Professional Documents

Culture Documents

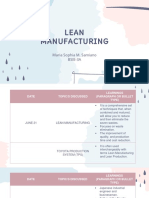

Lean Manufacturing: Gonzales, Ron Aldelene Bsie - 3A

Lean Manufacturing: Gonzales, Ron Aldelene Bsie - 3A

Uploaded by

Ron Aldelene Gonzales0 ratings0% found this document useful (0 votes)

40 views13 pagesThis document summarizes Ron Gonzales' learnings about lean manufacturing. It discusses key concepts like the seven wastes, Toyota Production System, Just-In-Time, 5S, and Kaizen. The Toyota Production System aims to eliminate waste and maximize efficiency. It was developed by Taiichi Ohno and has three pillars: Just-In-Time, autonomation, and respect for people. Methods like 5S, standard work, and visual management are used to implement continuous improvement.

Original Description:

A midterm requirement summarizing our lectures in summer.

Original Title

Lean Manufacturing

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes Ron Gonzales' learnings about lean manufacturing. It discusses key concepts like the seven wastes, Toyota Production System, Just-In-Time, 5S, and Kaizen. The Toyota Production System aims to eliminate waste and maximize efficiency. It was developed by Taiichi Ohno and has three pillars: Just-In-Time, autonomation, and respect for people. Methods like 5S, standard work, and visual management are used to implement continuous improvement.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

40 views13 pagesLean Manufacturing: Gonzales, Ron Aldelene Bsie - 3A

Lean Manufacturing: Gonzales, Ron Aldelene Bsie - 3A

Uploaded by

Ron Aldelene GonzalesThis document summarizes Ron Gonzales' learnings about lean manufacturing. It discusses key concepts like the seven wastes, Toyota Production System, Just-In-Time, 5S, and Kaizen. The Toyota Production System aims to eliminate waste and maximize efficiency. It was developed by Taiichi Ohno and has three pillars: Just-In-Time, autonomation, and respect for people. Methods like 5S, standard work, and visual management are used to implement continuous improvement.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 13

Lean Manufacturing

Gonzales, Ron Aldelene

BSIE – 3A

Date Topic/s Discussed Learnings

• It is a production method based on the

concept of increasing productivity while

reducing waste in a manufacturing

Lean Manufacturing process.

• Seven Wastes (muda).

• Toyota Production System (TPS).

June 21 • Used by the Japanese.

Toyota Production System • Eliminating waste and maximizing

production efficiency.

• Has 3 pillars.

• Japanese industrial engineer and

businessman and

Ohno Taiichi

• The father of Toyota Production System.

• He devised the seven wastes.

• Beyond Large-Scale Production.

Date Topic/s Discussed Learnings

• JIT is a form of inventory management

in which products are only obtained

from suppliers as they are required. This

method's major goal is to lower

inventory holding costs while increasing

inventory turnover.

June 21

Just In Time (JIT) • First Pillar of TPS.

• Just in time delivery involves careful

planning in order to complete the entire

process from start to finish, increasing

efficiency and removing the possibility of

error because each procedure is closely

monitored.

Date Topic/s Discussed Learnings

• A Japanese term which means

“Autonomation”.

• It’s the automatic detection of problems

JIDOKA or defects at an early stage and proceed

with the production only after resolving

the problem at its root cause.

• Automation with human intelligence.

June 21 • Over-production

• Waiting time

• Transportation

7 Types of Wastes • Processing

• Inventory

• Motion

• Defects

Gantt Chart • Scheduling your work and activities.

Date Topic/s Discussed Learnings

• Continuous improvement.

• Focuses on reducing waste, increasing

productivity, and delivering long-term

improvement in a company's specified

operations and processes.

KAIZEN

• 5 Whys

• It seeks to bring together employees

from many departments and levels of the

June 23 organization to solve an issue or improve

a process.

• Workflow management.

• It is based on the fundamental concept

that you must first know where you are

KANBAN

in order to travel to your target location.

• Can be applied to any type of work that

follows a repeating process.

• What-to do lists.

Date Topic/s Discussed Learnings

• Fool proofing or error proofing.

• It attempts to prevent an error from

occurring.

Poka Yoke

• Example is an elevator equipped with

sensors and alarms to prevent operation

when overloaded.

• 5S in workplace organization and

housekeeping.

• Stands for 5 individual s-words, namely

June 23 sort, set in order, shine, standardize and

sustain

• Seiri, Seiton, Seiso, Seiketsu, Shitsuke

5S • This concept is putting things back

where they belong and keeping the

workplace clean, making it easier for

individuals to complete their tasks

without wasting time or causing damage.

• Raises product quality and improves

work productivity, resulting in lower

costs and higher efficiencies.

Date Topic/s Discussed Learnings

• Sorting

• Identifying what is necessary and not

Seiri necessary items, then eliminating the not

necessary items.

• Example: Sorting goods in pantry.

June 23 • Set in order

• Systematic Arrangement.

• Arranging correctly and to make correct

Seiton preparations.

• Making thorough preparations

• Example: Arranging your files in your

computer in their proper folders before

doing what you have to do to them.

Date Topic/s Discussed Learnings

• Cleaning

• Shine

• Cleaning as a form of inspection.

• Finding minor problems to reduce

Seiso

number of accidents and machine

downtime.

June 23 • Example: Wiping the dusty and filthy

sink clean.

• Standardization

• Setting up standards and norms and

Seiketsu maintaining them.

• Acknowledging the 5S.

• Example: Creating standards on item

identifications in shelves.

Date Topic/s Discussed Learnings

• Self Discipline and Training

• Training people to follow good

housekeeping discipline.

• Always follows the rule and applying it

Shitsuke

as a habit.

• High employee morale.

• Example: Organizing your bed after you

woke up in the morning.

June 23

• It is a good way for companies to get

familiar with continuous improvement

cycles by involving workers to organize

and improve the workplace conditions.

Benefits of 5S

• 5S reduces waste, downtime, defects,

delays and questions.

• 5S improves safety, customer and

personal satisfaction, visual and process

control, and standardization.

Date Topic/s Discussed Learnings

1. Over-production

2. Waiting Time

3. Transportation

7 Types of Wastes 4. Processing

5. Inventory

6. Motion

July 01 7. Defects

• It is when the final product that is

produced is unable to be used or sold due

to lack of customer.

Over-production • Characteristics are batch processing,

excess equipment management, capacity,

scrap due to obsolescence, storage racks,

and large work in progress (WIP).

Date Topic/s Discussed Learnings

• Inventory that is sitting idle.

• Lack of operators

Waiting Time • Unexpected downtime of equipment.

• Causes are lack of proper equipment and

low effectiveness of man and machines.

• Is the movement of materials that adds

July 01

no value to the product.

Transportation • Causes are large batch productions and

large inventories that requires excessive

effort to move items between processes.

• Is a method adopted to compute the

Northwest Corner Rule initial feasible solution of the

transportation problem.

• The effort that is unnecessary and adds

Processing

no value to the product.

Date Topic/s Discussed Learnings

• Selection of project and adviser

• Preparation of Proposal

• Evaluation of proposal

(Design Project) • Analysis of design alternatives

Course Outline • Evaluation and selection of preferred solution

June 18 • Preparation of final project

• Presentation of the project

• Assessment of the project

• Example of possible titles for our project.

Sample of Recent Projects

• How to think of a good and an IE deserving

of BSIE

title and project to present.

Glowcap – product that provides a reminder when

it’s time to take your meds.

Edyn – sensor that collects and analyses data

Example of Products about current weather and soil conditions.

Quitbit – smart lighter that helps you to quit

smoking. Displays how many cigarettes you’ve

smoked and how long till your next one.

THANK

YOU!

You might also like

- Final Project InternationalTradeDocument21 pagesFinal Project InternationalTradeAssignment parttimeNo ratings yet

- Scrum Master NotesDocument20 pagesScrum Master NotesHerbert Weigelt75% (4)

- Poster Mustafa KonukR2Document1 pagePoster Mustafa KonukR2Ansar LawiNo ratings yet

- Toyota Production SystemDocument37 pagesToyota Production Systemjaiswalswatin87100% (1)

- Dressmaking NC Ii (320 HRS)Document8 pagesDressmaking NC Ii (320 HRS)Amir Hasan Nicko BaidanNo ratings yet

- Compare and Contrast of Noli and El FiliDocument1 pageCompare and Contrast of Noli and El FiliRon Aldelene Gonzales100% (2)

- KaizenDocument44 pagesKaizenmentariashNo ratings yet

- Cba 101Document2 pagesCba 101Alyssa Faith NiangarNo ratings yet

- 5s Pillars of The Visual WorkplaceDocument35 pages5s Pillars of The Visual WorkplaceSaravana kumar NagarajanNo ratings yet

- LEAN - What Does Kaizen MeanDocument25 pagesLEAN - What Does Kaizen MeanaaaNo ratings yet

- Lean ManufacturingDocument24 pagesLean ManufacturingBaljeetNo ratings yet

- Week 3Document27 pagesWeek 3Sabiha Meyra ŞahinlerNo ratings yet

- Just-In-Time Manufacturing: A Powerpoint Presentation by Swati (54), Meenal (39), Reenu (45), JayaDocument30 pagesJust-In-Time Manufacturing: A Powerpoint Presentation by Swati (54), Meenal (39), Reenu (45), JayaPranav ParikhNo ratings yet

- EfficiencyPart2 KarlAhlrichsAfternoonSessionDocument96 pagesEfficiencyPart2 KarlAhlrichsAfternoonSessionMT TMNo ratings yet

- 5.3 Lean ProductionDocument39 pages5.3 Lean ProductionP RushitaNo ratings yet

- Lean Manufacturing: Maria Sophia M. Samiano Bsie-3ADocument12 pagesLean Manufacturing: Maria Sophia M. Samiano Bsie-3ARon Aldelene GonzalesNo ratings yet

- Week 4-Agile Course PresentationDocument52 pagesWeek 4-Agile Course Presentationcarolinaceballos79No ratings yet

- Kaizen Event Workshop Aug.03Document19 pagesKaizen Event Workshop Aug.03Gunawan tNo ratings yet

- Lean Manufacturing: Suryansh Prakash SinghDocument20 pagesLean Manufacturing: Suryansh Prakash SinghSuryansh Prakash SinghNo ratings yet

- Pmi Acp Exam Cheat SheetDocument7 pagesPmi Acp Exam Cheat Sheetarie gembulNo ratings yet

- Jit System - Unit 3Document15 pagesJit System - Unit 3zaidkhanNo ratings yet

- Long - Term PhilosophyDocument25 pagesLong - Term Philosophymanivino100% (8)

- Kaizen: Performance Excellence Series Training Module ElementsDocument24 pagesKaizen: Performance Excellence Series Training Module ElementsRamanand YadavNo ratings yet

- Key Words FinalDocument28 pagesKey Words Finalsarvagyagoyal64No ratings yet

- Total Quality ManagementDocument38 pagesTotal Quality Managementashish RautNo ratings yet

- Kanban SystemDocument4 pagesKanban SystemDivakar RanjanNo ratings yet

- Jit ManufacturingDocument24 pagesJit ManufacturingAniket DhamaleNo ratings yet

- Week 3 HandoutDocument22 pagesWeek 3 HandoutMj Ong Pierson GarboNo ratings yet

- Sort Set-In-Order Shine Standardize Sustain: What Is 5-S?Document43 pagesSort Set-In-Order Shine Standardize Sustain: What Is 5-S?niratNo ratings yet

- Chapter - 2 Lean Manufacturing ProcessDocument21 pagesChapter - 2 Lean Manufacturing ProcessShaharyar AminNo ratings yet

- Chapter Two Lean Production SystemDocument31 pagesChapter Two Lean Production SystemIslam Abdou AbbasNo ratings yet

- 2022 Dme 483-8 TPM & OoeDocument51 pages2022 Dme 483-8 TPM & Ooemohammad umairNo ratings yet

- Utilizing A Lean Management SystemDocument19 pagesUtilizing A Lean Management SystemAshokNo ratings yet

- Just-In-Time Systems: Submitted To-Submitted by - Ms. Neha Gulati Tanvi VermaDocument35 pagesJust-In-Time Systems: Submitted To-Submitted by - Ms. Neha Gulati Tanvi VermaPankaj Khindria100% (1)

- Kaizen 2Document60 pagesKaizen 2Israfi MaulanaNo ratings yet

- Lesson 1 INTRODUCTION METHODSDocument13 pagesLesson 1 INTRODUCTION METHODSAllona Jean Pacquiao DayapNo ratings yet

- 5s MethodologicalDocument69 pages5s MethodologicalHoàng Thị NguyênNo ratings yet

- 2211-03 LeanManu 5S Presentation DemoDocument11 pages2211-03 LeanManu 5S Presentation Demomiso73No ratings yet

- Google Cloud DevOps and SREs PDF - 1594058313Document60 pagesGoogle Cloud DevOps and SREs PDF - 1594058313Daniel LemosNo ratings yet

- KaizenDocument34 pagesKaizenArpit ShahjiNo ratings yet

- BOSH ReviewerDocument7 pagesBOSH ReviewerGliönä Löu Ärënäs MërcädöNo ratings yet

- Agile and Scrum - PM POV (Autosaved)Document50 pagesAgile and Scrum - PM POV (Autosaved)akash78586No ratings yet

- Just-in-Time and Lean SystemsDocument32 pagesJust-in-Time and Lean SystemsruchierichNo ratings yet

- PDF Lean Implementation at Siemens Kalwa Plant DL - PDFDocument8 pagesPDF Lean Implementation at Siemens Kalwa Plant DL - PDFNamit BaserNo ratings yet

- 2 LeanDocument63 pages2 Leanhaidar khadourNo ratings yet

- Kaizenppt 1223192122317277 9 PDFDocument12 pagesKaizenppt 1223192122317277 9 PDFgcldesignNo ratings yet

- Continuous Process Improvement: Subject: Total Quality Management Instructor: Sumera KaziDocument10 pagesContinuous Process Improvement: Subject: Total Quality Management Instructor: Sumera Kazidua tanveerNo ratings yet

- Important KeywordsDocument28 pagesImportant KeywordsChandan YadavNo ratings yet

- Module 4Document11 pagesModule 4Dheeraj SivadasNo ratings yet

- Healthcare CEO Briefing: The "Lean Method" Approach To Performance ExcellenceDocument34 pagesHealthcare CEO Briefing: The "Lean Method" Approach To Performance ExcellenceAbhishek GajareNo ratings yet

- Ie 450 PP 2Document48 pagesIe 450 PP 2salesmuliamakmurNo ratings yet

- Systems and Techniques Used in Production Management: Topic 5Document21 pagesSystems and Techniques Used in Production Management: Topic 5Frank Eric ZombokoNo ratings yet

- 10 - Lean Manufacturing 10 - Improvement Strategies 2Document9 pages10 - Lean Manufacturing 10 - Improvement Strategies 2gerewalNo ratings yet

- Agile Software Development Scrum - ShortDocument54 pagesAgile Software Development Scrum - ShortHarol AchaguaNo ratings yet

- Software Configuration ManagementDocument33 pagesSoftware Configuration Managementyeswanth chowdary nidamanuriNo ratings yet

- Agile Software DevelopmentDocument26 pagesAgile Software DevelopmentMAITUMELO RADIPODINo ratings yet

- Innovation Management: Session: LeanDocument29 pagesInnovation Management: Session: LeanAamiTataiNo ratings yet

- Chapter 4 TQMDocument72 pagesChapter 4 TQMCarlo Gojo Cruz HalasanNo ratings yet

- Module 45. Quick ChangeoverDocument17 pagesModule 45. Quick Changeovertaghavi1347No ratings yet

- LAM Lecture 10-12 PDFDocument37 pagesLAM Lecture 10-12 PDFHayl KhadhamiNo ratings yet

- Lean Manufacturing in HouseholdDocument8 pagesLean Manufacturing in HouseholdRon Aldelene GonzalesNo ratings yet

- Timeline of Rizal's ChildhoodDocument4 pagesTimeline of Rizal's ChildhoodRon Aldelene GonzalesNo ratings yet

- Veneration Without Understanding (Reaction)Document4 pagesVeneration Without Understanding (Reaction)Ron Aldelene GonzalesNo ratings yet

- Lean Manufacturing: Maria Sophia M. Samiano Bsie-3ADocument12 pagesLean Manufacturing: Maria Sophia M. Samiano Bsie-3ARon Aldelene GonzalesNo ratings yet

- Financial StatementsDocument12 pagesFinancial StatementsDino DizonNo ratings yet

- Mas First Preboard Examination Batch 95Document11 pagesMas First Preboard Examination Batch 95Lhairyz Francine RamirezNo ratings yet

- Internal Financial Controls Sivaram SubramoniamDocument22 pagesInternal Financial Controls Sivaram SubramoniamKRISHNA RAO KNo ratings yet

- Banking ScamsDocument27 pagesBanking Scamsmadhav kaliaNo ratings yet

- Vincom Retail Joint Stock Company 2020 Performance and 2021 OutlookDocument28 pagesVincom Retail Joint Stock Company 2020 Performance and 2021 OutlookNeil NguyenNo ratings yet

- Consumer Research Insights On Brands and Branding - A JCR CurationDocument7 pagesConsumer Research Insights On Brands and Branding - A JCR CurationAlice MazumdarNo ratings yet

- Marketing Management: Business Studies Project - 1 Yashvi Bothra 12413 7891372295Document34 pagesMarketing Management: Business Studies Project - 1 Yashvi Bothra 12413 7891372295Geetika Jain100% (2)

- Chapter 4 BDocument58 pagesChapter 4 Bvaman kambleNo ratings yet

- CAPE Communication Studies 2012 P2 PDFDocument6 pagesCAPE Communication Studies 2012 P2 PDFGayatrie BhagalooNo ratings yet

- Itinerary Email v2 20221102201441470Document3 pagesItinerary Email v2 20221102201441470Late KillerNo ratings yet

- The Liquid Chemical Company Manufactures and Sells A Range ofDocument2 pagesThe Liquid Chemical Company Manufactures and Sells A Range ofAmit PandeyNo ratings yet

- First Warning Letter TemplateDocument4 pagesFirst Warning Letter Templatemam_mistNo ratings yet

- Project On Compensation and Benefits Ufone: Submitted To: Respected MR - Habib KhanDocument22 pagesProject On Compensation and Benefits Ufone: Submitted To: Respected MR - Habib KhanAbdul QadoosNo ratings yet

- Presentation 1 LDDocument13 pagesPresentation 1 LDMaaz AliNo ratings yet

- Electrolux Market Overview 2022Document6 pagesElectrolux Market Overview 2022Gere TassewNo ratings yet

- TEST 10 - Unit 3, 4, 5 (45 Minutes)Document3 pagesTEST 10 - Unit 3, 4, 5 (45 Minutes)Dương Đức BútNo ratings yet

- RMC No. 111-2022 AttachmentDocument1 pageRMC No. 111-2022 AttachmentPaulus PacanaNo ratings yet

- Lecture No5 - Equal-Payment - Series-ModifiedDocument13 pagesLecture No5 - Equal-Payment - Series-Modifiedpoqwuradfo apdsoaafNo ratings yet

- Sim CBM 122 Lesson 2Document7 pagesSim CBM 122 Lesson 2Andrew Sy ScottNo ratings yet

- The Cocoa Market in The 21 CenturyDocument118 pagesThe Cocoa Market in The 21 CenturyBerta FarellHNo ratings yet

- Seven Facets of Modern Category Management: 1. Real Customer Centricity-Walk A Mile in Your Customer's ShoesDocument4 pagesSeven Facets of Modern Category Management: 1. Real Customer Centricity-Walk A Mile in Your Customer's ShoesPriyanshu MishraNo ratings yet

- MCQ On Endogenous and Exogenous VariablesDocument7 pagesMCQ On Endogenous and Exogenous VariablesKhagendra PoudelNo ratings yet

- 2019 COM PG Handbook PDFDocument255 pages2019 COM PG Handbook PDFHaydnHenningNo ratings yet

- Mba Research Project ReportDocument88 pagesMba Research Project Reportketan monapara100% (1)

- TD MidsemDocument35 pagesTD MidsemAnjali YadavNo ratings yet

- Analisis Varians Dan Standar Products CostsDocument4 pagesAnalisis Varians Dan Standar Products CostsAhad KamisNo ratings yet

- Emily Guzman - DDDM 1 Artifact MemoDocument5 pagesEmily Guzman - DDDM 1 Artifact Memoapi-506897739No ratings yet

- United Food Pakistan Balance Sheet For The Year 2011 To 2020Document34 pagesUnited Food Pakistan Balance Sheet For The Year 2011 To 2020tech& GamingNo ratings yet

- Arrastre and Stevedoer Difference and DistinctionDocument2 pagesArrastre and Stevedoer Difference and DistinctionMarkyHeroiaNo ratings yet