Professional Documents

Culture Documents

Gps - VSM Board - Getrag

Gps - VSM Board - Getrag

Uploaded by

VENKATESHAN S0 ratings0% found this document useful (0 votes)

31 views2 pagesThis document outlines the process for conducting a value stream mapping analysis. It includes:

1. Conducting a current state map to document the product and information flows, process boxes and inventory, timeline, and key performance indicators. Opportunities for improvement are also identified.

2. Developing a future state map that designs an improved flow based on building to customer demand, implementing flow, first-in-first-out buffers, and other techniques.

3. Creating an implementation plan with tasks, projects, and kaizen events prioritized and assigned with timing and responsibilities to transition from the current to future state. The goal is to ensure sustainability and lead continuous improvements.

Original Description:

Original Title

Gps_vsm Board - Getrag

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the process for conducting a value stream mapping analysis. It includes:

1. Conducting a current state map to document the product and information flows, process boxes and inventory, timeline, and key performance indicators. Opportunities for improvement are also identified.

2. Developing a future state map that designs an improved flow based on building to customer demand, implementing flow, first-in-first-out buffers, and other techniques.

3. Creating an implementation plan with tasks, projects, and kaizen events prioritized and assigned with timing and responsibilities to transition from the current to future state. The goal is to ensure sustainability and lead continuous improvements.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

31 views2 pagesGps - VSM Board - Getrag

Gps - VSM Board - Getrag

Uploaded by

VENKATESHAN SThis document outlines the process for conducting a value stream mapping analysis. It includes:

1. Conducting a current state map to document the product and information flows, process boxes and inventory, timeline, and key performance indicators. Opportunities for improvement are also identified.

2. Developing a future state map that designs an improved flow based on building to customer demand, implementing flow, first-in-first-out buffers, and other techniques.

3. Creating an implementation plan with tasks, projects, and kaizen events prioritized and assigned with timing and responsibilities to transition from the current to future state. The goal is to ensure sustainability and lead continuous improvements.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 2

Value Stream Mapping – Current State

3. Information Flow 1. Product Flow

Plant Level

Process Boxes

Hobbing

Segment Level 单元级

2. Process H.Machine1, H.Machine2

Boxes &

Inventory ´3 / 3 2

Operators per day / Shifts No. of MCs

p/t 0,7 min

c/t 0,35 min

c/o 36 min

4. Time Line c/o frequency 3 #/day

Variants 3 #

5. KPIs Batch Size 1.000 pcs.

Lot Size 100 pcs. / stack

6. Identify Opportunities OEE 80 %

Library of VSM Icons

supplier / customer FIFO buffer

(qty. undefined !)

Process box (qty. defined !)

KANBAN Opportunities for improvements

(qty. defined !) KANBAN Box / (fixed programm)

1 June 2015; Lean Academy Collection Board

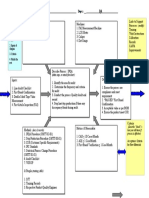

Value Stream Mapping – Kaizen Agenda 价值流图析 – 改善议程

1-3 days per segment 1-3 days per segment ~ 1 day per segment

1. Value Stream 2. Value Stream 3. Value Stream

Mapping Design Planning

Output: Output : Output :

Current Value Stream Future Value Stream Task, Project, Kaizen List incl. timing &

responsibility

Agenda: Agenda :

Segmentation Segmentation review

1.Customer & Supplier Data TT/CT-Diagram & Batch Size Data Agenda :

2.Process Boxes & Inventory 1. Define Main Topics of Opportunities

3.Information Flow 1.Build to Customer Demand

4.Timeline 2.Implement Flow

2. Define Method (Project, Kaizen, Task)

5.KPIs 3.FIFO-Buffer

6.Identify Opportunities 4.Supermarkets / Kanban

TT/CT-Diagram & Batch Size 5.Pacemaker Process

6.Level the Production Mix & Volume 3. Define Priorities

7.Finalize Value Stream

4. Define Timing & Responsibility

5. Define KPIs

GETRAG Production System Training No.2/ 2015 in China

1. Map the 2. Create Flow 3. Ensure sustainability & lead

Value Stream & Pull improvements

June 2015; Lean Academy

You might also like

- DMAIC - CSAT ImprovementDocument135 pagesDMAIC - CSAT Improvementbiswazoom100% (1)

- TG 244 Anal Write UpDocument14 pagesTG 244 Anal Write Upapi-347149977No ratings yet

- BIR Form 1906Document1 pageBIR Form 1906rafael soriaoNo ratings yet

- 7 - VSMDocument55 pages7 - VSMPranay NavaleNo ratings yet

- Product Family: Editor: Date:: Value Stream DesignDocument4 pagesProduct Family: Editor: Date:: Value Stream Designmiljane perdizoNo ratings yet

- Project Name: Cycle Time Reduction. Project Owner: S.N. Parmar, Ajay Kumar ChoudhariDocument50 pagesProject Name: Cycle Time Reduction. Project Owner: S.N. Parmar, Ajay Kumar Choudhariblitzkrig100% (1)

- Part & Information Flow ChartDocument4 pagesPart & Information Flow ChartAyub Gullick SihotangNo ratings yet

- Demand Chain Solutions: Value Stream MappingDocument58 pagesDemand Chain Solutions: Value Stream Mappingchteo1976100% (1)

- Value Stream MappingDocument11 pagesValue Stream MappingJonathan WenNo ratings yet

- QCPC Pmi FanDocument14 pagesQCPC Pmi FanMaelEdwardAritonangNo ratings yet

- 15EEL76-Power System Simulation LabDocument49 pages15EEL76-Power System Simulation Labmedanite ashebirNo ratings yet

- Good Sample IKWDocument23 pagesGood Sample IKWTs-Radzif OmarNo ratings yet

- Value Stream MappingDocument41 pagesValue Stream MappingmilesstuffNo ratings yet

- Value Stream Mapping - Casos PracticosDocument13 pagesValue Stream Mapping - Casos PracticosJOHAN FERNANDO QUIROZ SERNAQUENo ratings yet

- Material Requirement Planning (MRP) and Capacity Requirement Planning (CRP) Authored by DR AdilDocument105 pagesMaterial Requirement Planning (MRP) and Capacity Requirement Planning (CRP) Authored by DR AdilHarsh VaghelaNo ratings yet

- 4 Slides Value Stream MappingDocument13 pages4 Slides Value Stream MappingRanjan Raj Urs100% (2)

- Intro. To Operations Management123Document12 pagesIntro. To Operations Management123Mustufa RohailNo ratings yet

- Six Sigma Green Belt.8169983.powerpointDocument18 pagesSix Sigma Green Belt.8169983.powerpointsumit singhNo ratings yet

- Innovation ProcessDocument5 pagesInnovation Processfafo24633No ratings yet

- IPQA - QA: Turtle Diagram - Process: Dept.Document1 pageIPQA - QA: Turtle Diagram - Process: Dept.SMTT WORK OFFICIALNo ratings yet

- Session 24 Aug-VSM and Lab 5Document39 pagesSession 24 Aug-VSM and Lab 5V PNo ratings yet

- Kanban SystemDocument3 pagesKanban SystemsentaprilepNo ratings yet

- SOP Readiness ButDocument5 pagesSOP Readiness ButrianNo ratings yet

- 2 Mapping ProcessesDocument73 pages2 Mapping ProcessesIr Moise MatabaroNo ratings yet

- APQP Tier I AutomotiveDocument22 pagesAPQP Tier I Automotivegpb76No ratings yet

- Value Stream Analysis TrainingDocument78 pagesValue Stream Analysis TrainingWilmer Chacon100% (1)

- PR DV 04 (Facilities Planning & Deployment)Document3 pagesPR DV 04 (Facilities Planning & Deployment)Amit PathakNo ratings yet

- Basic Kaizen ToolsDocument14 pagesBasic Kaizen ToolsDaffa HanifNo ratings yet

- Lecture 4: Overview: Principles For Implementing Lean ManufacturingDocument20 pagesLecture 4: Overview: Principles For Implementing Lean Manufacturingthedjoss2000No ratings yet

- 6 - Demand FlowDocument25 pages6 - Demand Flowfilimendez64No ratings yet

- Value Stream - Ceramic TileDocument12 pagesValue Stream - Ceramic TileAlfred LiNo ratings yet

- Value Stream Mapping Training MaterialsDocument12 pagesValue Stream Mapping Training Materialsgandi shrtnNo ratings yet

- Turtle Diagram: Doc No.: TD-SM REV. No.: 00 Date: PAGE No.: 01 of 01Document1 pageTurtle Diagram: Doc No.: TD-SM REV. No.: 00 Date: PAGE No.: 01 of 01Rohit SoniNo ratings yet

- Process Analysis - HoutDocument12 pagesProcess Analysis - HoutANN MARY JOSE PGP 2023-25 BatchNo ratings yet

- Automotive Industry Cluster TPM Training Material Kobetsu Kaizen Step 0 - 1Document42 pagesAutomotive Industry Cluster TPM Training Material Kobetsu Kaizen Step 0 - 1raghavendrarh6464No ratings yet

- Aggregate PlanningDocument23 pagesAggregate PlanningNikhil NarayanNo ratings yet

- Presentation - Lean Manufacturing Techniques - Lecture 01Document30 pagesPresentation - Lean Manufacturing Techniques - Lecture 01Nadun NilupulNo ratings yet

- OM Session 1-4Document39 pagesOM Session 1-4Rashi GaikwadNo ratings yet

- Kelayakan Kapasitas Produksi Dengan Metode Rough Cut Capacity (RCCP) Di Seksi Ppm#6, PT. Indah Kiat Pulp and Paper, TBKDocument7 pagesKelayakan Kapasitas Produksi Dengan Metode Rough Cut Capacity (RCCP) Di Seksi Ppm#6, PT. Indah Kiat Pulp and Paper, TBKMoh. Faiz SukronNo ratings yet

- Six Sigma Session13 04042021 Six Sigma Examples 1617381322196Document112 pagesSix Sigma Session13 04042021 Six Sigma Examples 1617381322196FUNTV5No ratings yet

- 02-Process Analysis IDocument32 pages02-Process Analysis IEllaNo ratings yet

- Project Name (DMAIC) Courier Service Efficiency Improvement at BCEDocument31 pagesProject Name (DMAIC) Courier Service Efficiency Improvement at BCENaga ChaitanyaNo ratings yet

- IE IntroductionDocument34 pagesIE Introductionmungkin bisaNo ratings yet

- Kaizen Event Process Improvement Form - Demin - V0 - 30 Jan 23Document7 pagesKaizen Event Process Improvement Form - Demin - V0 - 30 Jan 23Jonas PadillaNo ratings yet

- Adidas - Line Balancing 2Document80 pagesAdidas - Line Balancing 2Juliano. PQMNo ratings yet

- KK (3) M02 L4 130607 PDFDocument4 pagesKK (3) M02 L4 130607 PDFIela TeoNo ratings yet

- NPVS Course Level 2Document30 pagesNPVS Course Level 2Edward ChirinosNo ratings yet

- QualitysystemsDocument8 pagesQualitysystemsádfa caNo ratings yet

- Value Stream MappingDocument16 pagesValue Stream MappingF13 NIECNo ratings yet

- Process Selection and Facility Layout: Learning ObjectivesDocument25 pagesProcess Selection and Facility Layout: Learning ObjectivesWinter NaiNo ratings yet

- Just in Time ManufacturingDocument39 pagesJust in Time ManufacturingPankaj PriyadarshiNo ratings yet

- Operation ManagmentDocument17 pagesOperation ManagmentSatheeshNo ratings yet

- PrintDocument14 pagesPrintLuvNo ratings yet

- Basic Problem Solving (BPS) Template - RevisedDocument38 pagesBasic Problem Solving (BPS) Template - RevisedgcldesignNo ratings yet

- KanbanDocument30 pagesKanbanlalitNo ratings yet

- Materi 4Document24 pagesMateri 4AuliamNo ratings yet

- Product Parameter Monitoring - Jul'16Document10 pagesProduct Parameter Monitoring - Jul'16Ragavi JayaramanNo ratings yet

- Basic Problem Solving (BPS) Template - RevisedDocument38 pagesBasic Problem Solving (BPS) Template - RevisedgcldesignNo ratings yet

- Explanation of Key Points For Inventory ManagementDocument18 pagesExplanation of Key Points For Inventory ManagementQui QiezNo ratings yet

- Value Stream Mapping: Array Architects January 16, 2014Document30 pagesValue Stream Mapping: Array Architects January 16, 2014puphNo ratings yet

- Scrap Process UATDocument5 pagesScrap Process UATLokesh ModemzNo ratings yet

- KANBAN: Streamlining Workflow for Effortless Efficiency (2023 Guide for Beginners)From EverandKANBAN: Streamlining Workflow for Effortless Efficiency (2023 Guide for Beginners)No ratings yet

- Theory of Constraints (TOC) - 1Document26 pagesTheory of Constraints (TOC) - 1VENKATESHAN S100% (1)

- The 20 Keys To Workplace ImprovementDocument82 pagesThe 20 Keys To Workplace ImprovementVENKATESHAN SNo ratings yet

- OEE Mini Booklet Revision 01Document74 pagesOEE Mini Booklet Revision 01VENKATESHAN SNo ratings yet

- Takt Time: Shared Resource Weighted Average Method Practical Usage ExamplesDocument17 pagesTakt Time: Shared Resource Weighted Average Method Practical Usage ExamplesVENKATESHAN SNo ratings yet

- Digital 5S KAIZEN - DownloadDocument48 pagesDigital 5S KAIZEN - DownloadVENKATESHAN SNo ratings yet

- Jindal Saw-AR-2017-18-NET PDFDocument274 pagesJindal Saw-AR-2017-18-NET PDFshahavNo ratings yet

- Option D Study GuideDocument32 pagesOption D Study GuidelietuvossavivaldybeNo ratings yet

- LDTP TutorialDocument46 pagesLDTP Tutorialjimmyjin_maillistNo ratings yet

- Elizabethtown Area School DistrictDocument1 pageElizabethtown Area School DistrictLancasterOnlineNo ratings yet

- Chemistry Paper 1 - 2018-2003 - QP PDFDocument539 pagesChemistry Paper 1 - 2018-2003 - QP PDFal_helu26No ratings yet

- Coke - Ethical Issues: The RecallDocument7 pagesCoke - Ethical Issues: The RecallPriya JainNo ratings yet

- Advances in Computer Entertainment: Dennis Reidsma Haruhiro Katayose Anton NijholtDocument692 pagesAdvances in Computer Entertainment: Dennis Reidsma Haruhiro Katayose Anton NijholtMauro GasparofNo ratings yet

- Cot DLP Oral Com q1-2019Document1 pageCot DLP Oral Com q1-2019monette refuerzo0% (1)

- RMT 11100Document63 pagesRMT 11100halle cNo ratings yet

- Canadian Importers Lists - Coconut OilDocument4 pagesCanadian Importers Lists - Coconut OilIndo Coconut PremiumNo ratings yet

- EinhellDocument128 pagesEinhellAnonymous t9zWrllKPNo ratings yet

- Lesson 4 - History of Development Economics (First Part)Document12 pagesLesson 4 - History of Development Economics (First Part)Rose RaboNo ratings yet

- Test 1Document4 pagesTest 1Nurul AqilahNo ratings yet

- Feasibility of Rainwater Harvesting in High Rise Building For Power GenerationDocument6 pagesFeasibility of Rainwater Harvesting in High Rise Building For Power Generationseventhsensegroup100% (1)

- (Download PDF) Handbook of Radar Signal Analysis Advances in Applied Mathematics 1St Edition Bassem R Mahafza Editor Ebook Online Full ChapterDocument53 pages(Download PDF) Handbook of Radar Signal Analysis Advances in Applied Mathematics 1St Edition Bassem R Mahafza Editor Ebook Online Full Chapterradjalvuyo30100% (7)

- Brkipm-2011 - Multicast MplsDocument106 pagesBrkipm-2011 - Multicast MplsmatarakiNo ratings yet

- Scus 942.54Document4 pagesScus 942.54Leeyo DesuNo ratings yet

- A Comprehensive Review of The Present and Future Antibiotic Susceptibility Testing Ast SystemsDocument9 pagesA Comprehensive Review of The Present and Future Antibiotic Susceptibility Testing Ast SystemsrehanaNo ratings yet

- Catalogue - Cambridge Exams Resources MaterialDocument162 pagesCatalogue - Cambridge Exams Resources MaterialBrinzea Laura100% (1)

- Catalogue of CSM Telescopic Boom Crane - OverseasDocument5 pagesCatalogue of CSM Telescopic Boom Crane - OverseasPhạm Thịnh LongNo ratings yet

- Pindex System InstructionsDocument6 pagesPindex System InstructionsJASPREETKAUR0410No ratings yet

- How To Read Newspaper in 1 Hour and Absorb All Important DetailsDocument12 pagesHow To Read Newspaper in 1 Hour and Absorb All Important DetailsLakshmish GopalNo ratings yet

- Inverted Tubes 2Document3 pagesInverted Tubes 2tihomihoNo ratings yet

- Categories Business-To-Consumer (B2C) (: Identify The Major Categories and Trends of E-Commerce Applications. E CommerceDocument9 pagesCategories Business-To-Consumer (B2C) (: Identify The Major Categories and Trends of E-Commerce Applications. E CommerceHajra NoorNo ratings yet

- Congress Program - Updated 09.05.2018Document4 pagesCongress Program - Updated 09.05.2018Booker DewittNo ratings yet

- Lesson 5Document10 pagesLesson 5Lerwin Garinga100% (1)

- NAPLAN 2011 Paper Test Answers: Numeracy Calculator Allowed Numeracy Non-Calculator Language ConventionsDocument2 pagesNAPLAN 2011 Paper Test Answers: Numeracy Calculator Allowed Numeracy Non-Calculator Language ConventionsnadaNo ratings yet

- Visit To PenthouseDocument12 pagesVisit To PenthouseTiu TonNo ratings yet