NEIGAPULANo ratings yet

- Assignment Questions (I)Document2 pagesAssignment Questions (I)Thirunavuk KarasuNo ratings yet

- Q4 General Chemistry 2 Module Merged Set A RevisedDocument24 pagesQ4 General Chemistry 2 Module Merged Set A RevisedCJ Rhodes100% (1)

- Advanced Reaction Engineering - 7Document49 pagesAdvanced Reaction Engineering - 7Anonymous 4jVlYsNo ratings yet

- Chemical and Materials Engineering Department: Course SyllabiDocument35 pagesChemical and Materials Engineering Department: Course SyllabiAbdullah SalemNo ratings yet

- 2types of Chemical ReactionsDocument13 pages2types of Chemical ReactionsLloyd Justine PoquitaNo ratings yet

- Chemical KineticsDocument10 pagesChemical KineticsitsshaunboteNo ratings yet

- Classification of Chemical ReactionsDocument7 pagesClassification of Chemical Reactionscalew17036No ratings yet

- Redox RaectionsDocument18 pagesRedox RaectionsBoy VillaNo ratings yet

- Rates of Reactions Notes and Practice QuestionsDocument10 pagesRates of Reactions Notes and Practice QuestionsEustina MumbireNo ratings yet

- Reactive Transport Modeling: Applications in Subsurface Energy and Environmental ProblemsFrom EverandReactive Transport Modeling: Applications in Subsurface Energy and Environmental ProblemsYitian XiaoNo ratings yet

- Mohammad AjazDocument17 pagesMohammad AjazMohammad Ajaz DeshmukhNo ratings yet

- Dissertation/Thesis Distinction Clarification: The Development of The Question/HypothesesDocument4 pagesDissertation/Thesis Distinction Clarification: The Development of The Question/HypothesesMohammad Ajaz DeshmukhNo ratings yet

- Radiocrafts: Open Wireless Standards Wireless M-Bus, KNX RF, Zigbee, 6lowpanDocument44 pagesRadiocrafts: Open Wireless Standards Wireless M-Bus, KNX RF, Zigbee, 6lowpanMohammad Ajaz DeshmukhNo ratings yet

- Chemical Reactor Design: 7 Sem, B.Tech. Chemical EnggDocument17 pagesChemical Reactor Design: 7 Sem, B.Tech. Chemical EnggMohammad Ajaz DeshmukhNo ratings yet

- Chemical Reactor Design: 7 Sem, B.Tech. Chemical EnggDocument20 pagesChemical Reactor Design: 7 Sem, B.Tech. Chemical EnggMohammad Ajaz DeshmukhNo ratings yet

- Chemical Reactor Design: 7 Sem, B.Tech. Chemical EnggDocument14 pagesChemical Reactor Design: 7 Sem, B.Tech. Chemical EnggMohammad Ajaz DeshmukhNo ratings yet

- Chemical Reactor Design: 7 Sem, B.Tech. Chemical EnggDocument16 pagesChemical Reactor Design: 7 Sem, B.Tech. Chemical EnggMohammad Ajaz DeshmukhNo ratings yet

- 01 Introduction KMDocument15 pages01 Introduction KMDiyana Sri WahyuNo ratings yet

- Database Design: Artificial, Composite, and Secondary UidsDocument17 pagesDatabase Design: Artificial, Composite, and Secondary UidsSladjan UgrenovicNo ratings yet

- Willcocks 2021b Chapter 1 PDFDocument20 pagesWillcocks 2021b Chapter 1 PDFMarc SeignarbieuxNo ratings yet

- DD Series Guide Rod Diesel Pile Hammer D Series Diesel Pile HammerDocument7 pagesDD Series Guide Rod Diesel Pile Hammer D Series Diesel Pile HammerMuqorobinNo ratings yet

- 02.06.05 3-Way Valve 1240 6519 - enDocument6 pages02.06.05 3-Way Valve 1240 6519 - enabuya3kubmNo ratings yet

- Lesson Plan Guide: Grade: SubjectDocument5 pagesLesson Plan Guide: Grade: Subjectapi-557528365No ratings yet

- Ship Collision Risk Assessment For The Singapore StraitDocument7 pagesShip Collision Risk Assessment For The Singapore StraitImam FirdausNo ratings yet

- Optimizing Your Music & SuDocument3 pagesOptimizing Your Music & SuShane CampbellNo ratings yet

- BPSMDocument3 pagesBPSMSoniaNo ratings yet

- Cambridge IGCSE: CHEMISTRY 0620/61Document12 pagesCambridge IGCSE: CHEMISTRY 0620/61Mina Abdou100% (1)

- Grounded Theory, Ethnography, PhenomenologyDocument15 pagesGrounded Theory, Ethnography, PhenomenologywhatsinausernameNo ratings yet

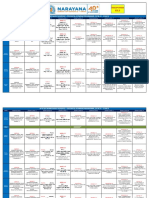

- Sy 2022 2023 - SHS Class Teachers ProgramDocument7 pagesSy 2022 2023 - SHS Class Teachers ProgramSirKingkoy FrancoNo ratings yet

- Voltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Document5 pagesVoltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Moustafa NassarNo ratings yet

- Cutouts and Cutout-Arrester Combinations: (Standard, Linkbreak & Loadbreak)Document16 pagesCutouts and Cutout-Arrester Combinations: (Standard, Linkbreak & Loadbreak)GennaroNo ratings yet

- Rangeland SystemsDocument664 pagesRangeland Systemsalfonso lopez alquisirezNo ratings yet

- Jin Jogot Web PDFDocument125 pagesJin Jogot Web PDFMubarak HossainNo ratings yet

- Activity 5 Educational OrganizationDocument4 pagesActivity 5 Educational OrganizationRaymart NaagNo ratings yet

- 910-911-914-915 Fanuc Ram Parity AlarmDocument2 pages910-911-914-915 Fanuc Ram Parity AlarmShumail JavedNo ratings yet

- 500 MW Boiler-1Document14 pages500 MW Boiler-1Priyal Patil100% (1)

- Reflective EssayDocument5 pagesReflective Essayapi-673517017No ratings yet

- Steel Futures April 09Document4 pagesSteel Futures April 09whwy99No ratings yet

- Comparison Between Scheduling Algorithms in Rtlinux and VxworksDocument9 pagesComparison Between Scheduling Algorithms in Rtlinux and VxworksRajesh GandlaNo ratings yet

- Article-Bioinspired "Wooden Armor" Based On Micro-Nano Lignocellulose With Bouligand StructureDocument6 pagesArticle-Bioinspired "Wooden Armor" Based On Micro-Nano Lignocellulose With Bouligand StructureYashwant MahajanNo ratings yet

- MSD7831 Z01 Da1Document1 pageMSD7831 Z01 Da1idonisNo ratings yet

- AP X-SSC Board Micro Schedule - Etechno&Olympiad - 23.08.21-11.09.21Document3 pagesAP X-SSC Board Micro Schedule - Etechno&Olympiad - 23.08.21-11.09.21Raj RaoNo ratings yet

- Basic Macroeconomics Module Part 2Document206 pagesBasic Macroeconomics Module Part 2Ikrima ibn abdisaNo ratings yet

- Review Article. J. H. Whitfield. The Machiavellian MomentDocument8 pagesReview Article. J. H. Whitfield. The Machiavellian MomentAnderson SilvaNo ratings yet

Chemical Reactor Design: 7 Sem, B.Tech. Chemical Engg

Chemical Reactor Design: 7 Sem, B.Tech. Chemical Engg

Uploaded by

Mohammad Ajaz Deshmukh0 ratings0% found this document useful (0 votes)

102 views10 pagesThe document discusses the syllabus for a 7th semester chemical engineering course on chemical reactor design. The syllabus covers topics like fluid-particle reactions, fluid-fluid reactions, solid catalyzed reactions, gas-liquid reactions on solid catalysts, polymerization reaction systems, and steady state non-isothermal reactor design. It also lists reference books and provides examples of unit operations covered, including models for fluid-particle reactions like the progressive conversion model and shrinking unreacted core model.

Original Description:

Original Title

CRD L1 (1)

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses the syllabus for a 7th semester chemical engineering course on chemical reactor design. The syllabus covers topics like fluid-particle reactions, fluid-fluid reactions, solid catalyzed reactions, gas-liquid reactions on solid catalysts, polymerization reaction systems, and steady state non-isothermal reactor design. It also lists reference books and provides examples of unit operations covered, including models for fluid-particle reactions like the progressive conversion model and shrinking unreacted core model.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

102 views10 pagesChemical Reactor Design: 7 Sem, B.Tech. Chemical Engg

Chemical Reactor Design: 7 Sem, B.Tech. Chemical Engg

Uploaded by

Mohammad Ajaz DeshmukhThe document discusses the syllabus for a 7th semester chemical engineering course on chemical reactor design. The syllabus covers topics like fluid-particle reactions, fluid-fluid reactions, solid catalyzed reactions, gas-liquid reactions on solid catalysts, polymerization reaction systems, and steady state non-isothermal reactor design. It also lists reference books and provides examples of unit operations covered, including models for fluid-particle reactions like the progressive conversion model and shrinking unreacted core model.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 10

CHEMICAL REACTOR DESIGN

7TH SEM, B.TECH. CHEMICAL ENGG.

LECTURE-I

Subject Teacher - Dr. S.R.Mote

The Syllabus

Unit 1: Fluid-Particle Reactions (Non-Catalytic Systems) Un-

reacted core model, Shrinking core model, Rate controlling resistances,

Determination of the rate controlling steps, Various contacting patterns

and their performance equations

Unit 2: Fluid-Fluid Reactions (Non-Catalytic Systems)

heterogeneous fluid - fluid reactions, Rate equation for instantaneous ,

Fast and slow reactions, Equipment used in fluid- fluid contacting with

reaction, Towers for fast reaction and slow reactions

Unit 3: Solid Catalyzed Reactions Rate Equation for Surface Kinetics,

Pore Diffusion Resistance Combined with Surface Kinetics, Porous

Catalyst Particles, Heat Effects During Reaction, Performance

Equations for Reactors , Experimental Methods for Finding Rates,

Product Distribution in Multiple Reactions, The Packed Bed Catalytic

Reactor

The Syllabus

Unit 4: Gas-Liquid Reactions on Solid Catalyst . Trickle Beds,

Slurry Reactors, Three Phase Fluidized Beds, The General Rate

Equation, Performance Equations, selection of various types of

Contactor

Unit 5: Polymerization Reaction Systems. Pseudo-Steady-State

Hypothesis (PSSH), Searching for a Mechanism, Step

Polymerization, Free-Radical Polymerization, Development of Rate

Laws for the Net Rate of Reaction, Modeling a Batch Polymerization

Reactor, Molecular Weight Distribution and Properties of

Distribution

Unit 6: Steady State Non-isothermal Reactor Design. The

Energy Balance, Non-isothermal continuous flow reactors,

equilibrium conversion, non-adiabatic reactor operations, multiple

steady states, non-isothermal multiple chemical reactions

Reference Books

O. Levenspiel, Chemical Reaction Engineering, 3rd

Edition, Wiley India, 2006.

H. S. Fogler, Elements of Chemical Reaction Engineering,

4th Edition, PHI, 2005.

J.M. Smith, Chemical Engineering Kinetics, 3rd Edition,

McGraw Hill, 1981.

S.D. Dawande, Principles of Reaction Engineering,

Denett & Co, 2007

S. M. Walas, Reaction Kinetics for Chemical Engineers,

McGraw Hill, 1959.

Unit 1: Fluid-Particle Reactions

(Non-Catalytic Systems)

A(fluid) + b B(solid) fluid products (1)

solid products (2)

fluid and solid products (3)

C (s) + O2 (g) CO2 (g) + ash (s)

2 C (s) + O2 (g) CO (g) + ash (s)

C (s) + H2O (g) CO(g) + H2 (g)

2 ZnS (s) + 3 O2 (g) 2 ZnO (s) + 2 SO2 (g)

4 FeS2 (s) + 11 O2 (g) 2 Fe2O3 (s) + 8 SO2 (g)

Fe3O4 (s) + 4 H2 (g) 3 Fe (s) + 4 H2O (g)

C (s) + 2 S (g) CS2 (g)

Models of fluid-particle reactions

For the noncatalytic reaction of particles with surrounding

fluid, we have

1. Progressive Conversion Model

2. Shrinking Unreacted Core Model

Progressive-Conversion Model (PCM)

We visualize that

reactant gas enters and

reacts throughout the

particle at all times,

most likely at different

rates at different

locations within the

particle. Thus, solid

reactant is converted

continuously and

progressively

throughout the particle

Shrinking Core Model (SCM)

We visualize that

reaction occurs first at

the outer layer of the

particle. The zone of

reaction then moves

on inner side, leaving

behind completely

converted material and

inert solid (ash). Thus,

at any time there exists

an unreacted core of

material which shrinks

in size during reaction.

SHRINKING-CORE MODEL FOR SPHERICAL

PARTICLES OF UNCHANGING SIZE

Step 1. Diffusion of gaseous reactant A through the film

surrounding the particle to the surface of the solid.

Step 2. Penetration and diffusion of A through the blanket

of ash to the surface of the unreacted core.

Step 3. Reaction of gaseous A with solid at this reaction

surface

Step 4. Diffusion of gaseous products through the ash

back to the exterior surface of the solid.

Step 5. Diffusion of gaseous products through the gas film

back into the main body of fluid.

You might also like

- 2ND Term S2 Chemistry... - 2Document44 pages2ND Term S2 Chemistry... - 2Adelowo Daniel100% (2)

- Case Study 2 - The Role of Ethics in Social Science ResearchDocument4 pagesCase Study 2 - The Role of Ethics in Social Science ResearchSushma100% (1)

- Chemical Reactor Design: 7 Sem, B.Tech. Chemical EnggDocument16 pagesChemical Reactor Design: 7 Sem, B.Tech. Chemical EnggMohammad Ajaz DeshmukhNo ratings yet

- Chemical Reactor Design: 7 Sem, B.Tech. Chemical EnggDocument16 pagesChemical Reactor Design: 7 Sem, B.Tech. Chemical EnggMohammad Ajaz DeshmukhNo ratings yet

- Scanter 2001Document4 pagesScanter 2001anteysNo ratings yet

- High Rise Concrete Construction Vs High Rise Steel ConstructionDocument4 pagesHigh Rise Concrete Construction Vs High Rise Steel ConstructionnanamallowNo ratings yet

- Catalysis and AdsorptionDocument3 pagesCatalysis and AdsorptionGayathri GanesanNo ratings yet

- Chemical KineticsDocument26 pagesChemical KineticsyusrahgoldNo ratings yet

- Modeling of Noncatalytic Gas-Solid ReactionsDocument20 pagesModeling of Noncatalytic Gas-Solid ReactionsLuis PaletoNo ratings yet

- Unit Ii - Gas-Solid Non-Catalytic ReactorsDocument18 pagesUnit Ii - Gas-Solid Non-Catalytic ReactorsThirunavuk KarasuNo ratings yet

- Heterogeneous Reaction KineticDocument48 pagesHeterogeneous Reaction KineticChristian NwekeNo ratings yet

- Adsorption and Desorption Process in Lab For H20, CO2, CO and Mixture of H2O-CO2 On AU SampleDocument39 pagesAdsorption and Desorption Process in Lab For H20, CO2, CO and Mixture of H2O-CO2 On AU SamplegauriNo ratings yet

- Reactivity of Solids-2021Document43 pagesReactivity of Solids-2021Md Mehrab Alam ShayikhNo ratings yet

- CREII-Module-I - Lecture 1Document38 pagesCREII-Module-I - Lecture 1Aditya parasNo ratings yet

- Experiment 2: Molecules, Moles, and Chemical Reactions: Post-Lab Assignment or ReportDocument3 pagesExperiment 2: Molecules, Moles, and Chemical Reactions: Post-Lab Assignment or ReportJane DoeNo ratings yet

- ChI06 Rates of Reaction TMA B 0817Document21 pagesChI06 Rates of Reaction TMA B 0817Husnul YaqinNo ratings yet

- Fluid Partical Non Catalytic ReactionsDocument22 pagesFluid Partical Non Catalytic Reactionsعوض أمحمدNo ratings yet

- STEM Gen Chem 2 Q3 M3Document29 pagesSTEM Gen Chem 2 Q3 M3Roland AgraNo ratings yet

- Kinetic Modeling of Catalytic Reactions: Short Reference OnDocument24 pagesKinetic Modeling of Catalytic Reactions: Short Reference OnAmino AcidNo ratings yet

- Isothermal Kinetics in Solids - 1ADocument30 pagesIsothermal Kinetics in Solids - 1AGil RolunaNo ratings yet

- Chemical KineticsDocument6 pagesChemical KineticsCarla MagnayeNo ratings yet

- Jurnal Evap 121 PDFDocument8 pagesJurnal Evap 121 PDFanon_628260182No ratings yet

- CRE-II - Chapter-04 Fluid-Particle Systems - HKB 2.10.18Document42 pagesCRE-II - Chapter-04 Fluid-Particle Systems - HKB 2.10.18Ananya DaveNo ratings yet

- Rate ReactionDocument10 pagesRate ReactionTsabit AlbananiNo ratings yet

- CREII-Module-I - Lecture 1 PDFDocument36 pagesCREII-Module-I - Lecture 1 PDFshubhamNo ratings yet

- Chemical Reaction KineticsDocument15 pagesChemical Reaction Kineticsantonio giovannoNo ratings yet

- Chemical Reaction Engineering: Prepared By: Ma. Junallie F. Pomperada Che, Mengr.,Phdt.MDocument24 pagesChemical Reaction Engineering: Prepared By: Ma. Junallie F. Pomperada Che, Mengr.,Phdt.MReynaldo CalitinaNo ratings yet

- Reaction Notes-ChemistryDocument19 pagesReaction Notes-ChemistrySirupyEwe GamerNo ratings yet

- Rate NotesDocument16 pagesRate NotesMegan GohNo ratings yet

- Portfolio Chemical Phenomena 2022Document48 pagesPortfolio Chemical Phenomena 2022omarleyvagaNo ratings yet

- "Diffusive" Heat and Mass Transfer: NPTEL, IIT Kharagpur, Prof. Saikat Chakraborty, Department of Chemical EngineeringDocument7 pages"Diffusive" Heat and Mass Transfer: NPTEL, IIT Kharagpur, Prof. Saikat Chakraborty, Department of Chemical EngineeringShanmukShannuNo ratings yet

- Pdpu/Sot/5 Sem.B. Tech. Chemical EngineeringDocument11 pagesPdpu/Sot/5 Sem.B. Tech. Chemical EngineeringMeetNo ratings yet

- Fluid-Solid Non-Catalytic Reaction: Kinetics: Lecture OnDocument13 pagesFluid-Solid Non-Catalytic Reaction: Kinetics: Lecture OnshubhamNo ratings yet

- Chapter 6 Review SolutionsDocument3 pagesChapter 6 Review SolutionshelloblargNo ratings yet

- Compr Solid State Chemistry Questions and AnswersDocument44 pagesCompr Solid State Chemistry Questions and Answersد.حاتممرقهNo ratings yet

- Kinetika Kimia: Bambang WidionoDocument77 pagesKinetika Kimia: Bambang WidionoFardaawNo ratings yet

- Chemistry F5C1Document9 pagesChemistry F5C1Mohammad Nur SyafiqNo ratings yet

- Teaching Malte Behrens Solid State KineticsDocument38 pagesTeaching Malte Behrens Solid State KineticskgbabuNo ratings yet

- Unit 1 Reaction Kinetics NotesDocument24 pagesUnit 1 Reaction Kinetics NotescutecatmaryamNo ratings yet

- Chemical Kinetics 2023: Prof. Dr. Sahar A. El-MollaDocument36 pagesChemical Kinetics 2023: Prof. Dr. Sahar A. El-MollaMohamed KhaledNo ratings yet

- 20 March 2021, Solid Fluid Reactions SCMDocument6 pages20 March 2021, Solid Fluid Reactions SCMShailesh ChavanNo ratings yet

- Ana) Ysis of Reaction Products and Conversion Time in The Pyrolysis of Cellulose and Wood ParticlesDocument54 pagesAna) Ysis of Reaction Products and Conversion Time in The Pyrolysis of Cellulose and Wood ParticlesAhmad SubiyantoNo ratings yet

- M.sc. ChemistryDocument20 pagesM.sc. Chemistrykunalprabhu148No ratings yet

- Reactions Station LabDocument2 pagesReactions Station LabNyjai BruceNo ratings yet

- Heterogeneous CatalysisDocument38 pagesHeterogeneous CatalysisGnanaprakasam ANo ratings yet

- Rate of ReactionDocument16 pagesRate of ReactionRohmatul FaizahNo ratings yet

- PCh. 4 Fluid-Particle SystemsDocument42 pagesPCh. 4 Fluid-Particle SystemsAnanya DaveNo ratings yet

- Module 7Document20 pagesModule 7Arlene OribelloNo ratings yet

- Achapter7 8TextbookSolutionDocument91 pagesAchapter7 8TextbookSolutionjimNo ratings yet

- A6. Collision TheoryDocument118 pagesA6. Collision TheoryMJ Madredijo SadpcsNo ratings yet

- Bab 1 TRKDocument21 pagesBab 1 TRKfiNo ratings yet

- Chemical Reaction TITANIUMDocument19 pagesChemical Reaction TITANIUMAashishNo ratings yet

- CC 8 SyllabusDocument3 pagesCC 8 SyllabusSANKARA RAO NEIGAPULANo ratings yet

- Assignment Questions (I)Document2 pagesAssignment Questions (I)Thirunavuk KarasuNo ratings yet

- Q4 General Chemistry 2 Module Merged Set A RevisedDocument24 pagesQ4 General Chemistry 2 Module Merged Set A RevisedCJ Rhodes100% (1)

- Advanced Reaction Engineering - 7Document49 pagesAdvanced Reaction Engineering - 7Anonymous 4jVlYsNo ratings yet

- Chemical and Materials Engineering Department: Course SyllabiDocument35 pagesChemical and Materials Engineering Department: Course SyllabiAbdullah SalemNo ratings yet

- 2types of Chemical ReactionsDocument13 pages2types of Chemical ReactionsLloyd Justine PoquitaNo ratings yet

- Chemical KineticsDocument10 pagesChemical KineticsitsshaunboteNo ratings yet

- Classification of Chemical ReactionsDocument7 pagesClassification of Chemical Reactionscalew17036No ratings yet

- Redox RaectionsDocument18 pagesRedox RaectionsBoy VillaNo ratings yet

- Rates of Reactions Notes and Practice QuestionsDocument10 pagesRates of Reactions Notes and Practice QuestionsEustina MumbireNo ratings yet

- Reactive Transport Modeling: Applications in Subsurface Energy and Environmental ProblemsFrom EverandReactive Transport Modeling: Applications in Subsurface Energy and Environmental ProblemsYitian XiaoNo ratings yet

- Mohammad AjazDocument17 pagesMohammad AjazMohammad Ajaz DeshmukhNo ratings yet

- Dissertation/Thesis Distinction Clarification: The Development of The Question/HypothesesDocument4 pagesDissertation/Thesis Distinction Clarification: The Development of The Question/HypothesesMohammad Ajaz DeshmukhNo ratings yet

- Radiocrafts: Open Wireless Standards Wireless M-Bus, KNX RF, Zigbee, 6lowpanDocument44 pagesRadiocrafts: Open Wireless Standards Wireless M-Bus, KNX RF, Zigbee, 6lowpanMohammad Ajaz DeshmukhNo ratings yet

- Chemical Reactor Design: 7 Sem, B.Tech. Chemical EnggDocument17 pagesChemical Reactor Design: 7 Sem, B.Tech. Chemical EnggMohammad Ajaz DeshmukhNo ratings yet

- Chemical Reactor Design: 7 Sem, B.Tech. Chemical EnggDocument20 pagesChemical Reactor Design: 7 Sem, B.Tech. Chemical EnggMohammad Ajaz DeshmukhNo ratings yet

- Chemical Reactor Design: 7 Sem, B.Tech. Chemical EnggDocument14 pagesChemical Reactor Design: 7 Sem, B.Tech. Chemical EnggMohammad Ajaz DeshmukhNo ratings yet

- Chemical Reactor Design: 7 Sem, B.Tech. Chemical EnggDocument16 pagesChemical Reactor Design: 7 Sem, B.Tech. Chemical EnggMohammad Ajaz DeshmukhNo ratings yet

- 01 Introduction KMDocument15 pages01 Introduction KMDiyana Sri WahyuNo ratings yet

- Database Design: Artificial, Composite, and Secondary UidsDocument17 pagesDatabase Design: Artificial, Composite, and Secondary UidsSladjan UgrenovicNo ratings yet

- Willcocks 2021b Chapter 1 PDFDocument20 pagesWillcocks 2021b Chapter 1 PDFMarc SeignarbieuxNo ratings yet

- DD Series Guide Rod Diesel Pile Hammer D Series Diesel Pile HammerDocument7 pagesDD Series Guide Rod Diesel Pile Hammer D Series Diesel Pile HammerMuqorobinNo ratings yet

- 02.06.05 3-Way Valve 1240 6519 - enDocument6 pages02.06.05 3-Way Valve 1240 6519 - enabuya3kubmNo ratings yet

- Lesson Plan Guide: Grade: SubjectDocument5 pagesLesson Plan Guide: Grade: Subjectapi-557528365No ratings yet

- Ship Collision Risk Assessment For The Singapore StraitDocument7 pagesShip Collision Risk Assessment For The Singapore StraitImam FirdausNo ratings yet

- Optimizing Your Music & SuDocument3 pagesOptimizing Your Music & SuShane CampbellNo ratings yet

- BPSMDocument3 pagesBPSMSoniaNo ratings yet

- Cambridge IGCSE: CHEMISTRY 0620/61Document12 pagesCambridge IGCSE: CHEMISTRY 0620/61Mina Abdou100% (1)

- Grounded Theory, Ethnography, PhenomenologyDocument15 pagesGrounded Theory, Ethnography, PhenomenologywhatsinausernameNo ratings yet

- Sy 2022 2023 - SHS Class Teachers ProgramDocument7 pagesSy 2022 2023 - SHS Class Teachers ProgramSirKingkoy FrancoNo ratings yet

- Voltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Document5 pagesVoltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Moustafa NassarNo ratings yet

- Cutouts and Cutout-Arrester Combinations: (Standard, Linkbreak & Loadbreak)Document16 pagesCutouts and Cutout-Arrester Combinations: (Standard, Linkbreak & Loadbreak)GennaroNo ratings yet

- Rangeland SystemsDocument664 pagesRangeland Systemsalfonso lopez alquisirezNo ratings yet

- Jin Jogot Web PDFDocument125 pagesJin Jogot Web PDFMubarak HossainNo ratings yet

- Activity 5 Educational OrganizationDocument4 pagesActivity 5 Educational OrganizationRaymart NaagNo ratings yet

- 910-911-914-915 Fanuc Ram Parity AlarmDocument2 pages910-911-914-915 Fanuc Ram Parity AlarmShumail JavedNo ratings yet

- 500 MW Boiler-1Document14 pages500 MW Boiler-1Priyal Patil100% (1)

- Reflective EssayDocument5 pagesReflective Essayapi-673517017No ratings yet

- Steel Futures April 09Document4 pagesSteel Futures April 09whwy99No ratings yet

- Comparison Between Scheduling Algorithms in Rtlinux and VxworksDocument9 pagesComparison Between Scheduling Algorithms in Rtlinux and VxworksRajesh GandlaNo ratings yet

- Article-Bioinspired "Wooden Armor" Based On Micro-Nano Lignocellulose With Bouligand StructureDocument6 pagesArticle-Bioinspired "Wooden Armor" Based On Micro-Nano Lignocellulose With Bouligand StructureYashwant MahajanNo ratings yet

- MSD7831 Z01 Da1Document1 pageMSD7831 Z01 Da1idonisNo ratings yet

- AP X-SSC Board Micro Schedule - Etechno&Olympiad - 23.08.21-11.09.21Document3 pagesAP X-SSC Board Micro Schedule - Etechno&Olympiad - 23.08.21-11.09.21Raj RaoNo ratings yet

- Basic Macroeconomics Module Part 2Document206 pagesBasic Macroeconomics Module Part 2Ikrima ibn abdisaNo ratings yet

- Review Article. J. H. Whitfield. The Machiavellian MomentDocument8 pagesReview Article. J. H. Whitfield. The Machiavellian MomentAnderson SilvaNo ratings yet